and follow my . Following it will minimize damage due to a miswired amp.

the easier they are to troubleshoot, so keep learning.

--sometimes over 700 volts AC and 500 volts DC. If you have not been trained to work with high voltage then have an amp technician service your amp. Never touch the amplifier chassis with one hand while probing with the other hand because a lethal shock can run between your arms through your heart. . You must before doing any work inside an amplifier chassis. See more .

Power tubes usually wear out quicker than preamp tubes but as they say, "tubular morghulis," "all tubes must die." --they can cause all kinds of problems including weird noises. Reverb driver tubes often have over 400 volts on their plates and die quicker than preamp tubes.

including complete loss of signal, red plating due to loss of bias voltage, weird noises, static, crackle & pop, weakening or thinning of signal output, loss of tube heat, higher than normal plate voltage, zero voltage on the cathode of a cathode biased amp--almost anything. Sometimes you can gently wiggle a tube and listen for noise. You can clean the socket by spraying contact cleaner on a tube's pins and inserting it into the socket a couple of times. See .

.

. Old weak filter caps can loosen up the bottom end and increase voltage sag and note bloom. A 30 year old, weak 25uF cathode bypass cap that has deteriorated to 1uF will trim a lot of low frequencies. To most of us that seems like a problem that needs to be fixed but these "defects" may be the cause of the "perfect tone" this amp gives its player.

With old classic amps I like to discuss this with the client. Do they want the amp brought back to original specs or do they want to keep the current amp tone? This is especially true for well known guitarists. You don't want someone famous telling everyone you ruined their favorite amp.

. No lights, no sound, no speaker hiss.

.

. Lights are on or you can hear speaker hiss.

.

.

.

.

.

.

(no speaker hum or hiss at all) then the problem can be just about anywhere in the amp but you should suspect a bad tube, blown fuse or the power supply in that order.

Try a new rectifier tube.

Try plugging in a guitar cable, turn up all the amp's volume, gain and master volume controls up a little and touch the tip of the guitar cable's other end. You should hear loud noise. If you hear noise jump to

If the pilot light does not light you can remove the bulb and test it for continuity across the bulb terminals using a multimeter's continuity or "beep" function. A blown bulb will not show continuity.

If none of the tubes show any heater glow (dimming the room lights can help you see the tube glow) the problem is probably with a blown fuse or the power supply.

. They can look good but still be blown.

Many amps have internal fuses mounted on the circuit board or on wires in in-line fuse holders. Any one of these fuses can make the amp silent. Again, test all the fuses for continuity with your multimeter. You should remove a fuse to test it because if left in-circuit you can get a false "good" reading.

If after replacing the fuse the amp blows the new fuse see the section.

and power it up. A allows you to power up a new or problem amp and limit damage to the amp from miswiring or other defects. If an amp is blowing fuses the limiter will allow you to power up the amp, not blow a fuse and troubleshoot. The limiter keeps the current flowing through the amp low enough to not blow the fuse. .

. If you can't find a 100 watt bulb for your limiter a 150 is the next best thing. You can not use an LED or fluorescent bulb.

if available. If you don't have a standby switch jump to .

I which is normal, .

then a problem is in the power cord, power transformer, heater wiring, fixed bias circuit (fixed bias amps only) or rectifier. These are the only things usually powered in standby.

then the rectifier tube or socket is the problem. Try another rectifier tube and inspect the rectifier tube socket.

check the rectifier tube socket and its wiring. .

. If the bulb glows dim (which is normal) then jump to .

if voltage is over 30v before doing any work inside the chassis.

and tape them off individually so they can't short to the chassis or make contact with one another.

Power up the amp, if the light bulb doesn't glow at all or glows dim then jump to the next paragraph. If the bulb glows bright then the power cord or transformer winding is shorting out internally. Drain the caps and disconnect all three power cord wires, wrap each one in electrical tape and plug in the amp. If the bulb doesn't light then the transformer is shorted internally and must be replaced. If the bulb glows bright the power cord is shorting so try a new power cord.

downstream in the rectifier, 6.3v heater wiring, 5v heater wiring or bias circuit.

Power down the amp and . . Power up, if the light bulb doesn't glow then its downstream wiring is OK. If the bulb goes bright you know there is a problem downstream of the connection in either the rectifier tube socket wiring or in amps with a solid state rectifier the problem can be in the rectifier, filter caps, output transformer or tube socket connections. If your bias circuit is powered by the high voltage taps then it is a suspect too. Unsolder the connection from the last filter cap that supplies the preamp. If the bulb doesn't light the preamp wiring is OK, disconnect the power tube screen connection and test. If it's ok then you probably have a shorting capacitor. Unsolder them and test.

If the high voltage connection tested good power down, drain the caps and connect the wires. Power up and if the bulb doesn't light the heater wiring is OK. If the bulb burns bright then there is a wiring problem in the heater wires, heater artificial center tap or tube sockets. Using a magnifying glass carefully inspect every heater wire connection. If you don't find a problem and your amp has an artificial center tap then replace both resistors.

If the 6.3v circuit tested good power down, drain the caps and connect the that power the tube rectifier. If your amp has a solid state rectifier skip this step and move to the fixed bias circuit. Power up, if the bulb doesn't light then move on to the bias circuit. If the bulb goes bright carefully inspect the rectifier tube wiring--there's a short somewhere.

If the 5v circuit tests good and your amp has a , power down, drain the caps and connect the fixed bias. If the bulb doesn't light the circuit is OK. If it goes bright there is a problem in the bias circuit. Carefully inspect the circuit looking for shorts to ground. If your fixed bias circuit runs wires under the circuit board then that wire may be shorting to the chassis. Test the bias circuit components.

You can also test a power transformer by measuring the resistance between leads. A healthy Hammond 270AX 240-0-240v power transformer measured: 14 ohms between primary leads, 223 ohms between the secondary center tap and HT wire 1 and 250 ohms from center tap to HT wire 2, 0.3 ohms between the 6.3v leads (this is low enough resistance to beep during a continuity test). Your power transformer should measure somewhere near these values and not show an open (mega ohms) or shorted (0 ohms) connection.

. Power down the amp and insert the tubes one by one, starting with the rectifier, then preamp tubes, then power tubes. After inserting each tube, power up the amp and check the light bulb.

(normal) pull that tube and insert the next tube (don't remove the rectifier tube, it is needed to power the other tubes). Repeat until the bulb goes bright.

then power down, it means you have found the problem area.

Replace that tube with a known good tube. with the new tube you had a bad tube and should be good to go.

with the known good tube then there is a short in the circuit near that tube. Closely inspect the tube socket with a magnifying glass for anything that would short two pins or short a pin to ground. Use your meter to check for continuity from socket pin to ground. Read the ohm rating color stripes of all the resistors in the circuit to verify their value. Closely inspect the components that are connected to that tube socket on the circuit board and check them for continuity to ground.

If you can then you know the mains fuse, power transformer, power tubes and output transformer are powered and at least partially working. The problem is probably between the input jack and phase inverter (or driver for single ended amps).

If the amp powers up but is quiet or sounds bad . You should have a spare set of known good tubes on hand so and see if that fixes your problem.

.

If one channel works and the other doesn't you know the problem is in the bad channel between the input jack and where the two channels join.

. Insert a jumper or guitar cable from FX Out to FX In to see if that cures the problem. If the jumper cable does fix your problem then try cleaning all the jack contacts, especially the switch contacts. If that doesn't fix it replace the bad jack.

a very common "no guitar sound" problem is incorrect input jack wiring. , with the amp off, insert a guitar cable into the input jack, then measure the other end of the cable from tip to sleeve for resistance. The Hi jack should measure about 1 megaohm which is the standard value for the input resistor which is connected across the input jack's tip and ground terminals. The Low jack should measure around 136k.

. Visually confirm that the tip and switch terminals separate when a plug is inserted. You can usually bend the terminals so that they close with no plug and open with a plug inserted.

. That will bypass the gain stages and circuitry upstream. If that works you know the problem is upstream of the Return jack.

. Many Fender amps ground out the signal if you plug only one speaker into the Aux speaker jack.

to verify its tone and function. You can also , if the amp sounds good you know you have a bad speaker.

at both ends of the speaker cable. Slide-on spade connectors can make intermittent connection and cause buzz, static and audio drop out. I do not like spade connectors--solder that speaker cable to the speaker terminals because you can blow the output transformer and/or power tubes if that connection breaks.

.

Start by pulling the first preamp tube, powering up and seeing if the noise is still present. If it is then you know the noise is being generated downstream of the tube you pulled. Power down, pull the next tube and continue until the noise goes away, then you know the noise is coming from between the last tube you pulled and the previous tube.

You can sometimes identify the problem by waiting for it to occur then carefully spray to cool amp components and solder joints. If spraying a part or solder joint causes the issue to go away or come back you've located the problem.

Weird noises, including squealing, wooshing, clicking, static, honking, motor boating, etc. can be caused by:

so swap out the tubes one at a time for known, good tubes.

can cause rattles, buzzes, rings and other strange noises in combo cab amps. If you connect your amp to an extension cab and disconnect the internal speaker and the noise goes away it's probably caused by a microphonic component or possibly a cab rattle. You can gently tap the tubes with a or wooden pencil with the amp on and listen for excessive noise. You can also put light pressure on each tube using a chopstick or gloved hand and then play the offending note to try to identify the noisy tube. High temperature o-rings placed on preamp tubes can help in combo cabs but metal tube shrouds won't fit over them.

. If wiggling the tubes causes noise then put some contact cleaner on the tube's pins and insert them into the socket two or three times. You can also for solid pin contact.

--both ends of the speaker cable. Slide-on spade connectors can make intermittent connection and cause buzz, static and audio drop out. I do not like spade connectors--solder that speaker cable to the speaker terminals because you can blow the output transformer and/or power tubes if that connection breaks.

Try sitting on the cab while playing or have someone put pressure on the baffle board to identify the problem area. Try a separate extension cab to verify it's a cab issue. You can glue and screw small braces to tighten up loose joints. To help troubleshoot you can use a signal generator (or phone ap) connected to the amp and play with the signal frequency to find the resonant tone that causes the rattle or buzz. Once you get a continuous buzz it will be easy to find the rattle using your hands to dampen different parts of the cab. You can also use a to put pressure on amp components to look for a microphonic component like a tube or capacitor.

can be caused by tube arcing or loose grounds. You can sometimes locate an actual arc by opening the chassis and playing the amp in the dark. Look for little flashes of light when the "zap" sound occurs. Look for loose, broken or unsoldered joints, especially on the ground bus and where the bus ties to the chassis.

. Insert a jumper or guitar cable from FX Out to FX In to see if that cures the problem. If it does fix your problem try cleaning all the jack contacts, especially the switch contacts. If that doesn't fix it replace the jacks.

. Dirty pots can cause intermittent contact, signal dropout and static. Most pots have a hole in their shells so you can squirt contact cleaner into them. Run the back and forth through their full travel very quickly several times right after you squirt them.

from the negative feedback circuit. When you start up a new build amp with an NFB loop or replace an output transformer you have a 50% chance of getting a loud squeal from positive feedback (usually not affected by the volume control). Swap the output transformer's primary wires to make the feedback negative. The primary wires run from the output transformer to the power tubes. You can usually swap the secondary wires (speaker jack wires) instead but you can not swap them if you have a multi-tap secondary (4-8-16 ohms for example). . In my 5F6A Bassman it just caused strange noise layered on top of all the notes.

causing capacitive coupling which can cause hum, noise, squeals and oscillation. the amp. You can use a non-conducting wooden chopstick to move wires around with the amp operating and volume full up to find the source of noise. It can also be used to apply pressure to components and solder joints to identify weak or broken components and joints.

(above human hearing) can cause lower than normal amp voltages, lower than normal (or no) output volume and temporary signal dropout. Use chopsticking to find lead dress issues that can cause oscillation. Snubber caps can be used to filter above human hearing frequencies. Temporarily alligator clipping a 1nF (1000pF) or 500pF snubber cap across the preamp tube plate load resistors, one at a time, can help find the problem.

can cause hum, oscillation, squeal and motorboating, especially in high gain amps. You can temporarily alligator clip a new cap in parallel with an existing cap. If the hum or oscillation goes away then replace the old cap.

can cause constant static, crackle and pop noise. Sometimes putting some pressure on the resistor with a chopstick or spraying it with freeze spray will change the noise and help you identify the bad resistor. I like to use 2 watt resistors for all preamp plate resistors to lengthen their lifespan and reduce amp hiss.

A bad 1M input resistor (usually mounted on an input jack) will allow the first gain stage grid to float in the short time between the jack shorting switch opening and the cable plug making full contact. You can test this by opening the input jack switch, if it squeals the input resistor is bad. Measure the resistance across the resistor and if it measures good re-flow its solder joints and check the input jack ground.

is sometimes caused by a weak component or bad solder joint that is affected by heat. You can sometimes identify the issue by waiting for the problem to occur then carefully spray to cool amp components and solder joints. If spraying a part or solder joint causes the issue to go away or come back you've located the problem.

(amp sounds like a boat engine) is usually caused by a weak or damaged power supply filter cap. You can temporarily alligator-clip an extra filter cap in parallel with the caps, starting with the first filter cap. If the temporary cap fixes the problem then replace the original cap. Also verify the power supply voltage dropping resistor values.

are caused by a noise mixing with a note to create a harmonic note that shouldn't be there. Hum, oscillation and other noise can cause them.

can cause a multitude of problems. Many classic Fender amps from the '50s to the '70s were made of a material that will hold moisture and conduct electricity from one eyelet to another. This can cause all sorts of problems and noise. Some old circuit boards were coated with wax to fight moisture but after 60 years the wax isn't holding up. You can sometimes measure voltage from a high voltage eyelet to the circuit board immediately around the eyelet to check for conduction. You can use a hair dryer to dry the circuit board for a temporary fix and troubleshooting. Replacing the circuit board is the best long term fix.

Nasty sounding guitar audio can be caused by many things including:

It can be caused by a dying tube but the typical culprit is an interaction between two wires. Ultrasonic oscillation (above human hearing) can block out guitar audio and silence the amp. Chopstick the amp wires, especially the tube socket wires and separate the grid and plate wires. Do this while the amp is in oscillation to see if you can get it to stop--if it's ultrasonic oscillation then feed a signal into the amp so you'll know when the oscillation stops. Use a "filter cap on a stick" (500pF cap with a ground clip on one end) to filter all the tube grids to see if you can kill the oscillation. When you find the guilty tube you can add a filter to the grid or bypass its plate load resistor with a cap. Use the smallest cap that solves the problem for the least side effect.

so swap out the tubes one at a time for known, good tubes.

. Insert a jumper or guitar cable from FX out to FX in to see if that cures the problem. If it does fix your problem try cleaning all the jack contacts, especially the switch contacts. If that doesn't fix it replace the jacks.

. Dirty pots can cause intermittent contact, signal dropout and static. Most pots have a hole in their shell so you can squirt contact cleaner into them. Run the pot back and forth through its full travel very quickly several times right after you squirt them.

. Applying pressure with a chopstick and hearing noise can identify a bad joint. can also help identify bad solder joints by cooling them and causing a change in noise.

are caused by a noise mixing with a note to create a harmonic note that shouldn't be there. Hum, oscillation and other noise can cause them.

. The speaker voice coil rubs its surround. Typically happens during loud, low notes. Try another speaker to identify a bad speaker. Sometimes mounting the speaker upside down will stop the cone from rubbing. You may have to have the speaker re-coned to get rid of cone rub.

--both ends of the speaker cable. Slide-on spade connectors can make intermittent connection and cause buzz, static and audio drop out. I do not like spade connectors--solder that speaker cable to the speaker terminals because you can blow the output transformer and/or power tubes if that connection breaks.

For a new or recently repaired amp using the can cause low output or funky audio. Verify the value of all resistors and caps.

. Component leads can break and wires can pull loose. Resistors can crack yet look perfectly normal. components and wires can help identify the loose connection or bad component.

can cause a multitude of problems. Many classic Fender amps from the '50s to the '70s were made of a material that will hold moisture and conduct electricity from one eyelet to another. This can cause all sorts of problems and noise. Some old circuit boards were coated with wax to fight moisture but after 60 years the wax isn't holding up. You can sometimes measure voltage from a high voltage eyelet to the circuit board immediately around the eyelet to check for conduction. You can use a hair dryer to dry the circuit board for a temporary fix and troubleshooting. Replacing the circuit board is the best long term fix.

:

. This is a common cause of a weak sounding amp. When a power tube blows it can short the plate and screen and cause the screen resistor to burn and blow. A blown or cracked resistor can look normal--gentle pressure from a chopstick can help find a bad resistor. Measure the resistance across the resistor.

. A leaking cap can cause scratchy pots and affect preamp and power tube bias. Measure the DC voltage on tube grids and look for anomalies.

. Measure the resistance across the resistor. A shorted resistor will show very low or even 0 ohms.

. Applying light pressure to the resistor and hearing noise can sometimes identify a bad resistor. Measure the resistance across the resistor. An open resistor will show a very high resistance well beyond the resistor's rating.

If the output transformer shorts between windings it can lead to no output, weak output or funky sounding output. You can test the transformer by measuring the resistance between its leads. and remove the rectifier and power tubes before making the following resistance measurements:

For push-pull transformers you should see approximately the same resistance between each secondary wire at each power tube and the center tap--typically somewhere between 10 to 200 ohms.

A will have much lower resistance compared to the other winding and typically measure at less than 10 ohms.

The will often measure less than 1 ohm between all the secondary leads so it is difficult to detect a shorted secondary.

If a transformer (break) it will show a very high resistance between the primary leads or between the secondary (speaker) leads (typically 500k or higher).

A will typically show less than 10 ohms resistance between the primary and secondary leads.

Measure the resistance between all the leads and chassis ground--low resistance of less than 10 ohms indicates a .

For comparison my healthy Hammond 125C push-pull output transformer measured: red center tap to brown 150 ohms, red center tap to blue 116 ohms, brown to blue 268 ohms. All secondaries measured .2 to .6 ohms between them. A Hammond 125GSE single-ended output transformer measured 53 ohms between the two primary wires. All of the secondaries measured .2 to .3 ohms. Both transformers measured an open circuit (no connection) between their primary and secondary wires and between all wires to the transformer outer metal shell.

If any of the above faults are present your best bet is to just replace the output transformer. For valuable vintage transformers it is possible to have them rewound.

.

because noise is often caused by dirty power (perhaps caused by a refrigerator's compressor motor) or radio frequency interference (RFI) caused by a cell phone, noisy light dimmer, fluorescent lights or other electrical equipment. Before taking the cover off your amp try it in another location, preferably in another building.

An input jack whose switch tab isn't making contact when no guitar is plugged in can cause loud hum or buzz (see jack picture above). Try pushing the switch tab closed and see if it kills the noise. amp noise.

Try sitting on the cab or putting pressure on different parts of the cab, speaker baffle and speaker frame (it helps to have a friend play while you prod).

can cause 50 or 60Hz hum from heater-cathode leakage but can also cause 100 or 120Hz hum so swapping out every tube should be done before going any further. .

After trying different tubes the next step is to Buzz has a sharp tone to it where hum has a smooth sound. A "buzz" is caused by noise that can be seen on an as a waveform with sharp spikes.

In the United States hum and buzz usually comes in two frequencies, 60 and 120Hz (Hz means cycles per second). If your power runs at 50Hz like in Europe you will have 50 and 100Hz hum and buzz. Determining the frequency of the noise will help you track down the source. See at 2:15 for samples of both types of hum. 50 and 60Hz hum usually comes from the power transformer circuit, fixed bias circuit or heater wires. 100 and 120Hz hum comes from the power supply after the rectifier.

. You can clean them by spraying contact cleaner on a tube's pins and insert it into the socket a couple of times.

. Touching the tubes gently with your chopstick or a gloved hand while playing something that makes it buzz can help you identify the bad tube.

--both ends of the speaker cable. Slide-on spade connectors can make intermittent connection and cause buzz, static and audio drop out. I do not like spade connectors--solder that speaker cable to the speaker terminals because you can blow the output transformer and/or power tubes if that connection breaks.

. The tape will need to make good contact with the chassis for it to act as an RFI shield. For the 5E3 Deluxe and other tweed amps the tape would be applied to the inside of the wooden back panel to cover the chassis opening. For more modern Fender amps you would apply the tape to the underside of the top of the cab.

by minimizing pulsing 120Hz ground return current.

If your amp has an unused triode you should connect the unused plate, cathode and grid to ground.

You can use a non-conducting wooden chopstick to move wires around with the amp on and the volume up to find the source of noise and identify lead dress problems. On my first amp build I had the V1A plate and grid wires lying on top of one another which created a moderate hum. Simply moving those wires apart made the amp almost silent. A chopstick can also be used to apply gentle pressure to components and solder joints to identify weak or broken components and joints.

and signal generator to track down the source of a difficult to identify hum or buzz. See the for more info.

50 or 60Hz is sometimes caused by power line noise and can be addressed by applying a small, high voltage filter cap across the high voltage rectifier input wires. This works well for this. I usually solder one across the rectifier tube socket where the two high voltage power transformer wires connect. For a solid state rectifier solder the cap across the high rectifier inputs.

Buzz can also be caused by AC components. I had a nasty 60Hz buzz that was caused by the placement of a 120v pilot light too close to the amp's signal wires.

Radio Frequency Interference or RFI can sometimes be heard as a 50 or 60Hz buzz. Adding copper or aluminum foil tape to the back of a chassis cover can help reduce RFI. Moving sources of RFI like cell phones, light dimmers and fluorescent lights away from the amp can also help.

100 or 120Hz buzz can be caused by a bad tube so swap in a new set of tubes. Buzz can also be caused by a noisy rectifier. This can usually be eliminated by placing in parallel with each rectifier diode. If the rectifier is inside a housing then running caps from the two rectifier inputs to the + and - terminals usually works well.

50 or 60Hz usually comes from the power transformer or its wiring, the fixed bias circuit, the tube heater wires or from external RFI caused by fluorescent lights, dimmers and other sources.

Assuming you've tried the amp in a different location, 50 or 60Hz hum must be generated by the power transformer circuit or the fixed bias circuit (if your amp has one). Keep as much distance from the power transformer's wires and the amp's wires and circuitry as possible. Heater wires should be twisted and the untwisted wire that goes to each tube pin should be as short as possible with no big loops. Signal wires should cross the heater wires at 90 degrees to minimize coupling.

. If your heater voltage is higher than approximately 6.6v it would be a good idea to reduce the heater voltage to 6.1 to 6.5 volts. See this link for information on .

If your amp's power transformer has no 6.3v heater center tap then the amp needs an . Verify there is an artificial center tap installed and check the resistance of its two resistors. A missing 6.3v center tap or a burned out resistor will usually cause loud hum.

To troubleshoot the fixed bias circuit verify its ground connections are good and you can check the caps by temporarily alligator clipping another cap in parallel with the circuit's caps. If adding the cap reduces hum then replace the cap.

. A Humdinger pot allows you to adjust the resistance between the two 6.3v heater lines to ground to achieve minimum hum. You adjust it by ear with the amp turned up to max to hear the hum best. You can also connect a Humdinger's ground connection (wiper) to a cathode biased amp's cathode resistor to elevate the heater ground reference for even more hum removal. See this link for .

Push-pull amps should have their power tubes wired in phase so the tubes can use common mode noise rejection. For in phase wiring each heater wire should connect to the same heater pin on the two power tubes. This is why it's a good idea to use two colors of heater wiring so you can keep the phase correct.

Parallel power tubes should be wired out of phase to help cancel hum between the power tubes.

so swap out the tubes for known, good tubes.

An that doesn't ground out when nothing is plugged in. If the jack's shunt switch does not make good contact with the jack's tip connector you will get loud hum when no guitar is plugged in but the amp will sound fine when you plug in a guitar.

. Electrolytic filter caps have a typical lifespan of 15 to 20 years. . If the new cap reduces hum then replace the original cap. If your amp is fixed bias don't forget the fixed bias circuit filter cap(s).

. Loud hum can be caused by components that should be grounded but aren't. Forgetting to solder a volume pot's ground wire or a cold solder joint on a cathode resistor's ground are two common causes of loud hum. probe all the amp's ground connections to see if I hear an improvement. Touch the ground probe to all volume pots' ground terminal, the ground side of preamp cathode resistors, etc. .

. If your input jacks are grounded to the chassis and you also run a ground wire between them then a ground loop is formed (chassis is one side, the wire is the other) which can act as an antenna and pick up RFI noise and hum. You will also form a ground loop if you use shielded cable inside the amp and ground both ends. You should only ground one end of shielded cable.

(wires too close to one another causing capacitive coupling) the amp's wires around with the amp on and the volume up to see if you can decrease the hum. Pay close attention to the tube grid and plate wires--keep them as far apart from one another as possible. My first amp build had a loud hum because the first preamp stage's grid and plate wires were sitting on top of one another. Separating the wires silenced the amp.

After I finished testing and tweaking the prototype in bare circuit boards I mounted them in a Hammond blank chassis. When I fired up the newly mounted amp I had a nasty buzz at max volume that wasn't there before I put it in the chassis. It didn't sound like smooth 60Hz heater wire hum or 120Hz power supply ripple hum so the investigation began.

The amp with no guitar cable plugged in was absolutely silent at max volume. The buzz could be controlled by both the volume and master volume controls. The amp's tone control could almost entirely eliminate it when turned full down. . Hmmm. The buzz didn't change with guitar movement or when touching the guitar's strings or grounded metal bridge.

--somewhere between the guitar and the volume pot.

. I tried another cable--no change. I tried my --no change. I tried a cable with no guitar connected and got the expected crescendo of noise.

that light the basement workshop. I turned them off and the amp looked cool in the dark as it spewed forth The Buzz.

. I diligently moved the amp to another part of the house and tried again--no change.

Time to get into the chassis. My first thought was a so I alligator clipped a wire to the chassis and carefully probed all the ground connections in the amp to see if I heard an improvement but found no success.

. I did find that the input jack wires that ran by the power switch and across both circuit boards were picking up some 60Hz hum from the power switch. I replaced the input jack and headphone jack wires with RG174 coax which eliminated the hum but had no effect on The Buzz.

. I injected a 500Hz .1v signal into the amp's input jack. I connected the oscilloscope's ground probe to the preamp ground and connected the probe to the input jack tip. I zoomed in on the 500Hz signal and played with the tone control to change the volume of The Buzz but couldn't see any signal artifact change with the guitar tone change. I jumped to the speaker output jack and tried again with no success. Next I tapped into V1A's output just after the coupling cap (to avoid high voltage DC on the probe) and repeated the tone change and again I couldn't see any change on the oscilloscope. . I zoomed in the scope's display and confirmed it was THE BUZZ.

I used the scope's horizontal scan knob to move the waveform left and right so I could measure the time between spikes--16.5 milliseconds. I took the reciprocal of 16.5ms (1/.0000165) to get the frequency and the answer was--60Hz, it was wall power related after all, or so I thought. I pulled out my trusty H&K Tubemiester 5 and plugged it into the same wall power socket and fired it up--no buzz. I figured the H&K might have some power line filtering built in so that test proved nothing.

I have seen some amps with a .01uF 3KV (3000V) disk capacitor across the rectifier tube socket's high voltage input pins to pre-filter high freq noise so I gave that a try. It did help a little but THE BUZZ still lived.

I sat there staring into the amp's chassis wondering what it could be. I noticed the 120V pilot light (not a standard 6.3V light) sitting next to the input jack. This was my first build using a 120V light so I had no experience with them. I hauled the amp back to the solder station and de-soldered the light's neutral wire and fired up the amp-- . It was that damn noisy bitch of a pilot light.

The fact that the amp was silent when no guitar cord was plugged in was a big clue here that I missed. With no cord plugged in the circuit from the input jack to V1A's grid is grounded so THE BUZZ was being shunted to ground. I should have focused the investigation on the input circuit from the start. 20/20 hindsight and all that. . .

When I stuffed the prototype B9A boards into the chassis I put them to the far left to make room to mount the power transformer on the far right. After getting the boards mounted I realized I had no front panel real estate on the left side of the chassis away from the inputs and preamp stages. actually and I had to pay a penance to atone for my sin.

The little prototype is now nice and quiet and just sounds killer.

--sometimes over 700 volts AC and 500 volts DC. If you have not been trained to work with high voltage then have an amp technician service your amp. Never touch the amplifier chassis with one hand while probing with the other hand because a lethal shock can run between your arms through your heart. . .

and flashlight to help spot bad or broken solder joints.

. Dimming the room lights can help see the glow. Most amp pilot lights are powered by the heater circuit, but not all so don't assume a lit pilot light means the tubes have heat. If a tube isn't lit measure the AC heater voltage from heater-wire-to-heater-wire, it should be around 5.7v to 6.9v which is 6.3v +/- 10%.

My next step is to starting at the rectifier output and filter caps (B+1, B+2, B+3). It's good to have a baseline voltage chart for your amps so you know what voltage to expect. A higher than normal B+ reading can be caused by a non-functional tube that's not drawing current from the power supply. A lower than normal reading can be caused by a tube that is pulling too much current which can be caused by a short, bias problem or in new build amps an incorrect component value.

there is a break in the power supply. Back up toward the power supply and find where there is voltage and where there is no voltage and look for the cause. A blown power resistor between the filter caps is a common cause of a break in the flow of voltage.

Next measure the voltage at the power tube socket closest to the power transformer. For octal power tubes (8 pins) I look for 5.7 to 6.9v heater voltage between socket pins 2 and 7.

: The power tube plates can have over 500 volts DC on them.

The power tube pins 3 (plate) and 4 (screen) should have high voltage DC and pin 5 (grid) should pop when probed with the meter. For fixed bias amps the grid should show a negative voltage but cathode biased amps will indicate near 0 volts on the grid. Pin 8 (cathode) will show 0 volts in fixed bias amps or show voltage between 10 to 25 volts DC in cathode biased amps. Nine pin power tubes like the EL84 have different pin functions so Google their data sheet to see their pin functions.

. . Next measure the voltage at every pin of the troubled tube's socket for clues to the problem.

can be caused by no electron flow through the tube. This can be caused by no heater voltage or a disconnect between the tube cathode, the cathode resistor (if used) and ground. High voltage on the plates can also be caused by a higher value cathode resistor like using a 15k resistor instead of the specified 1.5k.

is caused by too much current flow through the tube. This can be caused by an incorrect bias voltage on the grid. A leaking coupling cap can let DC voltage through to the grid and heat up the bias current. A lower value cathode resistor can also allow too much current to flow through a tube.

. If there is voltage on the plate but the cathode is zero this can be caused by a bad cathode resistor connection or no heater voltage. With the amp off measure the resistance from the cathode pin to ground. It should equal the cathode resistor value.

should show the cathode as connected to ground and show a negative voltage on the grid, usually between -30 to -50 volts DC. An incorrect grid bias voltage can make an amp sound bad.

Most preamp tubes should show no voltage on their grids (12A*7 tubes' pins 2 & 7) except tubes that function as phase inverters or cathode followers where voltage on the grid is normal. If the preamp tube's grid leak resistor is tied directly to ground it should not have any voltage on it. If there is voltage on the grid it's usually caused by a leaky upstream coupling cap (that must be replaced) or grid current. To verify the source of grid voltage you can pull the tube and see if the voltage on the tube socket grid pin goes away. If the grid voltage is still present then it's coming from a leaking capacitor or a wiring mistake. No voltage on the grid pin means the unwanted grid voltage was being generated by grid current. Try another tube and look for incorrect component values or wiring mistakes associated with that tube circuit.

. When a power tube blows it often shorts the tube's plate to the screen which results in a blown screen resistor. A blown screen resistor will normally fail open with infinite resistance. The amp can operate with one power tube but it will sound weak and funky. When you replace the blown tube it will still function poorly because the blown screen resistor will not allow any voltage to the screens so the amp will sound different than with a blown tube but still not sound good due the huge output imbalance between the good tube and the tube with no screen voltage. Verify the screen voltage and the resistance across the screen resistor.

If the first power tube checks out then which will be another power tube for push-pull circuits or the driver tube for single ended amps. so you can listen for a pop when probing the preamp tubes' grid.

. . Carefully check the voltages of that tube to find clues to why it's not working.

4 and 9, and 5 and 9 and verify you have voltage on pins 1 and 6 (plates), 3 and 8 (cathodes). . Nine pin tubes should have 0 volts on their grids unless the triode is being used as a phase inverter, cathode follower or uses grid bias.

If you have unexpected voltage on a tube's grid you may have a leaky coupling capacitor upstream allowing DC voltage through to the grid or a bad tube generating grid current.

. Too many electrons pound on the metal plates, heat them and make them glow red.

A bad tube can red plate so try another tube.

.

The tube's bias voltage, which is the voltage difference between the cathode and grid, controls the current flow through the tube.

If your amp has adjustable bias then measure the voltage on a power tube grid (usually pin 5 for 8-pin tubes) and adjust the bias pot for the largest possible negative voltage (usually around -60v DC) for the coolest bias. If this solves the red plating problem then and see if the problem remains solved.

If the power tube cathode has a connection problem the amp will stop passing current so the cathode usually doesn't cause bias and red plating problems so .

The fixed bias circuit is pretty simple so we want to closely inspect every solder joint and component with a magnifying glass.

Fixed bias amps need between -30 to -50 volts DC on the grid pins.

With the power tubes removed, power up the amp and measure the power tube grid voltages on all the tube sockets. This is pin 5 on typical 8-pin tubes.

If your amp has adjustable bias then set the highest negative voltage possible, usually around -60 volts. This will give us the coolest bias possible.

If you can't set a bias voltage between -40 to -60v DC then you may have a just upstream of the power tube grid. Un-solder one end of the coupling cap and see if you can set a bias voltage of -40 to -60v. This is especially true if you get different bias voltages on the power tube sockets. If nothing changes after lifting the coupling cap then the cap isn't the problem.

In the bias circuit we should have AC voltage where the power transformer connects to the circuit. We should have negative DC voltage after the bias diode. Move downstream and follow the negative DC voltage all the way to the tube socket. If you find a break in the voltage then look for the cause.

A bad solder joint, cracked resistor, dead, disconnected or reversed filter cap and bad bias pots can cause bias problems. A short to chassis will also kill the bias voltage. Gently push on bias components with a chopstick and look for movement due to loose solder joints or component cracks.

A loose socket grid pin can prevent bias voltage from getting to the tube which will cause instant red plating. Re-tension the tube socket pins.

The reverb driver tube is pushed very hard with high voltage in many amps so the tube tends to burn out sooner than all the other small tubes. A bad tube can also cause excessive hum in the reverb. with known good tubes and test the amp.

and cause hum, pops, crackling, weak or no reverb. Clean the connectors (male and female) with contact cleaner. Spray the male connectors and insert them into the female connectors several times. If the connectors are heavily corroded a toothbrush, small brass brush or steel wool may be needed to get them clean.

. They can cause intermittent signal drop out.

Mixing up the reverb input and output cables will result in . Swap the cables at the tank and try again. If it doesn't help or lowers reverb volume then swap the cables back.

and they are difficult to repair. Replace the tank if any of the wires are broken. I'm a fan of the MOD tanks for around $20.

If you with the power on and reverb turned up and hear the reverb spring crash you know the reverb tank's springs, output transducer and reverb recovery amplifier are functioning (the second half of the reverb circuit).

You can and bang on the amp again. If you hear the spring crash (it will be quieter this time) you know the input transducer is working. After this test you will know the problem is upstream of the tank, which is the reverb driver circuit including the reverb transformer. Swap the tank cables back to normal.

by verifying the voltage on the driver tube plate pins. For blackface and silverface amps the voltage should be around 400VDC (volts DC). If there is no voltage on the plate then try replacing the reverb driver tube. If that doesn't fix the problem then replace the reverb transformer.

by connecting an 8 ohm speaker to the reverb transformer secondary wires. When you play through the amp you should hear a fairly loud clean guitar signal through the speaker. If not, then the problem is probably the reverb driver tube or the reverb transformer.

. If they are loose put some glue on them to hold them solid or just replace the tank. MOD replacement tanks are my favorites.

can help cure reverb problems, especially those that occur at high volume and high reverb settings.

can sometimes quiet a noisy reverb. See .

due to positive feedback between V4A and V4B (Vibrato channel third gain stage).

A bad pan ground can cause the (add dirt). Check cables and cable plugs and sockets.

Try turning the reverb pan 180 degrees to reduce interaction between the power transformer and the pan's output transducer.

There are many reverb pan grounding schemes and an incorrect set of cables can lift the pan's ground or cause a ground loop. Look at your amp's schematic to verify what part of the tank and cables should be grounded and what shouldn't.

Temporarily clip a ground connection to the tank and see if that helps with the hum.

See for more info.

" the Amp . On my first amp build I had the V1A plate and grid wires lying on top of one another which created a moderate hum. Simply moving those wires apart made the amp almost silent. . You can also lightly tap on tubes to identify microphonic tubes. Don't forget to chopstick the speaker cable connections.

Intermittent problems are sometimes caused by a weak component or bad solder joint that is affected by heat as the amplifier warms up. You can sometimes identify the issue by waiting for the problem to occur then carefully spray to cool amp components and solder joints. If spraying a part or solder joint causes the issue to go away or come back you've located the problem.

For really tough troubleshooting tasks I and inject a 500Hz 100 milliamp (.1 amp) signal at an amp's input jack and by probing the tube grids. Start at the input jack and work towards the speaker and watch for the wave shape to disappear or change shape. There are tone generator apps for your phone but you will need an adapter with a 1/4" mono TS plug to plug into the amp's input jack. You will risk your $600 dollar phone every time you plug in though. You can play a single string on a guitar to generate a waveform but it's kind of a pain in the butt and a guitar's harmonics and timbre will make it harder to spot anomalies on the scope.

I also use a dummy load when doing this test so I don't have to listen to the damn tone coming through the amp's speaker. unless you use a high voltage rated probe. The grids normally have zero or low DC voltage so I take my signal sample from the grids unless I really need to examine the plate signal.

. It's safest to connect the scope probes to the amp chassis with the amp's power off.

Examine the amp from amp input to output and look for the tone generator or guitar signal to change shape (distort) or disappear (loss of all sound).

To examine the guitar or tone generator signal before amplification clip the scope probe onto the input jack center conductor and the probe ground clip to the preamp ground bus. This will be the smallest, lowest voltage signal you will encounter. Amplification through the amp will make the signal larger (higher voltage).

Adjust the scope time and voltage setting knobs until you can see at least one full wave on the screen. If you set the scope's trigger line to just above zero volts the signal wave should stabilize on the screen (the trigger line needs to touch the on screen signal to stabilize the signal for viewing).

To see the signal at the first gain stage grid move the probe to the tube socket grid pin. Tube grids are usually at zero volts DC (phase inverters and cathode followers can have up to 80v DC) so grids are safer to probe than plates which can have over 500v DC on them.

Move the scope probe to the second gain stage grid and increase the scope's voltage setting knob to shrink the signal to fit on the scope screen.

When probing the power tubes move the scope probe ground clip to the power amp ground.

Pay attention to the max AC & DC voltage ratings of your scope and probe. This is especially important when probing tube plates with high voltage DC on them.

Set the scope to AC coupling. This inserts a cap between the probe and scope circuit to keep high voltage DC out of the scope.

Set the X10 switch on the probe if needed for higher voltage signals. With the X10 switch on a 100v signal will show as 10 volts on the screen.

Clip the ground clip to an appropriate ground point with the amp turned off. For example use the preamp ground bus or last filter cap ground when probing the preamp and use the power amp ground or first filter cap ground when probing the power amp.

When chasing an oscillation or other signal artifact it can be helpful to disconnect the global negative feedback because NFB will try to correct and minimize the oscillation or artifact.

The very strong tremolo oscillator signal can induce ticking into the amp's signal stream. .

Another option is to use a shielded cable like RG174 for the tremolo driver plate wire (V5 pin) to stop the transmission of the tremolo signal. This is almost a 100% fix for tremolo ticking. Ground the cable shield at only one end (either end) to prevent a ground loop.

If the above don't work then adding a .02uF cap to the tremolo roach should stop it.

.

To test a diode make sure the circuit is powered down (drain the caps) and measure the diode's resistance both ways across it (measure, then reverse the meter probes, measure again).

A good diode will show resistance of 7 to 15 ohms in one direction (forward resistance) and almost infinite resistance in the other direction (reverse resistance).

Reading an open circuit (infinite resistance) both ways means the diode is open.

A zero resistance reading in either direction means the diode is shorted.

A diode with a resistance reading below 7 ohms should be replaced.

Measuring a series of diodes in a row should show about 12 ohms of resistance per diode in one direction and infinite resistance in the other.

The striped end of a diode is the cathode end, the other end is the anode.

donation to

Merlin Blencowe, , 2nd Edition.

Merlin Blencowe,

Morgan Jones, , 4th Edition.

Richard Kuehnel, , 3rd Edition.

Richard Kuehnel, , 2nd Edition.

Richard Kuehnel,

Robert C. Megantz,

It's fairly technical but it's the only book written specifically about guitar amplifier overdrive. It includes many graphs to help make the material easier to understand.

T.E. Rutt,

| ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] |

- Search Posts

- Solid State

- What causes motorboating with 4 ohms?

- Thread starter tmblack

- Start date 2005-02-13 10:37 pm

- 2005-02-13 10:37 pm

I have repaired an amplifier and it works correctly with 8 ohm loads. When I connect a 4 ohm speaker the amplifier starts to softly buzz and then grows into a full motorboat sound. I addes more caps across PS and this does not help. Adding 10 ohm resistor at output does allow it to drive 4 ohms but what a waste of power. Is the PS too weak? Any suggestions? Thanks Tom

More options

Alaskanaudio.

Additional trouble shooting is required I would suspect that the amplifier is unstable even with an 8 ohm load. Loading it with 4 ohms puts it over the edge and the oscillation that the instability produces becomes audible as motor boating and an also as a rise in noise level, buzzing as you describe it. This buzzing noise is probably due to the onset of nigh frequency oscillation. The instability may be due to an inherent design problem which may have been aggravated by having replaced active parts with ones with higher gains or changes in other characteristics. It is also possible that the amplifier may still have a part installed that was slightly damaged by whatever caused the amplifier to fail originally. Further trouble shooting may be needed to find such a part. Don’t rule out a potentially damaged trace on a circuit board or other problem that may affect circuit continuity, grounding or a change in the value of a part such as a resistor. I doubt that your problem is caused by the power supply. An oscilloscope would be nice to have so that you could see what is happing at the output of amplifier at various signal levels and loading. Care should be taken since oscillation in a power amplifier can lead to failure of the output devices and also damage tweeters. A variac with an AC current meter would also be nice to us so that the mains AC input current to the amplifier could be monitored during trouble shooting. Many amplifiers will show an increase in power consumption when oscillation starts.

Thank you for your suggestions Alaskanaudio. I used an AC voltmeter than is 0 when there is no load. I'll get an oscilloscope to confirm your suspections. Tom

If the output devices of your amplifier are TO-3 metal can MOSFETs whose cases are used as source terminal [like 2SJ50 and 2SK135] and the circuit is a source follower, then : Try grounding the heatsink to a point near the local supply decoupling capacitors of each channel

- Forum Listing

- Marketplace

- Advanced Search

- DIY Audio Discussions

- General Car Audio Discussion

Problem with amplifier.... "motorboating" noise?

I just installed a pyle amp and deck into my ski boat and am having many issues. I have done a stereo installation in my car before, but have never had these problems. The speakers worked when attached to the deck, however they crackled at high volume (not enough power?) so I hooked the speakers to the 4 channel amp and the amp to the deck using the high input jacks on the amp (not RCA cables) because the deck only has one RCA out. When I turn the deck on I get an ocilating interference noise, which I guess is called motorboating. I only get this when more than one speaker is hooked up to the amp. any ideas? THANKS!!!!

I've never worked on a boat, but are you sure that you're getting good voltage to the amp? Is it water-sealed properly?

yes, and yes.... it is a marine grade amplifier. the ground is connected directly to the negative battery terminal due to a lack of an good metal to ground to. the real catch is that it works with one speaker, but with multiple speakers it does not

Not sure this is it, but sometimes the HU grounds the speaker negative and it causes problems and a LOC can fix it (even if you don't really need a LOC). Otherwise Y the RCA and use those....I would guess that is the issue not sure what else other than a wire fault.

ok, so I am not really familiar with these amps. I have only used amps for subs, never speakers. So if I am using the amp for speakers do I use the "low input" which is RCA cables... or do I use the "high input"

excatly what amp and what head unit?

The amplifier is a Pyle PLMRA400 4channel 400watt and the head unit is a Pyle PLMRKT32WT

low impeadance input (labled high input) on your amp, for speaker level inputs, IE the speaker wire. the binding posts not the rca's the rcs are for the rca outs on the head unit, yep you only have two... seems you did say speaker wire to high on amp, try only the rca on low labled input, and see it you can get 2 speaker to working. try diffrent gound locations, moving power lines away from speaker lines, and for sure if running rca's well clear of both. try the floating ground type wiring in the amp manual???

alright I'll give those a try tomorrow.... thanks guys

Make sure the headunit is grounded well. My brothers truck did the same deal, omelet hours tracking it down. Pulled his headunit to find that the tard didn't ground it. I asked why, he said because he didn't think it was needed since his harness didn't have the wire. I still don't know how the thing even worked as long as it did.

However, these high-bandwidth, fast-settling op amps can easily become unstable if designers don't observe some special precautions. So, designers must understand common instability issues and how to avoid them. Click to expand...

Proper Design Techniques Solve High-Speed Op-Amp Stability Problems Successful, stable high-speed op-amp circuit designs need the right combination ... Grounding, bypassing, and decoupling techniques keep op-amps from self-oscillating. ... There are many good reasons to do this, including hum and noise ... Click to expand...

Oscillation Why It Happens Take a look at the CMoy pocket amp schematic. It's so simple. The voltage from the pot is presented at the op-amp's noninverting input, the feedback resistors tell the op-amp how much gain you want, and the op-amp puts out what you gave it magnified by that gain. So straightforward and neat. Oh, wouldn't it be wonderful if that's how things worked in the real world! In a real circuit, current doesn't just go from A to B, following the traces laid down on the printed circuit board. Some of it goes across the surface of the circuit board instead, because the surface is never 100% clean. Since PCB material isn't a perfect insulator, some also goes through the PCB material. Current finds other sneak paths past your feedback loop, too, such as nonzero power and ground impedances, parasitic components in the feedback loop, etc. And those are the easy ones. If things are really getting weird, you have still other paths, like RFI through the air. Why does this matter? It all comes down to op-amp action and phase shift. The thing that makes an op-amp an op-amp is that it always tries to make its two inputs have an equal voltage. We call this op-amp action. The purpose of adding resistors and such in the feedback loop is to modify this op-amp action. Let's see how op-amp action works to produce voltage gain. Imagine that we have 0.1 V at the amplifier's noninverting input. Imagine then that this voltage goes straight through the op-amp completely untouched: we get 0.1 V at the output. This voltage goes around the feedback loop, which contains a simple voltage divider in an amplifier like the CMoy pocket amp. For the sake of argument, let's say it's a 10× voltage divider. Our 0.1 V signal is reduced to 0.01 V by this divider. The op-amp wants to make its -IN voltage equal to its +IN voltage, so it raises its output voltage by a factor of 10. Now the output is 1.0 V, which is divided down to 0.1 V by the feedback loop resistors, so the op-amp is happy. We have voltage gain. Now imagine some force comes along — its nature doesn't matter here — and forces the op-amp's output voltage down a smidge. Through the feedback loop, this forces the inverting input down, too. The op-amp sees that the inverting input is trying to go lower than the noninverting input, so again op-amp action comes into play, forcing the output upward to counteract our mystery force. This is why op-amps have such low distortion and low output impedance when operating in their normal range. Op-amp action forces corrective measures to be taken any time there is a deviation from the expected behavior. The only reason op-amps have distortion at all is that we cannot create perfect op-amp action in the real world. Okay, so what about the real world, then? Let's imagine what happens if our amplifier is presented with a sine wave instead of a simple DC voltage. Let's also say there is some delay in the circuitry within the amplifier, such that it shifts the sine wave by 180 degrees as it goes through the op-amp. In a sine wave, 180 degrees of shift reverses the voltage: 2 V becomes -2 V, -0.3 V becomes 0.3 V, etc. Let's say that the sine wave has 1 V peaks, and that a positive peak is at the amplifier's input. Due to the delay within the op-amp, that means that the output is only now putting out what happened 180 degrees ago, which is -1 V. For now, we'll ignore gain and put -1 at the inverting input, too. The two inputs are unequal, so op-amp action kicks in to try and correct it. The noninverting input is higher than the inverting input, so the op-amp tries to raise its output voltage a smidge. But because there is 180 degrees of phase shift, this actually results in the output going down by a smidge instead! We have a self-reinforcing cycle called “positive feedback” that forces the output voltage hard one direction, and then because of real world limits it must go back the other way as fast as it can. The cycle repeats endlessly. Congratualations, you have created an oscillator. So obviously it would be Really BadTM to make an op-amp with 180 degrees of phase shift. But in the real world, we cannot make an op-amp with 0 degrees of phase shift. Real op-amps always have some phase shift. The difference between the amount of phase shift and 180 degrees is called the op-amp's phase margin. If nothing else in your circuit adds a delay, you can get away with 0.0001 degrees of phase margin. But life isn't that simple, of course. Remember all those sneak paths I listed above that avoid your carefully planned negative feedback loop? If conditions are right, any of these can set up a positive feedback loop and create an oscillator. In a real op-amp, phase shift varies depending on frequency. Since real signals like music are composed of many wanted frequencies plus unwanted ones like noise, the way a circuit reacts to a signal can be very complex. A circuit can operate without any oscillation in some circumstances, but if just the right frequency enters into the circuit, it can take off into oscillation. As a rule, the faster an op-amp is, the less phase margin it will have. Furthermore, wider bandwidth means there are a greater range of signals that the op-amp pays attention to. If you present an 8 MHz amplifier with 21 MHz noise, it's more or less going to ignore it. But if you present that same noise to a 220 MHz op-amp, it will amplify it right along with the rest of your signal. If that magnified noise happens to be of just the right frequency to trigger oscillation, your choice to use a faster chip will be fateful. Click to expand...

well your getting there, time to swap out known good channels for the bad one, keep touble shooting, think it through...

are your speakers blown? what are your speakers exactly? heard over the 351 Windsor??? I gotta say this, well just because I tell it like it is, sounds like a nice boat, with Pyle gear? you know gear takes a beating in boat, and pyle is pretty much at the bottom of the line gear. that said it should work out of the box, as long as your speakers were not blown to begin with and it was installed correctly, and if it does not return it… take this with a gain of salt, dont get pissed, this the way I see it. if it were me I would take the whole Pyle install as a leaning experience ..and start all over and get some gear more in like with a boat running a 351 Windsor. Its going to take some good solid power into speakers rated for said power, used within there limits, Well below the clipping stages of the amps …or x max of the speakers…as well as a clean install… On a boat I would myself tin, solider, and heat shrink everything, copper corrodes pretty darn fast on the water.. Just my two cents jl, alpine, polk, all make much better gear for marine audio..

Yea, I know Pyle is bottom of the line.... but it was within budget and i really just wanted a stereo installed. Its a ski boat on a lake so it doesnt see salt, and it stays in a covered lift so it stays very dry. In hindsight I wish I would have bucked up the $$$ for some nice gear like I used to have in my car.... but I didnt really want to spend that kind of money on a boat. but thanks for your input, I may just buy some nice speakers

Top Contributors this Month

- Search forums

- Scanners, Receivers and Related Equipment Forums

- New User / Getting Started Forum (Closed)

What is mean by "motorboating"?

- Thread starter sadatoni

- Start date Jul 10, 2010

- Jul 10, 2010

What is mean by "motorboating"? I see it mentioned often, but cannot find a definition.

Motorboating to me is digital trunking signals on a analog scanner. Mark

In my experience, when people complain about "motorboating", they're referring to a scanner receiving a digital voice transmission (e.g. P25 CAI voice) but not decoding it as "digital" - instead playing the undecoded digital noise as if it was an analog voice transmission. For example, a Motorola trunked system (3600bps control channel) on which some or all of the voice transmissions are digital. Unless explicitly programmed otherwise, the scanner has to wait for a short time at the beginning of each voice transmission, in order to determine if that transmission is digital or analog. If it's really a digital transmission, but the scanner "misses" that fact, you'll hear the undecoded digital noise: "motorboating". Another example: a non-trunked (conventional) P25 CAI voice frequency that isn't explicitly forced to digital mode (e.g. by telling the scanner, in some way, that it's digital - like programming a NAC value), or which is erroneously programmed as "analog" (e.g. by programming a DCS or CTCSS value). In the first case, the behavior would be like the trunking example above; in the second case, the scanner will always give you the digital noise, since you've told it it's "analog" (presuming the CTCSS / DCS programming doesn't "gate" the audio). You'll always get this behavior on an analog scanner programmed with such systems or frequencies. It's possible to get it on a digital scanner, as well, depending on signal quality, scanner settings, etc.

Thanks. I kind of thought it was a digital signal showing up in an odd places.

"motorboating" is a low frequency oscillation that resembles a motorboat putt-putting along. The term predates anything digital by about 6 decades or so.

zz0468 said: "motorboating" is a low frequency oscillation that resembles a motorboat putt-putting along. The term predates anything digital by about 6 decades or so. Click to expand...

cpsTN said: Did motorboating have the same meaning BEFORE digital, but not caused by digital apparatus? Click to expand...

cpsTN said: As far as you sig, I now know why I keep running into buildings when I drive! Click to expand...

Similar threads

- Jun 29, 2024

- Georgia Radio Discussion Forum

- Jul 9, 2024

- New Jersey Radio Discussion Forum

- Jul 7, 2024

- Motorola Forum

- Jun 20, 2024

- ICOM Land Mobile Radio

- Welcome to DIYstompboxes.com .

SMF for DIYStompboxes.com !

- DIYstompboxes.com

- ► DIY Stompboxes

- ► Building your own stompbox

- ► What causes "Motorboating"????

What causes "Motorboating"????

Started by vortex, September 30, 2005, 11:44:14 PM

Paul Marossy

- Posts: 13,367

- Just Another Guitarhead

- Location: The City of Lights with The Darkest Streets

- Posts: 1,635

- Location: Fort Worth, Texas

Quote That happened to me with the Ruby amp. Can't remember exactly what it was but it had to do with the + DC. It didn't take long to fix. It's like a type of oscillation from overload.

Paul Perry (Frostwave)

- Posts: 7,470

- Location: Melbourne, Australia

- Posts: 18,805

Quote Anothher thing about instability (from any cause)... usually, it is only noticed when the device goes into full oscillation and howls or groans or whatever. But, suppose it is just on the edge of doing this.. it is going to have pretty severe tonal effects on the signal. And, I suspect, this is where a LOT of the arguments about what sounds GOOD or BAD come from,

- Help | Terms and Rules | Go Up ▲

- SMF 2.1.4 © 2023 , Simple Machines SMFAds for Free Forums

Page created in 0.750 seconds with 22 queries.

Watch CBS News

Project 2025 would overhaul the U.S. tax system. Here's how it could impact you.

By Aimee Picchi

Edited By Anne Marie Lee

Updated on: July 12, 2024 / 1:42 PM EDT / CBS News

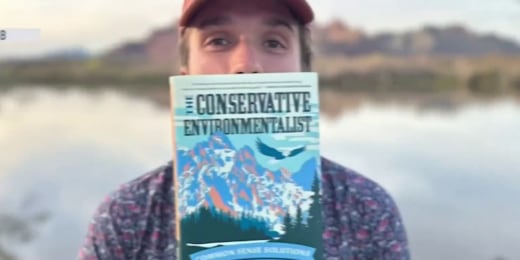

Project 2025, a 900-page blueprint for the next Republican president, is gaining attention for its proposals to overhaul the federal government. Among those changes: a major restructuring of the U.S. tax code.

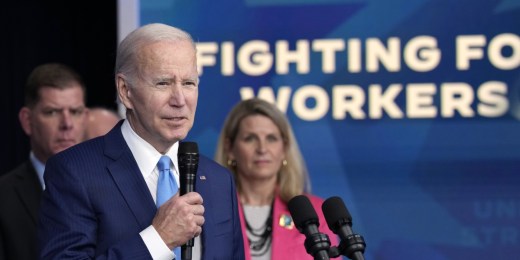

President Biden and Democrats have been citing Project 2025 in recent weeks as they seek to highlight what could be in store if former President Donald Trump wins at the polls in November and retakes the White House in January. Many of the blueprint's proposals touch on economic matters that could impact millions of Americans, as well as social issues such as abortion and diversity, equity and inclusion, or DEI, topics.

Project 2025 , overseen by the conservative Heritage Foundation, is spearheaded by two ex-Trump administration officials: project director Paul Dans, who was chief of staff at the Office of Personnel Management, and Spencer Chretien, former special assistant to Trump who is now the project's associate director.

Trump: "I know nothing about Project 2025"

For his part, Trump has distanced himself from the blueprint, writing on Truth Social early Thursday that he isn't familiar with the plan. His campaign has proposed its own goals through " Agenda 47 ," which tends to focus on social and political issues such as homelessness and immigration rather than taxes.

"I know nothing about Project 2025. I have not seen it, have no idea who is in charge of it, and, unlike our very well received Republican Platform, had nothing to do with it," Trump wrote Thursday.

His pushback comes after Heritage Foundation President Kevin Roberts opined in a podcast interview that the U.S. is "in the process of the second American Revolution, which will remain bloodless if the left allows it to be."

According to Project 2025's website, its goal is to have "a governing agenda and the right people in place, ready to carry this agenda out on day one of the next conservative administration."

A shift to two brackets

The tax proposals of Project 2025, if enacted, would likely affect every adult in the U.S. by tossing out the nation's long-standing system of multiple tax brackets, which is designed to help lower-income Americans pay a smaller share of their income in federal taxes compared with middle- or high-income workers.

Currently, there are seven tax brackets — 10%, 12%, 22%, 24%, 32%, 35% and 37% — with each based on income thresholds. For instance, a married couple pays 10% in federal income tax on their first $23,200 of income, and then 12% on earnings from $23,201 to $94,300, and so on. Married couples need to earn over $487,450 this year to hit the top tax rate of 37%.

Project 2025 argues that the current tax system is too complicated and expensive for taxpayers to navigate. To remedy those problems, it proposes just two tax rates: a 15% flat tax for people earning up to about $168,000, and a 30% income tax for people earning above that, according to the document . It also proposes eliminating "most deductions, credits and exclusions," although the blueprint doesn't specify which ones would go and which would stay.

"The federal income tax system is progressive, and people who make more money pay a higher marginal tax rate than people who make less money," Brendan Duke, senior director for economic policy at the left-leaning Center for American Progress, told CBS MoneyWatch. "Conservatives look at that, and they feel that that's unfair to the wealthy to ask them to pay a greater share of their income in taxes than lower income families."

The Project 2025 proposal "is a dramatic reform of how we fund our government, where we ask the wealthy to pitch in more than lower income families," he said. "This shifts taxes from the wealthy to the middle class, full stop."

Project 2025 didn't immediately respond to a request for comment.

In a statement, the Heritage Foundation said it will ultimately be up to the next conservative president do decide which recommendations to implement, adding "As we've been saying for more than two years now, Project 2025 does not speak for any candidate or campaign."

Project 2025's tax rates

Millions of low- and middle-class households would likely face significantly higher taxes under the Project 2025's proposals.

He estimated that a middle-class family with two children and an annual income of $100,000 would pay $2,600 in additional federal income tax if they faced a 15% flat tax on their income due to the loss of the 10% and 12% tax brackets. If the Child Tax Credit were also eliminated, they would pay an additional $6,600 compared with today's tax system, Duke said.

By comparison, a married couple with two children and earnings of $5 million a year would enjoy a $325,000 tax cut, he estimated.

"That 15% bracket is a very big deal in terms of raising taxes on middle-class families," Duke said.

Millions of U.S. households earning less than $168,000 would likely face higher taxes with a 15% rate. Currently, the bottom half of American taxpayers, who earn less than $46,000 a year, pay an effective tax rate of 3.3% — which reflects their income taxes after deductions, tax credits and other benefits.

Among other tax and economic changes proposed by Project 2025:

- Cutting the corporate tax rate to 18% from its current 21%, which was enacted in 2017's Tax Cuts and Jobs Act. Prior to the TCJA, the corporate tax rate stood at 35%.

- Reducing the capital gains tax to 15%. Currently, high-income earners pay a tax of 20% on their capital gains.

- Eliminating credits for green energy projects created by the Inflation Reduction Act.

- Considering the introduction of a U.S. consumption tax, such as a national sales tax.

- Eliminating the Federal Reserve's mandate to maintain full employment in the labor market.

To be sure, overhauling the tax system would require lawmakers to approve changes to the tax code, which could be difficult if either the House or Senate is controlled by the opposing party. For instance, Trump was able to get his Tax Cuts and Jobs Act passed by a Republican-led Congress, even though no Democrats voted in support of the measure.

What does Trump say about taxes?

Trump hasn't yet proposed any concrete tax plans, but analysts expect that he would seek to extend the tax cuts enacted through the TCJA if he is reelected. Currently, many of the provisions of the TCJA, including lower tax brackets, are set to expire at the end of 2025.

One likely scenario if Trump is reelected is that Republican lawmakers would extend the TJCA's tax cuts, while seeking to fund the reduction in tax revenue by repealing some of the clean energy and climate-related provisions in the Biden administration's Inflation Reduction Act, according to an April report from Oxford Economics. Lawmakers could also seek to cut spending on social benefits to offset the tax cuts, the research firm added.

Trump has suggested a proposal to create a 10% tariff for all imports and a 60% tariff for Chinese imports that could raise enough money to eliminate the federal income tax.

Tax experts also say the math doesn't work out because money raised from new tariffs would fall far short of replacing the more than $2 trillion in individual income taxes collected by the IRS each year. Consumers are also likely to pay more in higher costs for imported consumer goods and services with tariffs tacked onto them, experts note.

"A tariff is a consumption tax, and there is a throughline between [Project 2025's] tax reform and what Trump has talked about, getting rid of taxes in favor of a consumption tax," Duke noted.

Aimee Picchi is the associate managing editor for CBS MoneyWatch, where she covers business and personal finance. She previously worked at Bloomberg News and has written for national news outlets including USA Today and Consumer Reports.

More from CBS News

Highlights from the 2024 Republican National Convention

At Trump's GOP Convention, there's little to be heard on health care

2024 RNC Day 3 fact check of the Republican National Convention

Investors are putting their money on the "Trump trade."

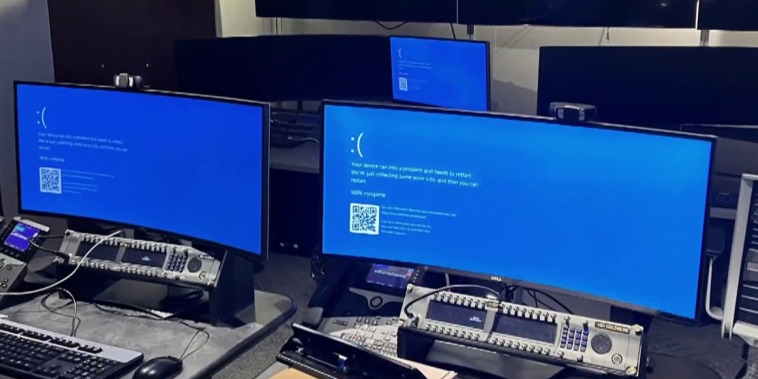

‘Pure chaos’: Travelers react to global IT outage amid flight delays

American Ballet Theatre’s Herman Cornejo celebrates 25 years with the company

Red Cross warns Gazan field hospital is at a breaking point following Israeli attacks

Emmy nominations 2024: See the surprises and snubs

Young conservatives push Republicans to take action on climate change

IT Cosmetics founder Jamie Kern Lima explains how to overcome self-doubt in business

New consumer data shows inflation is continuing to cool

Survey finds Gen Z is the most impacted by high living costs

Curtain Call: New show ‘Odd Man Out’ is performed in complete darkness

More than a third of states confirm cases of the West Nile virus

Understanding the health risks associated with extreme heat

Democratic lawmakers meet on 2024 election as pressure mounts for Biden

Jury selection begins in Alec Baldwin's manslaughter trial

France on course for political gridlock after a second round of elections

Wall Street waits for key inflation report which could reveal more clues about the economy