- Sailboat Hardware

- Sailboat Blocks

Mainsheet Blocks

Harken 40mm Zircon Catamaran Mainsheet System

Ronstan Two-speed Mainsheet System Bottom Blocks Only RONRF72900B

Ronstan Two-speed Mainsheet System Bottom Blocks Only

Ronstan Two-speed Mainsheet System Top Blocks Only RONRF72900T

Ronstan Two-speed Mainsheet System Top Blocks Only

92773-235 7:1 Mainsheet Blocks Set - Ratchet with Aluminum Cam Cleat

92774-440 8:1 Mainsheet Blocks Set - Ratchet with Aluminum Cam Cleat

92772-230 6:1 Mainsheet Blocks Set - Ratchet -Aluminum Cam Cleat and Central Aluminum Sheave

92772-330 6:1 Mainsheet Blocks Set - Ratchet

92773-335 7:1 Mainsheet Blocks Set - Ratchet with Aluminum Cam Cleat

Mainsheet Car Swivel Arm with Cam Cleat - Ht4416 - For 14 mm "H" Type Track

95303-00|4:1 mainsheet system set - plain line blocks- 45mm sheave..

92431 Single fixed for Mast Base 28mm

By Product Categories

Small Boat Blocks

Big Boat Blocks

Complementary Hardware

Travelers & Genoa Leads

Mainsail Handling

Headsail Handling

Mooring Solutions

Spare Parts

Accessories

Harken Canvas

Fly Soft-Attach Blocks

Carbo Air Blocks

Small Boat Classic

Flip-Flop Small Boat

GP Catamaran Ceramic Mainsheet Systems

Protexit™ Exit Blocks

Through-Deck

Wire High-Strength

Dinghy Vang

Small Boat Deck Organizers

Midrange Classic

Midrange Deck Organizers

Zircon Blocks

Element Blocks

Black Magic Air Blocks

Cruising ESP Blocks

Megayacht Blocks

Stainless Steel Blocks

Black Magic Air Runners

FlatWinder Powered Blocks

Mastbase Blocks

Over-the-Top

Crossover Blocks

Big Boat Deck Organizers

Cam Cleats & Kits

Cam Cleat Accessories

Cam Cleat Bases

Stand-Up Bases

Deck Organizers

Spinnaker Pole Cars

Soft Attachments

Fixed Padeyes

Removable Padeyes

Bolt-Down Fairleads

Grand Prix Jib Leads

Halyard Tensioners

Tiller Extensions

Peter's Desk Drawer

Dinghy Jib Leads

Crossbow Pivoting Self-Tacking Jib Traveler

13 mm Micro

22 mm Small Boat

27 mm Midrange

32 mm Big Boat

Windward Sheeting

42 mm Mini-Maxi

T-Track Genoa Lead

Access Rail System

13 mm AA Battcar System

22 mm A Battcar System

27 mm B Battcar System

32 mm C Battcar System

18 mm Switch Battcar System

26 mm Switch Battcar System

26 mm Trysail Switch

32 mm Switch Battcar System

32 mm Trysail Switch

40 mm Switch Battcar System

40 mm Trysail Switch System

Furling Mainsail Outhaul Systems

Single Line Reefing

Harken Vang-Master

Carbo Racing Foil

Small Boat Furling

Small Boat Underdeck

Reflex Furling

MKIV Jib Reefing & Furling

MKIV Underdeck Jib Reefing & Furling

Furling Accessories

Powered Furling

MKIV Ocean Furling

SnubbAir (Not a Winch)

Grand Prix Winches

Air Winches

Circuit Breakers

Analog Switches

Digital System Switch

Aluminum, Chrome & Bronze Winch Handles

Carbo OneTouch Locking Winch Handle

Service Kits

CLR Mooring Winches

Electric Captive Reel Winches

Hydraulic Captive Reel Winches

UniPower Radial

Single-Acting Integral Backstay Adjuster

Single-Acting Cylinders

Locking Cylinders

Double-Pull Cylinders

Grand Prix Cylinders

Hydraulic Cylinder Rod End Blocks

Hydraulic Cylinder End Fittings

Control Valves

Control Manifolds

Control Panels

Compact Control Panel

Rotary Pumps

Hydraulic Pump Handles

Power Systems

Repair Kits

Ball Bearings

Block Spare Parts

Traveler Cars

Furling Spare Parts

Winch Spare Parts

Winch Service Kits

Blockheads Gear

Promo & Gifts

Marine Grip

harkengear.com

Jeep/Truck tops

Garage storage

One-design Covers

Boat accessories

Canvas bags

By Type of Sailing

Dinghy / one-design, offshore racing, coastal / day cruising, bluewater cruising, megayachts / custom.

Service Guide

Tech/Service

deck layouts

Data Sheets (SDS)

How to choose

System diagrams

Calculators

Reeving diagrams

Traveler Purchase Selection Guide

How to Choose

Testimonials

Hoister Videos

Request a Quote

Request Samples

Fabric details

Cover Styles

Canvas Videos

Contract Services

Materials and Components

Our Equipment

Contract Cut-and-Sew Project Spotlight

- Harken at the front

- Safety & Rescue

- New Carbo Twing Block

Our new Carbo Twing block: Spring loaded to rig one-handed—and faster. Get a tour from its designer.

- 40 mm Zircon Cat Mainsheet System

Sailing legend Santiago Lange and Harken’s Matt Schmidt collaborate to make world’s most efficient mainsheet system even better.

- Harken Hoister

Move that singlehander from rafter to roof rack and back…singlehanded. Reintroducing Harken Hoisters. All units -12% on this site.

Electric Winches

Spring is coming–making it the perfect time to electrify a manual winch or purchase an electric one. Sailing with the push of a button.

More Protexit Protection

Sheaves get bigger and wider. More wear from side angle loading gets prevented.

40 mm Zircon Block

40mm Twing Block

1 Ton Twing Block

Bell End Track Slider

16mm Dogbone Block

Find products by type of sailing.

Latest news

Dinghy/Sport Boat Leech Control: Quicker, The Way We Like It

Our new Carbo Twing Block: Spring loaded to rig one-handed—and faster.

Santi Speaks. Harken Responds. Systems Improve.

Sailing legend Santiago Lange and Harken’s Matt Schmidt collaborate.

Harken Push Pull Captive Reel Winch

Throughout history, winches have pulled. Drums turn. Cordage or wire rope winds.

Product Categories

- United States

- New Zealand

- United Kingdom

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 02aa651d-e5fc-11ee-9b85-8943303ec44b

Powered by PerimeterX , Inc.

× You are using an outdated browser. Please upgrade your browser to improve your experience.

We Ship Worldwide! | FREE SHIPPING! for US Continental orders over $99. Click for details.

Shopping Cart

Your cart is currently empty..

FREE SHIPPING! for US Continental orders over $99 click for details

Harken Blocks

Lewmar Blocks

Ronstan Blocks

Sailboat Blocks

Sailing Blocks or pulleys for a sailboat can have single or multiple sheaves such as single blocks, double blocks, triple blocks and quadruple blocks. Sailboat Blocks when fixed to the end of a line are used to gain mechanical advantage. The larger use of sheaves in a configuration, the higher mechanical advantage gained. Blocks are used from small dinghies, to keelboats, sport boats, big boats and Maxis. The three most common alternatives for modern blocks are: plain bearings, ball bearings and roller bearings. MAURIPRO Sailing has the largest selection of blocks including fiddle blocks, ratchet blocks, snatch blocks, wire blocks, mainsheet systems, footblocks, cheek blocks, fairlead blocks, stand-up blocks, halyard lead blocks and more. Harken blocks, Lewmar blocks, Ronstan blocks, Selden blocks, Schaefer blocks, Antal blocks, Barton blocks, Allen blocks, Spinlock blocks and more sailboat blocks brands.

MAURIPRO Sailing, your direct access to Blocks and all your other sailing and boating needs.

Copyright © 2024 MAURIPRO Sailing LLC.

Yachting Monthly

- Digital edition

Easy ways to power up your mainsheet

- Duncan Kent

- May 7, 2021

The mainsheet is the most worked item of deck gear, so it's vital to choose the right system and set it up correctly for your boat

Making tweaks to your mainsheet system can prevent breakages and wear to fittings. Credit: Graham Snook

New production yachts often come with systems that have been designed more for convenience while moored than with a sensible engineering solution in mind, resulting in significant loads placed on the boom, kicker, boom-end fittings, mainsheet tackle and crew.

Duncan Kent is a technical writer for marine publications and websites

Making a few tweaks to how your mainsheet system is set up makes handling easier for you and prevents breakages and wear to your fittings.

Keeping complex sail control mechanisms away from vulnerable areas of the boat is paramount, which is why cruising boatbuilders often position the mainsheet up on the coachroof ahead of the main hatch garage.

Though this effectively keeps it ‘out of the way’, it’s often not ideal from an engineering point of view in that it invariably means the mainsheet is attached halfway along the boom, when best mechanical advantage is offered at the aft end.

When connected further forward on the boom, the load on the mainsheet is greatly increased, so too the amount of human effort required to operate it.

If it really must be on the coachroof, then it should be mounted directly under the first leech reefing point, giving you the same mechanical advantage when the wind is up and you’re reefed .

Mainsheet blocks

The key to any sail control system is to keep friction to a minimum, which means the dimensions of the blocks, sheaves and lines are all important, as well as the type of bearings they have.

In principle, you should choose a sheave diameter of at least six times the diameter of the sheet, within the safe working load of the system.

Upgrading the line to one with superior strength, such as Dyneema, and lower stretch can result in you being able to drop a couple of sizes in line diameter, reducing costs, effort and wear.

The type of bearing a block has makes an enormous difference to the friction in any high-load tackle.

Standard plain bearing models are strong, but hard to turn, whereas ball-race and roller types require far less effort.

However, though ball-race bearings reduce friction, they also reduce the working load capacity as Delrin balls (most common) can distort under load long before a plain metal bearing would.

For this reason, the more popular choice for larger yachts are blocks with roller bearings, that have the low-friction of the balls, but the load capacity of plain bearings.

Specialist Rutgerson supplies a range that’s even maintenance-free, thanks to clever ‘roll- links’ between the rollers that keep out dirt and salt.

Mechanical advantage

A 6:1 tackle theoretically reduces sheet loads to 1/6th, but in real terms it’s closer to a quarter due to the friction in the block bearings.

Upwind the average load on the mainsheet for a 35ft cruising yacht with the mainsheet attached at the boom end is said to be around 150kg in 16 knots of apparent wind.

This would result in an actual hand load of roughly 37kg (including friction) if you were to sheet her hard in at this point with a 6:1 tackle, dropping to a more manageable 15-20kg in 12 knots apparent wind.

Whilst it’s useful to have an idea of how these items are rated, most manufacturers will recommend which size line and block you should use for your set-up.

Overhead mainsheet tracks retain the mainsheet’s mechanical advantage while keeping the track out of the cockpit. Credit: Graham Snook/Yachting Monthly

You can make the main easier to sheet in by increasing the mechanical advantage via an additional purchase (more turning blocks) or, if possible, moving the attachment point further towards the end of the boom.

Remember, though, that the more parts a tackle has, the more line is required, which, when close-hauled, has to go somewhere in the cockpit!

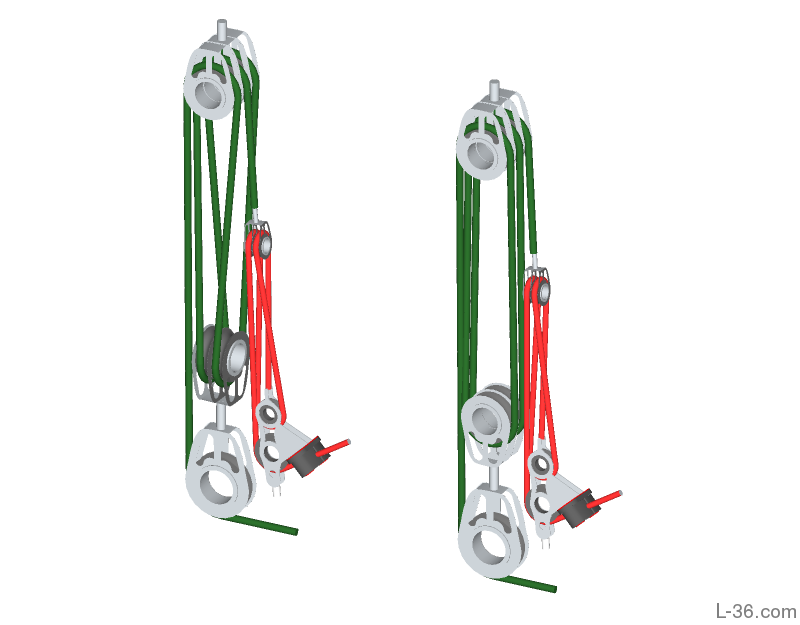

Alternatively, you could use a two-speed, double-ended tackle such as Harken’s self-contained system.

Pulling on both lines sheets it in quickly but requires more effort, whereas pulling just on one line doubles the mechanical advantage, halving the effort needed.

This method uses far less line than a traditional multi- way block arrangement and doesn’t introduce dangerous ‘flying’ blocks where a ‘fine trim’ block is positioned halfway up the mainsheet – just about at head level when tacking.

A widespread problem with any mainsheet system that incorporates a cam cleat can be difficulty with releasing the sheet under load.

Many folk don’t realise that on almost all blocks with a cam cleat attached the lead angle can be adjusted to suit the set-up, which can make life a whole lot easier and avoid you having to use your foot on the sheet to release it.

Sit in the cockpit where you normally would when sailing upwind and check that the cam cleat is in line with or just above where your hands are.

Twist can also be a problem on multi-part mainsheets due to the natural twist in the line, often exacerbated by having two swivels or the line being incorrectly reeved.

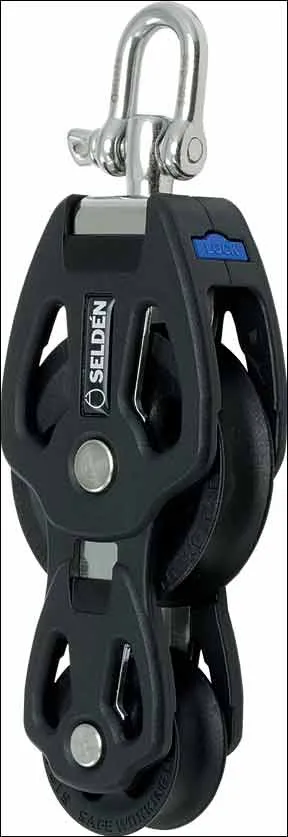

The former is simply cured by ensuring there is only one swivel, which is attached to the traveller end so that the lead angle can be changed easily when changing tack.

Some blocks, such as those from Selden, have lockable swivels.

Continues below…

How to reef to sail safely through any weather

Pete Goss delivers his masterclass on when to reef, and explains why it is critical to keeping control of your…

Mainsail furling systems: an expert guide

Some sailors swear by mainsail furling systems, others swear at them. Graham Snook looks at way to keep your furling…

How to repair a sail – video guide

Knowing how to patch up a sail can get you home safely, extend your cruise and save you money. Rob…

Rope, rigging & deck gear: how to choose the right rope

Rope continues to develop every year. We take a look at the plethora of options on the market

Reeving is an art form in itself and is by no means obvious.

Very often a multi-part tackle is mis- reeved causing two parts of the sheet to chafe against each other creating friction and the whole set-up to end up twisted.

Correct reeving (if in doubt ask the supplier) eliminates crossed lines and ensures load is balanced evenly across all of the sheaves.

Finally, some mainsheet tackles have a ratchet sheave, although they don’t really help much on a cruising yacht.

They do relieve some sheet load, but a larger mainsheet tackle needs a quick- release jammer to be safe and the faceted V-grooved rope channel simply puts extra wear on the sheet.

Sail control: Getting the most from your mainsail

The traveller.

- The traveller is one of the most important aspects of mainsail trim, yet I have been on numerous yachts where the traveller has been ignored all its life. Not knowing its purpose, many owners leave it fixed permanently in the centre. On one boat I sailed it was even screwed down!

- The reason for having the mainsheet attached to a traveller on a track is to enable it to be used to control the position of the boom under sail. Letting the traveller run down the track ‘spills’ the wind in the mainsail and reduces heeling momentum instantly, without affecting the shape or trim of the mainsail itself. When the gust has gone through all you need do is haul it back up the track to put the power back on, knowing the sail will be set as before.

- If you have an old boat with spring- release locking pins on the traveller, I would advise you modify it or replace it with a purpose-made system. If this isn’t possible, then you’ll need to rely much more on the kicker (see above) for controlling the sail shape when sheeting in and out.

The mainsheet track

- The position of the track is also important. The closer to the mast the mainsheet is attached to the boom, the shorter the track needs to be (as the outboard end of the boom moves in a much wider arc than the inboard end). However, mounting it ahead of a spray hood makes it extremely difficult to adjust the position of the traveller in a hurry.

- Tracks that are mounted overhead on a gantry, like those on the Hunter Legend range of yachts offer something of a compromise. To my mind their good points – long track right across the boat, mainsheet attached at the end of the boom, tackle kept well clear of the cockpit – are somewhat negated by the need for another turning block in the traveller adjusters, increasing friction and making them harder to adjust quickly.

- It makes sense to have the mainsheet track within reach of the helmsman with the mainsheet tackle as close to vertical below the boom end as possible. In some cases, especially on smaller boats, this will mean the mainsheet track is in the cockpit and can restrict access when not sailing. It is possible to install a removable track mounted across the centre of the cockpit well, for example, but quickly detached in port or at anchor to free up the space for relaxing. UK deck gear specialist, Barton produces a range of these for yachts right up to 36ft LOA, complete with traveller adjustment blocks mounted on the end-stops.

- Sometimes (particularly on coachroof- mounted tracks) the track has been ‘contoured’ to suit the curved cabin top. I’d strongly recommend replacing it with a straight, flat piece of track. A curved track encourages the traveller to remain in the centre. If you force it to the end using a powerful adjuster tackle it will simply pull the boom down.

The kicker is almost as important as the sheet for controlling the mainsail. Credit: Graham Snook

- The kicker (aka vang) is almost as important as the sheet for controlling the mainsail but is often ignored. The kicker’s primary purpose is to keep the boom from rising up when the mainsheet is eased. It is especially vital if you have a single-point mainsheet fixing or a bridle, rather than a track and traveller, as the former allow the boom to lift as soon as the

- mainsheet is freed.

- Because of the extreme loads it has to undergo, the non-boom end of the kicker should ideally be attached to a reinforced pad eye on the deck or to a stout collar around the mast, rather than a simple, riveted mast fitting.

- A gas-sprung or hydraulic kicker enables you to do away with the topping lift as, when the kicker is released, the spring-loaded vang pushes the boom upwards. It’s sensible to put the main halyard on the boom end to act as a topping lift when leaving the boat to take the permanent load off the spring.

Safety first

- Mainsheet tackles, tracks and travellers, kickers and boom fittings are all subjected to massive loads in heavy conditions, but should the yacht undergo an accidental gybe these loads can increase tenfold. For this reason, it can pay dividends to fit a boom brake of sorts. These ‘adjustable preventers’ not only allow for more control during an intentional gybe, but also stop the boom crashing over and possibly taking the rig down in the event of an accidental gybe. There are several on the market, including the Scott Boomlock, Wichard’s Gyb’Easy, Walder Boombrake, which can really offer peace of mind, particularly when sailing dead downwind.

Leech control

Leach control is important for gust response, adapting to conditions and preventing excessive heel. Credit: Graham Snook

Jeremy White of Elvstrom Sails shares his tips

- Traditionally you’re taught to pull in the mainsheet until you get the desired amount of twist (and so power in the sail), then take the slack out of the kicker, which will lock in that twist setting.

- The problem with mainsheet systems located forward on the boom, is you can’t get the leech tension you need. In this situation you’re forced to use the kicker alone to shape the leech. It is rare you are able to get as much tension via the kicker as you are via the mainsheet without using a winch and when cruising few of us are likely to do this.

- That is not to say it is always a negative outcome. The bonus to plenty of mechanical advantage is that when you ease the main, the leech remains tight which, in turn, gives more finite control. However, I often think the twist that develops in a mainsail when easing a mainsheet with less load in the kicker functions as a very effective safety valve. Racing sailors might want to have very specific control if someone is constantly trimming, but being able to lose a lot of power quickly by easing a small amount of sheet does have its appeal.

- If you are using your traveller then your leech will keep the same shape as you let the traveller down to depower in a gust anyway, so using this most of the time, there is no harm in being set up with less kicker than desirable as this will act as a macro adjustment in a really big gust.

Power up your purchase

- Consider an upgrade. Make sure your traveller is able to move easily while under load, and if possible can be adjusted from the helm. Consider upgrading your mainsheet track. Moving this to the cockpit will increase sail control and you can fit a removable track. At the same time, adding a purchase to adjust the traveller under load will also make sail adjustment much easier.

- Keep a clean sheet. Ensure your mainsheet system is free of twists, is correctly reeved and has the right rope and sheave sizes. Any unwanted friction in the system results in more effort for the crew, so make sure your mainsheet is reeved through the blocks correctly. You can also lock the top set of blocks so they can’t swivel, which will help keep the twists out.

- Here’s the kicker. Use your kicker. This is increasingly vital on those boats without a traveller or on those boats with a mainsheet system located mid-way down the boom. The kicker controls leech twist and gives you better control of power in gusty conditions and downwind.

- Increase the power . Move the adjustment point of the mainsheet further aft along the boom if possible, or add more purchase to your mainsheet system, or opt for a speed-sheet system to reduce sheeting loads. Consider adding more purchase to your kicker system too, to give you more control over the leech shape, though you may need to reinforce or change its mast attachment point. Adjust the angle of your cam cleat to make cleating and uncleating easier.

- Block busters. Get the blocks and cleats set up correctly to reduce friction and make it easier to use. Ratchet blocks are generally unnecessary on cruising boats and add friction, so get rid of these if you have them. Check the bearings of the blocks run freely under load – they may need replacing. Just washing the blocks out with fresh water and spraying with dry lubricant can work wonders with friction.

German mainsheets

German mainsheets that run to the end of the boom offer good control and minimise rope in the cockpit, but the sheet needs working. Credit: Graham Snook

The double-ended, or single-piece mainsheet has become known colloquially as the ‘German’ mainsheet.

Often the sheet will come back to a pair of primary winches, one either side of the cockpit.

With this system a crewmember can sit on the windward side with full access to the traveller and mainsheet winch.

It is a workable solution too for shorthanded sailing on dual-helm yachts, in that the helmsman can control the mainsheet from either helm.

A key disadvantage is that often you end up with all the sheet on one side, unless you constantly even out their use as you go.

To counter this, splicing the ends together makes a continuous loop, but this does make it harder to neatly coil and tidy away.

Increasingly these systems return to a cabin-top winch.

Though this does free up cockpit space, and means there is no mainsheet to catch an unwary crewmember in a gybe, it significantly reduces ease of use and accessibility significantly.

Enjoyed reading Easy ways to power up your mainsheet?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

What is a Sailboat Block?

Last Updated by

Daniel Wade

June 15, 2022

"Block" is the nautical term for a pulley. Blocks make it easier to lift heavy loads and overcome significant force with rope.

Blocks are located all over sailboats, and they're an integral part of the rigging. Blocks are pulleys, and they're most commonly found around the cockpit of the vessel. Blocks also allow ropes to go around sharp corners without rubbing on abrasive surfaces and causing damage.

Table of contents

How do Sailboat Blocks Work?

A block is an extraordinarily simple device. Fundamentally, a block is just a wheel inside a frame. A rope wraps around the wheel. When the rope moves, the wheel turns. There's very little friction inside of a block, and it doesn't matter which direction the rope moves or how much force it moves with.

All a pulley does is redirect the force of the rope. When blocks are used together, they work like a simple reduction gear system. The more blocks you use, the slower you'll lift an object. But the more you slow down the ropes, the easier it gets to lift the object.

Each additional block in a pulley system reduces the speed by one-half but multiplies the force by two. This is useful when lifting something heavy, like a spar or a topmast. Blocks work just as well against horizontal force, like the kind exerted on the mainsheet while under sail.

What are Sailboat Blocks Made Of?

Sailboat blocks are made of wood, metal, or plastic. Traditional sailboat blocks are large, heavy hardwood pulleys with wooden pegs and wooden wheels. A large metal shackle is attached to one end. It mounts to the deck or the object you need to exert force on.

Metal blocks are also quite common, and they're typically made of steel or various corrosion-resistant metals. Plastic blocks have become increasingly common over the years, and they're great for low-stress applications where the forces aren't too intense.

Block Sheaves

The sheave is the part of the block that rotates. It's a disc located within the frame of the block and secured by a pin. Sheave discs are grooved to encourage the rope to ride in the center, which keeps it from binding up between the parts.

Sheave is a term used to identify the number of discs in a block. The most basic block contains one sheave and is known as a "single sheave" block. Double and triple-sheave blocks are also common.

The force distribution of multi-sheave blocks works just like multiple single-sheave blocks. A set of two triple-sheave blocks accomplishes the same task as six single-sheave blocks, as long as they're connected to the load the same way.

Block Systems

There are four primary types of block systems that accomplish different tasks. You're likely to find at least three of the four common block systems on a typical cruising sailboat .

Fixed Block

A fixed block utilizes a single sheave block mounted to a fixed location, like the deck. Fixed blocks are often found in areas where ropes need to change direction, such as the base of the mast.

Moveable Block

A simple moveable block system is the opposite of a fixed block setup. Instead of mounting to a fixed spot, a moveable block mounts to an object that you need to lift. The sheave rides on top of the rope and manipulates the object attached to the block.

Compound Block

A compound block combines a fixed and moveable block in an "S" shape. The compound block reduces the force required to lift an object. Compound blocks are ideal for hoisting large objects. Remember, compound blocks reduce speed and increase your pulling power.

Block and Tackle

The simplest block and tackle requires two blocks. It's similar to a compound system, but with the blocks oriented directly below and above each other. The compound block line runs over the top block, down and around the bottom block, then to a fixed point at the base of the top block.

Types of Block and Tackle

Block and tackle are used on all kinds of sailboats for trimming the sail. Systems that use block and tackle include the mainsheet and the boom vang, among others. Here are the five primary types of block and tackle aboard a sailboat.

Gun tackle is the simplest block and tackle system. It utilizes two single sheave blocks. The line runs around the top of one block sheave then around the bottom of the opposite block sheave. The line returns and connects to a fixed point at the base of the original block.

Luff (Watch) Tackle

Luff tackle, which is sometimes called "watch tackle," utilizes three sections of line instead of two. Luff tackle uses a twin-sheave block and a single-sheave block. The end of the line affixes to the single-sheave block.

Two-Fold Purchase

Two-fold purchase tackle utilizes two twin-sheave blocks and four sections of working rope. Two-fold tackle applies more force than luff tackle at slower lifting speeds. The end of the line mounts to the top block, which is the entry point of the rope.

Double-Luff Tackle

Double-luff tackle has another multiple of two in the name, but it actually utilizes five sections of line. Double-luff tackle requires one twin-sheave block and one triple-sheave block. Double-luff tackle simulates, adding another block to the top and bottom of a luff tackle system.

Three-Fold Purchase

Generally speaking, the three-fold purchase is the most complex block and tackle system you'll find on a typical cruising sailboat . Three-fold tackle utilizes six working lines and two triple-sheave blocks. Three-fold purchase systems carry the most load with the least amount of effort.

Where to Find Blocks on a Sailboat

Blocks are located all over a typical sailboat. However, they're typically not used for stays and shrouds. Standing rigging is often tremendously tight and fixed, so there's little need for block and tackle.

Mast Blocks

Mast blocks are located on or around the mast. These blocks are involved in hoisting, lowering, and reefing the sails. Mast blocks reduce the force required to hoist and lower sails. Additionally, mast blocks are the points where halyards change direction from vertical to horizontal.

Vang Blocks

The vang applies a downward force to the boom. It connects the boom to the base of the mast and usually contains two or more blocks. The vang blocks on a sailboat make it easier to tighten down the boom and work against the force of the wind.

Traveler Blocks

Traveler blocks connect the mainsheet to a traveler, which is usually located towards the end of the cockpit. Travelers allow you to precisely adjust the trim of the sail using a set of pulleys and blocks.

Mainsheet Blocks

Blocks are an integral part of the mainsheet system on most cruising sailboats . Mainsheet blocks make it easier to trim the sail in heavy winds, and they reduce the load on sensitive deck hardware.

Choosing the Best Sailboat Blocks

Blocks are an essential part of sailboat rigging. They control everything from the speed of the boat to the tension of the mainsail luff. Blocks allow lines to move around corners, slide from side to side, and make it easier to manipulate them.

As you can see, it's probably not a good idea to cut corners when choosing blocks for your sailboat. The best quality blocks use strong corrosion-resistant materials, bronze or stainless steel. Wooden blocks are also an excellent choice for classic sailboats.

Bronze Blocks

Bronze blocks are costly and uncommon in the 21st century, though they're highly sought-after and make an excellent addition to any classic sailboat. Bronze blocks are available online and in second-hand marine stores.

Stainless Blocks

Stainless steel blocks are far more common and ideal for most modern sailboats. Well-made stainless blocks don't rust or corrode under normal conditions, which keeps them rolling smoothly for years.

The primary threat to stainless steel blocks is galvanic corrosion, which shouldn't occur unless stainless comes into direct contact with a dissimilar metal. However, inexpensive blocks made with inferior alloys can corrode rapidly on their own when exposed to saltwater.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Parts

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

Eximius - from the beginning

Our sailing experience on a 1987 Catalina 34 which we named 'Eximius' which google showed as the Latin translation for 'Special' We hope that our posts will help others looking to take their boat beyond the local waters as well as provide entertaining reading. I'm a Brit, so my view of entertaining may not match yours ;) See you on the water. The Journey Starts Here Paul

- Service History

Saturday, November 10, 2018

Upgrading the mainsheet block system.

- 3 Single Blocks with Shackles

- 1 Single Block with Shackle & Becket

- 1 Fiddle Block with attached Single Block with a shackle on the Fiddle Block

Update: Tuesday 11/20/2018

No comments:

Post a comment.

Got questions or suggestions about our boat, our sailing or our adventures? Leave a comment. Thanks.

- Manuals - Tech Info

- Nautos PDF Catalog

- (954)369 1842

- [email protected]

Shopping Cart

Welcome to Nautos-usa !

BLOCKS - Sailboat hardware

BLOCKS 20, 30 & 40 mm - DYNAMIC LINE (24)

BLOCKS 28, 39, 57 & 75 mm - CLASSIC LINE (115)

BLOCKS 45, 60 & 80 mm - PLAIN LINE (23)

BLOCKS 57 & 75 mm - OFFSHORE LINE (11)

BLOCKS 57, 75, 100 & 125 mm - MAXINOX LINE (8)

FRICTION SHEAVE (5)

MINI BLOCKS 20MM - MININOX LINE (26)

RATCHET SAILBOAT BLOCKS 57 & 75 mm - CLASSIC LINE (37)

SNATCH BLOCKS (3)

STAND UP BLOCKS (8)

ULTRALIGHT 40 & 57 mm - ORGANIC LINE (36)

1375 - Snatch Block 40 mm Sheave diameter with SS Ball Bearing - Open Pulley - Nautos Usa

Snatch Block

4475 - Snatch Block 30 mm Sheave diameter with SS Ball Bearing - Open Pulley - Nautos Usa

Shatch Block

57MM AUTORATCHET BLOCK - SENSITIVE LOAD - 57mm Sheave Diameter

Automatic Ratchet - Sensitive Load

92000 FIDDLE SWIVEL, BLACK

Fiddle Swivel - Black

92001-FIDDLE SWIVEL WITH BECKET- SAILBOAT BLOCK

Fiddle Swivel with Becket

92002-FIDDLE SWIVEL WITH ALUMINUM CAM

Fiddle Swivel with Aluminum Cam

92003 FIDDLE SWIVEL WITH BECKET & CAM , BLACK ONLY

Fiddle Swivel with Becket and Cam

92010 SINGLE SWIVEL, BLACK

Single Swivel - Black

92011 SINGLE SWIVEL WITH BECKET , BLACK

Single Swivel with Becket - Black

92012 SINGLE SWIVEL WITH CAM , BLACK

Single Swivel with Cam - Black

92013 - SINGLE SWIVEL WITH COMPOSITE CAM CLEAT AND BECKET.

Single Swivel with Aluminum Cam and Becket

92014 - SINGLE FOR WEB ATTACHMENT - ULTRALIGHT BLOCK

Single for Web Attachment - Ultralight Block

92015 - SINGLE WITH BECKET FOR WEB ATTACHMENT - SAILBOAT HARDWARE

Single Swivel with Becket for Web Attachment

92017-SINGLE FOR WEB ATTACHMENT WITH ALUMINUM SHEAVE- TORLON BALL BEARINGS

Single Swivel for Web Attachment with Aluminum Sheave

92018-SINGLE FOOTBLOCK WITH ALUMINUM SHEAVE

Single Swivel Footblock with Aluminum Sheave

92020- DOUBLE SWIVEL

Double Swivel

92021-DOUBLE SWIVEL WITH BECKET

Double Swivel with Becket

92024-DOUBLE FIXED

Double Fixed

92030 TRIPLE SWIVEL , BLACK

Triple Swivel - Black

92034-TRIPLE FIXED

Triple Fixed

92035 SINGLE SWIVEL , BLACK

Single Swivel with Becket

92040 SINGLE SWIVEL WITH BECKET , BLACK

92045 - SINGLE -WEB ATTACHMENT- 40 mm

Single Swivel for Web Attachment

92050 - SINGLE FOR WEB ATTACHMENT WITH BECKET

Single Swivel for Web Attachment with Becket

92055 - DOUBLE SWIVEL

92058- DOUBLE SWIVEL WITH BECKET

92061- TRIPLE SWIVEL

Triple Swivel

92069 - TRIPLE SWIVEL WITH BECKET

Triple Swivel with Becket

92070 FIDDLE SWIVEL RATCHET

Fiddle Swivel Ratchet

92072 FIDDLE SWIVEL RATCHET WITH CAM

Fiddle Swivel Ratchet with Cam

92073 FIDDLE SWIVEL , RATCHET WITH CAM AND BECKET

Fiddle Swivel Ratchet with Cam and Becket

92074 - SINGLE SWIVEL BLOCK, RATCHET- ULTRALIGHT

Single Swivel Block - Ratchet - Ultralight

92075 SINGLE SWIVEL RATCHET WITH BECKET

Single Swivel Ratchet with Becket

92076- RATCHET- SINGLE SWIVEL WITH CAM- SAILBOAT BLOCK

Ratchet - Single Swivel with Cam - Lopez Block

92077 - SINGLE SWIVEL /RATCHET/WITH CAM AND BECKET

Single Swivel Ratchet with Cam and Becket

92078 - FIDDLE SWIVEL WITH BECKET - RATCHET

Fiddle Swivel with Becket - Ratchet

92083 TRIPLE SWIVEL RATCHET WITH CAM AND BECKET , ALUMINUM SHEAVE

Triple Swivel Ratchet with Cam and Becket

92084 - TRIPLE SWIVEL RATCHET WITH CAM AND BECKET , ALUMINUM SHEAVE . HOBIE ORIGNAL

92100 FIDDLE SWIVEL

Fiddle Swivel

92101- FIDDLE SWIVEL WITH BECKET

92103-FIDDLE SWIVEL WITH ALLOY CAM AND BECKET

Fiddle Swivel with Alloy Cam and Becket

92110 SINGLE SWIVEL

Single Swivel

92111 SINGLE SWIVEL WITH BECKET

92118 - SINGLE FOOTBLOCK - SAILBOAT HARDWARE

Single Footblock

92124-DOUBLE FIXED

92125 - DOUBLE FIXED WITH BECKET - SAILBOAT HARDWARE

Double Fixed with Becket

92128 - DOUBLE FOOTBLOCK - SAILBOAT HARDWARE

Double Footblock

92130 TRIPLE SWIVEL

92131 - SINGLE FIXED-MAST BASE- OPEN HEAD - 6MM PIN

Single Fixed - Mast Base - Open Head

92132 - SINGLE FIXED WITH ALUMINUM SHEAVE-MAST BASE- OPEN HEAD - 6MM PIN

Single Fixed with Aluminum Shave - Mast Base - Open Head

- Technical Information

- Buyer Protection Plan

- Terms & Conditions

- Nautos Policy Orders

- Nautos Warranty

Mainsheet Rigging Diagram: A Comprehensive Guide

by Emma Sullivan | Aug 9, 2023 | Sailboat Maintenance

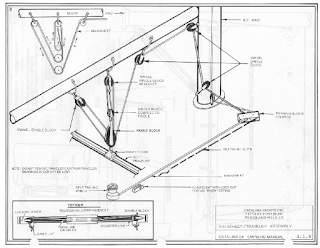

==Short answer mainsheet rigging diagram:== The mainsheet rigging diagram is a visual representation that outlines the setup and configuration of the mainsheet system on a sailboat. It typically includes details such as the location of blocks, cleats, and other hardware, as well as the path that the mainsheet follows. This diagram helps sailors understand and follow correct rigging procedures for optimal sail handling and control.

Understanding the Basics: A Step-by-Step Guide to Mainsheet Rigging Diagram

Welcome to our blog section where we dive into the nitty-gritty details of mainsheet rigging diagrams. If you’re new to sailing or just starting to familiarize yourself with this important aspect of boat handling, this step-by-step guide will provide you with all the necessary information in a professional yet witty and clever manner.

First things first, let’s understand the basics . A mainsheet rigging diagram is essentially a visual representation of how different components come together to control the tension and angle of your mainsail. It acts as your roadmap for properly setting up and adjusting your mainsheet system, ensuring optimal performance on the water .

Now, let’s break it down step by step:

Step 1: Identify the Components A good rigging diagram will clearly identify all the key components involved in your mainsheet setup. This includes the mainsheet itself, blocks, cleats, traveler car (if applicable), boom vang (if present), and any other relevant hardware. Understanding each component beforehand is essential for comprehending how they interact with one another.

Step 2: Determine Attachment Points Next, refer to your rigging diagram to find out where each component needs to be attached on your boat. The diagram will typically display specific locations such as boom attachment point, traveler car track position, or mast base attachment. Proper attachment ensures that everything is in its place, allowing for smooth operation during sailing maneuvers.

Step 3: Follow Line Pathways Lines play a crucial role in main control systems; therefore it is vital to follow their designated pathways as shown in the rigging diagram. These pathways illustrate how the lines route through blocks, fairleads or around various sheaves on both ends (boom and deck). Pay attention to any twists or crosses indicated on the diagram – avoiding these can prevent line jams when under load.

Step 4: Tackle Block Configuration Understanding block configurations outlined in your rigging diagram helps you achieve the right mechanical advantage. It may feature single, double, or even triple blocks, and understanding their set-up assists in distributing the load appropriately. Additionally, some diagrams might incorporate purchase systems using various line lengths to further enhance control.

Step 5: Adjust Tensions and Angles Lastly, your rigging diagram will provide information on how to adjust tensions and angles for different sailing conditions. It can include tips on optimal mainsheet tension for upwind versus downwind sailing or advice on adjusting boom height using a vang. This knowledge enables you to fine-tune your sail trim and maximize performance throughout your voyage .

So there you have it – a comprehensive step-by-step guide to mainsheet rigging diagrams! Following these instructions will ensure that you have a solid grasp of how all the components fit together, how lines should be routed, and how to make necessary adjustments when sailing.

Remember, while the topic might seem technical at first glance, we believe injecting some wit and cleverness into the explanation can make learning more enjoyable. So embrace this guide as your key to mastering mainsheet rigging diagrams with style!

How to Properly Set Up a Mainsheet Rigging Diagram: A Comprehensive Overview

Mastering the art of sailing involves not only skillful navigation but also a deep understanding of the recommended rigging diagram for your mainsheet. The mainsheet, which is responsible for controlling the position of the mainsail, plays a crucial role in dictating the overall performance and maneuverability of your sailboat. In this comprehensive guide, we will unravel the intricacies of setting up a mainsheet rigging diagram flawlessly. So grab your favorite maritime beverage and let’s dive right in!

The first step in establishing an impeccable mainsheet rigging diagram is selecting the appropriate equipment. Your choice of hardware will strongly influence how efficiently you are able to adjust and control the tension on your mainsail. Opt for high-quality blocks, preferably ball bearing ones, as they reduce friction and allow for smooth sheeting. Remember that investing in quality hardware now will save you from headaches later on when battling against strong winds or trying to make precise adjustments on gusty days.

Now that we have our top-notch equipment ready, let’s move on to positioning our blocks effectively along with all necessary lines (sheet) involved in this setup. It’s essential to ensure that there are no unnecessary twists or tangles in any part of the system as they drag down performance while causing unneeded frustration.

Begin by attaching one end of your sheet to a fixed point near the stern side of your boat . This point should be appropriately positioned for easy reach from your desired helm location—a smart sailor always plans ahead! Make sure the sheet runs freely through each block without any abrasion points or sharp corners that could snag it during rapid movements—smooth sailing is what we aim for here.

Next, work your way towards those strategic locations where blocks need affixing – typically at multiple points along either side deck or cabin roof – depending on the size and design of your vessel. These attachment points should be selected judiciously, considering factors such as angle, load distribution, and accessibility. Securing these blocks with reinforced backing plates or similar reinforcements will provide extra support, particularly in conditions that warrant additional strength.

Now let’s talk about the main sheeting technique—the final piece of the puzzle that brings your mainsheet rigging diagram to life! When properly executed, this technique allows you to gain full control over the position of your mainsail effortlessly. The most common approach is a 2:1 purchase system, offering mechanical advantage while maintaining manageable loads on your hands.

To achieve this setup, start by taking a free-running end from one of the blocks along the cabin roof or side deck and lead it around the backside of the mast towards an adjacent block located on the opposite side. Once there, thread it through this second block (which forms an inverted “V” shape with its counterpart) and bring it back towards you—forming what appears to be a rather fancy pulley system!

By doing so, you essentially create two segments of line – each running under different sides of your boom – that can be tied together using a simple knot or shackle hitch. This clever arrangement doubles up your pulling power without needing Popeye-like forearms to control sail tensions effectively—a truly elegant solution!

It’s worth mentioning that personal preferences might affect how you choose to set up your mainsheet rigging diagram. Some sailors opt for alternative systems like a 3:1 or even 4:1 purchase configuration for added convenience in rougher weather conditions or on behemoth-sized boats with correspondingly larger sails .

However, regardless of the sophisticated upgrades one may consider down the line, understanding and mastering the fundamentals we’ve discussed is vital before venturing into more complex setups. Take time to observe how everything interacts as you adjust sail trim and experiment with different adjustments both at sea and dockside – knowledge always grows best through hands-on experience.

In conclusion, setting up a mainsheet rigging diagram properly is a skill that every serious sailor should possess. By investing in top-quality equipment, positioning blocks effectively, and mastering proven sheeting techniques, you’ll gain complete control over your mainsail’s positioning—a game-changer when it comes to developing superb sailing skills. So go ahead, grab that sketchpad, and embark on the journey of designing the perfect mainsheet rigging diagram for your beloved vessel!

Frequently Asked Questions about Mainsheet Rigging Diagrams Answered

If you’re a sailing enthusiast or a boat owner, chances are you’ve heard about mainsheet rigging diagrams. These diagrams play an important role in understanding and setting up the mainsheet system on your sailboat. In this blog post, we will answer some of the frequently asked questions about mainsheet rigging diagrams, providing you with a detailed and professional explanation.

Q: What is a mainsheet rigging diagram? A: A mainsheet rigging diagram is a visual representation of how the components of your boat’s mainsheet system are connected and configured. It demonstrates how the various lines, blocks, travelers, and other hardware come together to create an efficient and functional setup for controlling the mainsail.

Q: Why are mainsheet rigging diagrams important? A: Mainsheet rigging diagrams serve as invaluable references for both beginners and experienced sailors . They help ensure that all components of the mainsheet system are correctly installed and properly functioning, promoting safety while maximizing sailing performance. Additionally, these diagrams make it easier to troubleshoot any issues that may arise during sailing.

Q: How do I read a mainsheet rigging diagram? A: Reading a mainsheet rigging diagram involves understanding the various symbols, lines, and labels used to represent different elements of the rigging system. Typically found in manuals or manufacturer guides, these diagrams often feature labeled arrows indicating line direction or block rotation. Familiarizing yourself with common symbols such as circles for blocks or triangles for shackles will greatly aid your comprehension.

Q: Can I customize my boat’s main sheeting arrangement using these diagrams? A: Absolutely! Mainsheet rigging diagrams not only provide guidance on standard setups but also give you options for customization based on your specific requirements or preferences. Whether it’s adjusting block placements, choosing different types of hardware, or modifying line configurations – these diagrams offer a starting point for personalizing your mainsheet setup to enhance performance and comfort.

Q: Are there any general tips for rigging the main sheet correctly? A: While specifics may vary depending on your boat’s design and rigging system, there are a few general tips to keep in mind when rigging the mainsheet. Firstly, ensure that all lines run freely through blocks or travelers without unnecessary friction or interference. Secondly, choose appropriate line sizes and materials, considering factors like load capacity and ease of handling. Lastly, regularly inspect and maintain your fittings, lines, and hardware to prevent failures or accidents.

Q: Where can I find a mainsheet rigging diagram for my boat? A: You can typically find mainsheet rigging diagrams in your boat’s owner’s manual or manufacturer’s guide. These resources are often available online from the manufacturers’ websites as downloadable PDFs. If you’re unable to find a diagram specific to your boat model, numerous sailing forums and communities share knowledge and useful resources where fellow sailors post their own diagrams.

In conclusion, mainsheet rigging diagrams hold significant importance in the sailing world. These comprehensive visual representations assist boaters in setting up their mainsail systems correctly while allowing room for customization. Reading these diagrams is crucial for ensuring safety onboard and optimizing sailing performance. So take advantage of this essential resource to make the most out of your sailing adventures !

Exploring the Benefits of Using a Mainsheet Rigging Diagram in Sailing

Title: Unraveling the Advantages of Utilizing a Mainsheet Rigging Diagram in the Art of Sailing

Introduction: Sailing, an age-old practice that seamlessly combines art and science, continues to captivate enthusiasts and novices alike. The precision and elegance involved in navigating the waters harnesses various elements, one of which is the mainsheet rigging diagram. Regardless of your sailing expertise, understanding the benefits of employing a mainsheet rigging diagram can greatly enhance your experience on the open sea. In this blog post, we will delve into the intricate world of sailing, unraveling why utilizing a mainsheet rigging diagram is both indispensable and enlightening.

1. Setting Sail for Success: Navigating through intricate maneuvers and controlling sail trim requires meticulous attention to detail. By utilizing a mainsheet rigging diagram, sailors gain access to a comprehensive visual representation that outlines every element involved in adjusting the main sheet. This invaluable tool acts as a roadmap, guiding sailors towards achieving their desired sail settings with precision and accuracy.

2. Enhanced Maneuverability: A well-configured mainsheet rigging diagram equips sailors with enhanced maneuverability capabilities by illustrating various configurations under different wind conditions – from light breezes to strong gusts. Through carefully planned adjustments outlined in the diagram, sailors can respond swiftly to changing conditions and optimize performance while maneuvering effortlessly through tight turns or executing challenging maneuvers.

3. Simplified Coordination: Collaboration between crew members is crucial during sailing expeditions, especially when it comes to handling the mainsail efficiently. Thanks to a well-drawn mainsheet rigging diagram, team coordination becomes simplified as everyone is referencing the same guidebook for execution and communication purposes. The clear depiction of specific lines or attachments ensures seamless coordination between crew members, eliminating confusion and promoting efficiency when making necessary adjustments.

4. Improve Safety Measures: Sailing inherently involves exposure to potentially adverse weather conditions at times. By utilizing a mainsheet rigging diagram, sailors gain an added layer of safety as the diagram acts as a preemptive measure against accidental mishaps. The diagram clearly outlines how various elements interact, thus allowing sailors to identify and resolve potential issues before they escalate into potentially dangerous situations .

5. Empowering Learning Experience: For beginners or even seasoned sailors seeking to enhance their skills, a mainsheet rigging diagram serves as an invaluable educational tool. Examining and understanding the intricate details of sail trim adjustments and the associated variables helps broaden one’s understanding of the principles governing maneuvering on water. Absorbing this knowledge through interactive exploration of the diagram sharpens sailing intuition and enables informed decision-making while on the sea.

Conclusion: Embracing the benefits offered by a mainsheet rigging diagram in sailing is undoubtedly a wise choice for any seafarer aiming to elevate their performance, coordination, safety measures, and overall navigational prowess. This comprehensive visual representation uniquely combines artistry with ingenuity to simplify complex maneuvers effectively. Whether you are an experienced sailor or embark on your maiden voyage, it is crucial to recognize that employing this visual aid will enhance your experience on the open waters significantly – ensuring smooth sailing every step of the way!

Mastering the Art of Mainsheet Rigging: Essential Tips and Tricks

Rigging your mainsheet is an essential skill for any sailor , whether you’re a seasoned pro or just starting out. The mainsheet is one of the most crucial control lines on your sailboat , responsible for trimming and shaping your sail’s angle to the wind. Getting it right can make all the difference in your sailing performance, and that’s why we’re here to share some invaluable tips and tricks to help you master mainsheet rigging like a true professional.

1. Understanding the Basics: First things first, let’s get familiar with the basics of mainsheet rigging. The mainsheet typically runs from a block on the boom through multiple blocks on deck before ending at a cleat or winch. This setup allows you to adjust tension and trim, affecting both boat speed and steering response.

2. Finding the Sweet Spot: The optimal position for your mainsheet block attachment points is essential for efficient sail control. Experiment with different positions until you find what feels comfortable and allows for easy adjustments while maintaining a proper angle between boom and cockpit.

3. Choosing the Right Materials: Investing in high-quality mainsheet lines can significantly enhance your sailing experience . Look for durable materials that offer low stretch, such as Dyneema or Spectra fibers, which provide superior strength without sacrificing flexibility.

4. Length Matters: It’s crucial to choose an appropriate length for your mainsheet line based on your boat’s dimensions and sailing conditions. Too short, and you won’t have enough leverage; too long, and handling becomes cumbersome. Find that sweet spot where ease of use meets efficiency.

5. Tidy Organization: Keep your mainsheet system tidy by using organizers or fairleads along your boat’s cabin top or cockpit coaming. These small guides redirect the sheet smoothly around corners or obstacles while reducing frictional losses, ensuring fluid adjustments even under heavy load.

6. Friction-Free Fittings: When setting up your mainsheet rigging, pay attention to areas where friction may occur. Consider using ball-bearing swivel blocks or low-friction rings to reduce resistance, allowing for smoother and more precise adjustments.

7. Controlling Boom Vang: The boom vang plays a crucial role in mainsail control, helping to maintain proper sail shape and control leech tension. Ensure your vang is properly rigged, adjusted, and easily accessible from the cockpit, allowing for quick modifications as wind conditions change.

8. Maintenance Matters: Just like any other equipment on your sailboat , regular maintenance is crucial for optimal performance. Inspect your mainsheet regularly for wear and tear, replace any worn-out components promptly, and keep everything clean and well-lubricated to ensure smooth operation.

9. Perfecting Your Technique: Practice makes perfect when it comes to mainsheet rigging! Experiment with different trimming techniques such as sheeting in incrementally or jumping from one trim point to another during acceleration. With time and experience, you’ll develop a nuanced understanding of how best to optimize sail shape given varying wind strengths and angles.

10. Safety Comes First: Lastly, always prioritize safety while rigging your mainsheet system . Avoid standing directly in front of the boom when releasing tension rapidly or handling heavy loads. Consider wearing gloves when working with lines under high pressure to avoid rope burns or injury.

Remember that mastering the art of mainsheet rigging takes time and practice; there’s no substitute for hands-on experience out on the water. By following these essential tips and tricks, however, you’ll be well on your way toward honing this critical skillset – all while enjoying the thrill and satisfaction of improved sailing performance.

Troubleshooting Common Issues with Mainsheet Rigging Diagrams

Title: Decoding the Enigma: Troubleshooting Common Issues with Mainsheet Rigging Diagrams

Introduction: When it comes to sailing, understanding and mastering the art of mainsheet rigging is imperative for smooth sailing. However, even the most experienced sailors can find themselves scratching their heads in confusion when faced with intricate rigging diagrams . Fear not, dear sailors, for today we shall dive into the depths of main sheet rigging diagrams and uncover common issues that plague many navigators. So grab your compass and join us on this thrilling adventure !

1. Demystifying Complexity: Mainsheet rigging diagrams may oftentimes resemble a complex tapestry woven by mischievous water sprites. However, fear not! The key to cracking this enigmatic code lies in approaching them with patience and logic. Break down the diagram into smaller sections, identify each component diligently, and let your curiosity be your guide.

2. Tangled Lines: A Gordian Knot Situation One of the most common woes encountered while deciphering mainsheet rigging diagrams is dealing with tangled lines. It’s as if Medusa herself decided to pay a visit to our sailboat! To combat this issue, mentally trace each line’s path throughout the diagram while referring to its corresponding written description. By tackling one line at a time, you’ll transform the figurative knots into a smoothly flowing sea breeze.

3. Lost in Translation: Bridging the Gap Sometimes, despite our efforts to comprehend every detail within a rigging diagram , there remains a lingering sense of confusion—an invisible language barrier between words and symbols. In such situations, turn to online resources or sailing communities where fellow adventurers may have tackled similar hurdles before you. Exploring different interpretations and perspectives can often provide valuable insights that bridge this communication gap.

4. Attention All Hands! Beware of Amplified Scale: Beware! The scale provided in mainsheet rigging diagrams isn’t always a true representation of reality. Properly understanding the scale is crucial in ensuring accurate rigging . Utilize measuring tools, such as rulers or calipers, to determine precise measurements and adjust them accordingly on your own personal diagram or setup. Vigilance in this regard will prevent unexpected surprises during the rigging process.

5. Know Your Knots: Ensuring a Secure Rig Just as an anchor secures a ship against the fury of the sea, knots are essential for maintaining rigging integrity. When deciphering mainsheet rigging diagrams, pay close attention to the types of knots employed throughout the system. Familiarizing yourself with these specific knots ensures efficient knot tying and enhances overall safety while cruising through waters both smooth and turbulent.

Conclusion: Navigating through mainsheet rigging diagrams can feel like unwrapping a mysterious treasure map leading us to adventure-filled destinations on land uncharted. While they may initially seem daunting, approaching these diagrams with patience and good humor allows us to overcome any obstacles that cross our path. So brave sailors, let curiosity be your compass and tenacity your guiding star—oh captain! Set sail confidently into the world of mainsheet rigging diagrams and conquer any challenges that await!

Recent Posts

- Approaching a Mooring Buoy: Essential Tips for Safe Navigation

- Best Tiller Autopilot: Enhance Your Sailing Experience

- Nautical Navigator: Essential Tools and Techniques for Seamanship

- Sail Making Material: A Comprehensive Guide

- 2 Person Dinghy: The Ultimate Guide to Choosing the Perfect Boat

- Sailboat Gear and Equipment

- Sailboat Lifestyle

- Sailboat Maintenance

- Sailboat Racing

- Sailboat Tips and Tricks

- Sailboat Types

- Sailing Adventures

- Sailing Destinations

- Sailing Safety

- Sailing Techniques

Mainsheet Systems

Papoose double ended 5:1 mainsheet system.

8:1 Beachcat

6:1/24:1 gross/fine, 4:1/16:1 gross/fine, 7:1/28:1 gross/fine, 4:1 with dedicated winch, 5:1 with dedicated winch, 2:1 with dedicated winches, admiral's cup 2:1 with dedicated winch, 3:1 with dedicated winch, admiral's cup 4:1 with dedicated winch, 2:1/4:1 swivel base, 3:1/6:1 swivel base, 4:1/8:1 swivel base, 6:1/24:1 cascaded.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

In Search of the Snag-free Clew

What’s Involved in Setting Up a Lithium Battery System?

Reducing Engine Room Noise

Breaking Point: What Can Go Wrong With Your Yanmar?

Mildew-resistant Caulks for Boats

Can We Trust Plastic Boat Parts?

Repairing Molded Plastics

Mailport: Marine plywood, fuel additives, through bolt options, winch handle holders

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Safer Sailing: Add Leg Loops to Your Harness

Resurrecting Slippery Boat Shoes

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

The Ultimate Guide to Caring for Clear Plastic

- Sails, Rigging & Deck Gear

Mainsheet Tackle Bench Test

Whats the best 4:1 mainsheet control system.

Stroll through your local marina, and you’ll likely see plenty of resurrected, vintage sailboats, sporting newly painted hulls and decks, and replaced sails and rigging. But all too often, antique mainsheet blocks have somehow escaped the upgrade. Part of the reason for this oversight is that the sheaves, ensconced between weathered cheekplates, get only an occasional, no-load test spin, and all but the most severely deteriorated pass the scrutiny. Theres also an If it ain’t broke, don’t fix it mindset that usually makes sense, but in this case, a relatively simple and cost-effective block swap can greatly improve mainsail handling.

Mainsheet tackle comprises blocks, shackles, swivels, and a wide array of attachment hardware that allows us to more efficiently trim and shape the mainsail. Some sailors seek mainsheet simplicity, while others want sheet-hauling speed and fine-tune control. Arguably, the mainsheet tops the list of sail-trim controls, allowing a crew to adjust the boom angle in reference to the boats centerline and respond to changes in apparent-wind angle. It also can influence the downward force that alters the leech twist of the mainsail. In short, the mainsheet and the jib sheet are the key players when it comes to efficiency under sail.

What We Tested

In this round of mainsheet tackle testing, we sought products that makers would recommend for a Pearson 30. We narrowed the field to eight systems, all sized for small to mid-size cruiser-racers and daysailers (20 to 30 feet) that employ the mechanical advantage of a 4-to-1 mainsheet tackle. The test field included products from Antal Marine Equipment, Garhauer Marine Hardware, Harken, Nautos, Ronstan, Schaefer Marine, and Seldn Mast-all well-known makers of deck hardware.

All of the tested tackle featured a pair of fiddle blocks (one with a becket and a cam cleat), and all came with shackle ends that could be locked or allowed to swivel. Except for the Seldn, all of the systems used ball or roller bearings, and all have alloy, stainless steel, or injection-molded plastic cheekplates or cage frames. All of the sheaves-except those in the Garhauer products and the Harken and Nautos ratchet blocks-were non metallic. Glass fiber, Acetal, Delrin, and other plastic composites have become a favored alternative to metal sheaves.

Each companys engineers develop their own fiddle-block geometry and settle on a diameter ratio between the smaller and larger sheaves. This influences line leads and clearance. Among the test products, cam cleat design showed a wide range of differing thought, and in some cases, the cam-cleat structure was the limiting variable in setting a safe working load for the fiddle block/cam cleat combo.

How We Tested

The classic 4-to-1 mainsheet tackle comprises two fiddle blocks; one is simply a pair of inline sheaves, but the deck-level block includes a becket and a cam cleat. Ideally, this simple machine makes hauling in the mainsail four times easier when it comes to line-pull effort. For example, if a single line were attached to the boom and it required a 100-pound pull to move the boom inboard, a 4-to-1 purchase would allow you to get the same job done with only 25 pounds of pull. The no-free-lunch rule does come into play, resulting in the need to haul in four times the length of rope in order to cut the load to 25 percent of what it was originally.

All of the above assumes a utopian world of zero friction, so one of our tests sought to determine how well the blocks kept friction at bay. In order to test block efficiency, we set up a carefully controlled load-lifting experiment. It mimicked normal sailing conditions, measuring efficiency in a range well under the safe working load limits of all of the hardware tested.

To accomplish this, we mounted a fixed weight on a vertical rail and used each of the eight tackles to hoist the load. Tension in pounds, smoothness of pull, and cam-cleat operation were recorded. Testers also set up a high-load-strain test jig to evaluate cam operation at a 200-pound load after an 800-pound momentary load had been imposed. The test mimicked a gust and faux knockdown, and measured how easily a mainsheet could be released.

Because all of the test systems were equipped with cam cleats that are intended to be traveler mounted or mounted on a fixed part of the deck, we added a cleating/uncleating test. We also scrutinized the blocks construction materials, and noted where problems could arise. Factors such as potential for galvanic corrosion, sheave and bearing exposure to UV irradiation, and a wide range of physical design characteristics were considered.

Antals 70 series fiddle blocks are made from a single piece of carefully machined and anodized aluminum. Both the upper fiddle block and the deck-level block are equipped with a unique swivel-head lock that allows the mainsheet tackle to be permanently aligned or to swivel. The composite bushing rides on a stainless-steel hub, and side race ball bearings lessen sheave friction. Testers found that the sheave leads are fair, and theres no sign of line-to-line chafe when an eye splice is used instead of a bowline. Testers liked the precise grip and release of the cam jaws.

The Antal system did not top the scale in any one area, but it did run in the front of the pack. Testers gave high marks to the smooth pull and elegant design of the anti-swivel fitting. One of the more significant features is the cams combination of easy clip and release, powerful grip, and a superior ability to be released under load.

Priced at $563, the Antal system was the most expensive one tested, but it also is rated with the highest safe working load (SWL): 2,860 pounds.

Bottom line: The Antal fiddle blocks are well-engineered and exactingly constructed, but priced at the top of the heap. For those with deep pockets, the OPF70 is our Recommendation for all-around, long-lasting mainsheet control.

Garhauer offers three options as ready-to-connect mainsheet tackle. Each Series 30 combo has a fiddle block and a block with a becket plus a cam cleat that comes rigged with 40 feet of half-inch braided sheet attached via an eye splice. These setups come with either anodized aluminum cheekplates or highly polished stainless steel. And at $115 for the former and $125 for the latter-both with 10-year warranties-they represent a very good buy.

Garhauers large-diameter ball bearing race fiddle blocks paid off in the pull-efficiency testing, topping out with the low score of 24 pounds. We tested all three Garhauer units, but we reported only on two because the only difference between the alloy-sided blocks was the color of the anodizing. Common dimensions and bearing design among all three resulted in near identical friction test scores. Its interesting to note that using a lower ratio between the big block and small block may have lessened small sheave friction, but it also caused the line running through the blocks to touch, raising concerns about long-term chafe.

Garhauers smooth, efficient cam cleat is welded in place, making it impossible to alter lead angles yourself. However, if the factory lead angle doesn’t work, Garhauer will change it to a custom angle, at no charge.

The screw shackles have shallow threads, but the pins are bored to accept a ring pin. The cam cleat exerts a bear trap-like grip on the sheet (32 pounds of release pull) when a 200-pound load was placed on the tackle. At 800 pounds of tension, it took 45 pounds of pull to free the line.

Bottom line: This is an efficient, ruggedly built set of fiddle blocks and the price is compelling. They get the PS Budget Buy.

Harkens 75-millimeter Carbo Fiddle blocks incorporate cheekplates made of glass fiber-filled nylon resin; they are UV stable and more immune to corrosion than metal alternatives. Harkens switchable ratchet control and easy grip cam cleat make it a user-friendly tackle for mainsheet sheeting. Its patented three-way cam lock adds versatility, and the high-load bearing races ensure smooth operation at the upper end of the safe working load.

Testers also liked the Harkens details, including shorter length, forged stainless-steel D-shackles and the nicely machined aluminum primary sheave in the ratchet block.

Harken has come up with another elegant fiddle block combo. Its strong but light, the cam has a very positive grab, and its versatile in fixed or swivel mode. In fact, testers were a little concerned about the cams alligator-like grip and the higher load release (28 pounds pull) necessary at 200 pounds of tension. We worried about load jamming under higher loads, but after testing at 800 pounds, we were pleased to discover that the release required only saw a small uptick to 32 pounds of pull. The Harken has a SWL of 1,212 pounds.

This Carbo fiddle block couplet also has a ratcheting feature favored by one-design and smaller racer/cruiser owners. The feature can be clutched in or out on the fly, and the only downside is the flat facets on the large sheave of the lower fiddle block-a feature that gives a slight thump-thump feel when hauling the mainsheet.

Bottom line: The Harken Carbo 75 ratchet mainsail systems is priced in the middle of the pack ($280), and its our Recommendation for the serious sailor.

Nautos delivers a well-made, double fiddle-block combo, with a ratcheting feature. The blocks were the smallest in the test field, and not surprisingly, they also had the lowest safe working load. Despite their petite size, the Nautos blocks held their own with bigger blocks, especially when it came to releasing under load.

The fiddle blocks have stainless-steel cheekplates and a cross-riveted construction that holds the bearing surface and sheaves in place. The cam angle is adjustable, but the cam causes the safe working load to be lower than that of the blocks alone (660 pounds versus 880 pounds). These compact blocks also offer a ratcheting feature that can be toggled on or off with the push of a small lever.

Priced right at $137, the blocks would be well-suited for smaller boats with less mainsail area.

Bottom line: The Nautos blocks are a worthy choice for smaller boats in this size category.

Ronstan Series 60 Core fiddle blocks have a rugged two-stage bearing system that helps them cope with the heavy loads that can deform a primary bearing race. The adjustable-cam fiddle block incorporates a fixed or swiveling head, and the design uses alloy cheekplates to spread tensile loads. The Acetal sheave is UV stabilized, and the shackle post and hub are 316 stainless steel.

The Series 60 fiddle block design eliminates the need for a becket extension as the lower block spindle hole acts as a becket. We found the large-diameter hole on the lower sheave to be a functional alternative that worked well with a simple bowline. It did not chafe on any of the running parts of the sheet, but if an eye splice was to be used, it had to be made up with the block in the loop. It was the only unit tested without a traditional becket.

Friction was higher in this fiddle block combo, but the pull was smooth and even. The cam cleat had an easy-to-engage feel and behaved well under high-load testing. It was interesting to note that although low-load friction was high, the blocks secondary bearing race design improved its high-load operation.