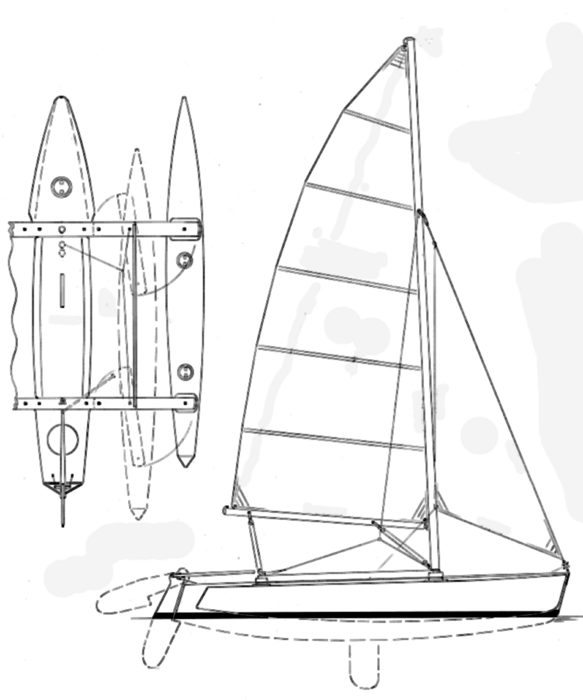

Boat Profile

Seaclipper 16

A folding trimaran for the home builder

From Issue January 2017

I ’ve built more than a few boats for myself in the past 38 years, and in all that time I have never been tempted to build a multihull. Why go to all the work of building two hulls, let alone three, when I’ve never found any of my single-hulled boats lacking in any significant way? I started getting answers to that question as soon as I stepped aboard a Seaclipper 16 designed by John Marples of Searunner Multihulls and one of nine designs in the Seaclipper series of trimarans. The hull is constructed of 7 sheets of 1/4″ six-ply marine plywood, five sheets of 3/8″ nine-ply, and lumber in commonly available sizes. Fiberglass-and-epoxy sheathing is optional. The instructions are geared for novice builders; full-sized templates for the bulkheads are provided in the plans. Stringers connecting the bulkheads define the shapes of the plywood panels for the hulls. The 15′ 11″ vaka (center hull) has a flat bottom that will take to landing on the beach without digging in or causing the kind of wear you’d get with a sharp V hull. The amas (outrigger hulls) have bottom panels set at an angle, deeper outboard than inboard. This configuration adds a fin-like element for increased lateral resistance for sailing in shallow water with the daggerboard pulled up. The angled ama bottoms also present an edge to the water, keeping the amas from slapping the waves when they’re close to the water’s surface; it’s a quieter ride. The amas’ bottoms are positioned higher than the vaka’s bottom, so their edges are not subjected to wear when the boat is hauled up on a beach.

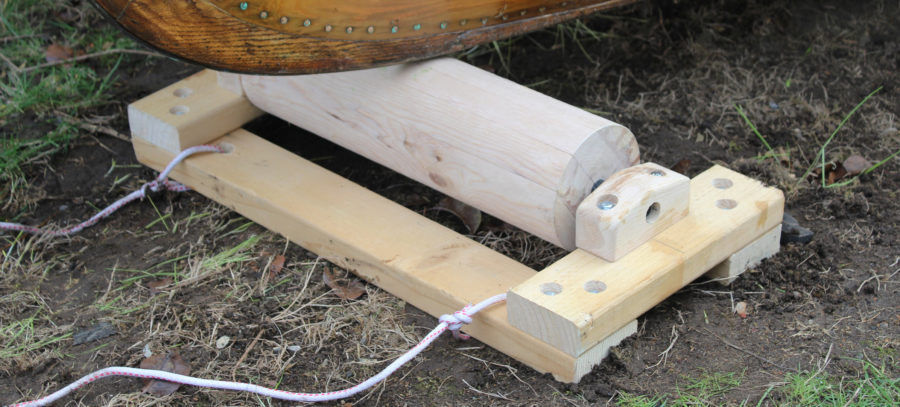

Each of the four swing-arm akas has three bolts: one securing the pivoting part of the aka to the ama, and two (one of those anchoring the shroud bridle) connecting the pivoting part of the aka to the fixed central section on the vaka. Removing the inboard bolt allows the swing arm to pivot, moving the ama aft and inward.

The akas (crossbeams) can be made in three ways: as one piece bolted to the three hulls, hinged to fold the amas on top of the vaka, or as swing-wings, like LIMONADA shown here. With the swing-wing, the amas pivot aft and nest against the vaka, bringing the beam down from 11′ 3″ to 7′ 7″ for trailering and to fit in a standard marina slip. The swing wings can function whether the boat is afloat or on a trailer, so they are handy when launching or landing at a crowded boat ramp. The swing wings don’t require any hardware beyond nuts and bolts, and have an advantage over the hinged akas: there’s no need to lift an ama and set it down gently on the vaka. The Seaclipper 16 can be built as an open-cockpit cruiser, or as a daysailer with a tandem cockpit, with the helmsman sitting in the aft position, legs straddling a centerboard trunk and the crew sitting forward. The 7′-long open cockpit has side decks between the akas that offer more options for seating, moving around while under sail, and sleeping aboard while moored.

John Marples, designer of the Seaclipper 16 and builder of LIMONADA, goes for a sail on the Mystic River.

L IMONADA, as an open-cockpit version of the 16, has a daggerboard deployed through a slot in the cockpit sole. A softwood stick wedged in the slot keeps the board down; it has a loop of line at its top for quick removal and raising of the board. The cockpit sole is high enough above the waterline that any water coming into the cockpit drains right out. The rudder is mounted on a false transom, hinged at the top, that allows the rudder to kick up when meeting an unexpected shoal or to be retracted when coming ashore. The downhaul at the bottom of the false transom leads to the cockpit for easy operation. The rudder blade is balanced and has enough of the blade ahead of the pintles and gudgeons to lighten the load on the skipper when coming about. It also allows the arms of the rudder yoke to be short and unobtrusive. The lines from the yoke lead forward to pedals in the cockpit to for hands-free steering. A tiller above the yoke allows steering while sitting on a side deck and is the means of raising the rudder when coming ashore.

A hinged false transom allows the rudder to be kicked up. The tiller pulls the rudder up and holds it. The line at the bottom of the false transom holds the rudder down while the boat is underway.

The Seaclipper 16 is designed to take a Hobie 14 sailing rig. The pivoting aluminum mast, roller-furling jib, and fully battened mainsail are readily available from a wide network of Hobie dealers and may be found used in online classifieds. The Hobie 14 has a beam of 7′ 8″, so the Seaclipper 16, with a beam of 11′3″ can take better advantage of the 146-sq-ft sail rig without flying a hull to the brink of capsizing. Dyneema shrouds, secured to bridles spanning the side decks, support the mast. The plans include specifications for an unstayed wooden mast. For auxiliary power, a short crossbeam aft of the port aka serves as a mount for a small outboard.

The side decks provide seating when two are aboard, and the steering is then done with the tiller, not the foot pedals.

I had a chance to sail LIMONADA, the Seaclipper 16 built by Marples for Mac MacDevitt, on Mystic River near Mystic Seaport. Stepping aboard, I got my first lesson in the values of a multihull. I didn’t have to lunge for the centerline as I do with my monohulls to keep them on an even keel. The trimaran has plenty of stability no matter where I put my weight and the amas (outer hulls) have enough volume of to support my 220 lbs. Without having my movement aboard the boat restricted by the nagging demands of a monohull, I could wander around the boat. The decks are all flat, so the footing is good everywhere. While I like the sweep of a curved sheer line, the Seaclipper’s flat decks simplify the construction of the boat and provide the geometry required for the swing-wing akas.

The deck surrounding the cockpit is large enough to set up a tent for sleeping at anchor. The windshield was added by the builder to block spray when sailing into a brisk breeze.

I liked being able to walk around the boat while it was under sail with Mac at the helm. I never get to see my own boats moving through the water, so stretching out on an ama to watch the vaka’s bow at work was a treat. The 7′-square deck around the cockpit offers a place to pitch a tent. Mac has a two-person tent with an oval hole in its floor to match the cockpit opening. He can sleep to one side of the cockpit, sit comfortably upright with his feet in the cockpit and have access to the gear stowed there. The amas and vaka offer plenty of room for cruising and camping gear; commercial plastic hatches offer access.

I took LIMONADA out by myself and enjoyed steering with my feet and having my hands free to manage the sheets. Nestled down in the cockpit on a padded seat with a backrest, I was very comfortable and relaxed. The sheets were right in front and could be cleated off, making sail-handling a breeze; there was no need to switch sides or do-si-do with a tiller when coming about. During my outing the weather was warm and the wind was light, perhaps 8 to 10 knots at best with a few gusts, but in a cold wind, being mostly below deck level would be a boon. Mac had made a removable windshield that wraps around the forward end of the cockpit for even greater protection from cold wind and spray.

With Marples and owner Mac MacDevitt aboard, LIMONADA flies the windward ama. The leeward ama still has plenty of freeboard.

The light wind was more than enough to get Mac’s Seaclipper going at a brisk pace and fly the weather ama. There was no spray, so I stayed dry, and even with the boat moving at a good clip I didn’t notice any water coming up through the daggerboard slot.

I was surprised by how well the Seaclipper could come about. With three hulls in the water, I thought there would be a lot of drag in the turns and that the boat would get bogged down, but the rudder blade and the centerboard have enough area to swing the bow around before the boat loses momentum. I never got caught in irons, but I backed the jib for a moment to hasten the bow’s falling off and the filling of the main.

LIMONADA owner Mac MacDevitt reports that his Seaclipper 16 is “super fun in a stiff breeze.” Here, sailing with a reefed main on Lake Champlain, he estimated his speed at about 13 knots. “It was exciting, but I felt safe and secure.”

Christopher Cunningham is the editor of Small Boats Monthly.

Seaclipper 16 Particulars

Length/15′ 11″

Beam/11′ 3″

Beam, amas retracted/7′ 7″

Draft, hull only/11″

Draft, board down/2′ 7″

Sail area/127 sq ft

Displacement, dry/400 lbs

Displacement, full load/800 lbs

Plans for the Seaclipper 16 are available from Searunner Multihulls for $180.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Monthly readers would enjoy? Please email us!

Share this article

Join The Conversation

We welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link.

Comments (2)

Thanks for the multi-hull perspective. Lots of cool ideas.

I’ve been looking. This could be the one!

Comments are closed.

Stay On Course

More From This Issue

From The Editor

Roller Carts

Like Ben Fuller, I have more boats than trailers to haul them, so when I read his article on the roller cart he built with Joe Liener, I was convinced...

I already had a sailing dinghy and a sail-and-oar skiff in our two-car garage, but I thought there was room for one more boat, a small one, alongside my wife’s…

I’ve built more than a few boats for myself in the past 38 years, and in all that time I have never been tempted to build a multihull. Why go to…

A Lakeland Row

A couple of years ago I spotted a long, lean traditional Finnish rowing boat for sale online. It had been designed and built for bi-stroke racing with a rower on a…

Joe’s Roller Cart

Decades ago, my friend Joe Liener introduced me to duckers and melonseeds at his little boathouse in Wittman, Maryland, on the eastern shore of Chesapeake Bay. Joe had retired some…

If I can keep my head, feet and hands warm while I’m rowing in cold weather, the rest of me stays warm; pogies are my winter hand covering of choice.…

Product Reviews

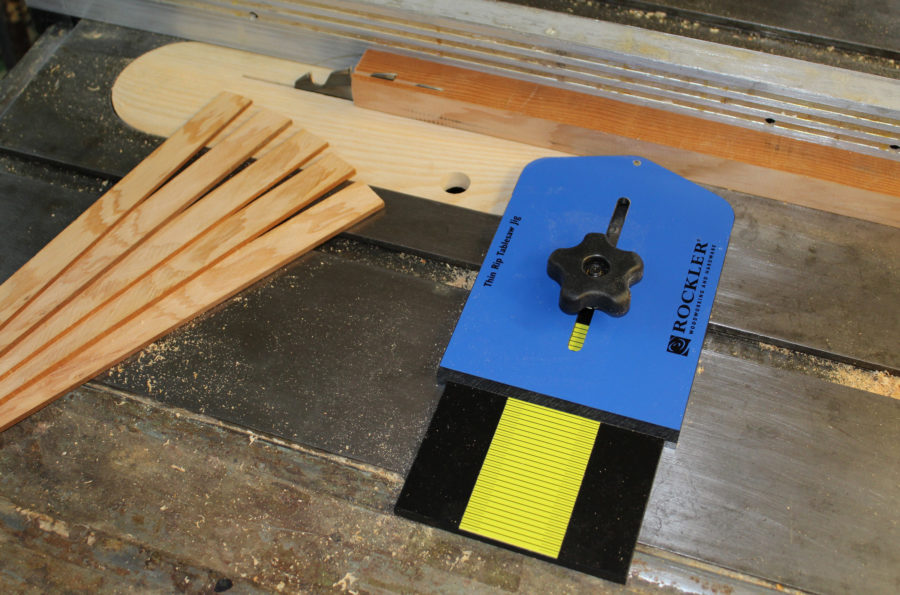

Thin Rip Table Saw Jig

If I had my druthers, I’d make knees, breasthooks, and stems—all those angle-reinforcing structural parts of boats—out of grown crooks, but they’re hard to come by and take time to…

Reader Built Boats

John Adamson visited the WoodenBoat campus in the fall of 2009 and was taken by two Jericho Bay Lobster Skiffs: the original plank-on-frame version built by Jimmy Steele in the…

More Boat Profile

Sponge Docks Skiff 13

When I happened across the Sponge Docks Skiff 13 by Bedard Yacht Design, I was immediately intrigued by the simple, practical interior and the gently curving sheer and transom sides.…

Belle Daysailer

After I saw the photograph in the calendar, I searched up BELLE and found that Dan Gonneau, the designer/builder, had written a blog post that was a stream-of-consciousness diary about…

Super Sailfish

In 1946, Alex Bryan and Cortlandt Heyniger had combined bits of their first names to create Alcort, Inc., and the first sailboat that they designed, in 1947, was the 11’7”…

Jimmy Skiff II

Eight plywood panels make up the kit’s hull; its bottom and sides are all composed of two pieces joined together with puzzle joints and the transom is built up of…

Subscribe Today!

Become a subscriber today and you’ll recieve a new issue every month plus unlimited access to our full archive of backlogged issues.

Already a subscriber? Sign In

Subscribe For Full Access

Flipbooks are available to paid subscribers only. Subscribe now or log in for access.

Seaclipper 16 Trimaran – Open Cockpit Version

by Small Tri Guy | Oct 7, 2015 | Self-built Small Trimarans , Small Tri Info - All | 3 comments

The main difference between this boat and the previous one is that this craft features the open cockpit version of this design. John Marples, the designer, added the open cockpit version to the original cockpit seating arrangement, that was initially offered in the building plans. Another major difference is the “swing wing crossbeams” that John also developed. This offers the sailor a major benefit because instead of having to fold the amas (which aren’t light) for trailering all that needs to be done here is simply swing them back alongside the main hull.

Barney sure builds pretty boats. But I know he has a great sailing machine here too. The Seaclipper 16, is a wonderful daysailer. It can either be fitted with a stayed Hobie 14 rig or an unstayed mast adorned with a custom sail design. (Both are featured in the building plans available from John Marples).

Barney shares the following with us below, including pics of the new boat. ( Thanks for sharing this boat with us too Barney ).

…………………..

Seaclipper 16 Trimaran – Open Cockpit Version by Barney G.

Here is the rollout of the shop for Sail52 of the Seaclipper 16. Built to plan with open cockpit design, daggerboard and swing wing amas. Will be rigged with a Hobie 14 rig (still to be purchased.)

This is new SC16, not a rebuild. The original red/white boat is up in Oregon with a new owner — sold in 2013. I rebuilt a ComPac16 for the 2014 Texas 200 Race but the boat is owned by a friend. I rebuilt it in exchange for its use that year.

In the shop, wings spread

Built another SC16 due to the ruggedness of the design and intention to sail the Texas 200 . I missed the 2015 T200 due to a schedule conflict, but am lining up hopefully for 2016.

Built a little heavy using 6oz glass cloth overall with 3 coats epoxy to fill weave. 3 coats System3 waterborne 2 pt polyurethane over 2 coats system 3 2pt primer. Electrical with voltmeter, two 12v plugs and 2w/5w USB chargers, solar charge controller pre-wired, 4 waterproof compartments for storage and self draining anchor locker. Swing wings laminated with carbon fibre.

Open cockpit with pedal steering and daggerboard trunk

Planning for heavy duty mainsail and hank-on 135 jib that can be poled out for wing on wing downwind sailing. And /or a screecher if I can find one reasonable. Steering pedals can be locked for short periods of relief from steering duties … right now going to use beach chair or kayak chair for comfort to the old bones.

For roll out, wings folded

Boat may be heavy but will be sailing in bigger winds and with bay rollers than most small boats usually see. Will be showing the boat without rigging at the Port Aransas Plywood Boat Show on Oct 17th. Targeting year end for fully rigged.

Here are more pics showing the folding system…

Nice! I’ll see you in the 2016 Tx200 while sailing the Little Tri. :)

Nice boat! How many inches do the swing-beams overlap? (looks ~ 18?). Did you use anything fancy for the beams? Spruce?

Hi Barney: I know this is an older thread. I see you are using the original style of Ama’s. Is this an option vice the SC20 style Ama’s shown on the Marples website?

How has she performed and held up for you given your intended use?

Submit a Comment

Your email address will not be published. Required fields are marked *

Notify me of followup comments via e-mail. You can also subscribe without commenting.

Blog Post Categories

- Production/Commercial Small Trimarans (291)

- Self-built Small Trimarans (678)

- Small Trimaran Audios (30)

- Small Trimaran Videos (289)

- Trimaran Design, Rigging, Construction Info/Links (222)

- Contact “Small Tri Guy”

Review of nine small, folding day-trimarans (2010)

by mike waters n.a.

As much as I like the basic concept of Jim's new boat, there are a couple of aspects that I need to mention. To put a light rig from a Hobie 16 on a boat that is FAR heavier and more stable than the boat for which it was originally designed, might prove too much for this mast, especially since the shrouds are more inboard than normal—so raising the mast compression. Normally, a Hobie would just 'go over' and so relieve the load—but not this beamy 800 lb twenty-footer! Also, the too-typical, puny 4-oz sail cloth of a regular Hobie 16 sail, is hardly man enough for this job. It's certainly a low cost start up solution and we've all admired Jim for his support to those with lesser means, but I think any builder should plan on something more substantial to be a better match for this cruiser. Finally, as the ama looks to be quite substantial in volume (guessing about 800 lbs buoyancy?), I have some concern for the strength of the single plank akas (cross beams) that act as swing arms for folding, should the builder decide to choose regular construction lumber. Sooner or later, someone will push this boat hard enough to bury an ama and that's a LOT of leverage on those arms, even if they are cleverly designed to act like huge flexible wooden leaf springs. But without seeing the details, I can only suggest that some good laminated material might be in order for these parts and perhaps Jim's plans already call for that or even some added carbon here as well. But I like the general concept and even though the boat will be no speedster, it's a design that can give a young couple on a small budget, a lot of weekend pleasure provided the conditions are within what the rig and swing arms can take.

- This particular Performance Index is simply a product of the principal things that affect multihull performance (LOA × BOA × Sail Area) all divided by the listed Weight. By taking the square root of this value, you then get a figure that very roughly reflects speed for comparison purposes. Yes, I agree there are a lot of factors NOT taken into account with this crude approximation, but the base figures used are easy to find and at least the general trend is indicated—and quite fairly so I believe.

TRIKALA 19 The Trikala 19 is from the board of imaginative designer Kurt Hughes. This boat was actually in production for a while in Spain but since then, a few have also been built by amateurs. A couple reportedly even cruised the Mediterranean in one! This is a boat design that always frustrated me—perhaps wrongly so.

For me as a designer, the looks of a boat are almost as important as its performance and the Trikala looks quite stunning from the bow, with its long fine entry and streamlined deck lines. But then, as it opens out to encompass a very wide cockpit aft, it always appeared to me that something distracted the designer or he just lost interest, as the view from the stern quarter is not so elegant. It's no doubt practical but it's a shame that its wonderful efficient appearance from the bow could not in some way be maintained at the stern. But with that very personal comment aside, this is an interesting boat with no doubt a good performance. It would be a particularly interesting boat to build for someone wanting to learn about composite construction with a larger boat in mind 'down the road', as the Trikala is lightly built of foam core under fibreglass skins and would therefore provide a good learning experience. The boat does not fold in a conventional way but like some other small designs by Kurt, uses a sliding system with tubular akas, the port ones, sliding into tubes with Teflon runners behind the starboard ones—so the two sides are not exactly symmetrical—a factor that some potential buyers find disturbing, though the difference is purely cosmetic. (The larger 7 m, L7 by Mike Leneman, also uses a similar sliding system – though in this case he uses fiberglass channels—see my REPORT on SMALL TRIMARANS for more on the L7, available through my website.)

W17 This design of mine was created during 2009 and completed in 2010. It's hard to review your own boat designs without being accused of inevitable bias, so I will simply tell you about it and point out the features I've incorporated and why. However, time has now shown [2020] it's as good as I had hoped and expected her to be.

This is a primarily a boat 'to just enjoy sailing in'. She's designed to be comfortable, way drier than average, fast and efficient and is just at home on a weekend camping cruise as on the circuit. With several boats now [2020] having each sailed and cruised over 1000 miles and with open sea passages of up to 60 miles safely accomplished, she is certainly proving very capable in experienced hands, employing intelligent sail reduction when things get rough. Her seemingly simple hull forms give a very high efficiency and she has proven quiet and dry through a chop and with her wing mast and unique ama shape, shows an unusual ability to climb to windward with minimal leeway. [Following an independent test and review by Wooden Boat Mag., I was asked to explain why the W17 performed so well with such simple shapes and my reply to this was published in the prestigious Professional Boatbuilding magazine #169 .. and is available to read on this website under 'Published Articles'].

Sailing this boat is indeed a magical experience and dozens of boats are now (2020 update) being built in over 30 countries. She's a little more time-consuming to build than others her size, but numerous owners have since dubbed her, 'The Miata of the Seas' . For them, a few more hours is well worth the effect and this boat will take you to a whole new level above any production boat of this size out there .... and also cost you less.

Comparison Chart (created in 2010)

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Homemade Weta Trimaran

Discussion in ' Multihulls ' started by jagercek , Mar 7, 2021 .

- diy boat building

- diy wooden boat building

jagercek Junior Member

Has anyone built yet a trimaran, very similar to weta?

Scuff Senior Member

When you say similar are you talking about dimensions, construction method?

Scuff said: ↑ When you say similar are you talking about dimensions, construction method? Click to expand...

gonzo Senior Member

It seems like a complicated and sophisticated method of construction. Are you looking specifically for a trimaran or catamarans work too? For example, look at the Tornado.

jagercek said: ↑ It would be best to be similar in speeds and dimensions. Click to expand...

Catamarans work too.

Is there something like a seaclipper 16, but with free plans?

oldmulti Senior Member

Please consider paying for plans, you will save money by not overbuying materials or having to redo things. But if you chose not support designers, some guide may be obtained by looking at Seaclipper 16 Trimaran – Open Cockpit Version Plans Now Available | Small Trimarans http://smalltrimarans.com/blog/seaclipper-16-trimaran-open-cockpit-version-plans-now-available/ Seaclipper 16 - Small Boats Magazine https://smallboatsmonthly.com/article/seaclipper-16/ Seaclipper 16 Trimaran Build http://skyhighshelters.com/mac-macdevitt-artist-builder-sailor-storyteller/trimaran-sailing/seaclipper-16-trimaran-build/

patzefran patzefran

I have built a Richard Woods Strike 15, very easy to built and faster than a Weta. Use the hard chine outriggers and slot in beams ! Sailing Catamarans - Strike 15 trimaran performance daysailer http://www.sailingcatamarans.com/index.php/designs-2/27-trimarans-under-25/223-strike-15-trimaran

Oldmulti is offering sound advice. Very small price for plans. The guidance from the designer is priceless. Good luck.

- Advertisement:

redreuben redreuben

Well there is always this. TC 4.4 Design/Weta http://www.tcdesign.co.nz/TC_Design/Special_Designs/Pages/TC_4.4_Weta.html

Trying to design a homemade catamaran..

WETA Company Foiler Development-a decade too early?

Weta: normal and turbo proposal.

- No, create an account now.

- Yes, my password is:

- Forgot your password?

Sky High Shelters

Mac macdevitt, installing the daggerboard trunk, building the daggerboard trunk.

Gluing up the daggerboard trunk

After the interior of the trunk has been glassed, the two halves are ready to be glued together.

Daggerboard trunk ready for fiberglassing on the outside.

Laying out the hole for the trunk in the hull bottom

The hole for the truck need to be exactly between the two hull sides

Lining up the top of the trunk

The trunk needs to be square and just below the cockpit floor.

1 1/2 inch epoxy fillet to secure the trunk to the floor.

The trunk needs to be strong and secure.

Installing the cockpit floor

Fitting the aft cockpit floor section

The cockpit floor needs to be carefully fitted to provide support to the hull sides and the daggerboard truck.

Fitted cockpit floor

With the floor in we can start to plan the deck and cockpit layout.

More building details to follow soon…..

I used a Festool saw and guide to make the stems. The Festool guide and similar saw guides positively restrict the saw to move along a linear path only. These guides do not allow the saw to drift from the intended line unless something really awry happens. Before you lose interest on grounds that you don't have a Festool saw, the method described here will work for any circular saw guided by a straight edge that positively holds the saw to a straight line. I don't think that I would recommend this method with a mere straight edge that allows the saw to drift without positive control. The drift doesn't affect the workpiece since the drift away from the guide is into waste. However, saw drift while ripping or even crosscutting is not safe, particularly with thick wood blanks used to make stems.

Here is the method step by step.

Step 1: Make your blank(s) from suitable stock and layout your stem pattern(s) full size on the blanks.

Step 2. Drill two counterbores in the stem for mounting screws. See Fig. 4. I drilled counterbores that were 3/4 inch in diameter to fit the self-tapping Kreg screws I used for mounting the stem blank to the work table. Later these bores and the screw holes will be filled with epoxy.

Step 3. Grab some scraps and make the work table shown in Fig. 3. If you screw your head blocks to the table, position the screws well to the outside and make sure that your saw path will never hit them. In Fig. 3, my head block at the top of the table is way too short. I had to use a supplemental block to help support and clamp my saw guide to the table.

Step 4: Mount the blank to the table using self-tapping screws. I like Kreg screws for this. Position the blank so the cutting path runs up the table center and not through any screws on the outboard ends of the support blocks. The wide face of the stem faces up. You can position the stem blank anywhere you want so long as the saw blade path misses the screws. The main stem is 36 inches long, so this table is long to accommodate that stem as well as the shorter ama stem shown in the Figures.

Step 5: Clamp the saw guide to the table, aligned with the desired cut line. Both ends should be secured as we will need to make multiple passes. This Festool saw has a lot of power and can crosscut a 2 x 4 easily, but the saw has to work way too hard to rip this tapered bevel in one pass. So, I used four passes, cutting deeper by about 12 mm (about ½ inch) with each pass. Because the saw guide keeps the saw on line, each pass goes successively deeper on the same cut line as long as the saw guide is not moved between passes.

Step 6: Set the saw depth for the first pass, about 12 mm. Place the saw onto the guide in position and make the first pass. Then increase the depth of cut about 10 mm to 12 mm with each successive pass until the cut is complete.

Step 7: We want to make a stem with a cross section that is a trapezoid, not a parallelogram (I almost made some parallelograms). So, we need to remove the stem blank and remount it to make the proper cut. Remove the screws to free the blank. Turn the blank around so that the end that was at the head of the table is now at the bottom. The wide face of the stem is still facing up. If you do this right, the first bevel is now on the left and new bevel to be made is on the right.

Step 8: Secure the saw guide in position. Remember to clamp the guide at both ends so there is no movement of the guide during the multiple passes used to make the cut. Make sure you are cutting on the desired line and not the center line (I almost did this, too, on one stem). Double check to make sure the saw will not hit any screws at the foot or head of the table. If there is a screw in the way, you will need to move and remount the stem blank to avoid this.

Step 9: Again using four passes, cut the second beveled taper. Your stem is now done and can be removed from the table. The holes made in the stem for the counterbore and screws can be filled with epoxy to protect the stem from rot.

Login to my account

Enter your e-mail and password:

New customer? Create your account

Lost password? Recover password

Recover password

Enter your email:

Remembered your password? Back to login

Your cart is empty

20' Seaclipper - STUDY PLAN -

Description

Single Study Plans are Only Available as Digital Downloads

Designed by Jim Brown and John Marples.

LOA: 20' LWL: 19' Beam: 15'6" (sailing) Beam: 8'6" (trailering... street legal!) Draft: 11" board up Draft: 3'2" board down Weight: 800 lbs. Sail area: 200-230 sq. ft.

Designed by Jim Brown and John Marples, this is ideal for the home builder. Unique for trimarans are the "swing wing" cross beams (akas) which allow quick/easy folding for trailering or fitting in tight spots--and you don't unrig the mast to do so. Construction is sheet plywood, and for a rig several standard rigs are suggested including a Hobie 16. Plans include 12 pages, plus there's a 37 construction manual.

————————————————————

“Your downloads are ready” will be the subject line of an email you’ll receive from us—once we’ve processed your digital order. That email has the link to click, so you can then download the file.

This isn't an "instant" process, so if we're asleep, you may need to wait for regular business hours for us to process the order. Although we are quite timely, we may not be processing on weekends & holidays.

There was a design review in WoodenBoat . See WB 217 below. And see WB 69 below for a profile on Jim Brown.

Customer Reviews

Recently viewed.

Our Store is in Brooklin, Maine

at 84 Great Cove Drive. We're open Mon-Fri 8am to 4:30 pm Call 1.800.273.7447. WE'RE RIGHT HERE .

Timely Shipping

We are 99-3/4% sure... that we will ship your order within 24 hours Granted, that does not include weekends and holidays.

Secure payments

Rest assured... not only is our site secure, we do not hold your credit card/payment info.

- Opens in a new window.

- Seaclipper 10

The Seaclipper 10 is a solo trainer and harbor racer is fun for the entire family. The crew sits in a secure cockpit, steering with foot pedals, with all sail controls arranged on a dash board, close at hand. Performance is lively, with good steering control in a comfortable, forward facing, semi-reclining position. Construction is beginner level stitch and glue plywood using epoxy adhesives. Most components are ¼″ thick plywood and ¾″ thick lumber. The mast and demountable cross-arms (akas) are aluminum tubing. Expect to spend 3-6 months part time effort to complete. Plans are well illustrated and easy to read. The overall beam is 8′ for trailering. ABOVE: When sailing a Seaclipper 10, the crew sits in the cockpit, steers with his or her feet, and controls all lines without leaving the cockpit. Picture by John Marples. IMAGE 1: SOUR GRAPES was built in the 1980s and restored and relaunched in 2013 by designer John Marples. Picture by John Marples. IMAGE 2: Seaclipper 10s and the Constant Camber 3-meters race together near Vashon Island. Picture by John Marples. IMAGE 3: The Seaclipper 10 BANANAS sailing in San Francisco Bay. Picture by John Marples.

- You are here:

- Seaclipper 13

- Seaclipper 16 Tandem

- Seaclipper 16 Open Cockpit

- Seaclipper 20

- Seaclipper 24

- Seaclipper 28

- Seaclipper 34

- Seaclipper 38 and 41

IMAGES

VIDEO

COMMENTS

John Marples sent the following Seaclipper 16 trimaran information to me today. The Seaclipper 16 is a model originally designed as a 2-person boat with cockpit-style seating. This new set of plans still allows for that type of setup (should a sailor/builder desire it).

A FAMILY BOAT FOR ALL SEASONS. The Seaclipper 16 Open Cockpit folding trimaran is designed for amateur construction from mostly ¼″ (6mm) plywood with epoxy adhesives and coatings. It can be built in less than 6 months by an individual or as a family project.The plans are highly detailed and easy to follow with full-size patterns for many hull parts provided to facilitate the process.

The Seaclipper 16 is designed to take a Hobie 14 sailing rig. The pivoting aluminum mast, roller-furling jib, and fully battened mainsail are readily available from a wide network of Hobie dealers and may be found used in online classifieds. The Hobie 14 has a beam of 7′ 8″, so the Seaclipper 16, with a beam of 11′3″ can take better ...

Seaclipper 16 Trimaran. By Gerry Lavoie - Comox, BC - Canada. I love sailing little boats. I sail on the local lakes as well as the nearby straits. The ocean frequently whips up some steep seas that concern me and would terrify my friends and the special-needs adults I work with. A year ago, I began building a Seaclipper 16 trimaran, designed ...

The Seaclipper 16 Open Cockpit folding trimaran is designed for amateur construction from mostly ¼″ (6mm) plywood with epoxy adhesives and coatings. It can be built in less than 6 months by an individual or as a family project.The plans are highly detailed and easy to follow with full-size patterns for many hull parts provided to facilitate ...

Seaclipper 16 Trimaran - Open Cockpit Version by Barney G. Here is the rollout of the shop for Sail52 of the Seaclipper 16. Built to plan with open cockpit design, daggerboard and swing wing amas. Will be rigged with a Hobie 14 rig (still to be purchased.) This is new SC16, not a rebuild.

Seaclipper 16 Trimaran Build. Getting started. John Marples. ... And dropped in on their class three years ago when they were building the Seaclipper 20. Why a Seaclipper 16. Windrider 17 in the North Channel. I recently sold my Windrider 17 trimaran. Over a six year period, with input from other WR 17 sailors, I modified the boat for adventure ...

The unstayed mast is laminated wood or an aluminum Hobie Cat 14 conversion. Check out this YouTube video of the Seaclipper 16 sailing at 14 knots in a fresh breeze. Expect to spend about 5 to 7 months part time effort to complete. The 11′3″ beam reduces to less than 8′ for trailering. Images of TRINKET were taken by Virgene Trygg ...

A video illustration for a review of the Seaclipper 16, published in the January 2017 issue of Small Boats Monthlywww.SmallBoatsMonthly.com

Boatbuilding. Main Forum. Seaclipper 16 Build. As many of you may know, I've been aching to build another boat. But the War Department wanted to know which boat I was going to eliminate, to make room for the new one. THE NERVE!!! Then, there was a person who wanted a trimaran, but was not in a position to build it.

SEACLIPPER 20 Well, Jim Brown (in partnership with John Marples) has been at it again and he's come up with something that could certainly interest those ready to go weekending in a small but tough and stable trimaran—a boat with enough heft to glance off a few underwater obstacles without much damage, as well as taming down the nervous excitement that a small light boat like the WETA offers ...

04-01-2015, 07:16 AM. Re: Seaclipper 4M new folding trimaran from John Marples. Plans are available, with full size bulkheads for $140. I have a Hobie Drive and a GRP moulded housing for it, so dug it out to see how it might fit. Need around 12" long, 7" high, 3" width at the bottom and 6" width at the top.

I built a seaclipper 16 for my second build. The plans and support were top notch. It uses a hobie 14 rig and mainsail. I added a jib it made a big difference in performance. ... But if you chose not support designers, some guide may be obtained by looking at Seaclipper 16 Trimaran - Open Cockpit Version Plans Now Available ...

Sailing a Seaclipper 16 at Lake Eufaula, OklahomaDriver-Peter FynnCrew-Bob TryggOwner/Builder-Bob TryggWindspeed 15 to 25 mphGarmin recorded max speed 13.9 mph

Trimaran Sailing. FOR SALE 2015 Seaclipper 16. Seaclipper 16 Trimaran Build. Hull and ama parts; Hull and ama assembly. Installing the daggerboard trunk; 2007 Windrider Trimaran; Sky High Shelters. ... With the floor in we can start to plan the deck and cockpit layout.

Designs / Plans The WoodenBoat Forum is sponsored by WoodenBoat Publications , publisher of WoodenBoat magazine. The Forum is a free service, and much like the "free" content on Public Radio, we hope you will support WoodenBoat by subscribing to this fabulous magazine.

Seaclipper 20. By David Kagan - Stillwater, MN - USA. Making Tapered and Beveled Stems for the Seaclipper 20. To date, all my boat projects have been monohulls. But, I've dreamed of building a trimaran for a long time. In the spring of 2010, Jim Brown and John Marples introduced their plans for the new trimaran design called the Seaclipper 20.

Unique for trimarans are the "swing wing" cross beams (akas) which allow quick/easy folding for trailering or fitting in tight spots--and you don't unrig the mast to do so. Construction is sheet plywood, and for a rig several standard rigs are suggested including a Hobie 16. Plans include 12 pages, plus there's a 37 construction manual.

The Seaclipper 16 is very similar and approaches the ama question differently (folds to side). Was not familiar with Scarab - wow. Love the idea of a cabin (I find the Corsair F24 really attractive and the concept of building one is exciting - but not 1st boat).

The first Seaclipper 20 under sail in Saint Augustine, Florida. The Seaclipper 20 is suitable as a family daysailer or an expedition trimaran. Mike O'Brien reviewed the design in WoodenBoat No. 217 (Nov/Dec 2010), and a class at the WoodenBoat School in the summer of 2011 built one in nine days (see WoodenBoat No. 227 (July/August 2012). The ...

Seaclipper 10. The Seaclipper 10 is a solo trainer and harbor racer is fun for the entire family. The crew sits in a secure cockpit, steering with foot pedals, with all sail controls arranged on a dash board, close at hand. Performance is lively, with good steering control in a comfortable, forward facing, semi-reclining position.