The Ultimate Guide on How to Build a Sailboat – Step by Step Instructions and Expert Tips

Alex Morgan

Building a sailboat can be a rewarding and fulfilling project for those with a passion for sailing and craftsmanship. Whether you’re an experienced builder or a novice, constructing your own sailboat allows you to customize it to your specific needs and preferences. This comprehensive guide will take you through the step-by-step process of building a sailboat.

To start, gather the necessary tools and materials required for the construction. The specific tools needed may vary depending on the design and complexity of the sailboat. Basic tools such as measuring tape, saws, drills, and sandpaper are commonly used during the building process. specialized tools like a planer, router, and clamps may be required for more intricate details.

In terms of materials, you’ll need various types of wood for the hull, frames, and deck, as well as epoxy resin, fiberglass cloth, and marine-grade plywood. Other materials like stainless steel screws, bolts, and fittings will be needed for assembling and securing the different components of the sailboat.

Choosing the right sailboat design is a crucial step in the building process. Consider factors such as the intended use, sailing conditions, and your own level of experience. Factors like the boat’s size, stability, and performance characteristics should also be taken into account.

Before diving into the construction, it’s important to prepare a suitable building site. This includes having enough space to work on the boat, a clean and organized area, and proper ventilation. A sturdy workbench or support system is necessary for holding the boat’s components during assembly.

The hull of the sailboat is a fundamental part of the construction process. Follow a step-by-step process for constructing the sailboat hull, which involves shaping and assembling the frames, planking the hull with marine-grade plywood, and applying epoxy resin and fiberglass for added strength and durability.

Once the hull is completed, it’s time to install the sails and rigging. Properly attaching and rigging the sails is essential for optimal performance and maneuverability. This includes setting up the mast, boom, and other rigging components in accordance with the sailboat’s design specifications.

Next, focus on essential systems and finishing touches. Install electrical and plumbing systems as per your requirements, ensuring they are safe and efficient. Applying finishes and sealants to the boat’s exterior not only enhances its appearance but also protects it from the elements.

Before launching your sailboat, conduct safety checks to ensure everything is in proper working order. Inspect the hull, rigging, and other components for any potential issues. Once you have done all the necessary checks, follow tips for a successful sailboat launch, ensuring a smooth transition from construction to the open water.

By following this guide, you’ll be well-equipped to embark on the exciting journey of building your own sailboat. With careful planning, attention to detail, and patience, you’ll soon have a vessel that reflects your skills and passion for sailing.

Key takeaway:

- Building a sailboat maximizes creativity and adventure: Constructing your own sailboat allows you to embark on a unique and fulfilling journey while enabling you to express your creativity and personal style.

- Gathering the right tools and materials is crucial: Having the necessary tools and materials is essential for building a sailboat successfully. Ensure you have the appropriate tools and high-quality materials to construct a sturdy and reliable sailboat.

- Choosing the right sailboat design is vital: Consider various factors such as size, intended use, and sailing conditions when selecting a sailboat design. This will ensure you build a sailboat that meets your specific needs and provides optimal performance.

Gathering the Necessary Tools and Materials

In order to build a sailboat, the first step is to gather the necessary tools and materials.

- Start by researching the specific type of sailboat you want to build to determine the required tools and materials.

- Make a list of tools in good working condition, including a saw, hammer, drill, measuring tape, and screwdrivers.

- Create a material list that includes plywood, fiberglass, epoxy resin, screws, and nails . Calculate the quantities based on the sailboat plans.

- Find reliable suppliers and compare prices and quality for the materials.

- Set a budget for the project, taking into account the cost of both tools and materials.

- Plan the layout of your workspace for maximum efficiency and keep the tools and materials easily accessible and organized.

Throughout the building process, it is important to prioritize safety by wearing protective gear and following the guidelines for tool usage. If needed, seek assistance from experts or experienced builders. Building a sailboat may pose challenges but it is also a rewarding experience. So, enjoy the process and take satisfaction in creating something with your own hands.

What Tools Do You Need to Build a Sailboat?

To build a sailboat, you need the following tools:

1. Measuring tools: To accurately measure and mark dimensions, use a tape measure, ruler, and carpenter’s square.

2. Cutting tools: For cutting large pieces of wood, use a jigsaw or circular saw, and for intricate cuts, use a coping saw or handsaw.

3. Joinery tools: Assemble and join parts using a hammer, screwdriver, drills, and chisels.

4. Sanding tools: Smooth and shape wood surfaces using sandpaper or a power sander.

5. Clamping tools: Hold pieces together while working using clamps and a vise.

6. Safety equipment: Ensure your safety with gloves, safety glasses, and a dust mask.

In addition to these tools, you’ll need a well-ventilated workspace with a sturdy workbench. This is crucial for building a sailboat. It’s also advisable to have a set of plans or blueprints to guide you through the construction process.

True story:

I always dreamt of building my own sailboat, so I gathered the necessary tools and materials. With dedication and passion, I started constructing the hull, following the step-by-step process. It was challenging but rewarding. Installing the sails and rigging was exciting too. I could already envision the boat sailing on open water. After applying the finishing touches and conducting safety checks, it was time for the sailboat’s launch. With a mix of nerves and anticipation, I set the boat into the water. To my delight, it sailed smoothly, taking me on incredible adventures. Building a sailboat was a labor of love that fulfilled my lifelong dream of being a boat builder.

What Materials Are Required to Build a Sailboat?

Materials Required to Build a Sailboat:

– Marine plywood : Several sheets

– Fiberglass cloth : Sufficient length

– Epoxy resin : Recommended amount

– Hardwood lumber : Various sizes

– Stainless steel screws : Sufficient quantity

– Aluminum mast : Appropriate size

– Sails : Multiple types

– Rigging hardware : Various components

– Navigation lights : Required number

– Steering system : As per design

– Electrical wiring : According to needs

Pro-tip : When choosing materials for building a sailboat, select high-quality marine-grade materials suitable for the intended purpose and capable of withstanding the harsh marine environment.

Choosing the Right Sailboat Design

Choosing the perfect sailboat design sets the course for an unforgettable journey on the sea . Discover the key factors to consider in selecting the ideal sailboat design that suits your needs. Get ready to navigate through a sea of options and explore the world of sailboat aesthetics , performance , and practicality . So, prepare to steer your way into understanding the vital elements that influence the decision-making process when it comes to selecting the ultimate sailboat design .

Factors to Consider When Selecting a Sailboat Design

When selecting a sailboat design, there are several factors to consider. First and foremost is the intended use of the sailboat. You need to determine whether you plan to race , cruise , or day sail . It is important that the design aligns with your activities on the water.

Another crucial factor is the size of the sailboat. Consider your experience and crew when deciding on the sailboat size. Keep in mind that larger sailboats may require more crew members and expertise to handle.

It is essential to evaluate the stability of different sailboat designs. Factors such as keel type and hull shape can significantly impact the stability and seaworthiness of the sailboat.

Performance is another important consideration. Determine the level of performance you desire. Some designs prioritize speed and agility , while others focus on comfort and ease of handling .

Budget is also a significant factor to keep in mind. Take into account the price of owning and maintaining different sailboat designs, as well as ongoing expenses.

The construction material of the sailboat is yet another factor to consider. Options include fiberglass , wood , aluminum , and steel , each with its own advantages and considerations.

It is important to note that sailboats come in various designs, each with unique features catering to different sailing preferences and conditions.

Preparing the Building Site

When preparing the building site for a sailboat, follow these important steps:

1. Clear the area: Remove vegetation, debris, and obstructions to create a clean workspace.

2. Level the ground: Ensure the site is level and stable for a solid foundation.

3. Mark out the dimensions: Use measuring tools to accurately mark the sailboat’s length, width, and height on the ground.

4. Prepare the ground: Dig or fill the ground to create a smooth surface that meets the required dimensions.

5. Install boundary markers: Place stakes or markers around the perimeter of the building site to clearly define the boundaries and prevent encroachment.

6. Establish access points: Create pathways or access points to allow for easy movement of materials and equipment.

7. Ensure safety: Take necessary precautions such as putting up warning signs, setting up barriers, and having appropriate safety equipment on site.

By following these steps, you can effectively prepare the building site for constructing your sailboat.

What Are the Requirements for a Suitable Building Site?

The requirements for a suitable building site for constructing a sailboat include:

- Ample space: The site should have enough room to accommodate the sailboat’s size and allow for easy movement around the boat.

- Flat and level ground: The ground must be stable and even to prevent structural issues during construction.

- Protection from weather: The site should be sheltered from strong winds, rain, and direct sunlight to prevent material damage and ensure optimal working conditions.

- Access to utilities: Electricity and running water are necessary for powering tools, equipment, cleaning, and maintenance.

- Proper drainage: The site needs good drainage to prevent water accumulation, which can damage materials and hinder progress.

- Secure storage: A secure storage area is essential to protect tools, materials, and equipment from theft and damage.

- Accessibility: The site should be easily accessible for material delivery and transportation of the completed sailboat.

- Permits and regulations: Compliance with local building codes, permits, and regulations is necessary for safety and legal compliance throughout the construction process.

Building the Hull of the Sailboat

Building the hull of a sailboat is an exciting journey that requires meticulous attention to detail and precise craftsmanship. In this section, we will embark on a step-by-step process for constructing the sailboat hull, guiding you through the essential stages of this intricate endeavor. From selecting the right materials to shaping the structure, we’ll cover everything you need to know to create a sturdy and seaworthy foundation . So, grab your tools and let’s dive into the art of crafting the perfect sailboat hull.

Step-by-Step Process for Constructing the Sailboat Hull

The sailboat hull can be constructed in a step-by-step process. Here is how you can construct a strong and durable sailboat hull:

Step 1. Create the hull mold : Start by building a robust and long-lasting frame that accurately represents the shape and size of the hull.

Step 2. Prepare the mold surface: Apply a release agent to ensure that the hull does not stick to the mold.

Step 3. Lay fiberglass : Soak fiberglass cloth in epoxy resin and carefully place it on the mold, forming multiple layers to create a sturdy hull.

Step 4. Apply resin and cure: Distribute epoxy resin evenly across the entire surface in order to bond the layers together. Let it cure as per the instructions provided by the manufacturer.

Step 5. Sand and fair: Smooth out any imperfections on the hull, creating a sleek and flawless shape.

Step 6. Paint the hull: Enhance both appearance and protection by applying high-quality marine paint to the hull.

Step 7. Install hardware: Securely attach cleats, hatches, and fittings to prevent any leaks or damages.

By following these step-by-step instructions, you will be able to construct a sailboat hull that is strong, durable, and ready for the next stages of building your sailboat.

Installing the Sails and Rigging

Get ready to take your sailboat to the next level as we dive into the section on installing the sails and rigging! We’ll be revealing the secrets to properly attaching and rigging the sails for optimal performance. With expert insights and practical tips , you’ll soon be harnessing the wind like a pro. So, tighten your ropes and get ready to set sail on this exciting adventure of sailboat building!

How to Properly Attach and Rig the Sails for Optimal Performance

To properly attach and rig the sails for optimal performance on a sailboat, follow these steps:

- Ensure all necessary hardware is securely attached to the sailboat.

- Attach the halyard to the head of the sail and hoist it up the mast to the desired height.

- Secure the tack of the sail to the tack fitting at the bottom of the mast.

- Attach one end of the mainsheet to the boom and the other end to the traveler .

- Connect the jib sheets to the clew of the jib sail.

- Rig any additional sails according to manufacturer’s instructions.

- Check all lines and rigging for proper tension and alignment.

- Test the rigging and sails in different wind conditions for optimal performance.

- Regularly inspect and maintain the rigging and sails.

By following these steps, you can learn how to properly attach and rig the sails for optimal performance on your sailboat.

Essential Systems and Finishing Touches

Make your sailboat dreams a reality with this guide to essential systems and finishing touches. Discover the ins and outs of installing electrical and plumbing systems, ensuring your vessel is equipped with everything you need for a smooth sailing experience . Learn the art of applying finishes and sealants to protect your sailboat from the harsh marine environment. Get ready to set sail with confidence and style !

Installing Electrical and Plumbing Systems

When building a sailboat, it is essential to install electrical and plumbing systems. Here is a step-by-step process to guide you:

1. Plan the electrical and plumbing layout: Determine locations for electrical outlets, switches, and plumbing fixtures like sinks and toilets. Consider placement for batteries, freshwater tanks, and wastewater holding tanks.

2. Install electrical wiring: Start by installing the main electrical panel and run wires to various components and outlets. Use appropriate wiring sizes and ensure secure connections. Include safety features like circuit breakers and grounding.

3. Connect plumbing lines: Begin by installing freshwater supply lines and connecting them to the freshwater tank. Install plumbing fixtures like sinks and toilets, ensuring proper sealing and secure connections. Then, install the wastewater plumbing system, including drain lines and a holding tank.

4. Install electrical and plumbing components: This involves installing electrical outlets, switches, and lighting fixtures. Ensure proper wiring connections and test the electrical system for functionality. For plumbing, install faucets, showerheads, and toilets, ensuring proper water flow and drainage.

5. Test the systems: Once everything is installed, test the electrical and plumbing systems to ensure correct functioning. Check for leaks, proper water pressure, and operational lights and switches.

6. Make necessary adjustments: If any issues are found during testing, make the necessary adjustments and repairs to ensure optimal functioning of the systems.

7. Secure and protect the systems: Once everything is working correctly, secure and protect the electrical and plumbing systems by organizing wires and pipes, using appropriate insulation, and securing any loose components.

By following these steps, you can successfully install the electrical and plumbing systems in your sailboat, ensuring functionality and convenience on your sailing adventures.

Applying Finishes and Sealants for Protection

Applying finishes and sealants is important in building a sailboat to protect the hull and ensure its longevity.

Clean the hull: Make sure the hull is clean and free from debris or contaminants. Use a marine-friendly cleaner and rinse thoroughly.

Sand the hull: Lightly sand the hull using fine-grit sandpaper to create a smooth surface. This will help the finishes adhere better.

Choose the right finish: Select a high-quality marine-grade finish suitable for the hull material, such as varnish, paint, or gelcoat.

Apply the finish: Follow the manufacturer’s instructions. Apply thin, even coats using a brush or roller and allow proper drying time between coats.

Seal the hull: After applying finishes and sealants for protection, use a marine-grade sealant specifically designed for boat hulls to protect it from water penetration.

Apply multiple coats: Depending on the desired level of protection, it may be necessary to apply multiple coats of finish and sealant.

Inspect and maintain: Regularly inspect the finishes and sealants for signs of wear or damage. Touch up or reapply as needed to maintain optimal protection.

In history, boat builders recognized the importance of protecting the hulls from the sea’s harsh elements by applying finishes and sealants for protection. They used natural materials like tar, pitch, or wax to seal the wood and prevent waterlogging. Advancements in technology and materials have led to more durable finishes and sealants. Today, boat builders have access to marine-grade products designed to provide exceptional protection and enhance the longevity of sailboats. By applying finishes and sealants for protection with care and proper maintenance, sailors can ensure their sailboats remain in excellent condition for years of sailing adventures.

Testing and Launching the Sailboat

Before launching your sailboat, there are crucial steps you need to take to ensure a safe and successful voyage. In this section, we will dive into the necessary safety checks to conduct before setting sail. We will also provide valuable tips from seasoned sailors to ensure that your sailboat launch goes smoothly. So, buckle up and get ready to embark on your sailing adventure with confidence !

Conducting Safety Checks Before Launching

Conducting safety checks before launching your sailboat is crucial to ensure a safe voyage. To guarantee a smooth sailing experience, follow these steps:

1. Carefully inspect the hull of the sailboat for any damage or cracks. Be sure to check the seams and joints thoroughly.

2. Take the time to check the rigging , including the mast , shrouds , stays , and halyards , for signs of wear, fraying, or corrosion.

3. Hoist the sails and test them to ensure they are functioning properly. Make sure that all sail controls are in good condition and working as they should.

4. It is important to examine the electrical system of the sailboat. Check the battery and wiring for any signs of damage. Verify that all lights and instruments are functioning correctly.

5. Inspect the plumbing system , testing the freshwater system and searching for any leaks or clogs that may cause issues during your voyage.

6. Take the time to review all the necessary safety equipment . Ensure that everything is on board and in proper working order.

7. Confirm that all navigation aids , such as the compass , GPS , and any other navigation instruments, are functioning correctly.

8. It is crucial to verify the functioning of all communication devices . Take the time to test the radio or any other communication devices that you may have on board.

9. Inspect the fuel and engine carefully. Check the fuel level, oil levels, and overall engine condition. Test the engine to make sure it is running smoothly.

By conducting these necessary safety checks before launching your sailboat, you can minimize the risk of encountering any issues during your sailing experience.

Tips for a Successful Sailboat Launch

Perform a safety check: Before sailing, inspect the boat for damage, ensure rigging is secure, and test essential systems.

Check weather conditions: Choose a day with favorable weather for launching. Avoid high winds or rough seas.

Prepare a launch area: Clear a suitable pathway, remove obstacles, and ensure sufficient depth and space.

Use adequate support : Use sturdy boat trailers or launch ramps for stability during launch.

Properly position the boat: Center and balance the sailboat parallel to the water’s edge using dock lines or ropes.

Release the boat gradually: Release the boat steadily to prevent damage or injuries.

Monitor the boat’s movements: Check for leaks or instability and address issues immediately. Adjust sails and rigging if necessary.

Enjoy your sail: Follow boating safety guidelines and have a great time on the water.

A friend built a sailboat from scratch and successfully launched it by following these tips. The weather was perfect, and everything went smoothly. With the boat securely supported and positioned, they released it into the water, and it floated beautifully. They had a memorable experience sailing without any issues. By following these tips, they ensured a safe and enjoyable journey on their newly built sailboat.

Some Facts About How To Build A Sailboat:

- ✅ Building a sailboat can take approximately 100 hours over 3 months. (Source: Instructables)

- ✅ The cost of building a sailboat can amount to around $1,000. (Source: Instructables)

- ✅ The first step in building a sailboat involves cutting out the parts using boat building plans and plywood. (Source: Instructables)

- ✅ Assembling the hull of a sailboat involves stitching and gluing the panels together. (Source: Instructables)

- ✅ Fiberglassing the hull of a sailboat makes it waterproof and strong. (Source: Sailboat Cruising)

Frequently Asked Questions

Faq 1: what are the different options for building a sailboat.

There are three main options for building a sailboat. The first option is refurbishing an old boat, the second option is purchasing a hull with the deck moulding already fitted, and the third option is to build a boat from scratch.

FAQ 2: How long does it take to build a sailboat?

Building a sailboat takes approximately 100 hours over a span of 3 months.

FAQ 3: Can I learn the necessary skills for building a sailboat along the way?

Yes, you can learn the necessary skills for building a sailboat slowly and avoid making mistakes along the way.

FAQ 4: Should I hire a professional surveyor before refurbishing an old sailboat?

Yes, it is advisable to involve a professional surveyor before taking on the project of refurbishing an old sailboat.

FAQ 5: What materials are needed for building a sailboat?

The materials required for building a sailboat include oak plywood, epoxy resin, epoxy hardener, silica thickener, wood flour thickener, masking tape, Japanese pull-saw, table saw, router, sander, jigsaw, drill, wire cutter, C-clamps, mixing cups, fiberglass cloth, glue, screws, and fasteners.

FAQ 6: How much does it cost to build a sailboat?

The cost of building a sailboat is approximately $1,000, excluding any additional costs for customization or specific features.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

How to Build a Boat

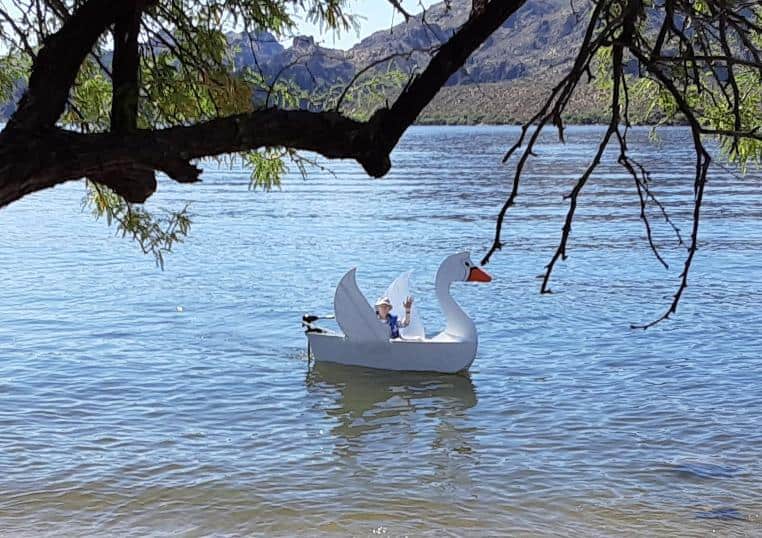

Whether you’re looking at an aluminum fishing boat , a cabin cruiser , or anything in between, you’re looking at a modern boat that took countless hours of designing, craftsmanship, and manufacturing to produce . And while you certainly can’t create that sort of advanced watercraft in your own back yard, that doesn’t mean you can’t build your own boat.

Small, simple craft like the row boat you might use to paddle out to your “real” boat, canoes, and toy boats built for a wet joyride or two can all be fun DIY projects that enhance your own personal experiences on the water.

Popular DIY Build a Boat Options

Some great examples of DIY boats include:

Plywood Sheet Boats

Duct tape & cardboard boats.

Before we get into each, let’s point out that not all of these are what you’d call “seaworthy.” Some will only be appropriate for use in small bodies of protected waters, where you can stand up if your boat sinks (yes, life jackets are still required!)

Others will work fine in ponds with no waves or current, but can’t be expected to have the stability nor wave-handling abilities of even the smallest dinghy that’s been manufactured to modern safety standards. In many of these cases the idea here isn’t to build a boat to go cruising or fishing —it’s to build your own boat for fun.

Explore Professional Boat Builder Models & Brands

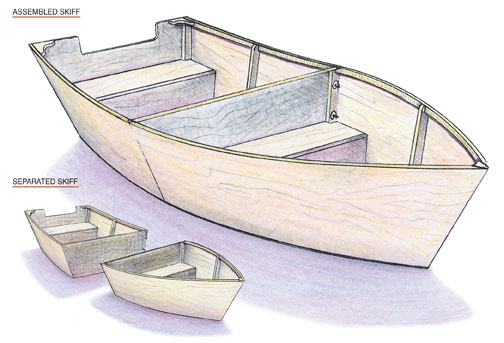

One of the simplest and least expensive methods of building a boat that you can use repeatedly in small, protected bodies of water, is to slap together plywood sheets into a box with a section angled up for the bow. Will it comfortable in any sort of waves? Not likely. But it is a quick and easy project that you can tackle with a budget of just a couple hundred dollars, and it results in a mini-boat that will last.

The process is quite simple:

- Sketch out the dimensions you want;

- Cut plywood sheets for the bottom, sides, transom, and bow;

- Cut trim (such as 1”-by-2” wood strips) to line all the joints;

- Secure the sides and bottom by driving screws through them and into the trim;

- Seal all the joints with an adhesive/sealant;

- Finally, give the boat a coat of paint to protect the plywood and extend its lifespan.

If you want to build a plywood sheet boat, it’s a good idea to look at some basic plans first (plenty are available on the internet). And always remember that this sort of craft isn’t meant for use on open water, nor without lifejackets being worn at all times. When you go for your first sea trial you’ll likely find it rather unstable and difficult to row in a straight line—but you’ll be rowing your very own boat, that you built with your own two hands.

Building a kit boat can result in a much more seaworthy craft than most of these other DIY backyard projects, however, it also costs quite a bit more money. In most cases, you’ll be paying for the plans, pre-cut materials, and shipping. Accessories like oars or sails generally will need to be purchased after the project is complete. Depending on the size and type of kit boat you build your budget can range from a couple thousand dollars to $10,000 or even more.

Different kit boat companies offer different building styles, ranging from:

- Strip planking over frames to stitch-and-glue construction (where the sheets of wood are connected by sewing wire through pre-drilled holes).

- In some cases, the wood framework of the boat will need to be encapsulated in epoxy resin and/or fiberglass once its assembled.

- Some kits have interlocking pieces and parts that snap together like puzzle parts, while others will need to be glued together or mechanically fastened.

Each of these different methods require different levels of skill, time, and expense, so before buying a kit boat you should thoroughly research just what’s involved with the construction method that’s to be used.

That said, the time and expense involved with building a kit boat is worth it to many people because the end result can be a rather substantial, long-lasting watercraft.

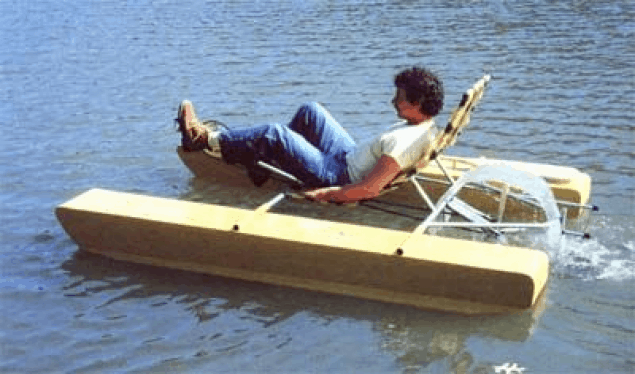

Can you merely cap off some PVC tubes to act as pontoons, strap on a deck or seat, and call it a boat? Sure you can. And while the end result is not likely to be a boat you’d ever want to launch in anything larger than a farm-pond, it will withstand the test of time.

PVC boats are also incredibly easy to build since the pieces and parts are all readily available at well-stocked hardware stores, can be glued together, and are fairly inexpensive. Depending on how ambitious you get you could spend a few hundred dollars on materials, even more if you built a plywood deck or added seating.

The most important thing to keep in mind when building a PVC boat is how much floatation you’ll get out of different sized pipes.

- As an example, 10-inch diameter pipe will float about 300 pounds per 10-foot section.

- So a pair of pipes can support around 600 pounds in total before becoming immersed.

- But you have to account for the weight of the PVC and any decking material you might use, and to make sure you stay above the waterline it’s a good idea to only plan for half the total weight capacity to be used. S

- So a boat you make with a pair of those pipes will be appropriate for a single adult of up to 200 or 250 pounds, give or take—depending on how willing you are to get wet.

There are some plans for PVC boats available for free on the internet, so a little bit of Googling can go a long way in making sure you end up with the type of boat you’re expecting.

We’re lumping duct tape boats and cardboard boats together, because quite often they’re one and the same. Often the boat’s structure will be cardboard and duct tape is used to (more or less) protect the cardboard from getting saturated. This is the most common construction method used for many of the cardboard boat races and contests held across the nation.

In some other cases, people build a basic framework out of thin PVC pipes, chicken-wire, or wood stripping, and then create multi-layer hull “plating” with the tape.

Although you can probably scrounge up plenty of cardboard without spending a dime, the expense of building a duct tape boat can be bigger than one might guess.

- You’ll need several rolls of tape (the thicker you layer it on, the better) so a budget of $50 or more is not out of line.

- Of course, neither cardboard nor duct tape are the best boatbuilding materials in the world. Often these are single-use boats that can be expected to sink in short order.

- So this is another case where you shouldn’t so much as step aboard without having your life jacket on, and the use of these boats should be close to the shoreline in protected waters.

Any way you look at it, however, building a duct tape or cardboard boat gets right at the heart of why you’d want to take on a DIY boatbuilding project in the first place: because it’s fun!

Read Next: 10 Easy, Affordable Boat DIY Improvement Projects

You May Also Like:

- How to Buy a Boat

- Boat Hull Types, Shapes & Designs

- Why Should I Buy a Certified Boat?

- How to Launch a Boat

- Find the Right Boat for Your Lifestyle

Join Our Newsletter!

Get community news, buying bargains, and how-to guides at your fingertips.

- Building Boats: Crafting Your Own Seafaring Adventure

Imagine gliding gracefully across the shimmering waters, the wind in your hair, and the sense of freedom that comes from steering your very own boat. Building boats isn't just a hobby; it's a journey that combines craftsmanship, passion, and a connection to the sea. Whether you're dreaming of a small sailing boat or a grand yacht, the process of building a boat is an exciting endeavor that brings your nautical fantasies to life.

Introduction: Embarking on a Boat-Building Adventure

The allure of the open sea has captured human imagination for centuries. Building your own boat allows you to immerse yourself in this seafaring romance and become the captain of your destiny. Whether you're a seasoned craftsman or just beginning your woodworking journey, building a boat offers a unique blend of challenge and satisfaction.

The Joy of Crafting: Building Your Dream Boat

There's a certain magic in creating something with your own hands, and boat building encapsulates this experience perfectly. From meticulously shaping the hull to fitting the finest details, every step of the process is an opportunity to pour your passion into your project.

From Dream to Reality: Steps to Construct a Wooden Boat

Choosing the right boat building kit.

Embarking on your boat-building journey starts with selecting the right kit. These kits come in various sizes and styles, catering to both beginners and experienced builders. The right kit will provide you with clear instructions and pre-cut materials, simplifying the construction process.

Tools and Materials You'll Need

Before diving in, ensure you have the necessary tools and materials. Basic woodworking tools, adhesives, and marine-grade materials are essential. Safety gear is also a must to protect yourself during construction.

Laying the Foundation: Building the Hull

The hull is the backbone of your boat, determining its stability and buoyancy. Constructing the hull involves assembling the ribs, keel, and other structural elements. Paying attention to measurements and alignment is crucial for a smooth build.

Navigating the Challenges: Assembling the Frame

The frame adds shape and structure to your boat. Connecting the ribs to the keel and other framing components requires precision. Challenges may arise, but each obstacle is a chance to learn and refine your skills.

Sailing Skiffs: A Unique Approach to Boat Building

Sailing skiffs offer an alternative to traditional boat designs. With a focus on simplicity and performance, these boats prioritize maneuverability and speed. Exploring skiff designs can open up new avenues for creativity.

Sailing in Style: Finishing Touches and Personalization

The art of paint and polish.

Once the construction is complete, it's time to bring your boat to life with paint and finishes. Not only do these elements enhance the aesthetics, but they also protect the wood from the elements. Choose colors and finishes that resonate with your nautical vision.

Installing the Deck and Cabin

The deck and cabin provide comfort and functionality to your boat. Installing these components requires careful planning to ensure they align with the overall design. Consider factors like seating arrangements, storage, and visibility.

Wiring, Plumbing, and Essential Systems

Modern boats often come equipped with electrical, plumbing, and navigation systems. Integrating these systems seamlessly into your boat requires technical know-how. Collaborating with experts can ensure a safe and functional vessel.

Nautical DIY: Building Your Own Boat Kit

Building your own boat from scratch offers the ultimate freedom in design and construction. While it demands more skill and time, the satisfaction of bringing a unique vision to life is unparalleled.

Read our top notch articles on topics such as sailing , sailing tips and destinations in our Magazine .

Benefits of plywood boat building.

Plywood boat building is a popular choice due to its accessibility and affordability. Plywood's flexibility and durability make it an excellent material for constructing small sailboats. Its ease of use opens the door for aspiring boat builders.

Step-by-Step Guide to Building a Plywood Boat

- Designing the Boat: Sketch out your boat's design, considering size and style.

- Gathering Materials: Acquire marine-grade plywood, epoxy, and fiberglass.

- Cutting and Assembling: Cut plywood pieces according to your design and assemble the hull.

- Fiberglassing and Sealing: Apply fiberglass and epoxy to reinforce the hull and make it watertight.

- Finishing Touches: Install seats, decking, and other features to complete the boat.

Charting Your Course: Following Sailboat Plans

Understanding yacht plans and sailboat kits.

Yacht plans and sailboat kits provide blueprints for building vessels of various sizes. These plans guide you through every step, from framing to finishing. Choosing a plan that aligns with your skills and aspirations is crucial.

Customizing Designs to Suit Your Vision

While sailboat plans offer a foundation, there's room for personalization. You can modify elements like cabin layout, deck arrangement, and interior amenities to match your preferences.

Floating Dreams: Embarking on Your Maiden Voyage

Sea trials and safety checks.

Before setting sail, conduct sea trials to ensure your boat performs as expected. Test its stability, speed, and maneuverability in controlled conditions. Additionally, perform safety checks on essential systems to guarantee a smooth journey.

Navigating Challenges and Celebrating Successes

Boat building is a journey of challenges and triumphs. Embrace setbacks as learning opportunities, and celebrate every milestone, from laying the keel to hoisting the sails for the first time.

FAQs About Boat Building

Can i build a boat if i have no prior woodworking experience.

Absolutely! Many beginners have successfully built boats by following detailed plans and utilizing available resources.

How much time does it usually take to build a small wooden boat?

The time required varies depending on factors like the complexity of the design, your experience level, and the amount of time you can dedicate. It could take a few weeks to several months.

Are boat building kits suitable for beginners?

Yes, boat building kits are designed to cater to all skill levels. They provide step-by-step instructions and pre-cut materials, making the process easier for beginners.

What safety precautions should I consider during boat construction?

Wearing appropriate safety gear, working in a well-ventilated area, and following instructions carefully are essential safety practices during boat construction.

Can I build a boat without expensive tools and equipment?

Yes, basic woodworking tools are sufficient for many boat-building projects. As you gain experience, you might invest in more specialized tools.

The Magic of Plywood: Crafting Small Wooden Sailboats

So what are you waiting for ? Take a look at our range of charter boats and head to some of our favourite sailing destinations .

FAQs: Boat Building: Your Questions Answered

How to Build a Boat

Classic boat plans from a 1937 issue of Popular Mechanics , updated for the 21st century.

It was a long time since anyone in my family had built a boat. The last was my Uncle Paul. He was a shipbuilder who learned his trade beginning at age 14 in Hamburg, Germany. Every morning, the boy rowed from the family's dock out across the shipping lanes of the Elbe River, which flows into the North Sea.

The trip to the shipyard where he was apprenticed took an hour and a half, longer in winter, when there was fog and floating ice on the water. After three years, Paul received a journeyman's certificate and a berth aboard a gigantic four-masted windjammer named Passat—"trade wind" in English. That was in the 1920s, before the fascists confiscated his family's own small shipyard and the Berendsohns left for America.

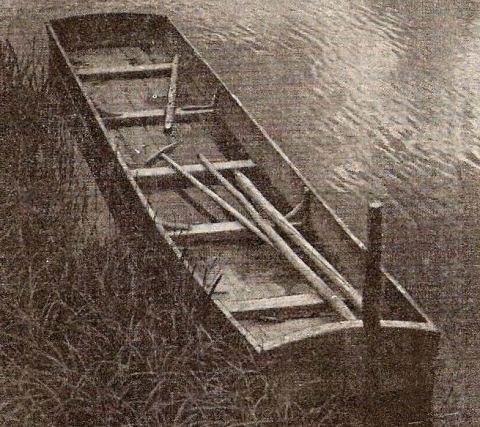

A few months ago, I decided to try my hand at the ancestral trade. I've built everything from houses to a blacksmith's forge , but there's no more evocative project than a boat, at least to me. Since before Austronesians first gazed across the Pacific, wooden vessels have stood for craftsmanship and the drive to explore. I sifted through PM's archives looking for a classic design and eventually settled on a 10-foot dinghy from our May 1937 issue . It looked elegant, yet simple enough to build on a pair of sawhorses.

It's been many years since my Uncle Paul was around to lend advice, so I ran the drawings past Timo White, a boatbuilder at Tuckerton Seaport, a small maritime museum on the New Jersey coast. It turned out that Timo was in the midst of restoring a surfboard built from plans in the July 1937 issue of PM. (It was a big year for seafaring projects, I guess.)

He confirmed that the dinghy was a good candidate for a first-time builder and agreed to lend a hand if needed.

Shipyard in the Driveway

On a wintry early spring morning I set out for Willard Brothers Woodcutters, a sawmill and lumber dealer in Trenton, N.J. You can spend hours there, roaming stacks of delicious-looking walnut, cherry and oak, some of the boards as wide as your arm is long. I bought red oak for the Sea Scout's frames (that was the name of the craft in the plans, and I chose to keep it) and a 2-inch-thick slab of white oak for the wedge-shaped stem at the bow.

Back home, I started making a racket feeding planks through a table saw. My skills were creaky--I've spent too much time in recent years fixing stuff and not enough building--but over a few days my old confidence returned. The Sea Scout began to take form.

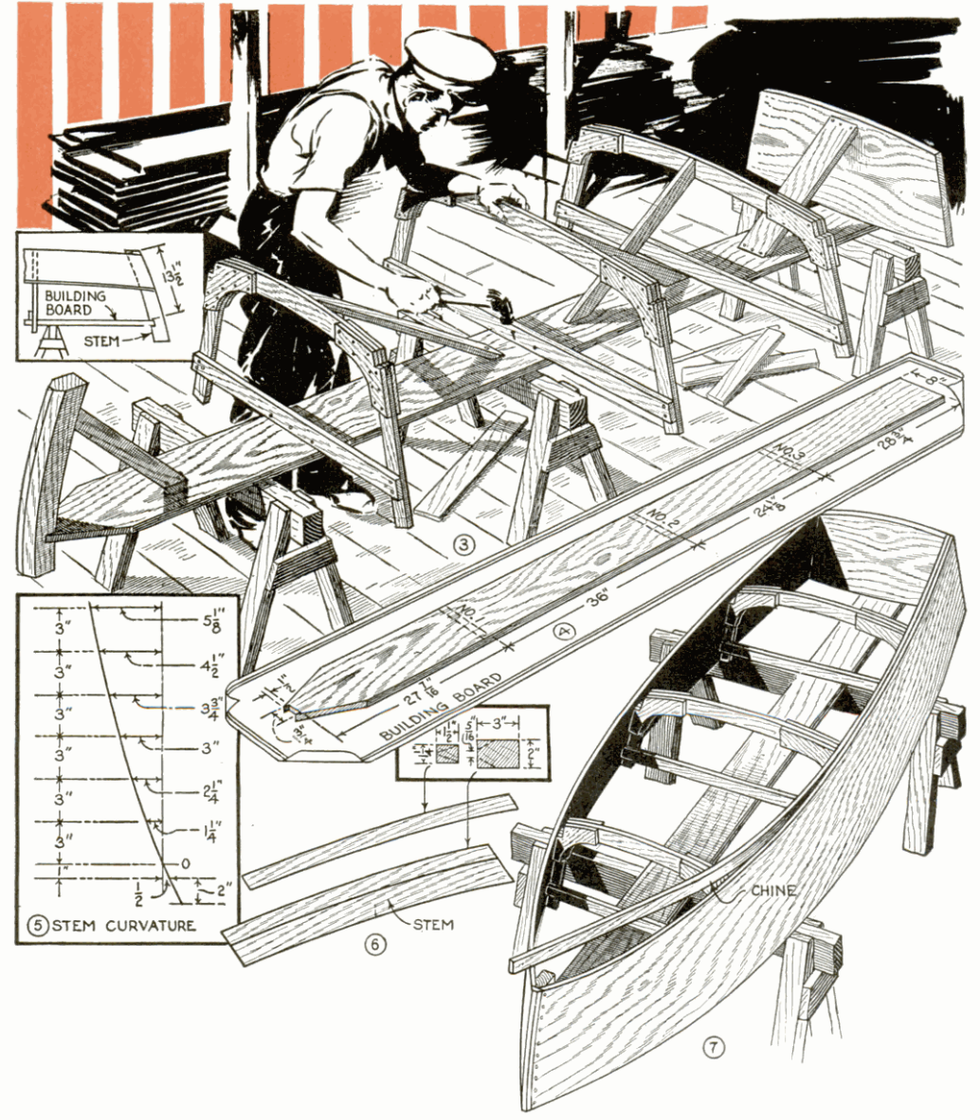

Most boats begin with the frames, the ribs that provide structure to the hull. I roughed them into shape, along with the stem and the gracefully shaped stern wall, or transom, which I cut from ¾-inch plywood. Then I braced it all to a building board--which is nothing more than a 2 x 10 with a chalk line marked down the center.

⚠️ To simplify the project, I omitted the mast and centerboard. Instead, I built the Sea Scout, named after the craft in the original article, to be rowed or powered by an outboard motor. She works well in either configuration. You can find the original plans and materials list here.

The boat's skeleton was in place, but each member still needed to be precisely beveled before I could secure the curved planks of the hull. The next step was to clamp thin strips of wood, called battens, to the frame to stand in for the planks, so I could measure and mark all those angles. Then, I took the parts off the board and finished shaping them.

Often, the weather confined me to the garage, but when the sun emerged I worked in the driveway. If you want to get to know the neighbors, start building a boat. Linda from next door asked whether the craft would be sailed, rowed or powered by an outboard motor. Others wondered where I would go with it, how I'd get it there and what I would name it. A truck driver from Tulnoy Lumber, dropping off some marine plywood, approached respectfully. "This is beautiful," he said, with an old-fashioned New York accent as broad as the hand he ran over the frames.

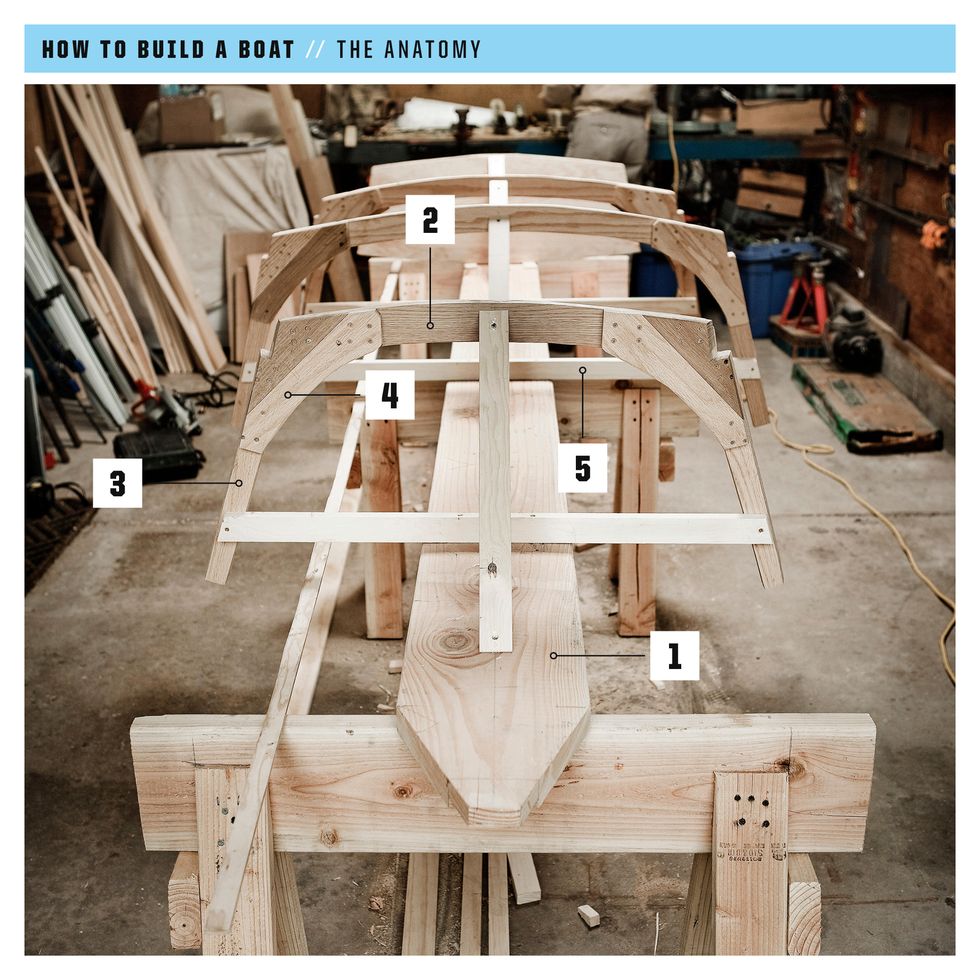

Anatomy of a Boat

Working the Plank

I don't know how Uncle Paul felt about it, but boatbuilding can be acutely frustrating. The bane of my weekends proved to be a small bronze screw. A No. 6 Frearson flat-head, to be exact. Like most modern DIYers, I'd been spoiled by drywall screws and other aggressive fasteners that practically plow into the lumber. Even using a specialized, tapered drill bit and a waxlike lubricant with the unlikely name of Akempucky, I managed to wreck screws by the dozen. The head on one would strip a moment before the screw was fully seated, while another would shear off on the last eighth of a turn, leaving me with a shiny Frearson-head penny.

Timo had tried to downplay the arcana I'd face--"It's more like house carpentry than fine-furniture building," he had said--but I still found myself floundering on occasion. One challenge was that the 1937 article was more an overview than a detailed set of plans. And, though it pains me to find fault with my forebears at Popular Mechanics, the sketch contained suspicious discrepancies. Timo helped me recalibrate some of the dimensions midway through the project—and I had to trim several pieces after they were assembled.

The biggest hurdle came when it was time to plank the hull. The classic way is to bend strips of solid wood to the frames. I'd chosen marine-grade fir plywood instead to save time, but now I was barely able to force the hull's 14-inch sheets into place. There was no way the half-inch plywood I'd planned for the bottom was going to work.

Timo advised me to switch to a special, wafer-thin marine-grade plywood and plank the bottom in two layers. He came swooping in one Thursday morning to show me the technique. He stepped out of his truck with a broad smile, and a block plane in each hand, and my mood lifted. He politely took a sighting down the chine logs where we'd attach the bottom, and spent a few minutes planing them to the last measure of precision. Then we got to work with staples, glue and screws--and in a couple of hours the project went from a plywood flower bed to a small craft with sensuous compound curves.

It was satisfying, but my mistakes still showed in details like the placement of screws and the shape of the stem. "You know what they say," Timo told me. "Putty and paint makes a boat what it ain't." I got out my paintbrushes.

Maiden Voyage

We launched the boat at Tuckerton Seaport on a cool, overcast day that felt more like September than June. Down at the dock, Timo produced a can of Amstel Light in lieu of champagne. "Go ahead," he said, "pour it over the bow." I popped it open and emptied the beer over the paint. "I christen thee Sea Scout," I said. Then we slid the little craft off the dock and into the water.

You might think a feeling of triumph came over me. Not so. The Sea Scout looked very small, almost helpless, as she sat bobbing at the end of the painter, the little rope that Timo had threaded across the bow. I felt humbled. A phrase from the Book of Psalms flashed in my mind: "They that go down to the sea in ships, that do business on great waters."

I wasn't aiming for any great waters myself. I eased off the dock and into the boat. Timo handed me the oars. Awkwardly, I drew the handles back, just above my hips. The craft slid forward gracefully, almost like she was on ice. As Timo watched, I braced the left oar down in the water and swept the surface with the right. The Sea Scout pivoted neatly, unexpectedly elegant and spry.

If the oars were a kick, you can imagine the thrill I felt when I mounted the 2.5-hp Mercury Marine outboard on the transom. It's a clean-running four-stroke engine, compact yet almost zippy on a boat this small. I gave the engine full throttle and cut some nice straight lines and a pleasingly tight curve complete with a crisp little wake.

With the afternoon gone, my first voyage was complete. In the end, I decided to donate the boat and engine to Tuckerton Seaport. Frankly, I needed the space in my garage and driveway: The Sea Scout was a good first foray into wooden boatbuilding, but I knew I could do better—and I'm already sifting through plans.

The Sea Scout, a Decade Later

Ask anybody who’s ever built a boat, and they’ll tell you one thing about it: you’re not the same after you’ve built one. And that goes for me, too. The little boat, which I built back in 2009, shaped me as much—or perhaps more—than I shaped it.

The Sea Scout project brought a flood of mail from our readers, some of whom had built the boat or knew someone who did. One woman still had the boat that her father built. She sent a picture of it and recalled the many pleasant hours she spent with her dad as her father taught her how to sail in it. She kindly offered to donate the boat to us, thinking that perhaps we could put it in our lobby. I wish I could have taken her up on the offer.

When you build a boat, you take your place in the long line of craftspeople—professional and amateurs alike—who have plied that trade and learned about the unique burden of building a craft upon whom someone’s safety and enjoyment will depend. Building a boat is humbling, you remember every mistake you made building the thing as it bobs up and down, and waves wash over its bow or crash into it from the side.

You feel it shudder, but it doesn’t give way as you look over the side at the murky depths. And afterward, you look at every boat with a more knowing eye, a greater respect...and you wonder if you could build it.

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.

.css-cuqpxl:before{padding-right:0.3125rem;content:'//';display:inline;} Pop Mech Pro .css-xtujxj:before{padding-left:0.3125rem;content:'//';display:inline;}

Inside the Development of America's New Nuke

Cooking Pizza in Breeo’s Live-Fire Oven

Ceiling Stains. Now What?

The Engine Driving Our Oceans Could Die by 2100

How Bessie Coleman's Sky-High Ambition Killed Her

The Incredible Case of NASA’S Missing Moondust

Could New Evidence Revive the Black Dahlia Case?

America's Next Stealth Bomber Will Rule the Skies

Can AI Help Solve Math’s Thorniest Mysteries?

You Can Give Your Body Back to Nature When You Die

The History of Pi

- PRO Courses Guides New Tech Help Pro Expert Videos About wikiHow Pro Upgrade Sign In

- EDIT Edit this Article

- EXPLORE Tech Help Pro About Us Random Article Quizzes Request a New Article Community Dashboard This Or That Game Popular Categories Arts and Entertainment Artwork Books Movies Computers and Electronics Computers Phone Skills Technology Hacks Health Men's Health Mental Health Women's Health Relationships Dating Love Relationship Issues Hobbies and Crafts Crafts Drawing Games Education & Communication Communication Skills Personal Development Studying Personal Care and Style Fashion Hair Care Personal Hygiene Youth Personal Care School Stuff Dating All Categories Arts and Entertainment Finance and Business Home and Garden Relationship Quizzes Cars & Other Vehicles Food and Entertaining Personal Care and Style Sports and Fitness Computers and Electronics Health Pets and Animals Travel Education & Communication Hobbies and Crafts Philosophy and Religion Work World Family Life Holidays and Traditions Relationships Youth

- Browse Articles

- Learn Something New

- Quizzes Hot

- This Or That Game New

- Train Your Brain

- Explore More

- Support wikiHow

- About wikiHow

- Log in / Sign up

- Hobbies and Crafts

- Woodworking

- Wooden Sports Equipment

How to Build a Boat

Last Updated: January 21, 2024 Approved

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 45 people, some anonymous, worked to edit and improve it over time. wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, several readers have written to tell us that this article was helpful to them, earning it our reader-approved status. This article has been viewed 288,756 times. Learn more...

Little boats are perfect for trips around the lake. They fit on the roof of your car and in the back of truck beds, making them perfect for spontaneous camping trips. This article describes a method for building a canoe, (12'x30", with 11" depth), using a stitch and glue style of boat building.

Building the Frame

- A long stick or batten is used to draw a line between these points giving the outlines of the canoe's panels. Make sure the lines drawn for the panels are all fair, smooth curves.

- Only three panels are needed per side. The four half sheets of 8' plywood are used to make 12 boat panels, then these 12 panels are put together in matching pairs with butt blocks or scarf joints to make up the total 6 panels or 3 per side.

- Finger joints, using a dovetail template and a router will also make good joints to join the panels. You have to allow for the 1" overlap of each panel when making the finger joint, as this gives the boat an attractive finished look.

- This system makes a simple but very nice boat and has a recognizable canoe look and shape with a gentle "v" bottom, rather than a flat bottom.

- Once you have cut the panels out, use a woodworkers rasp (file) to smooth up the edges as close to the lines on the panel as possible. A small block plane could be used instead.

- Now you can put the panel pieces together as stated above with finger joints, scarves or butt blocks. More specific instructions on how to do each of these joints is easily available online.

- This job is easier and faster if you lay the two matching panels (the corresponding panels on either side) together and drill the holes.

- This boat has only three panels per side, with each of the three being the same on either side of the canoe.

- Lay the two bottom panels on top of each other and wire the center/bottom edges together, but don't pull the wire too tight. Leave the wire loose, so you can open the bottom two panels up like a book. This will be the bottom of your canoe.

- Now, starting in the center, wire (stitch) on the next panel, putting a few stitches on each side of the center line. Keep working from side to side doing a few on each side until you get to the ends.

- When you get to the upper panels, line up the ends and stitch them together. Try to keep them as even as possible, with a nice canoe end curve. You should begin to see the canoe coming together at this point. [2] X Research source

- Is it fair, with nice flowing lines and no twist? If not tighten or loosen the wire stitches as necessary, or even add a stitch if needed. Make sure it looks pleasing to the eye.

- Check to see if there is any twist in the canoe, using winding sticks. Make sure the panel edges are all sitting on top of each other nice and tight and not overlapping at any point.

- You can also do a trick called cutting a transition joint, which is a 1/4 or 3/8" notch cut 24-36" (depending on the width of the panel and length of the canoe) into the bottom front edge of the top panels. This gives you a nice smooth side. More detailed instructions on how to do a transition joint can be found in many books covering stitch and glue boat building or on the internet.

- Finally, be sure that the panels are not pushed out from each other at any one point, you want nice, smooth-stitched seams.

Bonding the Panels

- Try to cover each edge about an inch on either side of the joint, making sure that it soaks into the joint to get a good bond. Make it look like you're painting a strip down the joint. Remember that the joints of the panels and stems only get epoxied on the inside for now.

- Repeat this process for each of the joints. Try not to let the epoxy run down the sides of the panels -- you only want it on the joint, no runs. If you have any runs, use another brush to wipe them up. This just makes life easier when it comes to sanding the inside of the boat. Remember to check the outside of the seams for runs as well.

- Put two coats of epoxy on the joints and stems (stems are the ends of the boat), letting the epoxy dry before re-coating. Be sure the stems are pulled tightly together (using the stitches) before applying the epoxy. Don't use clamps to pull the stems ends together, stitches only!

- Each coat of epoxy needs about 24 hours to dry, so try to have a little patience while dreaming of that smooth glassy lake!

- Do this with care, as the panels' joints are still fragile at this point. Try not to break the epoxy join, and don't leave any wire in the boat.

- If you pull out a wire and the joint opens, put a stitch back in and epoxy that joint area again.

- Mix the wood flour and epoxy to a smooth creamy mixture -- it shouldn't be runny. Apply this fillet to the joints that you put the epoxy on.

- Make a nice smooth bead about 1-1/2-2" wide over the center of each joint, then apply a smooth bead of fillet to the inside of the stem ends.

- Make the stem end fillets about 3/4" thick on the inside -- although this adds weight, it has the benefit of making the stem nice and strong.

- However, you should be careful not to add too much epoxy, as it can become brittle.

- Apply another coat of epoxy, smoothing it over the fiberglass until it turns clear. To make the joint as smooth as possible, add just enough epoxy to turn the fiberglass clear, then use a squeegee to remove any excess. Remember that applying too much epoxy is as bad as applying too little.

- Be gentle while doing this, as you don't want to push the fresh fillet mix out of the joint when you push down on the fiberglass with the squeegee.

- When you get to the stems, add a 3" wide strip of fiberglass to the inside of the stems (over the fillet). Allow the stem end fiberglass to come down over the center strip of fiberglass tape, as this will make one complete, strong joint.

- You will need to add a second coat of epoxy to these tapes after the first coat cures, again waiting 24 hours between each coat.

- Now use a fine rasp (woodworkers file) to smooth over the edges of the bottom and lower panel joints, being careful not to splinter the thin plywood. Then use sandpaper (80 grit) to smooth up the joint edge, being careful not to sand too deep into the plywood.

- Sand the entire outside of the boat, using a 120 grit sandpaper. Make sure to clean up any drips and runs from the epoxy that ran through the joints. Remember to sand with care - don't sand into the thin layers of the 1/8' plywood as this takes away from the canoe's outer skin and leaves hollow flat spots.

- When the sanding is done wipe off the excess dust using a cheesecloth, then use compressed air and a clean cloth to remove the more stubborn dust. Sweep the floor, and wait until the dust has settled before proceeding.

- Lightly sand the epoxy-coated outside of the boat with 120 grit paper. This is only necessary to provide a tooth for the next coat of epoxy and fiberglass to hold to.

- Now it's time to add fiberglass cloth to the outside of the boat. The fiberglass can weigh anywhere between 4 oz and 8oz, depending on the intended use of the canoe. The larger the fiberglass the heavier the canoe will be as the heavier fiberglass requires more epoxy.

- Use the same technique of applying the fiberglass to the outside of the boat, then applying a layer of epoxy on top. If you have never done this before, it's a good idea to read as much as you can about it first. Being informed will help you do a really nice job on the boat.

- If you wait until the epoxy hardens, it will be very hard to trim the excess fiberglass cloth from the edges of the canoe.

- To trim the fiberglass cloth, use a razor knife and trim off the cloth along the gunnel's edges. Be gentle while trimming -- try not to pull on the cloth as it is still wet and it will move and cause you problems.

- Be aware that it might take more than two coats to fill the weave of the cloth depending on the type and weight of the cloth.

- With the fiberglass on and trimmed, give the outside a light sanding with 220 grit sandpaper, then clean off all dust. You can now clear coat or paint the boat.

Finishing the Job

- Gunnels give a completed look to the canoe, while also serving to protect the sides of the canoe as rub rails.

- Each gunnel should be about 1-1-1/4"x3/8-1/2" square, with the top outside and inside edges rounded over. Use epoxy and brass or bronze screws to attach the gunnels at the front 24-30" of the gunnels. You can use the epoxy and spring clamps to attach the gunnels to the canoe until the epoxy dries.

- At the stem ends on top of the canoe you can fit small decks, on top of the rails or between them, if you take the time and effort to make a good fit. Flush decks look the best.

- When all the sanding is done, it's time to coat the inside of the boat with. For best results, do this in two or three thin layers of epoxy, waiting 24 hours between coats.

- When this is all done you can sand the last coat lightly with a 120 grit sandpaper and then a 220 grit to get a really smooth finish.

- Wipe away any dust, then paint or varnish the inside.

- All seats should be about 1-1-1/2" from the bottom of the canoe, not hanging from the gunnels.

- On a light canoe (such as this one) with a low freeboard, it's best to keep the center of gravity as low in the boat as possible.

Community Q&A

- Read all you can find about stitch and glue boat building. The more you know the less problems you'll have and the happier you'll be. Thanks Helpful 1 Not Helpful 0

- Don't get into a hurry, this is very hard to control, but an issue you must work on. Thanks Helpful 1 Not Helpful 0

- Only use epoxy plenty fresh air (ventilation) when boat building to avoid possible permanent nerve damage caused by inhaling fumes. Thanks Helpful 1 Not Helpful 0

- A wooden boat won't sink; it may swamp, but will still float, so if you fall out and the boat fills with water, stay with it, it could save your life. Thanks Helpful 34 Not Helpful 9

- Keep the area you work in clean, well vented and a fire extinguisher on hand all the time. Thanks Helpful 21 Not Helpful 11

- Epoxy is toxic and you can get very sick from prolonged exposure to epoxy. Try not to breath the fumes or let the epoxy (or its components) come in contact with your skin. Use safety gear, safety glass' prevent splatter into your eyes, an air filter (charcoal) and lots of ventilation are recommended, rubber or vinyl gloves, and an old long sleeve shirt. Thanks Helpful 2 Not Helpful 1

- Always use Personal Flotation Devices (PFDs) when you are in a boat. Do not sit on your PFDs. Certain states and local laws specifically require PFDs for young people. Thanks Helpful 2 Not Helpful 2

You Might Also Like

- ↑ https://www.christinedemerchant.com/stitch-and-glue-boatbuilding.html

- ↑ https://www.epoxyworks.com/index.php/bonding-with-fillets/

- ↑ https://www.youtube.com/watch?v=_tkR9hMq2wY

About This Article

To build a simple boat, lay the keel of the boat and then add ribs to form the shape of the boat. The ribs should taper to a point at the bow of most boats, curve outward in the middle, and narrow at the stern. To build the hull, you’ll want to use either strips of wood or sheets of fiberglass. Then, once you’ve completed the hull, paint the boat with special marine paint that won’t come off in the water. For more detailed instructions, read on! Did this summary help you? Yes No

- Send fan mail to authors

Reader Success Stories

Alan Houghey

Nov 18, 2021

Did this article help you?

Kobus Van Baalen

Dec 28, 2017

Joseph Slivinsky

Jan 14, 2018

Halt O'Carrick

May 8, 2017

Ayaan Gupta

Nov 2, 2018

Featured Articles

Trending Articles

Watch Articles

- Terms of Use

- Privacy Policy

- Do Not Sell or Share My Info

- Not Selling Info

Don’t miss out! Sign up for

wikiHow’s newsletter

- Architecture News – World Buildings

- Buildings by Country

- Buildings by City

- Architects by country

- Architects by city

- Architects alphabetical

- Competitions

- Building Events

- Architecture Design

Building a yacht: superyacht construction process

Building Your Own Yacht Process, Superyacht Construction, Marina Architecture, Buildings

Building A Yacht Of Your Own

29 June 2020

Building A Yacht Of Your Own – What Is The Process?

29th June 2020 – Imagine building your very own superyacht, designed to your specific needs, tastes and desires. While building a yacht is more complex and may take years of research and planning than buying new yachts or motor boats for sale , it will also be as exciting and fulfilling as all the future journeys you will enjoy onboard it. But where to start? How do you go about tackling your very own superyacht construction to realise your own new build yacht ?

A Look Into Building A Yacht – How To Go About It?

Every custom-built superyacht starts with a vision, based on personal preference and taste, and the type of onboard lifestyle desired. What kind of cruising is required, which luxuries would you like onboard, for example a spa or swimming pool, and is a helipad necessary? With a world of options to consider, the future owner will naturally be the driving force behind their own superyacht construction, but to ensure the smoothest journey possible, they will need a team of experts to work on such a big project.

The Superyacht Construction Team – Key Players

The process of building a yacht will involve a great number of decisions, so having the support of a knowledgeable and experienced team is imperative.

The owner may wish to engage a respected yacht broker to build the team, knowing that they spend a significant amount of time liaising with key players across the yachting industry. They will also ensure the owner’s interests are protected, while providing access to some of the world’s most exciting and ground-breaking yacht builders.

Key players will include a professional yacht designer and naval architect, who will be chosen depending on the type and style of superyacht construction required. An engineer will be engaged for detailed design, and an interior designer will need to work in conjunction with both, designing the layout and cabin suites to meet the owner’s requirements.

You will also need to engage an owner’s representative to oversee the superyacht construction on your behalf. In some cases, the vessel’s future captain may take this role, and offer guidance and reassurance throughout the design and construction stages. They will also negotiate the most favourable terms and protect the buyer’s interests.

Dedicated Project Management Team for Building A Yacht

In addition, when building a yacht, a project management team will be engaged to oversee the day-to-day details, from coordinating the production of the technical specs to running a tender process with shipyards, through to price and contract negotiations.

As the superyacht construction progresses, they will act as the go-between for the different parties involved, and ensure that every element of the project is handled efficiently and to the highest standard. Some will work full time, while others with short-term specialisms may be engaged during particular phases of the build.

The Shipyard – The Heart of Superyacht Construction

The shipyard is where the superyacht construction finally gets underway, using its state-of-the-art equipment, experienced representatives and skilled craftsmen. Involved from the design stage, the shipyard will work closely with the project manager and/or owner’s representative, as well as both the interior and exterior designers to ensure that the end result not only fits the owner’s specifications, but also meets marine legislation and technical requirements.

With the complexities of changing international legislation, it is the project manager’s job to liaise with all parties to ensure that everyone is kept up-to-date on any necessary design changes or alterations.

The Legalities

An experienced team of maritime lawyers will be engaged to write contracts that set the guidelines for the build and protect the buyer from technical issues and delays. Detailed build milestones and payment schedules will also be drawn up. On the vessel’s completion, lawyers will advise on flag registration and handle all other regulatory aspects, as well as the operational setup and ownership structure.

Sea Trial – Exciting & Essential

After successfully building a yacht to the owner’s requirements, surveyors will be needed to establish the vessel’s performance and seaworthiness during a sea trial, an essential part of the construction of any new superyacht. During a sea trial, all parties work together to fine-tune the systems and iron out any issues.

Typically a sea trial takes place on open water and can last several days. The yacht’s crew will usually be engaged six months to a year before completion, and will play an integral part in putting the superyacht through its paces. These will include testing the vessel’s speed, manoeuvrability, equipment and safety features.

Also present onboard will be technical representatives from the shipyard as well as those from any major systems used, the owner’s representative, and governing and certification officials.

The certification officials are employed by a classification society, a third-party service that assures the quality of construction – the nautical equivalent of an MOT. The classification certificate they issue will be required for registering the yacht and obtaining marine insurance. It may also be required before entering certain ports or waterways, and will be of interest to future charterers and potential buyers.

Owner’s Supply

Most custom yacht contracts do not include what is known as the Owner’s Supply – any additional items the owner desires after building a yacht, such as tenders and water toys, audio-visual and entertainment systems, loose furniture, tableware, and decorative objects. Each will need to be procured, insured, managed and integrated into the yacht itself before final delivery.

Building A Yacht – The Final Delivery

At last the big day arrives: the superyacht is delivered to her delighted owner, and launched with much fanfare and celebration. The proud new owner is now free to enjoy their very own, truly unique superyacht out on the open water.

The process of building a yacht might be a complex, long-term commitment and a major investment, but a custom-built vessel is limited only by the owner’s imagination. For all the effort and work involved, there can be nothing more thrilling than realising a new build yacht that fulfils all your dreams and requirements, enjoying it with family and friends for many years to come.

Boat Design Articles

Guide to best European shipyards

New Yachts 2018

Yachtsman’s House on the Isle of Wight

Marina Architecture

Building a Superyacht

Boathouse Articles

Comments / photos for the Building A Yacht Of Your Own – What Is The Process? page welcome

Affordable Sailboats You Can Build at Home

Last Updated by

Daniel Wade

September 13, 2023

Key Takeaways

- There are many sailboats that anyone can build from home depending on tastes

- Budget will be the biggest deciding factor on a majority of the process

- Consider kits that come with most of what you need or choose ones that are all-inclusive

- Design complexities and new materials may make the building time process longer

- Plan the best you can ahead of time to save money and your working hours

Buying a sailboat can be expensive, but building your own can save you money. So what are sailboats you can build from home?

Sailboats that you can build from home will likely be a small boat under 20 feet. These could be from many different boat suppliers such as B&B Yachts, Brooks Boat Designs, and Chase Small Craft. Boat plans will vary based on your budget and how much time you have on your hands.

Based on my previous experience, building your own boat will take much longer than if a professional were to do it. You also have to be able to study plans, consider various sailboat designs, and have tons of supplies such as fiberglass tape or fiberglass cloth. On top of that, you will also have to be good with your hands.

Table of contents

Top 10 Affordable Sailboats Anyone Can Build at Home

Building your own pocket cruiser or other styles from boat plans is an impressive feat, as this will need dedicated time and money to assure your boat sails safely. Boat building takes a lot of patience as well, especially since this will not be completed in a fast manner.

Finding boat plans and materials that fit your budget will be key to being able to complete the project. The time it takes to complete these projects will vary on your overall experience and needs. Below are 10 of the most affordable sailboats that you can build in the comfort of your home.

B&B Yachts

B&B Yachts have 14 different boat plans you can choose from to find the boat of your desires. Their shop is located along the Bay River in North Carolina where they construct all of the kits and have a 100 foot dock to show off your project once you complete it.

One popular model to check out is their Core Sound 15, as it is the perfect size for those wanting to build a modest size boat for a handful of people on board. Their website features some videos of completed projects and the plans or kits for purchase.

- 14 different models to choose from plus some dinghies

- Various monohull and multihull options

- Friendly customer service with attractive prices

- Might be too many options for some that are indecisive

- Not ideal for those wanting to have a motor sailer

Brooks Boat Designs

Brooks Boat Designs has a handful of options to consider for your next sailboat building project. They are located in Brookline, Maine and give the option to buy the kits or have them build one from scratch for you. They have plenty of knowledge, so do not be shy to ask about modifications or custom features you are looking for.

Depending on your specifics, they can attempt to accommodate some of their plans to help fit your desired outcome. By checking out their site, you can see many examples of their construction in progress and what the boats will look like when completed.

- Offers a variety of kits

- Plans vary around $50 and up, while materials will obviously add more costs

- Some plans can be rowing boats that can convert to sailboats

- Might take a while to hear back from them, as their contact section is a little outdated

- Their plans may not accommodate a ton of extras for your taste

Chase Small Craft

Chase Small Craft offers a simple process for building boats. Their kits are equipped with everything you need and will help save you time than just buying the materials outright and other parts you could need. This is arguably one of the best bang for buck instances if you want to save time and money searching for pieces to your boat.

They are located in Saco, Maine and will ship everything to your home from there. All the necessary materials are included and all you need are the proper tools and working space.

- All-inclusive kits with what you need

- Tons of knowledge on their site for boat building

- Easy process to order and customize

- Complete kits can range over $20,000 for larger boats

- Kits may take up to eight weeks to ship out

Chesapeake Light Craft

You can expect high-quality boat kits from Chesapeake Light Craft . They feature 18 different sailboat kits that vary from eight to 20 feet in length. This should be more than enough to find one for you if you are newer to boat building.

They also have a wide variety of other kits in addition to the sailboat, in the event that you wanted to order a small kayak or paddleboard in addition to your sailboat. The prices vary considerably when considering a small or larger boat, so check the complete list of options to in order to potentially fit your needs.

- Plenty of sailboat offerings to choose from

- Different beautiful hull form options to consider

- Easy to build and perfect for sailing

- Only has basic materials needed for kit, so you may need to purchase other items

- Has epoxy shipping fee no matter if you pick up item

Dudley Dix Yacht Design