Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: aacae6d4-f050-11ee-ad52-1e70aba5fb5e

Powered by PerimeterX , Inc.

- Clutches, Clam & Cam Cleats

- Deck Organizers

- Genoa Leads & Track

- Jib Reefing, Furling, Headfoils

- Lifeline Hardware

- Mainsail Travelers & Accessories

- Rigging Hardware

- Rope & Accessories

- Tillers & Tiller Extensions

- Whisker Poles & Accessories

- Winches, Parts & Accessories

- Emergency Gear

- Harnesses & Tethers

- Man Overboard

- EPIRBs, AIS, PLBs

- Electric Pumps

- Fresh Water

- Manual Pumps

- Seacocks & Valves

- Bags & Luggage

- BBQ Grills & Accessories

- Umbrella & Awning

- Waterproof Cases

- Audio & Video

- Charts & Cruising Guides

- Navigation Tools

- Books & Publications

- Clocks & Barometers

- Propane System

- Stoves & Cooktops

- Teak Accessories

- Ventilation

- DC Electrical

- Generators & Power Equipment

- Shore Power

- Accessories

- Foul Weather Gear

- Sailing Gloves

- Outboard Motor Parts

- Spark Plugs

- Boat & Motor Accessories

- Boat Letters & Numbers

- Highfield Boats

- Boat Maintenance

- Engine Maintenance

- Anchor Rodes & Chain

- Inflatable Boat Maintenance & Repair

- Outboard Motors Servicing

- 303 Products

- Adventure Medical

- Alexander Roberts

- Apex Inflatable Boats

- Aqua Signal

- Bete-Fleming

- Blue Sea Systems

- Boat Bright

- Bristol Finish

- Buck Algonquin

- Captains Choice

- Chesapeake Bay Magazine

- Chesapeake Marine Fasteners

- Cole Hersee

- Consolidated Thread

- CrewWatcher

- Cruise Products

- Ebinger Leather

- Fell Marine

- Gam Electronics

- GMCO Maps & Charts

- Gorilla Glue

- Green Mountain

- GSI Outdoors

- Handi-Man Marine

- HarperCollins

- Helly Hansen

- Henri Lloyd

- Honda Outboard Motors

- Inland Marine

- Johnson Marine

- Johnson Pumps

- Just Marine

- Kotap America

- Lord & Hodge

- Lunar Marine

- Master Lock

- McGraw Hill

- Moby Dick Specialties

- Nautic Sport

- New England Ropes

- Paradise Cay

- Poly-Planar

- PSS Shaft Seal

- Quicksilver

- Redtree Industries

- Rudder Craft

- Sailing Specialties

- SamplexSolar

- Sea-Dog Line

- Seattle Sports

- Sesamee Padlocks

- Shaft Shark

- Shakespeare

- Signal Mate

- Snappy Teak

- Standard Horizon

- Taylor Made

- Teknor Apex

- Teak Wonder

- Tip Top Teak

- Torqeedo Outboard Motors

- Trac Ecological

- Treadmaster

- Ultra Safety Systems

- Viking Life Rafts

- Waterway Guide

- Weems & Plath

- West System

- Western Pacific Trading

- Williams & Heintz Map

- Yale Cordage

September 4, 2023

Buyer's Guide to Boat Blocks

Boat blocks are essential for safe, efficient trips on the water. Without a quality boat block, you'll work harder than necessary when dealing with your rigging, and you might harm your boat. Use our expert boat block buying guide to help you learn all the basics of boat blocks and find the best system for your vessel.

What Is a Boat Block?

Boat blocks are boat pulleys — "block" is a nautical term. These are essential components for any sailboat rigging system. Without them, it is much more challenging to control the sailboat while dealing with the heavy loads created by wind and waves. They provide a more straightforward method for changing the vessel's direction and multiplying the mechanical advantage of the lines, or ropes, used to control the sails.

Sailboat blocks' core purpose is to provide smooth, efficient line movement, enabling sailors to trim the sails effectively. Boat pulleys help redirect the lines, reducing friction and redistributing the load so the sails are easier to handle and the boat's direction and speed are simpler to control. Boat blocks come in several sizes, materials and designs to accommodate all your sailing loads and needs. Finding the right one will help keep you safe on the water.

Boat Block Components and Their Uses

While they might seem small and simple, boat blocks have several components that all help the pulley system work effectively. These pivotal pieces allow for efficient movement and connection of lines, mechanical advantage, ease of sail control and improved safety.

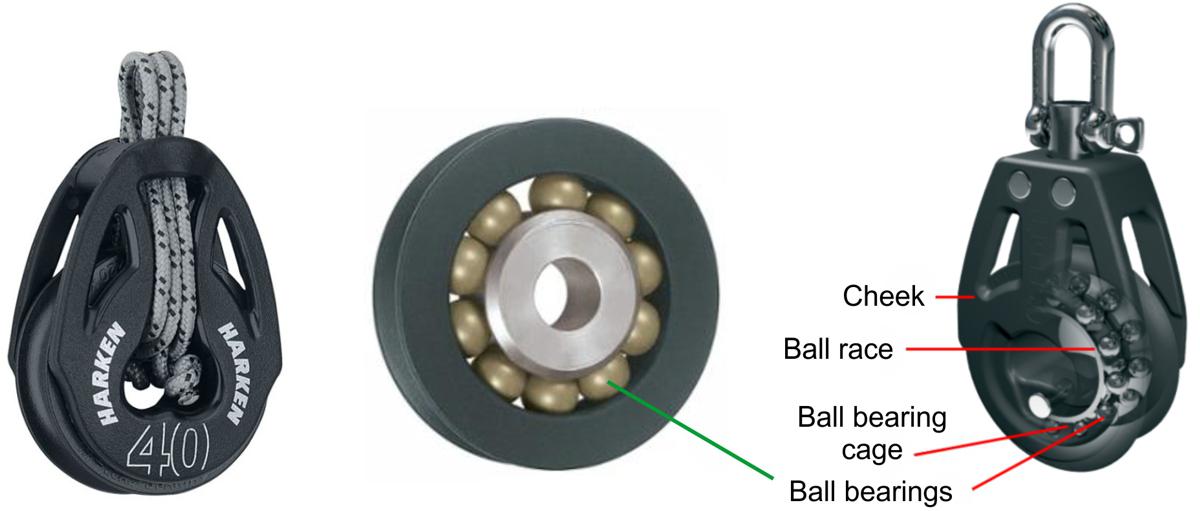

- Sheave: Sheaves are critical components in a pulley system. The sheave is a wheel with a groove in the middle. The line sits in this groove, which guides the line as it moves through the pulley. The sheave creates the pulley system, allowing the line control to work with less friction and more smoothly.

- Cheeks: Cheeks — or cleaves — are side plates that enclose the sheave. They stabilize the sheave and keep the lines in place as they move. Since cheeks sit against the sheave and also take wear from the outside, they consist of high-strength polymers or stainless steel.

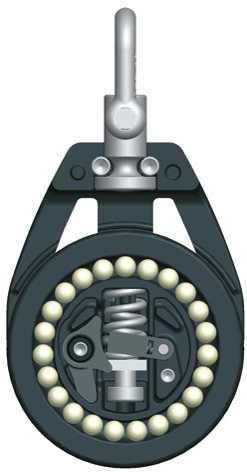

- Bearing: There are several bearing types, and each serves a slightly different purpose. Bearings are axles inside the sheave or pulley that minimize friction as the rope moves along the system. Plain bearing pulleys have a small steel pin the sheave rotates on. They're ideal for heavy loads and static purposes like masthead and mast foot blocks. Roller bearings have rollers instead of balls or pins. They can handle heavy loads for dynamic uses like main halyards. Ball bearings work well for low-load, active uses like spinnaker systems.

- Shackle: Shackles are metal connecting devices that attach the block to other rigging components like the deck or mast. They simplify block installing, adjusting and removal. There are various shackle types for different situations, including snap and bow.

- Becket: Beckets are small metal loops or eyelets attached to the side of the block. Beckets make convenient attachment points for shackles, ropes and other essential hardware. They allow you to create multiple line configurations or secure lines easily.

Types of Sailboat Blocks

Boat blocks come in several types, each with a unique function. Pulley blocks help make your rigging system safer and more efficient — investing in the right type for the job ensures your vessels work well on the water. Blocks can work in dynamic and fixed situations for all your rigging needs. Here are the primary block fitting types and their functions.

Single-Sheave Block

Single-sheave blocks are the simplest. They have only one sheave for the rope to pull along, changing the tension direction. All sheave blocks usually mount to the boom or deck. You'll see sheave blocks used with reef lines, the mast base and the foresheet. Additionally, the simplicity of single sheave blocks helps facilitate basic pulling and lifting tasks.

Multi-Sheave and Fiddle Blocks

The more sheaves on a block, the better the mechanical advantage. Increasing sheave count allows you to handle larger forces with minimal strain. Multi-sheave blocks are also valuable for tasks like constructing a mainsheet jib.

Fiddle blocks are a type of multi-sheave block. While most multi-sheave blocks feature sheaves connected side by side, fiddle blocks have sheaves stacked below each other. This configuration often resembles a fiddle, giving them their name. You'll usually see fiddle blocks on smaller boats as mainsheet foot blocks or boom vangs.

Snatch Blocks

You'll use snatch blocks in temporary situations. Though most blocks have closed sides, requiring you to feed the line through the sheave, snatch blocks have a hinged side plate, allowing you to open and close the block around the line without threading it. With this convenient design, you can attach them to ropes under tension and remove them when there's no slack. You'll use snatch blocks in situations where you need to quickly attach or redirect a rope under tension — like rescue operations or rigging setups that need frequent changes.

Ratchet Blocks

Ratchet blocks use a locking mechanism to prevent the line from slipping backward. This system lets you hold the load in place with the block without continuous manual tension. Ratchet blocks work through an inner sheave that secures the line while a pawl stops the sheave from turning toward the load. Ratchet blocks are ideal for boating applications where you need to secure a load for hands-free operation or at a specific height. You'll mainly use ratchet blocks in sheet systems since they can hold loads in place.

Deck Organizers, Cheek Blocks and Stand-Up Blocks

Various deck organizers are available to divert and lead lines across your deck. While standard sheave blocks follow the pull direction, these organizers sit fixed to a service. Cheek blocks make excellent deck organizers — they guide lines parallel to a surface, fitting them as closely together as possible. Stand-up blocks are another helpful deck organizer block. They stand fixed vertically and work well for uses where you want to avoid having the block hitting the deck.

Considerations When Choosing Boat Blocks

It's essential to consider all factors when deciding what sailboat block you need. Boat blocks perform vital functions on your vessel — getting the right block for the job enables you to safely and smoothly operate your raft on the water. When buying your boat blocks, you should evaluate the expected forces, rope diameter and brand. Examine these factors to help you find the best block for your needs.

Expected Forces and Breaking Loads

While you might think you need a block based solely on boat size, you must also calculate the expected forces and breaking loads you'll be dealing with. The larger your rig — the halyard and sheets — the more forces your vessel will deal with as they catch wind. Larger rigs typically have correspondingly larger lines, so a too-small block will break under sudden, strong tensile forces caused by rough seas. Selecting the correct block from the get-go is even more crucial, since damage will not be immediately apparent. Instead, it will seem fine, only failing the next time it's under load.

What loads will your blocks deal with? Determine each block's required maximum load capacity and select blocks that can surpass it. Exceeding the expected forces ensures your blocks can handle potential shock loads and all expected forces. All manufacturers state the maximum tensile force each block can handle without damage.

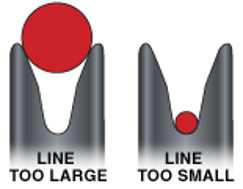

Rope Diameter

If you choose a block with a higher load-bearing capacity than your line, the rope material is not an essential detail for selecting a block. The rope diameter is much more critical to the block you choose. The rope's cross-section must match the block sheave's width to prevent early material wear. A too-small block will increase friction, causing decreased efficiency and possible damage. If the line is too thin, it will slip out of the sheave and affect performance.

Only wire rope blocks are an exception for this factor. Since their sheaves deal with extremely high demands, you'll want to get blocks made for use with wire ropes to ensure the best performance and minimal wear.

Getting the appropriate block type is essential for maintaining boat safety and efficiency. Otherwise, your block will not perform correctly. Checking your block location and usage on the boat will help you match the hardware to the job. If you need help choosing a block type, consult your boat supplies retailer for assistance. Their experts can help direct you to the correct block for your needs, ensuring you get a trustworthy system for your boat.

Various hardware brands have different pricing and performance. Going with a higher-priced manufacturer like Harken, Lewmar or Schaefer will increase your expenses but provide you with a lasting piece of hardware. Other brands like Ronstan offer excellent quality at a lower price, though you might need to replace their products sooner. Choosing a reputable brand ensures you get a reliable product. Whatever brand you select, ensure its quality so you can trust it to support you on the water.

Boat Block Maintenance

Once you install your boat blocks, you must keep them in top shape. Otherwise, you'll have to replace them much earlier than necessary, compromising safety when they fail and increasing your expenses. Taking time to perform regular maintenance helps reduce friction, prevent failures and avoid premature wear. Remember these best practices to protect your boat hardware.

- Inspect: You should regularly inspect your boat blocks and other hardware for signs of corrosion, wear or damage. Closely check cheeks, sheaves and other components for deformations, cracks and excessive wear. Inspect attachment points like shackles and mounting hardware to ensure they have secure connections. Inspections allow you to proactively catch problems. The faster you can detect and address any issues, the better you'll be at preventing further damage and accidents.

- Clean: Clean boat blocks to remove debris, dirt, salt and other contaminants. Buildup can affect block performance, reducing efficiency and leading to accelerated wear. Use a specialized marine cleaner or a mild soap combined with a soft cloth or brush to clean the hardware. After gently cleaning the blocks, rinse thoroughly with fresh water to remove all residue. Never use harsh chemicals when cleaning, as they could damage the block's materials or functionality.

- Lubricate: Proper lubrication is essential for reducing friction and maintaining a smooth operation. Apply the correct marine lubricant to the block's sheaves, bearings or brushings according to the manufacturer's instructions. Lubrication helps minimize wear and maintains efficient block rotation. Always use lubricants specifically designed for marine use, with formulations that prevent corrosion.

- Check ropes: Check ropes used with boat blocks for wear and fraying. Clean your ropes regularly to shield them from damage. You should also store them properly to prevent UV damage and entanglement. Finally, consider rotating your ropes so they wear evenly.

- Replace: Regularly monitor your boat blocks and replace them if they start showing signs of severe wear and tear or as they reach the end of their recommended life span.

- Professional help: If you have a complex or critical rigging system, consider getting a professional rigger to inspect your setup. Periodic professional inspections provide a thorough breakdown of your system's condition and allow you to get expert recommendations on repairs or replacements.

High-Quality Boat Blocks From Fawcett Boat Supplies

Boat blocks are critical for ensuring your boat's enjoyment and safety. Investing in high-quality boat supplies helps protect you and your vessel whenever you want to enjoy some time on the water. Fawcett Boat Supplies provides you with an unmatched selection, enabling you to maximize your boating experience. We've offered exceptional products to our customers since 1948, making us an industry leader in supplies and expertise. You can trust us for all your boating needs.

From an extensive array of boating supplies to expert boating services , Fawcett has everything you need for safe, efficient boating. Contact us online today to learn more about our product selection!

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.

- Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

Net Orders Checkout

Shipping address, shipping methods.

Sign up now for our WhatsApp newsletter and receive a FREE SVB set of playing cards!

- Spare parts

- SVB@Youtube

- Saved Guides

- My Skipper profile

- My boat on Portmaps.com

- General settings:

- Newsletter and messages

- NEW WhatsApp & SMS

- Compare list

Are you missing items that you have already placed in your shopping cart? Log in to see your saved items.

- Sailing, Rigging & Deck

Blocks: How to find the right block for your yacht

In this guide we tell you everything there is to know about which block to buy, what they are used for and the types of bearing available. We also have valuable tips to make sure you get the most life out of your blocks on board.

- Blocks then and now

- Block manufacturers and what to know when replacing them

Types of block and distinguishing features

- Sheave block

- Fiddle block

- Snatch block

- Ratchet block

Which block is the right one for my boat?

- Rope type and diameter

- Intended use

Which bearing is best and for which purpose?

- Plain bearing

- Roller bearing

- Ball bearing

Use & maintenance

- Can I use a thinner line diameter than is recommended?

- How often should maintenance be carried out?

„Blocks then and now"

Blocks have been and still are an essential part of boating equipment. In the past, just as their name suggests, they were simply a block of wood, or to get technical, they were wooden blocks with a hole. They were used on board not only to run sheets and line, but also to facilitate carrying loads. Today, little has changed in principle. However, modern blocks feature an integrated bearing and are less prone to wear and tear, and above all, they are much easier to use.

Bestsellers in Blocks

What are the various block manufacturers and what is important when replacing them?

Blocks come in a wide variety of designs and sizes. This is hardly surprising, as most rig manufacturers, such as Lewmar or Seldén , produce their own blocks. They usually come with clear instructions as to exactly where and how they should be used. If a block needs to be replaced and it is a fixed part of the rig at a particular location, for example the mast base or masthead, it's worth looking at the rig manufacturer's specifications. This way, you can make sure it will work perfectly and you shouldn’t have any issues using it.

When replacing blocks, warranty claims can sometimes also be affected. It's important to comply with manufacturer specifications, for example on back stays. If a block fails due to it being the wrong type, not only do you risk damaging the rig, you could also have a problem with your yacht insurance.

This shouldn’t be the case if you are planning to set up a new rig, such as a self-tacking jib conversion or lazy jack system, and you can go ahead and buy whatever blocks you wish to use. Nevertheless, care should be taken when selecting the size of the block. You can use so-called mini blocks for lazy jacks, while self-tacking jibs require blocks that can carry much heavier loads. Sometimes, original parts are no longer available for older yachts and new blocks are needed. To meet the demand for this equipment, various manufacturers offer a broad range of blocks, and a number of specialist manufacturers can satisfy the needs of any sailor with their own niche products:

Made in Germany: Pfeiffer and Sprenger blocks, for dinghies and cruising sailboats

The German manufacturers Pfeiffer and Sprenger focus on cruising sailors with their tough blocks designed for durability. Both have a wide range of blocks, and they also supply all kinds of special fairlead blocks and so-called mini-blocks, e.g. for pennants or Lazyjacks lazy jacks as mentioned above. Blocks from Sprenger Blocks from Pfeiffer

Wood-look blocks from Hye

Hye’s blocks have been favourites with veteran sailors for a long time, as their blocks look great on classic yachts. With their distinctive red-brown synthetic resin fabric made of Tufnol, Hye has created a classic block. They look similar to a classic wooden block, but are much lighter and more robust. Blocks from HYE

The specialists: Blocks by Barton, Ronstan and Antal

Also using Tufnol, but not coloured, is Barton. Barton blocks are designed for more sporty sailors and yawl boats, where the low weight of Tufnol is a special feature of its products. A further manufacturer in the sports sector, the Australian manufacturer Ronstan, has made a name for itself with its Orbit blocks. Similar to Antal blocks, Dyneema loops replace the classic metal eyes for mounting on the fitting. The loops do not feature any bearings, but they have the advantage of being extremely lightweight and easy to handle, without requiring any maintenance. Both manufacturers make blocks with a technical performance and stylish appearance to match. Blocks from Barton Blocks from Ronstan Blocks from Antal

Harken: The Rolls Royce of yacht blocks!

The American manufacturer Harken offers a wide range of different blocks and sheet systems. They have sailboat blocks with high-tech bearings in wooden casings, as well as carbo blocks for the highest regatta demands. Harken dominates at high-profile sailing events, such as the Americas Cup, Volvo Ocean Race and the Olympics. But high quality comes at a price and some blocks may be excessive to all requirements. Blocks from Harken

Our conclusion

The choice is indeed large, so for those who do not want to limit their search to one manufacturer, you should first determine what kind of block you need and where you intend to use it, then compare the different manufacturers.

What types of blocks are there for boats and what makes them different?

Sheave block - the most common design.

Sheave blocks are usually mounted on the deck or boom with a shackle and run a line over a sheave. They are used wherever direction of tension has to be changed ( mast base, foresheet, reef lines , etc.) Depending on the number of sheaves built into the block, they are referred to as single sheave blocks or multiple sheave blocks. The number of sheaves, whether one, two or three, depends largely on the mechanical advantage desired for the respective sheet. In addition to single blocks, double blocks are the most commonly used blocks. Double or multi-sheave blocks are used, for example, in the construction of a mainsheet jib

Fiddle block – perfect as a boom vang

A fiddle block . is another type of multi-sheave block. Here, the individual sheaves are not mounted side by side on a common axis, but one below the other, creating a shape similar to that of a violin or fiddle. This block is often found on smaller vessels and dinghies as a boom vang or mainsheet foot block. A cleat on the block can also help adjust and quickly release rope directly.

Snatch blocks - for quick line reeving

In special cases where a block is only needed temporarily, a special type of block can be useful i.e. a snatch block. Snatch blocks can be opened on one side, allowing them to be attached to a line under tension and removed again, even when the line is still taut. Snatch blocks are therefore often used as barber haulers on spinnakers. However, they are also suitable wherever lines need to be reeved quickly, as line does not need to be passed through individual blocks one after the other.

Our top-selling fiddle blocks

Ratchet blocks – perfect for reducing pressure on a sheet

Sheets are often pulled by hand on smaller boats. A ratchet block reduces the tug on a line, or sheet. Here, an inner sheave grips the rope, and a pawl prevents the sheave from turning in the direction of the load, producing the familiar ratchet sound. When the sheet is furled, the line, which then runs over the bearing roller, is also held. Because the sheave can rotate and grip, this allows for controlled easing of the line. On larger yachts where sheets are operated using winches, the reverse direction of the winch does this. Ratchet blocks are therefore mainly found in the sheet system of dinghies. They're often used with spinnaker sheets or in the mainsheet block. Many high-quality ratchet blocks also have a small lever to adjust the amount of hold.

Dynablock – a light-weight all-round wonder

Less weight is not only an advantage in regattas. Ultra-light Antal Dyna blocks can be used as a snatch block or mounted where fixed eyes and fittings are missing. Instead of a metal shackle, simply attach the Dynablock with a Dyneema eyelet. A popular choice on cruising yachts, not only because of the lighter weight, but more because they eliminate sources of squeaking and rattling on deck. On top of that, Dynablocks are extremely easy to install and can therefore also be added to a spinnaker or jib sheet as a barber hauler.

Deck organisers - lead / divert lines easily across the deck

Organisers and deflection blocks are designed to lead / divert lines across the deck. They come in many shapes and sizes and can consist of one or more sheaves. However, where a normal sheave block adapts to the direction of pull, blocks like this are designed to be fixed to a surface. Cheek blocks guide lines as low as possible to the surface they are attached to. Examples can almost always be found between the cockpit and the mastbase, to lead / deflect lines in a tidy fashion and avoid running them over a deck hatch. Cheek blocks are often used as deck oganiser blocks for this reason. Blocks that are designed to stand in a vertical position are called stand-up blocks. They are usually found at the mastbase, as a sheet block on a genoa car, or other applications where you don't want the block to hit the deck. Stand-up blocks, cheek blocks and organisers could be summarised as deck blocks. Also included here are deflection blocks that are mounted on a stanchion for leading furling lines aft, for example.

Our top-selling deck organisers

Summary of block types

- Sheave block: Usually mounted on the deck or boom with a shackle. Use: Mastbase, foresheet, reef lines etc. Find them as single blocks or blocks with more than one sheave.

- Fiddle block: Often found on smaller vessels and dinghies as a boom vang or main sheet foot block.

- Snatch block: Often used to rig barber haulers on spinnakers.

- Ratchet block: Reduces the pull on a line, or sheet. Mostly used on dinghies.

- Dynablock: Dynablocks are extremely light, do not squeak or rattle and are easy to mount. Perfect for barber haulers.

- Organisers: Organisers are fixed in place and immovable. Footblocks and are used, for example, to reduce the pressure on the mainsheet.

What role does the size of the boat play?

The choice of block is usually determined by the halyards and sheets used, not by the boat size. Larger rigs are often subjected to greater forces and lines have larger diameters. The crucial factors in determining which blocks to use here are the expected forces and the resulting breaking loads. If the block chosen is too small, it will not be able to withstand sudden tensile forces, for example caused by rough seas, and the block could break or bearings become damaged. Damage caused by this kind of excessive stress is not visible on the outside of the block. It only becomes apparent when the block is placed under load again, and the bearing jams due to uneven rolling surfaces. Manufacturers specify the maximum tensile force a block can withstand without damage.

SVB tip: It's best to keep the normal stress you place on your block to about half the breaking load of the line you are using. This should be the so-called working load, which allows for sufficient reserves in case of sudden, brief forces. Matching blocks directly to the line is not necessary for all installations. The angle of a diversion also plays a role in determining the size of the block to be used.

Example: When a jib pulls on a sheet, half of the force is distributed between the knot on the clew and half on the winch. In the case of a self-tacking jib, the line is fed through about 180 degrees to the bow via the fitting on the track and then diverted again through 180 degrees to the winch. 50 per cent of the force pulls on the respective ends of the line, but 100 per cent on the track and 100 per cent on the bow. Changing the direction by only 90 degrees instead of 180 degrees reduces the pull on the block fitting by about half. A change of only 45 degrees reduces the pull to a quarter. The lower the angle of diversion, the lower the expected load.

What role does rope diameter and rope type play in choosing a block?

In general, rope material doesn't really matter when it comes to blocks. As long as the line is used within the limits of its respective breaking load, choose a block with a slightly higher load-bearing capacity. A much more important factor than rope material is its diameter. The cross-section of the rope must match the width of the block sheave to avoid material wear. On the other hand, of course, the line must not be too thin, otherwise it will not grip the bearing and slip through. Wire rope blocks are an exception here. Their sheaves are subjected to particularly high demands. For this reason, especially suitable blocks should always be used for wire ropes.

What are different blocks used for and where?

Various blocks are used on yachts for different purposes. Multi-sheave blocks are used to reduce force and, for example, in jib sheet rigging. Where the block is located also often determines the type of block: on the barber hauler on the spinnaker, for example, light weight is a key factor. The block must not pull the sheet down in light wind conditions and thus cause the spinnaker to collapse. Conversely, for multi-sheave blocks, the mounting point on deck must take the combined force of the lines in the block. If direction of pull cannot be determined exactly, it is worthwhile to install a block with a swivel. This protects the deck fitting from excessive stress due to shear forces.

Summary of choosing the right block

- Size of the boat: Not important when choosing the type, but relevant for halyards and sheets used.

- Rope diameter: More important than rope material is rope diameter. The rope cross-section must match the width of the sheave in the block.

Which boat block bearing is suitable for which purpose?

Sheave, bearing, fitting. At first glance, all blocks look very similar. However, the differences are in the details and we need to take a look inside. Where a block is used determines not only its design, but also the recommended bearing. Yacht blocks are really tested at the mast base: during the course of a season, control blocks here are constantly subjected to halyard tension, especially after a roller furling system has been installed in the spring, for example. It will still be in place even when in the harbour, provided the genoa remains furled on the forestay. Therefore, the sheet block at the mast base must be particularly stable.

Plain bearings - run lines and halyards in one direction.

A halyard block at the mast base , and possibly also the masthead, must not only run smoothly to provide adequate halyard tension when setting the sails, it must also be able to withstand forces and loads acting on one point. This stress is exacerbated when a rig is working in swell. Water is by no means a rigid element, so the boat moves almost continuously. The bearings in a halyard block are therefore prone to uneven wear and must be manufactured to a particularly high standard. In such places, plain bearing blocks are the best choice. In such places, plain bearing blocks are the best choice. They have many advantages compared to roller bearings: starting with low space requirements, resulting in a more compact design of the entire block. This is due to the running surfaces of the plain bearing block moving directly on top of each other. Only a thin film of lubricant reduces resistance.

Within a plain bearing block, the constant force of the halyard tension is distributed over a contiguous area. This significantly reduces wear and tear and increases service life. Moreover, plain bearings are usually manufactured to be maintenance-free and will not become dirty even if the bearing is not moved for a while. However, if tensile forces are not applied in exactly the right direction, they can be more sensitive, and due to the way they are designed, faults can occur in this case. Both running surfaces must be perfectly smooth, with exactly the right amount of force, so that there is no resistance. Plain bearing blocks are therefore always used where halyards can follow a clearly defined path and are mounted in exactly the same direction of pull.

Rolling bearings - when forces can act in all directions

One of the earliest types of roller bearing was discovered in the early days of shipbuilding. In order to launch entire ships into the water, logs were used to roll the finished hull down the beach and into the water. This principle can still be seen today in so-called rolling bearings. Instead of heavy tree trunks, cylindrical rolling elements and ball bearings are used. Ball bearing blocks are also a kind of roller bearing, since the balls roll between an inner and an outer ring, which reduces frictional resistance.

As load capacity is distributed over the contact surface of the bearings, in ball bearings, it is more specific. However, in roller bearing blocks, load capacity is distributed more evenly, since they have more surface area contact. The more rollers in the bearing, the smaller they are and more surface areas carry the load. Blocks with very small rollers are referred to as needle roller bearing blocks. Roller bearing blocks are not as sensitive as plain bearing blocks. They can also absorb lateral fluctuating loads well. With needle bearings, however, the pull should come from the same direction of installation. They should therefore only be used in places where direction of pull is fixed, as with deck blocks.

Ball bearings - the first choice for barber haulers, movable block fixtures and sheets

Classic ball bearings, on the other hand, are designed to rotate freely and can handle both radial and thrust loads. Ball bearing blocks are therefore always the first choice for all movable blocks on sheets, barbers and similar places. Their minimal resistance to movement. is achieved by the balls lying in a groove inside the bearing. These deep groove ball bearings can absorb lateral loads well without increasing rolling resistance.

Our top-selling ball bearing blocks

Summary of choosing the right bearing

- Plain bearing: Plain bearings are maintenance-free and seldom get dirty, but lines must run precisely for this.

- Roller bearings: Can carry higher loads than plain bearing blocks.

- Ball bearings: Ideal where loads are more moderate and dynamic. For spinnaker sheets and barber haulers.

Can I use a thinner line diameter than is recommended for a block?

In principle, blocks should be matched to the lines used. If line diameter is too large, you’ll usually be able to tell because the line won’t run freely through a block without shearing. But too small a rope diameter can also be problematic. This is because the guide groove of the roller in the block is matched to lines with the corresponding diameter. About half of them are carried and deflected by this groove over their entire surface. Thinner lines, on the other hand, take up a proportionally smaller part of the surface. Under tension, a line that is too thin line is then no longer run evenly around the sheave, but pulled down at the apex and squeezed into the groove. The result is a loss of breaking load of the line, as well as higher wear in the rope.

How often do I have to carry out repairs and replacements on the blocks on my ship?

Most blocks in sailing are maintenance-free. The housings are also usually riveted. A riveted block can therefore only be inspected from the outside. Open ball bearings or roller bearing blocks should be rinsed with clear water from time to time, especially when used in salt water. This will prevent salt deposits and the consequent formation of grooves. Lubrication is not necessary with these bearings and is even counterproductive, as grease in particular tends to slow down the rollers and prevent them from rolling freely. Moreover, plain bearings are usually enclosed systems, which makes maintenance unnecessary. However, blocks are also among the most stressed parts on board. Maintenance-free therefore does not mean that you don’t need to pay attention to them. A brief check from time to time can help prevent serious damage caused by block failure. Ideally, the roller should always move a little, even under tension. If it does not run smoothly, makes noticeable noises or you can see mechanical defects such as cracks, the complete block should be replaced immediately. - Therefore, always make sure you have a set of spare blocks on your ship.

Share our guide on social media

Author Hinnerk Weiler

Hinnerk Weiler is a sailing journalist, long-distance sailor and real "old salt". An experienced sailor and expert in boat technology, when it comes to the world of blocks on board, he knows what he's talking about.

Find out more about the author »

The sailboat block (commonly referred to as a pulley ) is used to turn a line or wire as well as to facilitate a purchase.

The parts of a block , in simple terms, consist of the following:

- a sheave for the line to run on

- a sheave pin or axle for the sheave to spin on

- a strap or a shell (depending on design) which provides the structure between the sheave pin and the attachment point. A shell acts as both strap and cheek.

- Cheeks to house the strap and protect it from snags

- an eye, hook, fork, shackle, strop or loop to attach the block to something

Another term that you’ll need to be acquainted with but not all blocks are equipped with, is Becket – an attachment for the end of a line to be affixed to; typically for a multiple part purchase system. There are yet even more fun parts of a block that aren’t as important for the layman, for example: crown, face, breech, swallow, tail, Tally Plate, score, and I’m sure I’m missing some. I just wanted to show off :-0)

HOW DO I KNOW WHICH ONE TO BUY!?

As with most things in the sailboat parts world, things end up more confusing than clear once we actually get into it. For this reason alone many boaters trust those decisions to industry experts, such as riggers. Replacing a sailboat block unfortunately is no exception. When talking about modern day cruising or racing boats (anything not made of wood), there are many block manufacturers and model options available on the market. This can lead to the boat owner ending up needing to make more decisions than he or she was perhaps prepared for. Before embarking on the seemingly simple task of choosing blocks, allow The Rigging Company to shed some light on how we go about selecting the right block for the job…

First let’s start with a list of popular manufacturers and go from there. In terms of brands: Antal , Holt , Ronstan , Harken , Schaefer , Lewmar , Karver and Selden are some of the popular options available to choose from. Here is where the easy part ends and the confusion begins. Before you can figure out what type of block you’ll need, you still need to figure which model you like/want/need. Each one of these manufacturers will offer various design choices with even more jargon to add to your list: Carbo, ESP, Black Magic, Series 5, Series 7, OPF, Stainless, Classic, Looper, Orbit, Synchros, HTX, Core, Plain Bearing, Low load, Ball Bearing, High load; and on, and on, and on…

…Then, after that you’ll have yet even more decisions to make, like which size : 40mm, 45mm, 57mm, 60mm and so on. The final decision will be, what type … is it a double, triple, single, becket, snatch, cheek, foot, fiddle, ratchet, or any combination thereof…

…and when you’re all done figuring it out you may find yourself going home with a 57mm Harken Carbo Becket Fiddle Ratchet Cam….Block .

Confused yet :-p.

Lets see if we can’t clear this up a bit…

WHICH MANUFACTURER: Of all of the brands listed above you will find that they all have something to offer that is worthwhile, some more than others. So this part of it many times can be narrowed down to what matches the already existing stuff on your boat, which brand you’ve heard good things about, or simply who offers just the right look for what you want. If you’re still not sure, a good place to start is the two brands that are sold the most here at our shop: Schaefer and Harken. Schaefer is typically our first choice for the dedicated classic looking cruiser, and Harken is typically our ‘go to’ for the more modern looking racer-cruiser. As long as you take the time to size a block properly for its use, any new block that you want to equip your boat with will surely offer you years of trouble free service. Simple as that; you really can’t go terribly wrong in terms of which manufacturer you pick.

WHICH MODEL: Now we get into a bit more detail and this is where you’ll have to narrow it down based on what type of boat you have and what your budget might be. To keep this short, we’ll talk about what The Rigging Company (TRC) is always looking for in a good block. When choosing non-metal bearings look for Torlon or Delrin ball bearings. For UV resistance, we recommend choosing a black colored bearing over white, if there is a choice. For the same reason we always prefer a black color if choosing a non-metal, composite sheave.

Torlon is the premium choice when it comes to roller bearing material.

The staff at TRC will tend to lean towards metal sheaves and cheeks, when available, for block longevity. If the block’s sheave pins are removable and the block can be disassembled and serviced, this is a big plus in our book. Also, it’s worth mentioning that we prefer blocks with forged shackles instead of stamped shackles. Having said that, other than the bit about white plastic ball bearings and white sheaves, none of these parts and what they’re made of are hard lines to our decision making, as much more goes into it.

BALL BEARING or PLAIN BEARING that is the question: Of course we always prefer roller bearings, right? Not always, as it turns out you don’t always need the rip roaring action of ball bearings, particularly in applications where the block isn’t especially free running, but under a lot of tension for long periods, like a boom topping lift or cascading backstay. Roller bearing blocks like to move and don’t particularly favor being under static loads for long periods of time. This can cause flat spots in the bearing, causing the block to not operate properly. If nothing else, ball bearings can start to become a noise nuisance when the boat and its rigging experiences very slight vibrations, causing a harmonic effect. Those of you that have heard that sound at anchor know what I’m talking about, it’s likely the ball bearing topping lift block hanging above your boom. Although we at TRC use and recommend mostly roller bearing blocks, keep in mind, less moving parts make for less maintenance.

SIZE and TYPE: These last criteria, likely the most critical, are perhaps also the easiest. Deciding the type or style of block is simply a matter of what is required, e.g. 2 sheaves, 1 sheave and a dead end (Becket), etc… Once that has been figured out we’re down to size. Typically the manufacturer categorizes their sizing using sheave size. Some manufacturers will use metric sizing such as 60 mm and some may use imperial terms like 2-3/8″. You will find that in most cases this sizing relates to the recommended line diameters, as well as load capacity. Paying attention to these last two details is the most crucial component to choosing the right block. This information should be listed on the product packaging or online specifications.

OH! Perhaps one other final consideration in the type or style category is: does the sheave need to ratchet or maybe support a metal wire?

Do youhave any additional thoughts? Tell us what you think . What is your favorite block and why? We’d love to hear from you!

Similar Posts

Views from aloft.

Today was a HOT one! We went aloft to see if this boat can accept an all rope jib halyard. As you can see, it is not the sheave that is the problem but rather space between the head-stay and sheave, it is simply too tight to fit anything other than wire. Other than the…

Chain Plate Service Anyone?

YIKES! [youtube http://www.youtube.com/watch?v=7iKRiBShhlQ&w=420&h=315] If it inspired you to consider your chainplates then read here for more information on chainplate service and inspection. ~T.R.C.

The JP54 Performance Ocean Cruiser

Now that we are discovering fixed wing sails and hydrofoils, the world is starting to accept canting keels as standard equipment. Super accomplished sailor, Jean Pierre Dick’s new yacht building company designs us a blue-water cruiser with an ocean-racer soul. Not only does the JP 54 claim sea worthiness to circumnavigate the globe, but it…

There are many styles of mast boots and spreader boots. Just like with anything else, choosing the right product and installing it properly is essential to its functionality. Installing a mast boot that doesn’t leak, has a low profile, ensures that the chocks (pictured below) or Spartite material stays put, and looks good, is essential…

More Dollars Than Sense!

Just had to share this find. Not sailing related but fun to watch……. [youtube=http://www.youtube.com/watch?v=M38GhA-2Quo&w=560&h=315]

Single Sideband Insulators for Backstays

SSB is a commonly used abbreviation that stands for single side band radio. We are certainly not radio experts here at The Rigging Company. When it comes to specific radio product knowledge, we always recommended that our customers seek the advice of a certified marine electrician. However, just like with all other mast related electrical items,…

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

You are missing the brand Allen from your list of block manufacturers, the picture of the Holt snatch block is a copy of the Allen one which we first designed and manufactured. Our products can be found on dinghies and small keel boats throughout the world and are used by National, European, World and Olympic champions. Success so far this year, International Dragon Worlds in Perth, Western Australia.

Thank you Graham for noticing. You know I am embarrassed to say that perhaps we didn’t account for this split up when we wrote the article. It’s been republished at least once since the original. I don’t even see that snatch block that on their site anymore. So it is just an Allen Snatch Block now? Part #A4475, right? I will update the link in the article.

Again thank you for noticing, I am sure we would noticed when we updated the article, but perhaps not.

No Worries, we split over 10 years ago due to Holtâs relationship with Nautos. Allen were always the manufacturer of the products and we continue to do so with ever greater success. We sponsor a number of Olympic teams to ensure our products are always up to scratch. We also supply the worlds leading dinghy brands. We have also just started fitting out the Petticrow International Dragon last Autumn (Fall) which has already culminated in a World Championship in Perth, Australia, in January. We will also be fitting out the new Etchells being built in Cowes in the coming months. To cut a long story short, if you have been using Harkenâs Carbo Magic range, you may well want to have a closer look at our Dynamic range, both in quality and price.

If you are interested in any of our products, please donât hesitate to give me a call or send an email, Iâd be happy to help.

Best Regards

Graham Adams +44 (0) 1621 773715 +44 (0) 7736 132880 [email protected] [cid:[email protected]] [cid:[email protected]] Cert No. 11184-QMS-001

2019 Catalogue

Thanks will do.

Username or Email Address

Remember Me

Lost your password?

Review Cart

No products in the cart.

- Privacy Overview

- Strictly Necessary Cookies

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Currency: GBP

- Worldwide Delivery

Mooring Warps and Mooring Lines

- LIROS 3 Strand Polyester Mooring Warps

- LIROS Braided Dockline Mooring Warps

- LIROS Classic Mooring Warps

- LIROS Green Wave 3 Strand Mooring Warps

- LIROS Handy Elastic Mooring Warps

- LIROS Moorex12 Mooring Warps

- LIROS Octoplait Polyester Mooring Warps

- LIROS Polypropylene Floating Mooring Warps

- LIROS Super Yacht Mooring Polyester Docklines

- Marlow Blue Ocean Dockline

Mooring Accessories

- Mooring Cleats and Fairleads

- Mooring Compensators

- Mooring Shackles

- Mooring Swivels

Mooring Strops

- LIROS 3 Strand Nylon Mooring Strops

- LIROS Anchorplait Nylon Mooring Strops

- Small Boat and RIB Mooring Strops

Mooring Bridles

- V shape Mooring Bridles

- Y shape Mooring Bridles

Mooring Strops with chain centre section

- 3 Strand / Chain / 3 Strand

- Anchorplait / Chain / Anchorplait

Bonomi Mooring Cleats

- Majoni Fenders

- Polyform Norway Fenders

- Dock Fenders

- Fender Ropes and Accessories

- Ocean Inflatable Fenders

Mooring Buoys

Max power bow thrusters.

- Coastline Bow Thruster Accessories

50 metre / 100 metre Rates - Mooring

Mooring information.

- Mooring Warps Size Guide

- Mooring Lines - LIROS Recommended Diameters

- Mooring Rope Selection Guide

- Mooring Warp Length and Configuration Guide

- How to estimate the length of a single line Mooring Strop

- Mooring Ropes - Break Load Chart

- Mooring Compensator Advisory

- Rope Cockling Information

- Fender Size Guide

- Majoni Fender Guide

- Polyform Norway Fender Inflation Guide

Custom Build Instructions

- More Article and Guides >

Anchor Warps Spliced to Chain

- LIROS 3 Strand Nylon Spliced to Chain

- LIROS 3 Strand Polyester Spliced to Chain

- LIROS Anchorplait Nylon Spliced to Chain

- LIROS Octoplait Polyester Spliced to Chain

Anchor Warps

- Leaded Anchor Warp

- LIROS 3 Strand Nylon Anchor Warps

- LIROS 3 Strand Polyester Anchor Warps

- LIROS Anchorplait Nylon Anchor Warps

- LIROS Octoplait Polyester Anchor Warps

- Aluminium Anchors

- Galvanised Anchors

- Stainless Steel Anchors

Calibrated Anchor Chain

- Cromox G6 Stainless Steel Chain

- G4 Calibrated Stainless Steel Anchor Chain

- Lofrans Grade 40

- MF DAMS Grade 70

- MF Grade 40

- Titan Grade 43

Clearance Chain

Anchoring accessories.

- Anchor Connectors

- Anchor Trip Hooks and Rings

- Anchoring Shackles

- Bow Rollers and Fittings

- Chain and Anchor Stoppers

- Chain Links and Markers

50 / 100 metre Rates - Anchoring

Chain snubbers.

- Chain Hooks, Grabs and Grippers

- Chain Snubbing Bridles

- Chain Snubbing Strops

Drogue Warps and Bridles

- Lewmar Windlasses

- Lofrans Windlasses

- Maxwell Windlasses

- Quick Windlasses

Windlass Accessories

- Coastline Windlass Accessories

- Lewmar Windlass Accessories

- Lofrans Windlass Accessories

- Lofrans Windlass Replacement Parts

- Maxwell Windlass Accessories

- Quick Windlass Accessories

Anchoring Information

- How To Choose A Main Anchor

- Anchoring System Assessment

- Anchor Chain and Rope Size Guide

- The Jimmy Green Guide to the Best Anchor Ropes

- What Size Anchor Do I Need?

- Anchor Size Guides

- Anchor Rope Break Load and Chain Compatibility Chart

- How to Choose Your Anchor Chain

- How to Establish the Correct Anchor Chain Calibration?

- Calibrated Anchor Chain - General Information

- Calibrated Anchor Chain Quality Control

- Calibrated Chain - Break Load and Weight Guide

- Galvanising - Managing Performance and Endurance expectation

- Can Galvanised Steel be used with Stainless Steel?

- Windlass Selection Guide

- More Articles and Guides

Stainless Steel Wire Rigging and Wire Rope

- 1x19 Wire Rigging

- 7x19 Flexible Wire Rigging

- Compacted Strand Wire Rigging

- Insulated 1x19 Wire Backstays

Wire Rigging Fittings

- Swaged Terminals

- Swageless Terminals

- Turnbuckles / Rigging screws

- Turnbuckle Components

- Backstay Insulators

- Wire Terminals

Rigging Accessories

- Backing Plates

- Backstay Adjuster and Fittings

- Backstay Blocks

- Pins, Rings and Nuts

- Rigging Chafe Protection

Fibre Rigging

- DynIce Dux Fibre Rigging

- LIROS D-Pro Static Rigging

- LIROS D-Pro-XTR Fibre Rigging

- Marlow Excel D12 MAX 78 Rigging

- Marlow M-Rig Max Rigging

Fibre Rigging Fittings

- Bluewave Rope Terminals

- Colligo Marine Terminals

Dinghy Rigging

- Dinghy Rigging Fittings

- Fibre Dinghy Rigging

- Stainless Steel Dinghy Rigging

Wind Indicators

Guard wires, guardrails and guardrail webbing.

- Guard Rail Fittings

- Guard Rails in Fibre and Webbing

- Guard Wire Accessories

- Guard Wires

Furling Systems

- Anti-torsion Stays

- Headsail Reefing Furlers

- Straight Luff Furlers

- Top Down Furlers

Furling Accessories

- Continuous Furling Line Accessories

- Furling Line Accessories

50 / 100 metre Rates - Wire and Fibre

Standing rigging assistance.

- More Articles and Guides >

- Cruising Halyards

- Performance Halyards

- Dinghy Halyards

Rigging Shackles

- Bronze Snap Shackles

- Captive and Key Pin Shackles

- hamma™ Snap Shackles

- Selden Snap Shackles

- Soft Shackles

- Standard Snap Shackles

- Tylaska End Fittings

- Wichard Snap Shackles

Lashing, Lacing and Lanyards

- LIROS 3 Strand Lashing, Lacing and Lanyards

- LIROS Braided Lashing, Lacing and Lanyards

- Cruising Sheets

- Performance Sheets

- Dinghy Sheets

- Continuous Sheets

- Tapered Sheets

Running Rigging Accessories

- Anti-Chafe Rope Protection

- Barton Sail Handling

- Lazy Jack Sail Handling

- Rodkickers, Boomstruts

- Sail Handling Accessories

- Slab Reefing

Shock Cord and Fittings

Control lines.

- Cruising Control Lines

- Performance Control Lines

- Dinghy Control Lines

- Continuous Control Lines

Classic Ropes

- 50 / 100 metres - Classic

- Classic Control Lines

- Classic Docklines

- Classic Halyards

- Classic Sheets

- LIROS Classic 3 Strand Polyester

50 / 100 metre Rates - Running Rigging

- 50 / 100 metres - Cruising Ropes

- 50 / 100 metres - Dinghy Ropes

- 50 / 100 metres - Lashing and Lanyards

- 50 / 100 metres - Performance Ropes

- LIROS Ropes

- Marlow Ropes

Running Rigging Resources

- Running Rigging Rope Fibres and Construction Explained

- How to Select a Suitable Halyard Rope

- How to select Sheets and Guys

- Dyneema Rope - Cruising and Racing Comparison

- Dinghy Rope Selection Guide

- Rope Measurement Information

- Running Rigging - LIROS Recommended Line Diameters

- Running Rigging Break Load Comparison Chart

- Colour Coding for Running Rigging

- Selecting the right type of block, plain, roller or ball bearing

- Replacing your Furling Line

- Recycling Rope

- Running Rigging Glossary

Custom Build Instructions for Sheets, Halyards, Control Lines

Low friction rings, plain bearing blocks.

- Barton Blocks

- Harken Element Blocks

- Seasure 25mm Blocks

- Selden Yacht Blocks

Wooden Blocks

Ball bearing blocks.

- Barton Ball Bearing Blocks

- Harken Ball Bearing Blocks

- Holt Dynamic Blocks

- Selden Ball Bearing Blocks

Ratchet Blocks

- Harken Ratchet Blocks

- Selden Ratchet Blocks

Roller Bearing Blocks

- Harken Black Magic Blocks

- Selden Roller Bearing Blocks

Clutches and Organisers

- Barton Clutches and Organisers

- Lewmar Clutches

- Spinlock Clutches and Organisers

Genoa Car Systems

- Barton Genoa Sheeting

- Harken Genoa Systems

- Lewmar HTX Genoa Systems

Traveller Systems

- Barton Traveller Systems

- Harken Traveller Systems

Deck Fittings

- Bungs and Hatches

- Bushes and Fairleads

- Deck Eyes, Straps and Hooks

- Pad Eyes, U Bolts and Eye Bolts

Rudder and Transom Fittings

- Pintles and Gudgeons

- Tiller Extensions and Joints

Stanchion Blocks and Fairleads

Snatch blocks.

- Barton K Cam Cleats

- Harken Ball Bearing Cam Cleats

- Holt Cam Cleats

- Selden Cam Cleats

- Spinlock PXR Cleats

Block and Tackle Purchase Systems

- Barton Winches, Snubbers and Winchers

- Coastline Electric Winch Accessories

- Harken Winches, Handles and Accessories

- Karver Winches

- Lewmar Winches, Handles and Accessories

- Winch Servicing and Accessories

Deck Hardware Support

Blocks and Pulleys Selection Guide

- Barton High Load Eyes

- Dyneema Low Friction Rings Comparison

- Seldén Block Selection Guide

- Barton Track Selection Guide

- Barton Traveller Systems Selection Guide

- Harken Winch Selection Guide

- Karver Winch Comparison Chart

- Lewmar Winch Selection Guide - PDF

- Winch Servicing Guide

Sailing Flags

- Courtesy Flags

- Red Ensigns

- Blue Ensigns

- Flag Accessories

- Flag Staffs and Sockets

- Flag Making and Repair

- Signal Code Flags

- Galvanised Shackles

- Stainless Steel Shackles

- Titanium Shackles

- Webbing only

- Webbing Restraint Straps

- Webbing Sail Ties

- Webbing Soft Shackles

Hatches and Portlights

Sail care and repair.

- Sail Sewing

Maintenance

- Antifouling

- Fillers and Sealants

- Primers and Thinners

- PROtect Tape

Fixings and Fastenings

- Monel Rivets

- Screws, Bolts, Nuts and Washers

- U Bolts, Eye Bolts and Pad Eyes

Splicing Accessories

- Fids and Tools

- Knives and Scissors

General Chandlery

- Barrier Ropes

- Canvas Bags and Accessories

- Carabiners and Hooks

- Netting and Accessories

- Rope Ladders

Seago Boats and Tenders

Chandlery information, flag articles.

- Flag Size Guide

- Bending and Hoisting Methods for Sailing Flags

- Courtesy Flags Identification, Labelling and Stowage

- Courtesy Flag Map

- Flag Etiquette and Information

- Glossary of Flag Terms and Parts of a Flag

- Making and Repairing Flags

- Signal Code Message Definitions

Other Chandlery Articles

- Anchorplait Splicing Instructions

- Antifoul Coverage Information

- Hawk Wind Indicator Selection Guide

- Petersen Stainless - Upset Forging Information

- Speedy Stitcher Sewing Instructions

- Thimble Dimensions and Compatible Shackles

Jackstays and Jacklines

- Webbing Jackstays

- Stainless Steel Wire Jackstay Lifelines

- Fibre Jackstay Lifelines

- Jackstay and Lifeline Accessories

Safety Lines

Lifejackets.

- Children's Life Jackets

- Crewsaver Lifejackets

- Seago Lifejackets

- Spinlock Lifejackets

Buoyancy Aids

Life jackets accessories.

- Lifejacket Lights

- Lifejacket Rearming Kits

- Lifejacket Spray Hoods

Overboard Recovery

- Lifebuoy Accessories

- Purchase Systems

- Slings and Throwlines

Floating Rope

- LIROS Multifilament White Polypropylene

- LIROS Yellow Floating Safety Rope

- Danbuoy Accessories

- Jimmy Green Danbuoys

- Jonbuoy Danbuoys

- Seago Danbuoys

- Liferaft Accessories

- Seago Liferafts

Safety Accessories

- Fire Safety

- Grab Bag Contents

- Grab Bags and Polybottles

- Handheld VHF Radios

- Sea Anchors and Drogues

Safety Resources

- Guard Wires - Inspection and Replacement Guidance

- Guard Wire Stud Terminal Dimensions

- Webbing Jackstays Guidance

- Webbing Jackstays - Custom Build Instructions

- Danbuoy Selection Guide

- Danbuoy Instructions - 3 piece Telescopic - Offshore

- Liferaft Selection Guide

- Liferaft Servicing

- Man Overboard Equipment - World Sailing Compliance

- Marine Safety Information Links

- Safety Marine Equipment List for UK Pleasure Vessels

Sailing Clothing

- Sailing Jackets

- Sailing Trousers

- Thermal Layers

Leisure Wear

- Accessories

- Rain Jackets

- Sweatshirts

Sailing Footwear

- Dinghy Boots and Shoes

- Sailing Wellies

Leisure Footwear

- Walking Shoes

Sailing Accessories

- Sailing Bags and Holdalls

- Sailing Gloves

- Sailing Kneepads

Clothing Clearance

Clothing guide.

- What to wear Sailing

- Helly Hansen Mens Jacket and Pant Size Guide

- Helly Hansen Womens Sailing Jacket and Pant Size Guide

- Lazy Jacks Mens and Womens Size Charts

- Musto Men's and Women's Size Charts

- Old Guys Rule Size Guide

- Sailing Gloves Size Guides

- Weird Fish Clothing Size Charts

The Jimmy Green Clothing Store

Lower Fore St, Beer, East Devon, EX12 3EG

- Adria Bandiere

- Anchor Marine

- Anchor Right

- August Race

- Barton Marine

- Blue Performance

- Brierley Lifting

- Brook International

- Brookes & Adams

- Captain Currey

- Chaineries Limousines

- Coastline Technology

- Colligo Marine

- Cyclops Marine

- Douglas Marine

- Ecoworks Marine

- Exposure OLAS

- Fire Safety Stick

- Fortress Marine Anchors

- Hawk Marine Products

- Helly Hansen

- International

- Jimmy Green Marine

- Maillon Rapide

- Mantus Marine

- Marling Leek

- Meridian Zero

- MF Catenificio

- Ocean Fenders

- Ocean Safety

- Old Guys Rule

- Petersen Stainless

- Polyform Norway

- PSP Marine Tape

- Sidermarine

- Stewart Manufacturing Inc

- Team McLube

- Technical Marine Supplies

- Titan Marine (CMP)

- Ultramarine

- Waterline Design

- William Hackett

Clearance August Race Boat Cleaning Kit £26.00

Clearance LIROS Racer Dyneema £55.08

Clearance Folding Stock Anchor £123.25

Clearance LIROS Herkules £0.00

Clearance Barton Size 0 Ball Bearing Blocks - 5mm £10.13

Clearance Marlow Blue Ocean® Doublebraid £18.48

Mooring Clearance

Anchoring clearance, standing rigging clearance, running rigging clearance, deck hardware clearance, chandlery clearance, safety clearance.

Sailing Blocks are used for various purposes onboard a yacht or sailboat.

Here is a guide to the different types available and the various uses for sailing blocks.

The term Block (also known as a pulley) refers to a manufactured part incorporating a wheel and an axle, which allows the wheel to rotate.

The wheel has a groove, and the rope or wire sits in the groove. The wheel may also be called a drum but is commonly called a sheave.

The axle is also known as the pin, bush or bearing.

The pulley or block is used to lift or lower heavy objects and facilitate a rope or wire's smooth change in direction.

Onboard a yacht or boat, the pulleys have specific names depending on the task. Blocks have many uses, from simply hoisting flags to managing heavy sails.

Over centuries, new technological developments have advanced the design of sailing blocks to become faster, smoother, stronger, and more dynamic in their specific use, depending on the task.

The main types of blocks are as follows:

Rachet Blocks

The main characteristics of each type of block are explained below.

The plain bearing block, the mainstay of the running rigging on a cruising yacht, is developed from the traditional dead eye, which has no moving parts and originated as a piece of hardwood, e.g. lignum vitae, with carefully grooved holes. Things have gone full circle with the advent of the modern-day low-friction ring equivalent.

Plain bearing means that the sheave rotates directly on a simple central axle, i.e. the transverse pin between the cheeks of the block. The sheave (pulley wheel) may have a load-bearing bush, also known as a bushing or sleeve bearing. The aim of adding a bush is to reduce friction and resultant wear. The bush that bears the load originates from the term Plain Bearing.

Plain bearing block features:

- No ball bearings, no roller bearings!

- Simple construction with only one moving part, the least possible to construct a serviceable pulley.

- Low maintenance

- The sheave rotates directly on a simple axle pin, which may have a load-bearing bush - sheaves have a groove designed to accept rope or wire sympathetically and are machined from nylon, aluminium alloy, brass or similar materials.

- Cost effective - reasonably priced compared with ball bearing or roller bearing blocks.

- Excellent for high static loads

- Excellent all round, multi-purpose functionality

- Excellent working life – no bearings to be crushed or fall out

Blocks with rolling elements are an engineering development of the plain bearing block.

Ball Bearing Blocks are ideal for running rigging applications where the line needs to run fast through the system and where the line needs constant adjustment under load, e.g. racing sheets - "release, pump, tension, release, pump, tension".

Blocks with bearings will run faster under light load and cope much better with fine-tuning adjustment under extreme load.

Ball Bearings in blocks are designed to rotate freely and can be identified by the fantastic whizzing sound they make when spun by hand under no load.

Ball Bearings are a set of multiple, relatively small diameter, spherical balls encapsulated in a ball 'race or cage' between the sheave and the rotating axle.

The inner and outer ball race holds the balls captive and allows them to roll so freely that they are as close as possible to frictionless.

The hardened, round surfaces of the spherical balls can handle both radial and thrust loads.

The minimal contact surface area between the small spherical balls is the reason for their negligible resistance to movement.

However, because the load-bearing surface is also low, ball bearings are susceptible to distortion when subjected to heavy force.

The picture shows a Harken ball bearing block, a ball bearing and a Selden ball bearing block.

Ball bearing block features:

- Virtually frictionless sheave rotation for free-running lines

- Outstanding response under dynamic loads

- Ultimate performance and functionality for racing

- Suitable for rapid release and continual tuning

- Excellent durability with Delrin/Torlon ball bearings

Roller Bearing Blocks are the 'Rolls Royce' premium choice for high load-bearing capability and low resistance under dynamic load. Go for roller bearings if you want exceptional performance for Racing, Regatta or Performance Cruising, especially for applications where it may be necessary to release or adjust a control line under extreme tension. Prompt, safe and efficient manoeuvers can be more easily achieved if the control line can be fine-tuned or released under pressure, e.g. your running backstay/vang/kicker purchase, main sheet or spinnaker halyard.

Roller Bearings are a succession of small diameter tubes or cylinders fitted into a roller 'race or cage' between the sheave and the axle. Roller bearings have more surface area contact than ball bearings. The increased surface area increases the load capacity and distributes it more evenly so that roller-bearing blocks generally have a much higher resistance to distortion under load than ball-bearing blocks. Roller bearings run less freely than ball bearings but have exceptionally low friction.

The picture shows a roller bearing on a sheave, an exploded diagram of a Harken roller bearing block, and another roller bearing design.

Roller bearing block features:

- Ultimate dynamic load capacity

- Premium Choice for severe conditions

- Excellent effectiveness under extreme static loads

- Outstanding response under acute dynamic loads

- Ultimate all-round, multi-purpose, high-performance functionality for Regatta sailing

- Excellent durability with Torlon roller bearings

Ratchet Blocks are ball-bearing blocks with an extra built-in braking mechanism.

The sheave is designed to grip the line and allow the brake to take the load. The braking feature is a ratchet system which stops the sheave from rotating.

The sheave design on a ratchet block differs from the smooth, rounded finish on a standard plain or roller-bearing block. Ratchet sheaves are typically designed with eight-sided facets (they look a little bit like shallow gypsy wheel pockets). These facets (flat angled surfaces) grip the line when the ratchet is working under load.

The ratchet works like a socket wrench or the internal workings of a sheet winch. There are ratchet pawls which drop into teeth as the sheave rotates. This is what makes the distinctive clicking noise. When rotation is ceased, the ratchet pawl engages the aligned tooth and holds a share of the load, using the friction created between the rope and the faceted sheave.

Ratchet blocks make it easier for your crew to haul in, manually hold and adjust lines, which would otherwise be impossible to physically manage under load. They also allow lines cleated under extreme tension to be eased without jumping out and ripping through your hands as soon as the jammer is released.

On dinghies, dayboats and small yachts, ratchet blocks counteract the need for jamming cleats on jib, spinnaker and mainsheets. However, a jammer may still be necessary to free your hands, for, e.g. adjusting control lines or giving your fingers a much-needed rest! On larger yachts, they offer extra control for trimming the spinnaker on a winch.

Ratchet Blocks are available in two distinct variations:

- Manual Ratchet Blocks feature a switch for on/off engagement - When the ratchet is on, the sheave will only operate in one direction to pull the line in. The ratchet mechanism that takes the load prevents any rotation in the other direction, which means that when the line is eased, it will have to run around a static crenellated sheave.

- Automatic Ratchet Blocks are fitted with an automatic tension sensing mechanism, which engages at a pre-set load and automatically releases when the line is eased. The roller bearings run freely in both directions under low loads and automatically engage as the pressure increases. Shifting between heavy and light loads is intuitive and seamless.

Ratchet blocks are, in effect, a miniature version of a winch without a winch handle (also known as a snubber), which can perform a similar function within the limits presented by a much smaller surface area due to the narrower diameter.

Some class rules outlaw any mechanical advantage for pulling in the sheets, which prevent the use of winches, e.g. Beer Luggers, where there is a great onus on ratchet blocks and snubbers to enable the crew to haul in, hold and control a loose-footed mainsail of around 300 square feet by hand. Ratchet blocks require less effort to control the sail than a normal free-running block.

Ratchet blocks are generally suitable for sheets on boats up to and including 6-metre sports boats and on larger boats in tandem with a winch with some caveats (these are not exhaustive):

- Mainsheet systems must be attached to the boom in multiple spots near the stern end (away from the gooseneck) to reduce/spread the load.

- Spinnaker sheets require a winch back-up option if the breeze gets up.

- Jibs and Genoas generally don’t need ratchets. The shorter sheet lengths mean the sail can usually be secured in a cleat or around a winch before it becomes fully loaded

- Ratchet blocks can be mounted in series so that spinnaker sheets on, e.g. Sports Boats like the Melges and J24s, can be hand trimmed in all conditions. The holding power can be fine-tuned by engaging/disengaging the ratchets to match the breeze strength.

Line Diameter and Specification – Important Factors:

Select the correct diameter line for the block because only a correctly matched diameter line will grip effectively in the flat facets on the sheave.

Select the appropriate rope finish - ropes with a smooth, hard feel will not hold as effectively as those with a more supple, pliable construction.

Select a line that will withstand the massive wear and tear increase caused by continuous adjustment on the faceted sheave. This means a regatta performance line is normally required, preferably with Dyneema or Technora blended with polypropylene (lighter weight) or polyester (heavy duty).

Snatch Blocks are an extremely useful addition to the rigging spares inventory on any sailing yacht because they can quickly and efficiently provide a temporary solution to various line routing issues.

- Jimmy Green offers various options from leading block manufacturers: Holt, Allen, Lewmar, Harken and Wichard.

What is a Snatch Block? A snatch block is a single sheave pulley where one of the side cheeks/straps opens to allow a rope to be inserted, without the rigmarole of reeving the line through the entire system. The opening function is achieved in varying designs by different manufacturers, but the purpose remains the same, e.g.

- Holt, Allen, Lewmar and Wichard - hinged head located on the sheave pin

- Harken and Wichard - soft attachment, removable on one side

Soft blocks perform a similar function to snatch blocks - made from a horseshoe shape fairlead - effectively an open-ended low friction ring - with a Dyneema loop which can be attached and detached.

Snatch Block Facts, Features and Plus Factors:

- The extra design and manufacturing process makes snatch blocks much more expensive than standard design blocks.

- The opening design allows a rope to be inserted without any reeving required - especially helpful if the line is long and it passes through multiple leads and clutches.

- Open the block, insert the line, close the block securely and attach the head of the block to your intended strongpoint.

- Quick and effective solution for changing sheet or control line leads.

- Excellent as temporary or spinnaker sheet-turning blocks.

- Can also be easily employed to create a 2:1 purchase, doubling the pulling power.

Visit our Deck Hardware category to explore the range of blocks available.

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Best Day on the Water

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Lifestyle

Advertisement

"Block" is the nautical term for a pulley. Blocks make it easier to lift heavy loads and overcome significant force with rope.