March / April Issue No. 297 Preview Now

Sailboats - Cruising

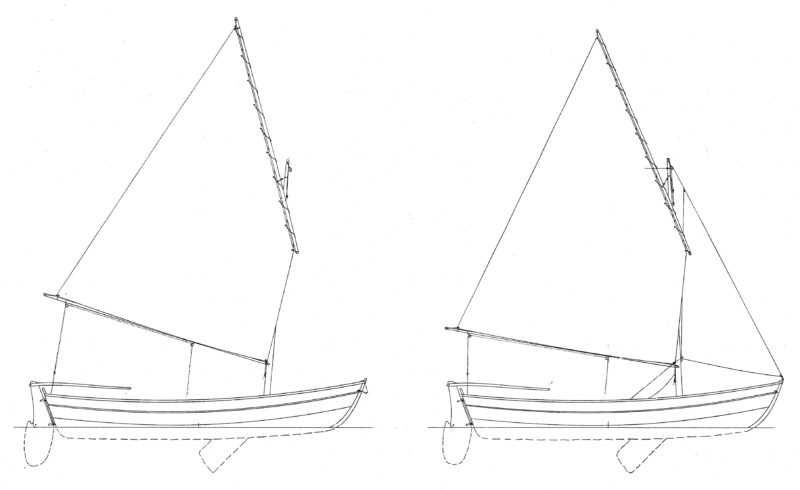

12' 10" pooduck skiff.

This dinghy could be considered a big little boat.

She has a lot of excellent qualities: excellent rowing and sailing ability, easy construction, and mannerly towing habits.

Construction: Glued-lapstrake plywood.

Alternative Construction: Traditional lapstrake.

No lofting is required.

Plans include 6 sheets.

Design Specifications

The WoodenBoat Store Post Office Box 78 Brooklin, Maine 04616 USA Phone: 1.800.273.7447

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from plans & kits.

PuddleCat 9

Fisherman 23

Voyager dss 543 cruising sailboat.

From the Community

1968 Chris Craft Custom

1968 Chris Craft has been updated and customized for the classic boat lover.

50 years of WB, Sails, more

All original issues of WB, $375; Sails for sloop rig, new condition, luff 29’5” 2 jibs, bagged, $

1941 36' Stephens motor yacht

She's FREE to anyone who can take on the project.

Register of Wooden Boats

I aquired Maverick in November of 2023 for $1.

POODUCK SKIFF

In the Summer of 2011, we bought a small used sailboat. It's a nice little boat, and it was fun enough to inspire me for my next project... to build a small plywood sailing skiff. My goal is to get my boys involved in this project.

This is the boat we bought; it's an Interlake 18 (a class racing boat from Ohio area)...

We bought the plans from the Wooden Boat Store in Maine, and the skiff is the Pooduck Skiff designed by Joel White (a naval architect from NY, and son of E.B. White). The plans are for a 13 foot boat which can be sailed or simply rowed. This design is popular and very similar to the Shellback Dinghy, which is very popular and has quite a bit of available publications documenting its construction. Since this is my first boat build, I will need that guidance.

There are several images of the Pooduck Skiff on the internet, so I'll refrain from stealing one and posting it here. However, there are several videos on YouTube as well, and I've already done my share of watching and daydreaming. OK, on with the build...

STARTING OUT

AUGUST 2011

The first step was to take the plans and copy them to plotter paper (so we wouldn't ruin the original plans) and then copy that to plywood. We used film plotter paper so we could see through, similar to tracing paper but much sturdier.

A common complaint from other builders is that the "centerline is off" on the plans. Once we traced the originals, we flipped them left to right and found that the left and right sides are simply different. As you can see below, the left side flipped onto the right doesn't match. So what we did was to split the difference.

Before you can build the boat, you have to build a jig to hold the boat. The center frame and the forward stem is used in the jig and becomes a permanent part of the boat, so we had to build those first.

First step: cut a bending jig to laminate the frame around.

We took the plans and tacked them to some plywood. Along the curve we needed cut out, we used a nail to mark several holes (this pokes holes through the plans which is why we made copies first). Once you remove the plans, you simply connect the dots.

Now I didn't take pictures of the lamination process, it was a hard and frantic job. What we did is we cut a good board of 1-1/2" thick Douglas fir into 1/8" strips. Each strip was coated in epoxy and then stacked until we had about a 2" stack. This stack is then bent around this bending jig and clamped in place. When the epoxy sets up, you have a nice curved frame piece.

It's a heck of a messy job. Epoxy gets everywhere and sticks to everything. And since you don't want epoxy on your skin, I was wearing protective gloves and long sleeves. The jig was covered in plastic (otherwise the jig and the frame would become one).

The next step was to plane down the sides of the frame. Some use a hand plane, some use a planer. I used a router on a stand.

The same process was performed for the stem (the front edge of the boat).

Eli is happy to see you...

And he's thinking about growing a mustache...

Getting rid of his brothers "Pac Man" style...

Enough goofing around, this is what the building jig looks like when set up...

SEPTEMBER 2011

The plans call for plywood that is longer than eight feet long. The common solution is to scarf two sheets together. This entails beveling the ends at an 8:1 slope and then epoxying them.

After a little sanding, they looked good.

When epoxied together, you have a board that is almost 16 feet long.

Traditionally, one would "loft" the curves from the plans. This entails using coordinates to measure a series of points that you would then connect by drawing a smooth curve. It was easier for me to do this on the computer and plot out a large sheet. The boys could then use this plot to poke a bunch of holes and connect the dots.

This was done for the bottom piece...

And here they are marking all the lapstrakes (the sides).

BUILDING THE HULL

The bottom is the first to get connected to the construction jig. This was screwed in place.

The edges were then planed at an angle to match the angle of the garboard (the first strake).

This planing and sanding continues until the strake lays flush on the previous board; It overlaps the previous board, thus the term "lapstrake". This continues for each following board.

By leaving the overlapped edges square, it forms chines. The bottom, however, gets sanded flush.

Everything is epoxied and temporarily held together with screws...

OCTOBER 2011

At this point, it's removed from the construction jig...

...and carried into an already crowded garage.

Now that we are out of the rain, we can fair the chines a little...

The lapstrakes were trimmed where they met the transom...

At this point, the front edge of the hull is planed down and the outer stem is placed.

More sanding...

BUILDING A SHED

DECEMBER 2011

What I really need is another 2,400 square foot shop (but I left mine in Illinois when we moved). Given the space limitations at our new house, 200 square feet will have to do...

Our new boathouse...

After hiding from the weather for a few months, we are back at it. At this point, we cut and installed the breasthook, the knees, the gunwales, and rub rail...

(Eli's just blowing dust around with a leaf blower)

DAGGERBOARD AND RUDDER

I read on the internet where some stated that they were "whittling another boat". I didn't know what they meant until I started building. This isn't like building shelves, where you cut a board and then install a board. This is cut, fit up, remove, trim, fit up, remove, trim, fit up, remove, trim, and then install. Yikes.

The plans call for a centerboard (a keel that swings down into place), but the simpler option is to install a daggerboard (this just slides down into place). The centerboard requires a weight, a sealed pivot pin, but will swing up out of the way when you hit something below the water. The daggerboard is simpler, but will break or rip the boat apart if you hit something below water. Like a fool, I went with the daggerboard.

Cut and whittle...

Here I'm working on the daggerboard, the daggerboard trunk, and the rudder. I epoxied the interior of the trunk to seal it; hopefully it will last longer than if I painted it.

Daggerboard trunk installed.

With the trunk installed, I can slice a big hole in a perfectly good hull.

Stitching up a sail:

Laminating mast material (when it came time to whittle these into the mast and spars, I forgot to take pictures):

Cutting the keel:

August 2012

Oops... It was left out in the weather without interior paint, and apparently that's not good. Time to redo the gunwhales and finish the interior:

New coat of Rustoleum (it's oil based and it's easy to acquire!):

DIY Sailboat Project

Wednesday, may 17, 2017.

- pooduck skiff boat plans

I really like the lines and features of the pooduck skiff, designs / plans; pooduck skiff; built and sailed a pooduck skiff and though i enjoyed the boat,. 12' pooduck skiff sailboat w/trailer $5,500 strictly adhered to woodenboatstore plan mahogany marine plywood , hornbeam, chestnut and yellow pine wood (pine mast and. Sailing the pooduck skiff shanghai948. subscribe subscribed unsubscribe 83 83. loading melonseed skiff by crawford boat building - duration: 10:48..

This dinghy could be considered a big little boat. she has a lot of excellent qualities: excellent rowing and sailing ability, easy construction, and mannerly towing. This dinghy could be considered a big little boat. she has a lot of excellent qualities: excellent rowing and sailing ability, easy construction, and mannerly towing. Designs / plans; anybody built or sailed a pooduck skiff; the pooduck is certainly a beautiful boat. go to my boat and click on don bailey's pooduck skiff..

Related Posts by Categories

Posted by bari at 2:18 AM

Labels: Boat Plans

0 comments:

Post a Comment

- ► April ( 51 )

- ► March ( 79 )

- ► February ( 73 )

- ► January ( 71 )

- ► December ( 79 )

- ► November ( 70 )

- ► October ( 68 )

- ► September ( 201 )

- ► August ( 204 )

- ► July ( 207 )

- ► June ( 106 )

- ► April ( 15 )

- ► March ( 76 )

- ► February ( 100 )

- ► January ( 113 )

- ► December ( 177 )

- ► November ( 125 )

- ► October ( 119 )

- ► September ( 244 )

- ► August ( 157 )

- ► July ( 165 )

- ► June ( 147 )

- harris boat works canada

- speed boat plans and kits

- build model wooden ship

- build your own boat kits

- arch davis design boat plans

- build your own layout boat

- plywood dory boat plans

- wooden race boat plans

- duck boat plans plywood

- aluminum offshore boat plans

- fishing boat plans wooden

- wooden boat plans whitehall

- free plans boat building stitch and glue

- simple aluminum boat plans

- flat rat boat plans

- build rc boat plans

- kayak building kits uk

- how to build a model boat out of cardboard

- rc boat scratch built

- boat planter outdoor

- harris boats fort wayne in

- dave harris boat for sale

- how to make a model jet boat

- boat plans free canoe

- sailboat design software

- small boat building forum

- isle of harris boat hire

- wooden catamaran boat plans

- 16 ft flat bottom boat plans

- build your own houseboat

- sailboat building business

- free wooden boat plans uk

- josh harris boat

- aluminum jon boat plans free

- model boat builders mauritius

- build your own rc boat trailer

- build your own model sailing boat

- centurion rc boat build

- acorn skiff boat plans

- build your own boat workshop

- outboard boat plans free

- boat shaped window planter

- modern plywood boat plans

- lightweight plywood boat plans

- plywood layout boat plans

- scratch build model ship plans

- how to build a model boat free plans

- whitehall rowing boat plans

- wooden ski boat plans australia

- fiberglass boat building step by step

- build your own boat garage

- build a rc boat kit

- offshore plywood boat plans

- wooden model ship building kits for beginners

- harris lake boat ramps

- building model lobster boat

- harris lake boat storage

- one plywood boat plans

- model boat plans balsa wood

- hydroplane boat plans for sale

- simple boat plans free

- building flat bottom boat with 1/4 in plywood

- panga boat plans free

- model boat building books

- catamaran boat building

- carolina skiff work boat

- fibreglass boat building forum

- building model ships from scratch kent porter

- small flat bottom boat plans

- wood rc sailboat plans

- flat bottomed scow boat plans

- build fe rc boat

- build your own boat bimini

- build your own pontoon boat furniture

- rc boat hull construction

- build your own u boat magazine

- flat boat building

- making model boat stanchions

- 518 boat plans free download

- layout boat plans free

- plywood rowboat plans

- rc boat how to build

- boat planters filey

- flat bottom fishing boat plans

- harris st kilda boat trips

- how to make your own model ship display case

- how to build model boat

- model boat building ideas

- how to build a boat motor cover

- micro skiff boat plans

- how to build a model jet boat

- catamaran fishing boat plans

- build your own boat interior

- glen l boat plans free

- building wooden model ships from scratch

- harrac boat

- how to make model boats out of wood

- ► April ( 90 )

- ► March ( 51 )

- ► February ( 71 )

- ► January ( 84 )

- ► December ( 88 )

- ► November ( 147 )

- ► October ( 106 )

- ► September ( 56 )

- ► August ( 65 )

- ► July ( 63 )

- ► June ( 60 )

- ► May ( 188 )

- ► April ( 191 )

- ► March ( 129 )

- ► June ( 68 )

- ► May ( 66 )

- ► April ( 72 )

- ► February ( 4 )

Login to my account

Enter your e-mail and password:

New customer? Create your account

Lost password? Recover password

Recover password

Enter your email:

Remembered your password? Back to login

Your cart is empty

12'10 Pooduck Skiff - STUDY PLAN-

Description

Single Study Plans are Only Available as Digital Downloads

Designed by Joel White.

This dinghy could be considered a big little boat. She has a lot of excellent qualities: excellent rowing and sailing ability, easy construction, and mannerly towing habits.

LOA - 12' 10" Beam - 4' 6" Draft (cb up) - 6 1/2" (cb down) - 1' 9" Weight - about 130 lbs. Sail Area - 65 to 79 sq. ft. Construction: Glued-lapstrake plywood. No lofting is required. Skill level: Basic to Intermediate. Plans include 6 sheets.

————————————————————

“Your downloads are ready” will be the subject line of an email you’ll receive from us—once we’ve processed your digital order. That email has the link to click, so you can then download the file.

This isn't an "instant" process, so if we're asleep, you may need to wait for regular business hours for us to process the order. Although we are quite timely, we may not be processing on weekends & holidays.

Customer Reviews

Usefull and allowed me to evaluate the boat. I choose another model to build

Told me everything I needed to know.

Recently viewed

Our Store is in Brooklin, Maine

at 84 Great Cove Drive. We're open Mon-Fri 8am to 4:30 pm Call 1.800.273.7447. WE'RE RIGHT HERE .

Timely Shipping

We are 99-3/4% sure... that we will ship your order within 24 hours Granted, that does not include weekends and holidays.

Secure payments

Rest assured... not only is our site secure, we do not hold your credit card/payment info.

- Opens in a new window.

Article Tag: eric dow

Pooduck skiff.

T he Pooduck Skiff had long been a bucket-list item for me. Almost 20 years ago I bought and read Eric Dow’s book, How to Build the Shellback Dinghy , and every so often I’d take it off the shelf and reread it, rekindling the longing to build a boat and learn how to sail. It wasn’t until recently, as an empty-nester, that I finally had the time, means, and space to build a boat. I bought the plans for the Pooduck Skiff, designed by naval architect Joel White for sailing, rowing, and, sculling.

The Pooduck, at 12′10″, is 20″ longer than White’s Shellback, but they are otherwise quite similar and Dow’s book—with its step-by-step instructions for the glued plywood lapstrake construction, outfitting the interior, and building the sailing rig—can be used as a guide for Pooduck as well. I entered the project with moderate woodworking skills acquired from years of home-ownership and taking woodshop classes, so I appreciated the book’s tips on what tool is best for what job, and on building useful jigs. As an example, I don’t know how I would have transferred the angle and curve of the hull to the edge of the seats, without the using the jig presented in the book. I also had some help from my friend Steve, who had some boatbuilding experience. Still, we both learned a lot with this project. I approached the build as several smaller projects ranging from tool sharpening to knot tying, and got a lot of help along the way from instructional videos on YouTube.

While this skiff has only a single rowing station, the plans call for a second station at the thwart that serves as the mast partner.

I have a fairly well-equipped woodshop, and while my power tools were invaluable and did some jobs faster and more precisely, not all tasks lent themselves to using a bulky tool with an electric motor. The Pooduck project deepened my experience with hand planes, and I made certain they were sharp. A bullnose rabbet plane is especially handy for working in tight spaces and for shaping plank bevels and gains.and

The plans I purchased from The WoodenBoat Store are straightforward and contain every bit of information you need to build a Pooduck, though novice builders will benefit from Dow’s book as an supplement. The six pages of plans include full-sized patterns of the molds, stem, transom, breasthook, knees, and the boat’s single frame. Patterns for the planks are not full size, but described by a measured drawing. When plotting out the coordinates of the planks on the 3/8″ plywood, double-check your measurements. The plans note: “it is advisable to get out the planks a little oversize (1/4″ to 1/2″ in width), then determine the final shape on the jig.”

The plans don’t call for floorboards, but they’re easily added to separate the occupants from water in the bilge. Note the elongated hole for the mast and crescent-shaped plug on the thwart. The plug goes forward of the mast when the jib is used, and aft for sailing with the main alone.

The Pooduck Skiff materials list calls for 3/4″ (18mm) mahogany marine plywood for the bottom and transom and 3/8″ (9mm) for the planking. The 12′ and 14′ sheets called for may have been available when the plans were drawn up in 1990; the 8’ sheets available today will need to be scarfed together to get the necessary length for the planks and the bottom. Solid mahogany is specified for the gunwales, breasthook, knees, and trunk cap; white pine for the thwarts; oak for the maststep and jam cleats. I wasn’t able to purchase mahogany in lengths sufficient to form the gunwales, so there was some scarfing done here as well.

The center frame is laminated from twenty 1/8″- thick strips cut from dimensional lumber. The plans call for fir or mahogany, but Steve suggested sawing the strips from clear 2×12 spruce. The quality of 2x12s is better than that of 2x4s because they come from bigger trees, and usually have fewer knots. I cut more strips than I needed and selected only clear strips from the best part of the 2×12. It’s best to buy quality lumber, so I avoided the big box stores and went to my neighborhood lumberyard.

The mast and spars are also made of spruce. The plans recommend using two clear 2x4s for this. As with the spruce we used for the frame, I found the quality of 2x12s to be better. With a little care, one can select the optimum pieces from the best part of the 2×12. A portion of it may go to waste, but the added expense is minimal.

An advanced builder could do it alone, but I had an extra pair of hands when attaching the planks. I found there to be a little variation between the planks as drawn and the shapes determined by the molds (as one should expect), which necessitated having a helper to locate each plank and refine its shape. Likewise, it was also nice to have someone around to help align the drill when drilling the pilot holes for fastenings, especially where the planks meet the transom.

For a bit of style I strayed from the plans, and instead of using a single piece of pine for thwarts in the bow and stern, I used leftover 18mm marine plywood to make slat seats. I used the same material to make floorboards. The one frame in the boat is under a thwart, so it’s possible to find comfortable seating anywhere in the bottom of the boat, but I’d rather be seated above any water that might get aboard. I also added two Shellback-style knees made from solid mahogany to the thwart that serves as the mast partner for additional strength. I adhered these to the hull using 3M 5200 marine adhesive instead of epoxy so it would be possible to remove them if necessary, to touch up the paint. The transom is drawn with a notch for sculling, but I didn’t include that in my boat because I had no intention of propelling it in that manner.

T he boat is light, only about 200 lbs even with my extra features, and it trailers well. I treated myself to a brand-new trailer which came with two flat, carpeted bunks. They mate pretty nicely with the flat bottom of the boat. I use a ratchet strap to secure the boat to the trailer, with rags under the straps where they meet the gunwales to prevent chafing.

Empty, the Pooduck Skiff draws only about 6″, which makes it easily managed on the beach. Getting in and out of it isn’t bad either, though you have to get your weight planted in the center or have a shipmate holding the opposite side, or you may have a couple of gallons of water come over the side. It’s easier moving in and out of the boat while it is at a dock because you don’t have to climb over the gunwale. Once you’re aboard, the skiff is stable enough to stand in while afloat.

While rowing, Pooduck moves right along with little effort and tracks very well. With one person rowing, the skiff sits right on its lines with the transom just out of the water. There is plenty of room and freeboard to accommodate three average-sized people.

The option to shift the rake of the mast helps keep the rig balanced. The mast is angled aft here, shifting the main’s center of effort aft to compensate for the addition of the jib to the sail plan.

I found that rigging for sail is best done on the trailer. The running rigging consists of the main halyard, sheet, and downhaul and the jib halyard and sheet. It can get a little awkward keeping them all straight and in the proper position if the boat is bouncing in the surf or spinning in the wind.

Under sail, I found it somewhat difficult to move from sitting on the floor to a position up on the gunwale. This winter I plan to extend the middle seat to provide an intermediate place to sit. Under sail, two adults are the limit. My buddy and I are both about 5′6″ tall, and I suspect two large individuals would feel a bit cramped for space.

The skiff sails equally as well with or without flying the jib. The hole in the thwart that serves as a mast partner is elongated and equipped with a crescent-shaped plug, allowing the mast to be angled and maintain the rig’s balance when shifting between sailing the main alone or main and jib. I’m not an experienced sailor, but I couldn’t tell the difference between sailing her with or without the jib. She seemed to beat to windward equally well under main alone or main and jib. Sailing without the jib is much easier, as you have less to do and there are two fewer lines to tend to.

When taking the helm, sitting on the bottom is the most convenient position. Floorboards make that a more comfortable option when some water gets aboard.

On one occasion, my inexperience led to capsizing in a strong gust. The skiff righted easily, but this is mostly because it was full of water. I did not have an easy time bailing out and I was not able to get back in without refilling the hull with water. I had to be towed to shore, with the boat half swamped. The incident turned out okay because I was on a small lake, but it got me thinking about equipping the boat for self-rescue. Flotation isn’t mentioned in the plans or Dow’s book, but I’d recommended at least adding some foam under the two center seats as close to the bottom as possible.

Tom Guertin lives in Warner, New Hampshire, 15 miles from Lake Sunapee and near several other lakes. His love of boats began in his youth fishing on Long Island Sound, not too far from Mystic Seaport. He sails, paddles, and fishes for bass in the many lakes of New Hampshire’s Lakes Region. He works for the State of New Hampshire’s Department of Environmental Services.

Pooduck Skiff Particulars

Length/12′10″ Beam/4′6″ Draft, board up/6.5″ Draft, board down/1′9″ Weight/about 130 lbs Sail Area/Main, 65 sq ft; Jib, 14 sq ft

Plans for the Pooduck Skiff are available from the WoodenBoat Store for $75.

Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Monthly readers would enjoy? Please email us!

D avid MacLean lives in Sedgwick, Maine, a town surrounded by the waters of Penobscot Bay. He sails a 32′ Eastport pinky, INTEGRITY, built in Rockport in 1972, and wanted to have a tender that would complement his classic sloop. A peapod, he thought, another smaller Maine-coast double-ender, would fit the bill.

INTEGRITY is currently getting a new, more easily managed ketch rig. When she’s afloat again she’ll take HARMONY in tow.

Work began with 13 molds and two plywood forms for the stems.

David, an architect, said he decided to design his own peapod, “to expand my design sensibilities and thoughtfully explore the world of naval architecture.” His pinky is a scaled-down version of a Howard Chapelle boat, so he turned his attention to Chapelle’s American Small Sailing Craft and took an interest in the “Old Sailing Peapod” on page 220. The lines for the type were taken from a peapod built around 1886. It was “the last of its kind in Washington County when taken off in 1937” and “of a type once much in favor among lighthouse keepers.” David saw a strong resemblance between the peapod and his pinky.

During the planking of the hull, cam-buckle straps pulled each new strip tight against its neighbor. A mahogany sheer strake, finished bright, will give the peapod a more traditional appearance when the rest of the hull is painted.

With the cypress planking completed, the centerline can be smoothed for the installation of the keel and false stems.

He purchased the plans for the Old Sailing Peapod from the Smithsonian and used the lines as the starting point for his tender. At 15′ 3″, the peapod was a bigger boat than he required; he opted for an overall length of 13′6″. He also decided to strip-plank his peapod to save on the weight of the original lapstrake construction.

Work resumed on the hull after moving the project to Eric Dow’s shop in Brooklin, Maine.

While many peapods have curved stems fore and aft, HARMONY, like its 1886 predecessor, has a straight sternpost, which simplifies the installation of a rudder.

The strip-built hull, reinforced with fiberglass inside and out, offers a clean, easily maintained interior.

Tom Wolstenholme of Rivendell Marine in Monument Beach, Massachusetts, was just 4 miles up the road David’s office in Cataumet, and David apprenticed himself to Tom from the lofting to the completion of the bare hull. Together, the two planked the boat with 3/8″ bead-and-cove strips topped with a mahogany sheerstrake before work paused as Tom got busy with other projects. Progress resumed when Eric Dow in Brooklin, Maine ( WoodenBoat ’s hometown), agreed to help David bring the boat to completion. The hull, still on its strongback, was loaded on a U-Haul truck for the drive north. Mahogany seating and trim were soon installed along with white oak rubrails and knees and iroko floorboards.

Trailered up in Eric Dow’s boat barn, HARMONY is ready for the water.

HARMONY is equipped with two rowing stations, one in the center for rowing solo or with two passengers, and one forward for rowing with a single passenger.

The finished peapod was launched on Walker Pond, a short drive from Brooklin, and christened HARMONY. David reports the tender has “proven to be a dream to row and sail.” The first year’s sailing has been done with a sprit rig meant for one of Eric’s 13′ 6″ peapods. It proved a good fit for HARMONY, and the new rig David had Eric build is nearly identical.

David reports: “HARMONY rows effortlessly, feels very stable, and…”

“…her acceleration under sail is quite impressive.”

Have you recently launched a boat? Please email us. We’d like to hear about it and share your story with other Small Boats Monthly readers.

Subscribe For Full Access

Flipbooks are available to paid subscribers only. Subscribe now or log in for access.

Welcome to Search-Boats The Ultimate Boating Marketplace

Welcome to our premier boats and yachts marketplace, where the seas of opportunity await! Whether you're a seasoned sailor, an avid fisherman, or a leisurely adventurer, our platform is designed to connect boat enthusiasts with their dream vessels. Explore our diverse selection of motorboats, sailboats, and fishing boats, each offering a unique experience on the water.

Back to Search Results

Joel White Design Pooduck Skiff

- Make: Custom

- Model: Pooduck

- Condition: New

Seller notes

12' Pooduck Skiff Sailboat w/Trailer Strictly adhered to WoodenboatStore planMahogany Marine Plywood, Hornbeam, Chestnut and Yellow Pine Wood (Pine Mast and a spare)Retractable Keel (w/lead weight) and HelmAll metal parts made of solid brassAll paints fillers and paints International Brand two part epoxyDacron brand heavy duty sailsTwo sets of Caviness (Made in USA) brand two piece oars.25' floating rope and anchor Fully rigged ready to sail all you need is your life vest.CE Smith (Made in USA) ...

- Specifications

- Location: ******* , Kocaeli, Turkey

Contact us regarding this boat

Contact owner

IMAGES

VIDEO

COMMENTS

I bought the plans for the Pooduck Skiff, designed by naval architect Joel White for sailing, rowing, and, sculling.The Pooduck, at 12′10″, is 20″ longer than White's Shellback, but they are otherwise quite similar and Dow's book—with its step-by-step instructions for the glued plywood lapstrake construction, outfitting the interior ...

This dinghy could be considered a big little boat. She has a lot of excellent qualities: excellent rowing and sailing ability, easy construction, and mannerly towing habits. Designed by Joel White. LOA - 12' 10". Beam - 4' 6". Draft (cb up) - 6 1/2". (cb down) - 1' 9". Weight - about 130 lbs. Sail Area - 65 to 79 sq. ft.

12' 10" Pooduck Skiff. This dinghy could be considered a big little boat. She has a lot of excellent qualities: excellent rowing and sailing ability, easy construction, and mannerly towing habits. Construction: Glued-lapstrake plywood. Alternative Construction: Traditional lapstrake. No lofting is required.

The Yankee Tender is a cedar-planked, flat-bottomed skiff that weighs less than 150 pounds and can be rigged to sail. Its design was a collaboration between Joel, Jon Wilson, Spencer Lincoln and Maynard Bray based on Mystic Seaport's Asa Thomson Skiff. Building plans for the hull were drawn by Spencer Lincoln.

This is the boat we bought; it's an Interlake 18 (a class racing boat from Ohio area)... We bought the plans from the Wooden Boat Store in Maine, and the skiff is the Pooduck Skiff designed by Joel White (a naval architect from NY, and son of E.B. White). The plans are for a 13 foot boat which can be sailed or simply rowed.

Well, everybody, I really appreciate the responses. Billy - great photos - great boat and, might I add, a nice pair of dogs. I've almost decided on the pooduck. I know, I know, it'll look pretty funky towing a skiff half the size of my boat but there were other considerations.

Join Date: Apr 2009. Posts: 19442. #2. 07-22-2012, 08:03 AM. Re: Joel White Pooduck Skiff. For rowing, it would be no problem. For sailing, though, the thinner planking might allow the hull to twist or flex. Perhaps beefing up the framing in the mast area would help. I was born on a wooden boat that I built myself.

You can see pictures and some information about the boat at www.CABBS.org That is a wooden boat club I belong to out of Cleveland, Oh. At the CABBS site, go to my boat and click on Don Bailey's Pooduck Skiff. There's about 4 pictures there. Bob Ketterling out in California also built one. There might be threads on the Forum under Pooduck and ...

July 07, 2008. At long last, after 17 months of boatbuilding I've finally completed my Joel White Pooduck Skiff! I launched her Saturday afternoon during a Small Craft Advisory and occasional showers, and christened her Annabel Lee. The conditions didn't make for very good photography but the sailing was great.

The Pooduck skiff provides a good feel for traditional boatbuilding. After it leaves the shop, it is easily trailered, well suited for rowing, and gorgeous u...

While there is plenty of scope for general advice and step by step small boat construction details on Youtube, I thought from time to time I might contribute...

The WoodenBoat Forum is sponsored by WoodenBoat Publications, publisher of WoodenBoat magazine. The Forum is a free service, and much like the "free" content on Public Radio, we hope you will support WoodenBoat by subscribing to this fabulous magazine.

12' Pooduck Skiff Sailboat wailer Strictly adhered to WoodenboatStore plan Mahogany Marine Plywood, Hornbeam, Chestnut and Yellow Pine Wood (Pine Mast and a spare) Retractable Keel (w/lead weight) and Helm All metal parts made of solid brass All paints fillers and paints International Brand two part epoxy

pooduck skiff boat plans. I really like the lines and features of the pooduck skiff, designs / plans; pooduck skiff; built and sailed a pooduck skiff and though i enjoyed the boat,. 12' pooduck skiff sailboat w/trailer $5,500 strictly adhered to woodenboatstore plan mahogany marine plywood , hornbeam, chestnut and yellow pine wood (pine mast ...

I chose his Pooduck Skiff for its excellent rowing and sailing ability as well as ease of construction. She took 17 months to build and was christened July 5th, 2008. LOA 12 ft 10 in, beam 4 ft 6 in, draft (centerboard up) 6.5 in, draft (centerboard down) 1 ft 9 in.

Boat Profile. Pooduck Skiff An able dinghy by Joel White. The Pooduck skiff provides a good feel for traditional boatbuilding. After it leaves the shop, it is easily trailered, well suited for rowing, and gorgeous under sail. It carries a lug-rigged mainsail that can be sailed with or without a jib. A cleverly designed mast partner allows the ...

Boat Profile. Pooduck Skiff. The Pooduck, at 12′10″, is 20″ longer than White's Shellback, but they are otherwise quite similar and Dow's book--with its step-by-step instructions for the glued plywood lapstrake construction, outfitting the…

Description. Single Study Plans are Only Available as Digital Downloads. Designed by Joel White. This dinghy could be considered a big little boat. She has a lot of excellent qualities: excellent rowing and sailing ability, easy construction, and mannerly towing habits. LOA - 12' 10". Beam - 4' 6". Draft (cb up) - 6 1/2".

The Pooduck Skiff materials list calls for 3/4″ (18mm) mahogany marine plywood for the bottom and transom and 3/8″ (9mm) for the planking. The 12′ and 14′ sheets called for may have been available when the plans were drawn up in 1990; the 8' sheets available today will need to be scarfed together to get the necessary length for the ...

Seller notes. 12' Pooduck Skiff Sailboat w/Trailer Strictly adhered to WoodenboatStore planMahogany Marine Plywood, Hornbeam, Chestnut and Yellow Pine Wood (Pine Mast and a spare)Retractable Keel (w/lead weight) and HelmAll metal parts made of solid brassAll paints fillers and paints International Brand two part epoxyDacron brand heavy duty sailsTwo sets of Caviness (Made in USA) brand two ...

Custom. DailyBoats.com lists Custom built pooduck sailing skiff for sale , with prices ranging from $5,950 for the more basic models to $5,950 for the most expensive. These yachts come in various sizes, ranging from 12.83 ft to 12.83 ft, with the oldest yacht built in 2010. This page features Custom boats located in United States of America.

Buy Custom built pooduck sailing skiff. Custom built pooduck sailing skiff for sale on DailyBoats.com are listed for a range of prices, valued from $5,950 on the more basic models to $5,950 for the most expensive. The boats can differ in size from 3.91 m to 3.91 m. The oldest one built in 2010 year. This page features Custom boats located in ...

Complete Sail Plan Data for the Pooduck Skiff Sail Data. Sailrite offers free rig and sail dimensions with featured products and canvas kits that fit the boat. ... Sailboat Data ; Pooduck Skiff Sail Data ; Pooduck Skiff Sail Data. Pinit. SKU: X-SD-5483 . Quantity discounts available . Quantity Price; Quantity -+ Add to Cart . You may also like ...

12' Pooduck Skiff Sailboat w/Trailer $5,500. Strictly adhered to WoodenboatStore plan. Mahogany Marine Plywood, Hornbeam, Chestnut and Yellow Pine Wood (Pine Mast and a spare) Retractable Keel (w/lead weight) and Helm. All metal parts made of solid brass.