A Complete Guide to Teak Maintenance on Your Sailboat

By Joshua Bremmerer, CEO at Komodo Covers Teak surfaces are divisive in the boating world—loved by some for their sparkling appearance and perfect grip, loathed by others for the perceived difficulty of teak maintenance. The reality is that teak is nothing to be afraid of, as long as you follow some essential tips to take care of the material properly, minimizing costs in the process.

Teak is famed for its various grains of hard and softwood, making it naturally adhesive and anti-slip in practically any weather condition. Furthermore, it maintains a relatively cool temperature , insulating a boat to avoid engine overheating. Due to the several types of wood, different teak maintenance methods can drastically affect its ability to last.

So, it’s crucial to take the following steps into account to make sure you don’t mark the surface and keep your boat in excellent condition.

Cleaning is king

First things first, whatever you do, don’t use high-pressure cleaners on your teak because they will destroy the softer wooden elements, leaving ridges and areas that can quickly rot. Additionally, hard brushes or powerful cleaning detergents will cause a similar effect, damaging the vulnerable soft sections.

Instead, it’s much better to do regular cleaning—weekly if possible—with a very soft brush or Brite pad. You will see good results from lightly brushing against the grain with a mild detergent. If you see mildew or just want to make your sailboat sparkle, you could consider using a tiny amount of bleach, but do it with caution.

Smooth sailing with sanding

Most boaters with a teak deck consider it a standard practice to sand the surface once a year before the start of a season. Sandpapers come in various grits—for a teak deck, between 80 and 120-grit is the ideal level. The higher the number of grit, the more slippery the deck will be, so a medium level is suitable for teak as it will maintain the characteristic non-slip.

Seal the deal

Once you have cleaned and sanded the teak evenly, you can be forgiven for clapping your hands together and proclaiming a “job well done.” But you are still missing one last step—and it is a crucial one. A teak sealer will prolong the natural appearance of the wood for years to come while maintaining the pristine condition. Depending on the type of seal, some can contain biocides and even UV inhibitors which go that extra step in terms of preservation.

Aside from sealers, you can also consider using teak oil products, but be careful on how much you apply as sometimes overapplication of oil can promote mildew growth. If your boat isn’t going to be used regularly, this may not be the best course of action. The other issue with teak oil is that it doesn’t last particularly long, usually 4-12 weeks, depending on how well you have applied it.

Following these tips will put you in a great position to get your boat ready for a season on the water. If you choose the right cleaning products, sand your deck appropriately, and seal it with a good sealer, you should be able to maintain your sailboat deck for longer than you had ever imagined!

About Josh Bremmerer

Josh Bremmerer is an innate navigator, an experienced leader in the boating industry with over a decade of experience in management and company development and a lifelong passion for boating. As the manager of Glacier Ski Shop, Josh grew the small Shop into a nationally recognized business and increased profits by 400%. With that background, it’s no wonder Josh started his own business in the boating industry: Komodo Covers .

4 Step by Step Tips to Reproof Your Waterproof Jacket and More

Three sail care tips to save you money, 7 bluewater cruising sailboats we love, five best places where to sail at least one time in your life, live your passion, subscribe to our mailing list.

MARITIME Custom Teak Decks are made from patterns for each individual yacht.

- Deck sections are made up to 40 feet long.

- Planking can be straight-laid, or sprung to shape.

- We provide for king planks, margin boards, hatches and other deck fixtures.

- Decks of any width can be made by joining sections at caulk seams.

- The completed custom deck is delivered to your facility pre-assembled, pre-trimmed, and ready for final fitting and installation.

Maritime Wood Products consistently delivers the finest and most well thought-out deck systems. Contact us to learn more about our services.

We work closely with production boat builders to provide everything needed for the successful installation of our products. We can visit your facility and help design, engineer and pattern a custom fit deck for your application. We work within your production schedule and are responsive to time-sensitive orders and changes.

MARITIME™ Teak Deck Kits come pre-caulked and ready for installation. Maritime Wood Products supports Just In Time (JIT) inventory and delivers decking systems that improve manufacturing efficiency and quality. Contact us for more information.

- We fabricate our custom teak decks and teak deck panels either with or without a substrate (i.e. backing material), depending on application.

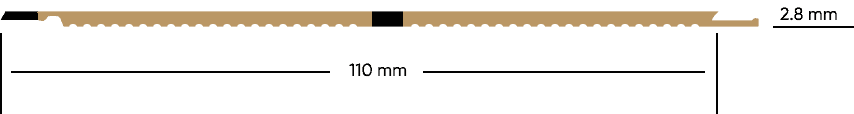

- Seams are caulked to the full depth of the planking for the longest possible deck life, and the panels are then sanded to a uniform thickness.

- Our standard plank width is 1-7/8". The caulk seam is 3/16" wide. Other widths are available upon request.

- Our standard deck thicknesses are 1/4", 3/8" and 1/2". Other deck thicknesses are also available upon request.

Proudly Made in the U.S.A.

PLASDECK ECO SERIES: A Revolutionary New Boat Decking Product

Three Ways to Get PlasDECK Decking on Your Boat:

- 1. Send us a template and order easy-to-install custom panels - Available in over 20 colors.

- 2. Find a PlasDECK installer in your area to do all of the work for you.

- 3. If you're pretty handy, use our rolls of DIY shiplap material - Available in the classic teak color.

- You can also add custom inlays to personalize your deck!

- Award-winning new product! Learn more about PLASDECK ECO SERIES.

PlasDECK Colors

PlasDECK is committed to bringing you quality boat and yacht decking that looks like real teak but without the maintenance!

Sample Packs

You can see and feel PlasDECK by ordering a sample pack!

Synthetic Boat Deck, Yacht Decking, Marine Teak Decking

PlasDECK is a patented synthetic teak boat decking option that provides the elegant look of a teak deck without any of the time-consuming and costly maintenance associated with natural wood teak. Made out of flexible PVC, this material is easy to work with and maintain. It’s the perfect option to upgrade your boat and replace the dingy old carpet. PlasDECK will hold up to the sun and marine environment for years while you enjoy more of your free time.

PlasDECK is specially formulated with ingredients that will prevent the material from drying out or cracking over time. It also has the highest possible UV protection to prevent fading, antifungal inhibitors, superior adhesion… and PlasDECK is proud to say that we offer the only synthetic teak decking option that’s made in the USA! With over 20 colors to choose from, PlasDECK is the most customizable boat decking option on the market.

Support & Customer Service

- Customer Service

- Find a PlasDECK Installer

- International Orders

- Boat Decking Installation Guides

- PlasDECK Installation & Repair Videos

- Returns & Refunds

- Shipping Information

- Boat Decking In-Store Pickup

Research & Information

- PlasDECK Cleaning Guide

- Boats on File

- Boat Decking FAQs

- How Shiplap Works

- Synthetic Teak Deck Specifications/SDS Sheets

- The PlasDECK Synthetic Decking Difference

- PlasDECK Boat Deck Weathering Study

- PlasDECK 5 year Warranty

- Synthetic Teak Boat Decking Repair

Select a Language

- Yachting World

- Digital Edition

Teak alternatives: 4 options for decking that doesn’t cost the earth

- May 7, 2020

Rupert Holmes explains what’s wrong with the marine industry’s obsession with hardwood and looks at real world teak alternatives

Photo: Lignia Yacht

Everyone loves an immaculate teak deck. They look great at boat shows and at chic Mediterranean quays, as well as providing excellent non-slip properties in the most demanding of conditions.

However, teak also has drawbacks. Firstly it doesn’t last forever, especially if a modern, and likely relatively thin, teak deck is scrubbed regularly. At the extreme I’ve seen a deck lose 1mm of thickness each year through scrubbing. Given the high cost of replacement this can have a significant impact on a yacht’s resale value.

The material also easily absorbs heat from the sun, making it uncomfortable to walk on in bare feet when in the tropics or Mediterranean summer. This also contributes to heating the interior of the boat.

Ocean Cork is one of many firms to offer eco-friendly teak alternatives

Teak doesn’t look good from a sustainability perspective either. A key problem is illegal logging of rainforest in Myanmar, one of the only four countries in which the species grows. Unfortunately, a ban on importing this illegal timber into the EU hasn’t stopped the trade, as evidenced by court cases in countries including Denmark, Sweden, Germany and Holland following the discovery of illegally imported teak.

As a result, the only way to be absolutely certain a source of teak is sustainable is to use salvaged material (or to ensure that the teak can be GPS-traced back to stump).

Timber at risk

“Teak is now considered a high risk timber,” confirms Nigel Stuart, MD of Spirit Yachts . “We take our responsibility to the environment very seriously and we are not prepared to risk using unsustainable wood.”

Teak alternatives have been available for many years and are gaining wide acceptance. In many cases they also offer multiple advantages over real teak, including better longevity. Many can be factory-made to match a template or CAD file, which significantly reduces labour and installation costs, while customisation can extend to logos and boat names.

Available products can be split into four broad categories:

- Modified softwoods

Expanded foam

Many of these don’t absorb liquids and are therefore easy to keep clean as any dirt stays on the surface.

Article continues below…

4 eco-friendly improvements to upgrade your yacht

1. Ditch the teak Teak is no longer universally popular. The price has gone up dramatically, supply is dwindling, and…

How hybrid sailing yachts finally became a feasible option

Every sailor is familiar with the wet cough of the diesel engine, and the acrid smell of its exhaust. For…

Many manufacturers offer a range of colours, with the most popular being shades close to freshly-scrubbed teak, or silvered, weathered teak. The former can look amazing at boat shows, though in the real world it can maybe look incongruous to those who understand the damage regular scrubbing does to real teak.

We’ve tried to give indicative prices for different options, but these are exceptionally difficult to pin down. Different products may need vastly different amounts of labour, which obviously affects cost, while detailing and edging is a major factor in the price of factory-made panels. The total cost for boats of similar sizes can therefore vary dramatically depending on the complexity of each of the panel shapes.

1. PVC decks

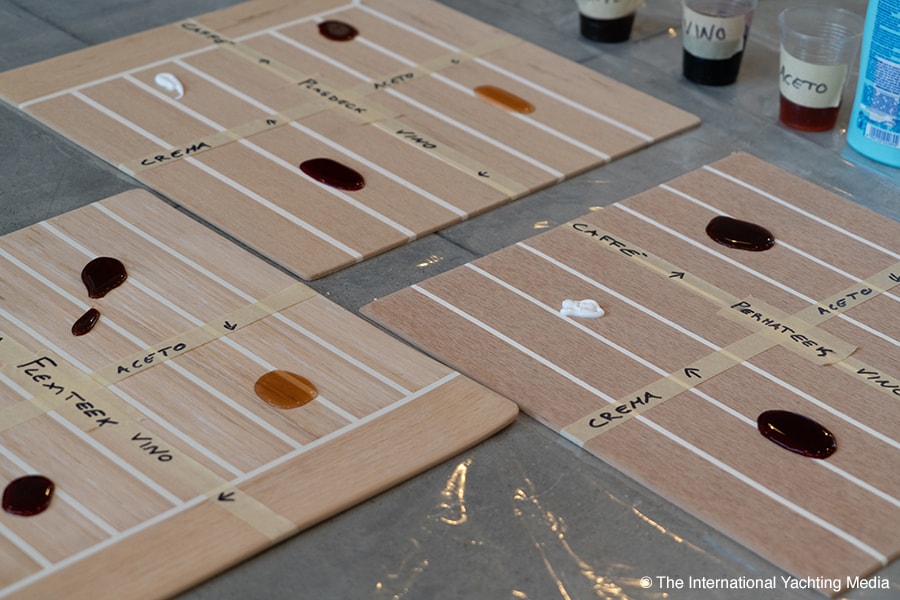

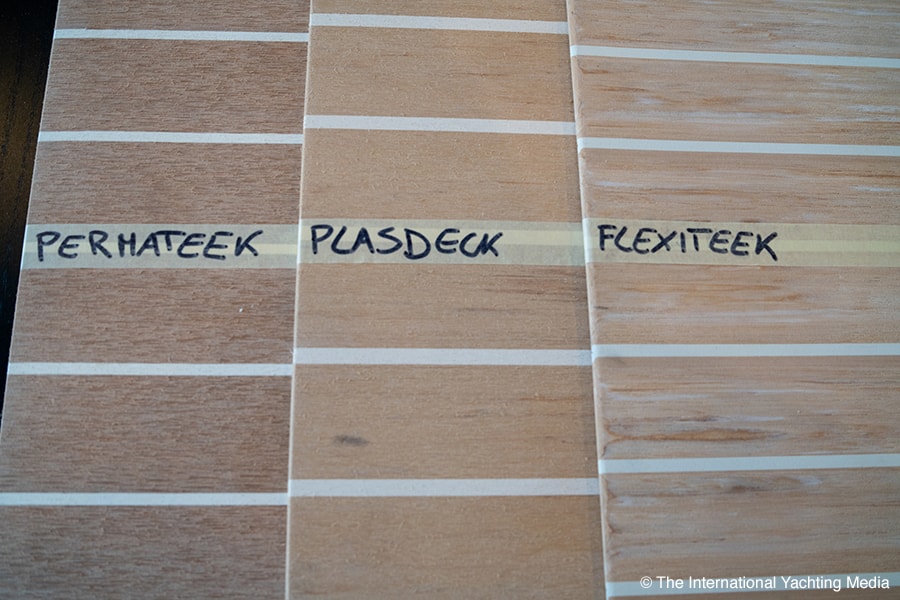

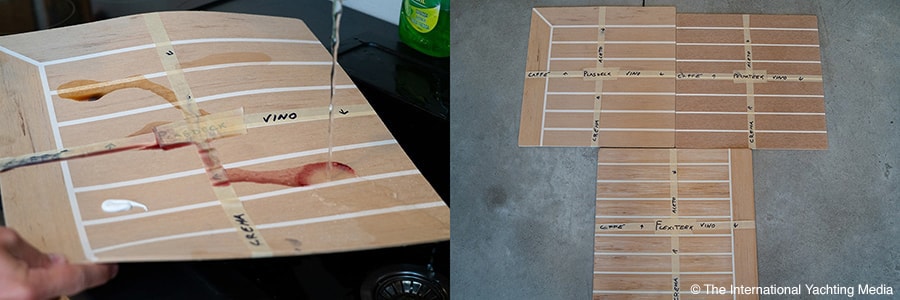

This option has historically offered some of the most convincing alternative teak products, with the grain, texture, impact resistance and non-slip properties of the real thing. As a result many of the new yachts seen at boat shows actually have simulated teak decks made of PVC.

Flexiteek decking on the SW105 Kiboko III

Despite their slightly textured surface, which replicates the grain of real wood, dirt and stains stay on the surface of PVC decking, so it can be cleaned relatively easily with a wet cloth and maybe soapy water. Unlike real teak, which has a mix of hard and very soft fibres, PVC decks can also be pressure-washed. Another bonus is that damaged areas can be sanded back to reveal fresh material that looks new.

One of the best-known brand names, Flexiteek, is celebrating its 20th anniversary and is expanding rapidly, with demand consistently growing at 20% annually. The company now produces 80,000m 2 of its decking product each year.

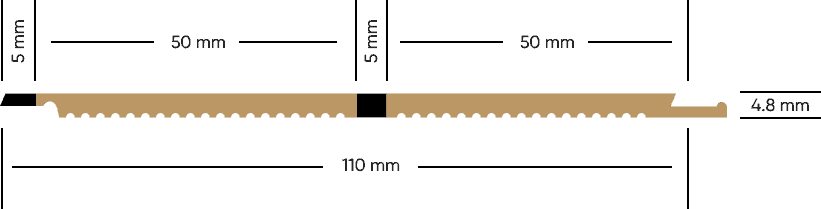

The 2G version, launched six years ago, is fully recyclable, while microballoons are used in place of chalk filler, which reduces heat absorption (certain PVC deck types and colours have been known to get very hot in direct sun). Flexiteek is available in a standard 5mm thickness and 11 colours, with plank widths from 45mm-200mm to replicate everything from planking to covering boards and cappings.

Flexiteek says PVC experts suggest the surface may start to crack after 25-30 years, but no problems have been observed on 20-year-old decks so far and the life span may be considerably longer. High traffic areas can become glossy, but these can be gently coarse sanded back by hand to the original matt finish.

Esthec seamless decking installed on a Princess R35

Esthec is a part of composite floor specialist Bolidt, which makes flooring in any shape for industrial applications through to decking for ships. Dutch yard Saffier has been fitting Esthec to its range of daysailers since 2008.

“We made one deck with Esthec and set this right next to a real teak deck,” managing director Dennis Hennevanger remembers, having been immediately taken by the product. “We invited all the customers who had ordered a Saffier with teak deck and gave them the choice… they instantly all went for the Esthec deck.”

Saffier has since built nearly 500 yachts with Esthec decks, “all without any problems”. Hennevanger says it is not necessarily a cheaper option to teak, but thinks it should last forever.

Saffier’s SE37 daysailer is fitted with PVC decks from Esthec

“I also like the technical side of Esthec,” he adds. “It is made completely seamless [the caulking doesn’t go right through], so it is impossible to have any leakages.” Additional benefits are that it is maintenance free, with no fading, has excellent anti-slip properties and comes with a complete freedom of design.

PlasDeck is less well known in the UK but has been established for 15 years, offering a range of PVC products in 28 shades that look and feel like wood. The company holds patents for non-migratory plasticisers that are bound to the molecular structure. The product is therefore very UV resistant and remains elastic as the oils don’t evaporate over time.

Fungus inhibitors throughout the material hold back the formation of the green mould that can all too easily grows on real teak decks, especially during persistently damp winters.

Permateek decking on a Contest 38

Permateek is another popular brand name and has recently introduced new shades that better mimic the grain of real teak. From a sustainability perspective, a big drawback with PVCs is they are plastics and will therefore remain in the environment forever. To offset this Flexiteek plants one tree for every 10m 2 of product sold. Esthec, meanwhile is formed from natural components, without the harmful ingredients commonly found in PVCs.

Prices for PVC products tend to range from €150 to €1,000 per square metre, varying according to the design and size of each panel. As a guide, in the UK Permateek costs £150-£350/m 2 depending on the complexity of the design. This compares to a material cost of around £285/m 2 for 6mm teak – but don’t forget there’s far more labour involved in laying a real teak deck.

Gisatex offers a more economic PVC product, at €69 per square metre, but in a thinner textured, non-slip material that makes no attempt to match the grain of teak. The company, which has been established for 10 years, sells matched repair kits for €10 and says a “very long lifespan is expected.” Light weight is a further advantage, but custom panels are not available.

Gisatex sits at the lower end of the PVC price bracket

There’s an increasing trend towards cork decking, according to Piet van der Staay of Marinedeck 2000, especially among younger boat owners. It’s a natural product harvested from FSC certified forests, largely in Portugal.

Common advice is to look for a product with large cork grains as these cope better with impact. In any case the material is inherently resilient and is significantly better than teak at resisting wear and abrasion.

Cork is also is a good insulator, so decks remain comfortable to walk on even in strong sun. Over a three to five year period it will slowly take a light grey hue, but this can be sanded back to reveal the original colour.

Marinedeck claims that its decking is popular among younger boaters

Marinedeck 2000 consists of cork granules with a synthetic polyurethane binder. It’s produced under high pressure, which gives the feel of high-density material, but is still flexible and absorbs knocks well. It’s supplied as individual planks, or as preformed finished pieces with a standard thickness of 9mm. The company has been in operation since 1986 and says there are still decks in good condition from its early days. As a result van der Staay quotes a 40-year expected lifespan.

Prices for Marinedeck 2000 start at €320/m 2 (ex VAT) including adhesives, while custom panels cost €520/m 2 (ex. VAT).

Another supplier, Ocean Cork, produces 8mm planks as standard, but 4mm is available if weight is critical. Given it’s one of the lightest decking materials available, at only 2.4kg/m2, for cruisers the thinner option appears to offer little benefit. Prices start at €349 (inc. VAT) for 1m 2 DIY kit (including glue and caulking) and approx €400/m 2 (inc. VAT) for larger custom made panels.

Ocean Cork is available in 8mm and 4mm thickness

This is a material with a soft cushioned feel, excellent grip underfoot and good shock-absorbing properties. SeaDek, which is made from a closed-cell PE/EVA foam is popular throughout the racing world, from sportsboats to the America’s Cup and the Ocean Race. It can be made in custom panels and in different thicknesses and is manufactured with an effective acrylic-based pressure sensitive adhesive for quick peel-and-stick application.

SeaDek’s Jason Gardner says the large range of colour, thickness, density and design options means the price range can be very wide. Whether or not there’s already a pattern for that model of boat in the company’s database also impacts pricing.

Sean Roebuck of ProCast, SeaDek’s leading UK fabricator, says prices including VAT generally work out in the range of £114-£151/m 2 .

SeaDek is popular with ocean racers. Photo: Ainhoa Sanchez/VOR

Cer-Deck, sold by Italian company Ceredi, also has a soft, slightly cushioned feel, very high resistance to degradation in sunlight and is colour stable.

It is 6-8mm thick and is available with a strong 3M self-adhesive backing to minimise labour costs when fitting. Custom panels cost around €250/m 2 (ex. VAT).

Life expectancy for expanded foam materials is around five to seven years for harsh use, and longer for less-heavily used boats. On the downside these materials are susceptible to damage from impact or pets’ claws.

Cer-Deck has a soft, cushioned feel

Modified softwood

Lignia is the latest product to be launched on the market, based on pine grown in FSC certified forests. After harvesting, the timber is impregnated with resin, before being dried in a curing process to ensure the resin is locked in at a molecular level. This gives Lignia performance and durability that can surpass tropical hardwoods.

It has a similar appearance to teak and can be worked in the same way, but has an expected lifespan of 50 years. The impregnation of resin means end of life disposal is not as easy as for untreated timber – the recommended option is to use it as fuel in biomass generating plants.

Anyone who saw the Spirit 50CR at last year’s Southampton Boat Show can attest that a quality yacht with Lignia decks will look stunning. It also has the benefit in being faster to dry than teak, which is handy in areas used for seating. Material costs are a little less than for teak, with typical savings around 5-20%. However, Lignia decks are just as labour intensive to lay as real teak.

Lignia, shown to great effect here on the decks of the Spirit 50CR, is a real softwood product treated to give it the appearance and longevity of teak

Price gauge

Tye Conway of UK-based decking specialist Elite-Teak says that typical installed prices in the UK are often lower than elsewhere in northern Europe, with many jobs falling into the following price ranges (ex. VAT) per square metre:

Synthetic teak: £200-£300 Foam decking: £150-£200 Cork decking: £200-£300 Real teak decking: £500-£600

Teak-effect solar panels

Italian solar panel manufacturer Solbian has a range of panels with a pigmented layer that creates different colour schemes. The teak option reduces output by only 6-8% compared to an equivalent standard panel, while custom sizes and shapes can be created without increasing prices.

The upcoming Spirit 44E will be fitted with teak-effect solar panels

The company has been working on projects with major boat manufacturers – the panels will be used, for instance, on the locker hatches of the aft deck of the Spirit 44E that’s currently in build. Solbian is also developing a version of the teak-effect panel with a non-slip finish.

Colour shades can also be matched to products of companies such as Flexiteek. Prices are typically 50% to 60% above those for the company’s standard solar panels .

First published in the April 2020 edition of Yachting World.

Everything You Need to Know About Your Boat's Teak Decking

Sep 24, 2021

There is a lot to love about teak.

Golden brown, long grain, fresh-cut teak bestows an unquestionable aesthetic elegance to any boat deck. But boat owners don’t just love teak for its looks.

TOUGHNESS AND DURABILITY

Teak is a naturally water-resistant wood from southeast Asia which has been hailed in its ability to beat many wood alternatives (like mahogany and pine) in terms of toughness and durability.

An abundance of silica in teak makes it so tough that it is known to quickly blunt the tools of expert craftsmen. Bad news for craftsmen, good news for boat owners.

Teak can withstand any weather it cruises through, and the same high silica content that dulls a tool’s edge bestows a non-skid surface that provides necessary traction on wet decks.

Teak’s high oil content also forestalls shrinking, expanding, and cracking, helping well-maintained teak decks last up to 40 years before replacement beckons.

HOW TO MAINTAIN YOUR TEAK

Here’s how to best maintain teak decking on your yacht, without too much extra effort:

Embrace Teak’s Color Changes

As teak is exposed to weather, it naturally takes on a silver-gray patina. But some boat owners prefer to luxuriate in the sun-kissed gold brown of fresh-cut teak.

Maintaining this hue long-term means using harsh brightening agents and committing to a regimen of extensive scrubbing, two things guaranteed to shorten the lifespan of your teak deck to fifteen years or less.

You can lengthen your deck’s lifespan by falling in love with the silver patina it prefers and updating accents on your boat to match.

Cleaning Teak

Though teak’s grain is hard, the soft fibers between grains are easily damaged by hard scrubbing or too-strong cleaners.

To clean your teak deck, simply rinse regularly with fresh or saltwater. Use a mop or soft-bristle brush to wipe away tough dirt, but avoid high-pressure nozzles or washers that damage the wood’s top layer.

How often should I deep-clean my teak deck? Many boat owners will want to undertake a deeper clean one to four times a year (depending on location and wear).

- Most experts advise you to steer clear of two-step cleaning solutions and choose single-part wood cleansers and soaps to limit corrosion and maximize your teak deck’s longevity.

- If a single-part cleaner is not available, use a non abrasive, powdered dishwasher detergent (like Bon Ami or Calgon). Dilute 1/4 to 1/3rd cup of the detergent in 2.5 gallons of water before applying.

- With a mop or soft scrub brush, apply the single-part cleaner or powdered detergent solution to your deck. If using a scrub brush, use care to only scrub across the teak’s grain.

- For localized stains, put a drop or two of liquid dish detergent (like Joy) on a terry cloth and rub it into the stain gently. Give the area a thorough rinse before checking your fully clean teak.

Combating Mildew

When mildew inevitably appears on the grain of your teak, softly scrub the spot with a 50/50 solution of white vinegar and water.

Resisting the urge to use bleach will benefit your deck in the long run. However, if the urge proves too strong, mix 1 cup of bleach in 1/2 bucket of water and apply it to the areas in need. Thoroughly rinse the solution away before the decks dry.

Oiling Teak

Boat owners striving to maintain the warm gold of fresh-cut teak will often reach for teak oils (usually tung or linseed) to bring out their wood’s young shine.

Teak oil “feeds” the wood, brightening its grain patterns and intensifying its rich colors. Unfortunately, oiling teak is more about aesthetics than maintenance.

Teak oils do not protect the wood, and only bring back that young color for a month or two at a time. Some experts even claim that these oils catch and hold dirt, leading to blotchy, stained wood over time.

Sealing Teak

Teak sealers are a popular method of care among boat owners looking to achieve their teak’s natural look while extending their deck’s durability.

Rather than “feeding” the wood, sealers block against moisture and dirt while sealing in its natural oils and resins.

A good teak sealer only requires reapplication once a year, making it a more practical option for most boat owners with teak decking.

UNDERTAKING (AND AVOIDING) A MAJOR REFRESH OF YOUR TEAK

When teak decking is properly cared for throughout the year, boat owners can avoid a major refresh or teak restoration project.

However, all boat owners should keep a careful eye on their deck’s caulking and be quick to repair loose strips or gaps that allow water to quickly and destructively penetrate the teak.

Do not trust what you see at first glance. To fully check your boat deck for needed repairs, wet the deck fully and make note of any area that stays wet longer than the surrounding teak. These lingering wet patches give clues to where caulk may need to be removed and reapplied.

In addition to proper cleaning, properly caring for your teak decks means sanding the deck every 12-18 months. (Regular cleaning will minimize the need for regular sanding, and sanding is not recommended for any boats less than a year old.)

Luckily, you can avoid a major restoration project and enjoy the timeless style of your teak decking for decades by putting a little time into cleaning and care now.

SIGN UP FOR EMAIL UPDATES

- Teak Decks: Navigating the World of Boat Decking

When you picture a luxurious yacht or a classic sailboat, what's one common feature that instantly comes to mind? Teak decks! These stunning wood surfaces have been a hallmark of marine craftsmanship for decades. In this comprehensive guide, we'll set sail through the world of teak decks, exploring everything from their history and allure to the various options available in the market today. So, fasten your lifejacket , and let's dive into the world of teak decking for boats.

The Rich History of Teak Decks

Teak, scientifically known as Tectona grandis, is a hardwood native to Southeast Asia. Its use in boat building can be traced back centuries. We'll journey through time to uncover the rich history of teak decks and why they have stood the test of time.

Defining Teak: A Wood of Distinction

Before we proceed, let's define teak wood and its exceptional qualities that make it a prized material for boat decking. We'll explore its natural characteristics and why it's highly sought after in the marine industry.

The Allure of Teak Decks

The aesthetic appeal.

Teak decks are renowned for their breathtaking aesthetics. We'll discuss how the warm, golden hue of teak wood enhances the visual appeal of boats, adding a touch of elegance and luxury.

Unmatched Durability

Teak wood's natural oils and density make it exceptionally durable in the harsh marine environment. We'll delve into the longevity and robustness of teak decking, explaining why it's a preferred choice for boat owners.

Comfort Underfoot

The comfort of teak underfoot is often praised by sailors. We'll discuss how teak decks provide a non-slip surface and a comfortable feel, even in the most challenging sea conditions.

Types of Teak Decking

Traditional teak decking.

Traditional teak decking involves individual teak planks assembled on the boat's deck. We'll explore the craftsmanship involved and its classic appeal.

Synthetic Teak Decking

For those seeking a low-maintenance alternative, synthetic teak decking is gaining popularity. We'll discuss the benefits and drawbacks of this modern solution.

Teak Deck Systems

Teak deck systems offer innovative installation methods. We'll explain the different systems available and their advantages.

Maintenance and Care

Preserving the beauty.

Teak decks require proper maintenance to keep their beauty intact. We'll provide tips on cleaning, sealing, and preserving your teak decking.

Restoring Weathered Teak

Over time, teak can weather and lose its luster. We'll explore the process of restoring weathered teak to its former glory.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine.

Navigating the Market

Teak decking for boats in the uk.

If you're a boat owner in the UK, we've got you covered. We'll guide you through the options available for teak decking for boats in the United Kingdom.

Teak Yacht Decking

Yachts demand the utmost in elegance. We'll discuss teak yacht decking and how it caters to the discerning tastes of yacht owners.

In conclusion, teak decks are not just a functional element of a boat; they are a symbol of timeless elegance and craftsmanship. Whether you're a boat owner looking for a classic touch or a modern solution, the world of teak decking offers a variety of options to suit your needs. So, set sail with teak, and elevate your boating experience with its allure and durability.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite

sailing destinations .

Practical Boat Owner

- Digital edition

The truth about teak decks

- Ben Meakins

- March 1, 2016

Shipwright Robin Benjamin says modern, thin teak decks need lots of regular care, and so it’s vital to follow his advice on how to keep them looking good

In the last 15 years I have worked on more teak decks than I care to remember, writes Robin Benjamin : I think I’ve seen every problem that exists. What you have to know straight away is that, like anything, teak decks need looking after. If you take care of your decks they may last 20 years or more, if you don’t you’ll be appalled at how awful they look after only five. Because solid teak decks have been the norm for hundreds of years they have understandably earned a serious reputation for longevity. Today’s teak decks are not the same thing at all.

In many cases modern teak decks are little more than a quick way for the manufacturer to up the ‘class’ of their product. Many are poorly fitted, the wood is too thin and the caulking gap too narrow. Because of the minimal amount of wood involved the best plug on the deck might only be 3mm deep. Likewise, the caulking, unless of adequate depth and width, will not remain glued as the wood moves. However, all these problems would amount to little if folk took care of their teak decks. The most important advice is to wash the deck every week but few people can spare the time. It’s quite simple however: if you don’t wash your deck regularly it will soon go grey and dirty.

Don’t scrub

This is how worn teak decks can become after only five years of regular scrubbing and sanding

I’ve seen it done: the owner is standing there, his trouser legs rolled up, his knees red. True, his deck looks great… from the pontoon. But if you look carefully you’ll see grooves in the planks where the softer areas of grain have simply vanished. This is how it starts. Consider that you began with a lovely smooth surface, like a CD for example. After scrubbing it looks more like an LP record, but worse, much worse. Imagine now how quickly the ‘peaks’ will wear down as you walk on them. Of course it doesn’t end here, this is only the beginning. To keep your deck clean there is only one way, and that is a gentle wash with nothing more violent than a light detergent and a large sponge or very soft brush. If you do this regularly you will not wear down the teak, but you will wash off the dirt before it gets ingrained. Dirt contributes to the wear of a teak deck. If this approach doesn’t work then you can try oxalic acid. Dissolve some crystals in warm water, do not breathe the vapours and make sure you wear gloves. It burns. Rinse well. Oxalic acid should not harm anything on the boat except your skin. There are plenty of products that do the same thing but cost a lot more. If acid doesn’t bring back the colour then there’s only one thing left to do if you want a lovely looking teak deck, and that is to sand it. But if you want my advice: continue to wash it carefully and often, with soap, and live with the deck not looking its best. For some reason no one listens to me. I gladly advise people on how to look after their decks for free, even if it means I don’t get any work. It’s better for everyone, except me, that you take my advice. Yet despite this I still see people scrubbing their teak. I shake my head in wonder. Did I not explain what would happen if they scrubbed? ‘But it looks so great!’ they say. ‘So what’s the problem?’ The problem is that the next time they see their decks they will look grey and dirty again. The only difference will be that there is less teak than there was before. If your feet don’t wear down the peaks then they’ll fill up with dirt, making it look even worse. There’s only one way to get it out – more scrubbing. This time you’ll have to scrub harder to see a result. Can you see what’s happening? There will come a point soon when you decide the decks are looking pretty rough and need a good sanding.

Sand me timbers!

New decks get sanded to make everything look nice and flush – but it’s not a good idea to repeat this too often

Boatyards are very keen to do this work for you and why not? Next time you see the boat it will look great and they know you’ll be back, because soon the caulking will start to roll out in long spaghetti-like strips and the plugs will fall out, exposing the screws and making water ingress all the more likely. Now you’ve really got a problem. The plugs are not too much trouble but there will be hundreds to do. The real problem is the caulking. Just because some of it comes out really easily does not mean that it will all be like that. No, some of it will be sticking just like the manufacturer intended. You can make a special scraper to remove it but inevitably you will slip, damage areas and, even worse, you will enlarge the groove. If you’re really lucky you might be able to use a router for about 35% of the deck, but routers are vicious and it’s all too easy to make a mistake. Even a small enlargement of the slot will look terrible. Not only that but you’ll need a curved guide to run the router along for each slot. This takes ages. Bad enough if you’re doing it yourself, but it’s unbelievable if you’re paying a yard. Specialist tools exist but they are hideously expensive and it’s only the specialist yards that are likely to have them. Unfortunately the yard will be charging by the hour and there’s always a lot of work on any teak deck. So what are the options now that your deck is worn out? You can’t just remove it, because underneath it will be horrid. If it was laid properly in the first place they will have keyed in the glued surface and that means taking to it with a grinder on a plastic boat. And you’ll still have to cover the decks to hide the mess. So I hope you can see that I’m advocating care and prevention for your lovely teak deck. To just leave it uncared for is an outrageous waste of a precious resource. If that isn’t enough to make you care for your deck, then consider the cost of replacement. Teak costs approximately £3,000 a cubic metre. But you’ll need a lot more than you think, because just cutting down a big plank to size wastes a hideous amount of wood. The cost of the teak is a large part of the final bill. Basically you can quadruple the price of the teak to take into account the cost of first measuring and photographing the original deck to ensure everything fits properly, the cleaning up of the surface underneath and finally replacing the wood. To do the job properly you may have to remove the chain plates and that means dropping the mast and completely readjusting it afterwards. Not only that, but all those deck fittings that haven’t been touched for years will need to be removed. And don’t be surprised if many of the bolts are hell to get out or break in the process. It’s possible that some of the bolts were made specially or have been glassed over. You’ll need somewhere to do all this. Perhaps it’s possible to make a good cover but even this adds to the cost. The alternative is to put the boat in a shed somewhere. Anything is possible but it always costs. Replacing a teak deck is a massive job. To replace the decks on a 9m (30ft) boat is six weeks’ work – three months for a 15m (50-footer). We are talking about many thousands of pounds and your boat out of action for a while. There are other considerations before you decide on a teak deck. They weigh more: the caulking is surprisingly heavy, not to mention the wood and the thousands of screws. Perhaps what worries me most about laid decks on glassfibre boats is that you have to make thousands of holes in an otherwise perfectly waterproof surface to hold the deck down. Many fibreglass boats’ decks are balsa cored, that is to say, the deck is made of two layers of fibreglass with a layer of balsa wood in between. Balsa wood will not last long if it gets wet, yet this strikes me as very likely. The law of averages suggests that if you make 2,000 holes in a deck the chances of them all staying waterproof for years on end is pretty slim. What happens when the balsa has rotted away? I just don’t think making thousands of holes in a deck is wise. It is possible to lay a teak deck without screws, but it takes longer and therefore costs more.

So let’s sum up and cover up On the one hand I am thankful for owners and teak decks since they allow me the life I lead, but on the other I am very sad at the waste of it all. People could save themselves a lot of time, inconvenience and money if they just took care of their decks. And for some reason no one wants to spend money on ‘posh’ covers to protect their boat. Covers are initially expensive but they will repay their cost several times over. Not only will you not be required to replace your decks but you’ll be able to sell your boat for more because it has obviously been well looked after. It’s not just teak decks that will benefit from protection – plastic windows, instruments and gel coat will all last longer if kept out of the sun, wind and rain. The Grand Canyon was created by erosion from the elements. When you think like that, surely you can understand why I recommend covering up. I can only do my bit. I can’t change the world and I can’t change fashion, but I hope I can slow down the damage by telling the truth. So now you know. And remember: don’t scrub!

The good, the bad and the ugly

With decking that is very thin, the plugs over the fastenings are even thinner and can lift if the glue fails

This plug seems to have a problem. It could be loose and holding moisture, or the fastening is corroding

s Covers over vulnerable varnished work make sense, but a complete cover will also protect the deck

s Stains from oil and ferrous metal can be very awkward to remove from teak – try oxalic acid

Even old-style decks can have their problems. Here, to avoid butt joints, the planks had been scarfed together and, after many years, the feathered edge started to lift. The owner simply fixed it with epoxy

This thin timber decking has lost its caulking compound and the corner is starting to deteriorate

Tips for keeping teak in top condition

- Wash gently once a week

- Use a light detergent and soft sponge or very soft brush

- Tackle tough stains with oxalic acid solution

- Fit a cover over the whole deck

- Repair loose caulk and plugs promptly

- Scrub with a hard brush

- Leave decks to get really dirty

- Sand except as a last resort

This article was originally published in the June 2007 issue of PBO.

10 Teak Cleaners tested

We get scrubbing to find out what effect a variety of teak cleaners have on the woodwork of a Sigma…

Masking up teak decks

get the tape that sticks...

Cutting expensive teak-faced ply

How to get a neat edge

9 tips for using sealant

Premium bonding: some techniques for getting the most out of sealant without ending up covered in the sticky stuff!

How to stop a swing keel leak

John Taylor finds a car steering rack gaiter stops leaks from the lifting cable of his swing keel

Winterising a boat: 61 point checklist

PBO experts offer their top tips for winterising a boat, helping to keep your vessel and gear in good condition…

The great UK antifouling test for cruising yachts

20 antifouling paints tested in 13 UK locations: which works best where you keep your boat?

The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Pricing Plan

- Superyacht Insight

- Product Features

- Premium Content

- Testimonials

- Global Order Book

- Tenders & Equipment

Have we reached peak teak?

Teak decking has long been regarded a superyacht’s crowning glory, but the controversy around “conflict wood” from Myanmar forced the industry to come up with ethical and sustainable alternatives. Marilyn Mower speaks to the pioneers leading a new wave of deck innovation.

We’ve known for decades that teak decking, the golden crown of a fine private yacht, has become problematic. Particularly contentious is old-growth Myanmar (Burmese) teak, or Tectona Grandis . It may be the highest-quality, most durable teak in the world, known for its warm colour and superior water resistance, but it is also clouded in environmental and humanitarian controversy.

Rumours of mass destruction of forests and exploitation of the Burmese people began filtering west in the 1960s, about the time the country dissolved into a military dictatorship. Tumultuous years followed, then, in 2021, after a brief period of stability, things took a turn for the worse when a regime with a brutal ethnic-cleansing programme took control (it still holds a grip over the country today). Bent on financing itself, it instilled a state-controlled timber monopoly, allowing traders to indiscriminately log as long as the government got a share of the profit. At the current rate of logging, the Environmental Investigation Agency (EIA) warns that the country will lose its forests by 2035.

Over the years the US and EU have implemented various bans and regulations to prevent illegally harvested Myanmar teak from entering their markets. In June this year, the EU Timber Regulation, which sought to curb imports based on a somewhat voluntary due diligence, was replaced by a new broader and stricter methodology. Now any operator or trader who places these commodities on the EU market, or who exports from it, must prove that the products do not originate from recently deforested land or have contributed to forest degradation.

All these interruptions in sales of Burmese teak led to scarcity and rarity, resulting in a hike in prices, which simply heightened the demand for it. It also created an explosion of new teak plantations in other countries where it has always grown naturally but in smaller quantities.

Plantation teak has been touted as a solution, but it’s not quick-growing. Plant a teak tree today and it will be 30 to 50 years until it can be harvested. Even then, compared to the lumber from an 80- or 100-year-old forest tree, there are differences. While hardly noticeable in furniture, when it comes to decks, boards milled from young trees are shorter and narrower and the grain is not as tightly packed. The other issue is that the expansion of teak plantations – when not responsibly managed – can contribute to deforestation as well as the elimination of naturally biodiverse rainforest habitat and the people and animals that depend on it.

While the superyacht industry is a bit player in the global teak market, it is a high-visibility target for those who could criticise its environmental footprint. One company making a stance is UK design firm Harrison Eidsgaard , which says that teak as a deck material makes them “uncomfortable”. “While durability is paramount for all the obvious reasons, we feel owners should be involved in the thought process and discussion [of] alternatives,” says co-founder Ewa Eidsgaard.

Alternatives include ethically sourced teak, exotic woods, farmed hardwoods chemically treated to stop rot and imitation teak (man-made “composite” wood, often made up of wood fibres blended with plastic or glue) but, Eidsgaard points out, each of them has an environmental impact.

“Ethically sourced teak is scarce,” she says. The problem is that there are not enough officially audited forests to supply all the teak needed to meet demand. As Eidsgaard says, “The next batch of lots of teak trees is not going to come up any time soon.” Exotic woods or chemically treated hardwoods also trigger questions about future recycling and imitation teak is PVC based, “and that opens a different can of worms”.

Marnix Hoekstra, co-creative director of Vripack , notes that he’s surprised how “addicted” people – including himself – are to the look of teak decks on a yacht and how difficult it is proving to step away from them. “I think [decks are] one of the largest surfaces on a yacht and are very undeveloped from a design perspective. At the same time, we do have to acknowledge that it is a working surface for the crew, so it is not only aesthetics, but durability and non-skid qualities are very important,” he says. “Alternatives with those qualities are scarce. At the same time, it’s up to us as designers to make the world see how it could be different.” Farmed hardwood, for example, is perfectly usable from a technical perspective, but “global demand is so high that it is impossible for the foreseeable years that we will have enough forests to meet demand”.

For Vripack, it isn’t sufficient to just use less teak in a design proposal. Instead, they suggest a different solution. “From day one, I am not forcing the client to make a choice; I am giving them something which is greater than the original,” says Hoekstra. As an example, he cited a 60-metre Vripack explorer currently in construction where they consciously chose a synthetic decking material called Esthec. “We use it in a very innovative way. It absolutely resembles the finish you are used to, but [with the patterns we have made] it is not a copy of a teak deck.”

Esthec is a patented thermoset (heat-hardened) material that, unlike many composites, uses biomaterials and doesn’t contain PVC or wood. Marcel van der Spek co-founded Esthec in 2007. “Despite the fact that sustainability has been part of the conversation for five years, builders are finally asking about synthetics because teak isn’t available, and the ones who stockpiled teak three years ago are realising that won’t last,” he says. Esthec’s recipe is continually being refined, he says. “Our goal is to be completely bio-based by the end of 2024. We don’t import anything from India or China and our factory is not more than 350 kilometres away from where we obtain our raw materials, so that [reduces] our CO2 footprint.”

On Project Zero , currently under construction at Vitters , Vripack appeased the owner’s desire for wood differently. Following considerable research they selected Tesumo, an engineered product made from a fast-growing African tree that matures in 50 years or roughly one-third the time of premium teak. “I think we will be using it on all projects that require wood decks,” Hoekstra says. “Every board comes with a QR code on the back of it and every tree can be traced back to the source and the person who cut it. We have had it thoroughly tested in the Netherlands. It is the future of decking.”

Tesumo was developed from a research project conducted by Lürssen shipyard, German superyacht decking company Wolz Nautic and the German University of Göttingen. The wood, which comes from managed forests with Forest Stewardship Council (FSC) or Origine et Légalité des Bois (OLB) certificates, is modified with a patented process using heat, resin infusion and drying. The result has the same appearance, dimensional stability, elasticity and rot resistance as teak. “The use of easily available wood reduces the ecological risks that go along with logging a rare raw material,” says Philipp Warnecke, Tesumo’s managing director.

Another new alternative is the Dutch product Accoya, which, like Tesumo, uses an easily available certified sustainable softwood as its base material. Instead of being injected with resin, the wood is “catalysed” – a strong type of vinegar called acetic anhydride is forced into the raw timber under temperature and pressure, which changes the wood on a molecular level. It makes the wood virtually unable to absorb water, expand and rot. Accoya has a life expectancy of 25 to 50 years and can be reused, recycled or burned as biomass (fuel).

Richard Strauss, CEO of Teakdecking Systems, has been negotiating the hot potato that is Myanmar teak for seven years, with the exception of periods where the US and EU could not legally obtain it. “Teak is a bit taboo,” he admits. But, he says, what the world forgets is that ethical teak is also grown responsibly all over southeast Asia, India, Panama, Costa Rica, Brazil and central Africa, in natural forests as well as plantations. “We have four people who source wood. They go to the forests and to the sawmills to check on compliance. The FSC really has its finger on where teak is grown, and they make sure it is logged properly and the paperwork is in order.”

Most lumber importers rely on companies like DoubleHelix to oversee certifying sustainability compliance for wood stocks. “They are like the blockchain for wood,” says Strauss. “But we are taking it further; we subject our lumber stocks to a DNA test to make sure it is 100 per cent clean. In the future, all yacht builders will want this.”

Strauss says that in the past, superyacht-quality teak decking came from trees 80 years old or more. “In this reality, superyacht-quality teak is 30 to 35 years old. The standard for deck exports used to be inch-thick boards four inches wide and 12ft long.” Now he says the standard deck board is thinner: “Just one by three inches and the boards are just eight or nine feet long,” he notes. “The teak available now requires a re-education process and new designs and decorative patterns to make efficient use of shorter boards.”

So with restrictions in place now, is the price of teak stabilising? Strauss gives a resounding “no”. The price in Europe for old growth teak is around €30,000 (£26,000) per cubic metre. Plantation teak is not far behind, “about what we paid for Burmese teak four years ago.”

One of the latest adaptations is so-called “green teak”, which reduces waste by incorporating parts of a tree that would have been rejected for traditional deck boards because they had knots or imperfections. A sawmill slices the timber into thin veneers, stacks them and laminates them. The laminated veneers are then turned on their side and sliced into three-inch-wide boards. Strauss says the stacked veneers look almost exactly like the vertical grain of a teak board. “We have a 107-metre yacht under construction now in Northern Europe with all green teak decking. The response at METS last year was huge. We had three requests for proposals on superyachts over 100 metres that originally wanted Myanmar teak but have switched their request to other teaks. We see wealthy people asking questions now.”

Teakdecking is an employee-owned company that saw the writing on the wall for teak eight years ago and began a rigorous testing programme for Accoya, which Strauss notes is harder than teak and very stable. The company has been testing its longevity with caulk and adhesives and has panels that are now seven years old with no degrading. “The other thing we are trying to do is to get builders to use composites in wet areas such as working decks and tender garages,” he says. (Teakdecking uses Esthec and Herculan as its composite offerings.)

The search for decking alternatives has also led to cork, which the production boat market adopted as a non-skid deck material years ago because it is lightweight, requires little maintenance and the surface does not get hot. Hinckley Yachts and several catamaran builders offer it as an option.

Cork trees may live 200 years and their soft bark can be safely harvested every eight or nine years. For deck material, cork is ground into uniform pellets and mixed with a binder. Companies such as Marinedeck 2000, AquaCork and SeaCork all have proprietary mixtures and either compress the product into blocks to be cut into planks or extrude it into sheets that can be templated for installation in large sections.

SeaCork is made in France and sold in 100 countries. Randy Fraser in the UK office says that the most common applications have been for tenders and refits, usually to cover a leaking deck or applied over existing faux teak that gets too hot. “We find in general that people [think] the surface is going to be like the cork board they remember from school, which is the cheapest, least durable. It’s not even the same species of tree as the cork oaks used to make wine stoppers. It’s like comparing a Twinkie and a proper French baguette.” Fraser notes that cork graces the floors of many high-traffic institutions like Frank Lloyd Wright’s Fallingwater, the Library of Congress, National Archives and the Los Angeles Public Library.

Chris Groves, managing director of Eco Marine Deck UK, is an advocate of Marinedeck 2000, which uses Portuguese cork and holds full FSC accreditation. Groves says it’s easily repaired, easier to work with than wood and more stable. “It doesn’t get hot or cold, it’s not expanding and contracting, so it has better adhesion and is less likely to lose its bond to the deck.”

Other substitutes include the very dense hardwood species iroko and greenheart, which have natural resistance to rot and termites. The trees grow to a very large size and yield wide, long boards. In truth, iroko is difficult to work, splinters and easily blunts tools, as does greenheart. Greenheart is often used in Caribbean construction because it stands up to a wet climate and is resistant to carpenter ants. It is a great choice for docks and ship hulls – Ernest Shackleton’s ship Endurance was clad in greenheart – but not so great for yacht decks. Some existing tall ships have decks made of iroko.

Esthec’s van der Spek says the next leaps must come from designers in terms of how they use the material. He points to how Mercedes-Benz Style used the material aboard the Arrow460 in ways that looked nothing like teak boards. “The material begins as a liquid so we can pour it on anything with an aluminium substrate in practically any pattern. We can make it on ceilings and walls and curved surfaces.”

Van der Spek sees a lot of shipyards doing studies of alternative materials,“but most of them are comparing Burmese teak to other teak materials. The next step should be innovation with other materials. It’s time to move on.”

Teak alternatives

ESTHEC The patented thermoset (hardened by heat) material uses biomaterials and does not contain PVC or wood. Now in its third generation, the 8mm- thick material does not absorb water and is resistant to most oils and grease. Compared to teak, it weighs less than teak and remains about 8°C cooler. At the end of its life, Esthec can be recycled or reworked locally with a new top layer for a second life cycle.

TESUMO Developed by Lürssen, Wolz Nautic and the University of Göttingen, this engineered product is made from a fast-growing African tree. The wood from managed forests is modified with a patented process using heat, resin infusion and drying. It has the same appearance, dimensional stability, elasticity and rot resistance as teak. Dr Georg Behr, Tesumo’s head of research and development, says it can be “thermically utilised” (disposed of by burning).

ACCOYA This modified wood uses a sustainable softwood as its base material that is “catalysed” when a strong type of vinegar called acetic anhydride is forced into the raw timber under temperature and pressure, which changes the wood on a molecular level. This makes the wood virtually unable to absorb water, expand and rot. Accoya has a life expectancy of up to 50 years and can be reused, recycled or burned as biomass (fuel).

GREEN TEAK This type of teak uses the parts of a tree that normally would have been rejected for traditional deck boards because they had knots or imperfections. A sawmill slices the timber into thin veneers, stacks them up and laminates them with a polyurethane glue. The laminated veneers are then turned on their side and sliced into three-inch-wide boards. These stacked veneers are nearly indistinguishable from the vertical grain of a teak deck board.

MARINEDECK 2000, AQUACORK, SEACORK Cork is naturally waterproof and can be harvested every eight years. Marinedeck 2000, AquaCork and SeaCork all have proprietary mixtures and either compress the product into blocks to be cut into planks or extrude it into sheets that can be templated for installation in large sections. Easily repaired if damaged, cork is easy to work with, doesn’t get hot and is more stable. Marinedeck 2000 has been installed on a Feadship.

IROKO AND GREENHEART These dense hardwoods from Africa and South America, respectively, have natural resistance to rot and termites. Iroko is sometimes called African teak, although the species are not related. Iroko lumber starts out yellow but ages to a darker copper colour, while greenheart is highly variable. Greenheart is a great choice for docks and ship hulls but not so great for yacht decks as it is difficult to work with. Iroko makes up the decks of some existing tall ships.

More stories

Most popular, from our partners, sponsored listings.

Installing a new teak deck on your boat

A new teak deck enhances the value and aesthetics of your boat, while providing a non-slip surface and long-lasting durability. Learn how to install one with our comprehensive guide.

Installing a New Teak Deck on Your Boat

As you embark on your sailing adventure, one of the most important aspects of your boat is its deck. A well-maintained and aesthetically pleasing deck not only adds value to your boat but also enhances your overall sailing experience. Teak has long been the preferred choice for boat decks due to its durability, natural non-slip properties, and timeless beauty. In this comprehensive guide, we will walk you through the process of installing a new teak deck on your boat, covering everything from materials and tools to step-by-step instructions and maintenance tips.

Table of Contents

Why choose teak for your boat deck, materials and tools needed, preparing your boat for teak deck installation, installing the teak deck, finishing touches and maintenance.

Teak is a tropical hardwood that has been used for centuries in shipbuilding and marine applications. Its natural oils and silica content make it resistant to rot, decay, and insects, while its tight grain and minimal shrinkage provide excellent dimensional stability. Here are some of the key benefits of choosing teak for your boat deck:

- Durability : Teak is one of the most durable hardwoods available, with a life expectancy of 30-50 years when properly maintained.

- Non-slip surface : The natural texture of teak provides excellent traction, even when wet, making it a safe choice for boat decks.

- Aesthetics : Teak’s golden-brown color and attractive grain pattern add a touch of elegance and warmth to your boat.

- Low maintenance : Teak requires minimal maintenance compared to other decking materials, such as synthetic or composite options.

Before you begin the process of installing a new teak deck, it’s essential to gather all the necessary materials and tools. Here’s a list of what you’ll need:

- Teak decking : Choose high-quality, quarter-sawn teak planks or pre-manufactured teak decking panels.

- Adhesive : A marine-grade, flexible polyurethane adhesive is recommended for bonding the teak to your boat’s deck.

- Sealant : A high-quality, marine-grade sealant is required for sealing the seams between the teak planks.

- Backing material : A thin layer of closed-cell foam or EVA foam is often used as a backing material to provide cushioning and sound insulation.

- Tools : You’ll need a variety of tools, including a circular saw, jigsaw, router, drill, caulking gun, notched trowel, straightedge, clamps, and sanding equipment.

Before you can install your new teak deck, you’ll need to prepare your boat’s existing deck surface. This involves several steps:

Remove any existing decking : If your boat has an old teak deck or another type of decking material, you’ll need to remove it completely. This may involve unscrewing or prying up the old planks, scraping off any remaining adhesive, and cleaning the surface thoroughly.

Inspect and repair the deck : Once the old decking has been removed, inspect your boat’s deck for any damage, such as cracks, soft spots, or delamination. Repair any issues before proceeding with the teak deck installation.

Level the deck surface : It’s essential to have a level and smooth surface for your teak deck to adhere to properly. Sand the deck surface to remove any high spots or imperfections, and fill any low spots with a marine-grade filler.

Create a template : Measure your boat’s deck and create a template using heavy-duty paper or cardboard. This will help you accurately cut your teak planks or panels to fit the deck’s shape and contours.

With your boat’s deck prepared, it’s time to install your new teak deck. Follow these steps for a successful installation:

Dry-fit the teak planks or panels : Lay out your teak planks or panels on the deck, using your template as a guide. Make any necessary cuts or adjustments to ensure a proper fit. Leave a small gap (approximately 1/8 inch) between each plank for the sealant.

Apply the adhesive : Using a notched trowel, spread a layer of marine-grade polyurethane adhesive onto the deck surface. Be sure to cover the entire area where the teak will be installed.

Install the backing material (if applicable) : If you’re using a backing material, such as closed-cell foam or EVA foam, lay it down on top of the adhesive, ensuring it’s properly aligned with the teak planks or panels.

Lay the teak planks or panels : Press the teak planks or panels firmly into the adhesive, ensuring they’re properly aligned and spaced. Use clamps or weights to hold the teak in place while the adhesive cures.

Secure the teak with screws (optional) : Some boat owners choose to secure their teak decks with screws in addition to the adhesive. If you opt for this method, pre-drill holes through the teak planks or panels and into the deck, then insert stainless steel screws and countersink them slightly below the teak surface.

Allow the adhesive to cure : Follow the manufacturer’s instructions for the adhesive’s curing time, which may range from 24 to 48 hours.

Once your teak deck is installed and the adhesive has cured, you’ll need to complete a few finishing touches and establish a maintenance routine to keep your deck looking its best:

Seal the seams : Apply a marine-grade sealant to the seams between the teak planks, using a caulking gun. Smooth the sealant with a plastic spatula or your finger, ensuring it’s level with the teak surface. Allow the sealant to cure according to the manufacturer’s instructions.

Sand the deck : Lightly sand the entire teak deck with a fine-grit sandpaper to remove any rough spots and create a smooth, even surface.

Clean the deck : Regularly clean your teak deck with a soft brush and mild, soapy water to remove dirt, salt, and other debris. Avoid using harsh chemicals or high-pressure washers, as these can damage the teak’s natural oils and fibers.

Apply a teak protector (optional) : Some boat owners choose to apply a teak protector product to help maintain the wood’s color and prevent graying. Follow the manufacturer’s instructions for application and reapplication frequency.

Installing a new teak deck on your boat is a rewarding project that can significantly enhance your sailing experience and your boat’s value. By following this comprehensive guide and using high-quality materials and tools, you’ll be well on your way to enjoying the beauty and functionality of a teak deck for years to come. Remember to establish a regular maintenance routine to keep your deck looking its best and to prolong its lifespan. Fair winds and smooth sailing!

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

Replacing Teak Decks is a Monumental Job

- By John Kretschmer

- Updated: February 13, 2018

Like many Taiwanese boats built in the 1980s, my Kaufman 47, Quetzal, was slathered in teak. Side decks, foredeck, cabin trunk, handrails, coamings — a veritable forest afloat. As someone capable of rationalizing almost anything, and because I was able to buy the boat for a great price, I not only accepted the abundance of teak, I embraced it. Of course I knew that practical-minded sailors scorned external wood; indeed, I was one of them before I felt the magic of teak beneath my bare feet, at least on cloudy days when the decks were not scalding. And yes, I knew that teak decks were becoming scarce on new boats and seen as a liability on older boats. But that didn’t stop me from bragging about teak’s unrivaled nonskid capabilities and excellent insulating properties. And I loved the aesthetic, boasting that a handsome renewable resource like teak softened the cold, oil-derived glare of a utilitarian fiberglass deck. I was more than a teak-deck apologist; I was a teak-deck snob.

I bought the boat in 2003, and to my dismay, my decks started to show signs of wear and tear just a few years later. I sail a lot, around 10,000 miles a year, and the decks were subjected to cascades of seawater washing over them and the roughshod treatment of an offshore training vessel doing her job, scribbling rhumb lines across the Atlantic. Although I tried, I couldn’t ignore the screw heads appearing under sprung bungs, the raised and missing caulking on the foredeck and a couple of weathered planks that had splintered. But it was a mugging in Trinidad that hastened the demise of my teak dreams.

I left the boat on the hard for a couple of weeks and hired a highly recommended chap to lightly sand the decks, reseat a few fasteners, replace missing bungs and caulk the worst sections. I returned to a crime scene. My beautiful teak decks had been attacked by a belt sander armed with 16-grit assault paper and smeared with black caulk. At first I wanted to cry, then I wanted to commit a crime of my own. But the damage was done, the life of the decks shortened and, when Quetzal slinked out of Chaguaramas like a shorn English sheep dog, I vowed never again to commission work from a contractor I didn’t know, especially when I was thousands of miles away from the yard.

I kept sailing and mending as I went, but the decks became more and more of an eyesore. When they started to leak, I knew something had to be done. My friends and shipmates grew weary of my incessant fretting over the decks. “Stop complaining and do something,” I told myself, but I could not decide what to do.

I considered replacing them with new fastener-free decks manufactured from templates and mounted with adhesives. These modern teak decks are lovely in every respect except price. When I received an estimate from Teak Decking Systems of $55,000 to $60,000, I became less of a teak-deck snob.

I looked into synthetic teak, also known as fake teak, and was impressed by its appearance and practicality. I gathered a box full of samples and laid them on deck like playing cards. But after boasting about real teak for years, I just couldn’t pull the trigger on installing a synthetic replacement.

I looked seriously at cork and invited myself aboard several aluminum and steel boats to inspect their cork decks. Cork is a natural, sustainable product, but it’s also expensive, the installation seemed beyond my talents and my wife, Tadji, really didn’t like the look. “Cork,” she assured me, “is for wine bottles.”

“I kept sailing and mending as I went, but the decks became more and more of an eyesore. When they started to leak, I knew something had to be done.”

With the realization that every option required the same process to prepare the sub deck, I finally decided to remove the teak, fill the thousands of fastener holes with epoxy, and fair and then spray the decks with nonskid mixed in the paint. My teak-deck days were behind me, alas. It was on to whiter pastures.

The decision was liberating, but I underestimated what a massive job it was going to be to create a utilitarian, low-maintenance fiberglass deck.

I chose the boatyard at Spring Cove Marina in Solomons, Maryland, just south of Annapolis, for the project. Spring Cove has been Quetzal ‘s home away from home, and the talented crew had already made many valuable upgrades and repairs over the years. Full disclosure, the yard is owned and operated by my sister and brother-in-law, Liz and Trevor Richards, vastly experienced sailors who have been cruising off and on aboard their Endurance 37, Wandering Star , (including a circumnavigation) for many years.

My cost-controlling plan called for a mix of DIY and professional work. My friends and I were responsible for the destruction phase of the project, removing the old decks. Time was of the essence, as the gap in my training schedule gave us one month to complete the entire project. The doubters were plenty.

The first step was to pull the mast, haul the boat and block it up in the paint shed. Working under cover freed us from weather concerns. Next, we removed every deck fitting — every cleat, clutch, track, anything mounted directly on teak. Fortunately, designer Mike Kaufman and builder Kha Shing used several solid fiberglass islands to mount high-load winches and the traveler base. Still, this was a time-consuming process, requiring one person on deck, one below, and the removal of just about every headliner to gain access to the stubborn nuts anchoring the through-bolts.

The next task, removing the teak, filled me with emotion. With a heavy heart and cold chisel in hand, I surveyed the once-beautiful teak deck and sighed, remembering times I’d gone forward to reef the main or set the staysail, always with secure footing.

I imagined a process for removal that combined controlled physical effort with a sense of quality and renewal, something Robert Pirsig, author of Zen and the Art of Motorcycle Maintenance, would understand. “A person who sees quality and feels it as he works is a person who cares,” he wrote. I cared. I was even filled with a sense of tranquility; it was going to be OK. I imagined saving teak planks and sending them to former shipmates as keepsakes.

In the most caring of ways, I slipped the chisel under the teak on the coachroof and pried. Nothing happened. I pushed harder; still not much movement. I pushed even harder (I have been accused of having the touch of a Russian midwife) and the chisel popped out and gashed my hand. I cursed, then caught myself. "Come on, Quetzal , I care." I reset the chisel and pushed with all my might. An inch, maybe 2, of teak popped free and cracked at the fastener. Hmm? This was going to require a lot less caring and better tools or it might take a year to strip the teak off.

My team and I regrouped at Lowe’s. Bigger chisels, propelled by 3-pound sledgehammers, started to get results. Then we discovered the rotary hammer and demolition bits. Soon, wood was flying and dust filled the air. So much for Zen and deck souvenirs, this was hand-to-hand combat. The Art of War, by Sun Tzu, became our new playbook. “If you know your enemy, and know yourself, victory will not stand in doubt.” Stubborn teak planks, tenacious old caulk and too many stainless fasteners were the enemy.

My fellow soldiers were dear friends and frequent Quetzal crewmembers. Alan Creaser, from Lunenburg, Nova Scotia, was our captain, pushing us through low moments when our knees buckled, backs ached and spirits drooped. Alan, who is currently managing the operations of the legendary Bluenose schooner, reminded us that the original Bluenose, built in 1921, went from "tree to sea in 96 days," crafted entirely with hand tools — surely we could knock off old teak decks in just a few days.

"I am in the sail-training business, after all, and could have been charging them for this invaluable experience. Tom Sawyer wouldn’t have missed that opportunity."

Ron Sorensen, an engineer by trade who has crossed the Atlantic twice aboard Quetzal , has round heels when it comes to my pleas for help. He's a pushover. Bruce Steely fell for Quetzal in the Caribbean, and came to work by boat. His small trawler was loaded with tools, and by the end of the project we had used them all.

I have, unfairly I must say, been accused of being the Tom Sawyer of the sea, working my friends to the bone and offering them nothing but lunch and a few slaps on the back in return. It’s not true. I am in the sail-training business, after all, and I could have been charging them for this invaluable experience. Tom Sawyer wouldn’t have missed an opportunity like that. All joking aside, I am incredibly fortunate to have many talented friends. There is a camaraderie about offshore sailing that breeds genuine friendships.

"Six days after we started, Quetzal ’s deck was clean. We didn’t rest on the seventh day; we celebrated at the tiki bar down the road, a questionable call as the next morning proved."

We have had many shared adventures aboard Quetzal , and those of us who sail her feel a deep connection to her. She's our conduit to blue water and the good life waiting at sea. And when she needs work, we all pitch in. It's just not always easy to explain this utopian ideal to spouses. "You paid this guy how much to sail with him and now you're working on his boat for free?"

By the end of Day Two, the teak was in serious retreat. We had most of the cabin top cleared and were making progress on the more challenging side decks. Nothing about the task was easy. We discovered that leaving fasteners in place and zipping them out with a drill afterward was the best tactic. When the head was stripped, we used vice grips to remove them, and of the 3,000-plus screws that once littered the deck, fewer than 20 remain entombed in fiberglass today.

After four days, every last bit of teak was in the scrap bin. We then went after the remnants of the caulk, a tough slurry concocted in Taiwan, but it couldn't hold out against four determined air sanders. Six days after we started, Quetzal 's deck was clean. We didn't rest on the seventh day; we celebrated at the tiki bar down the road, a questionable call as the next morning proved.