Why Aluminium .

The vq art of aluminium.

One of the reasons Vanquish clients love their bespoke driver’s boats is because so many specific wishes have been met by our expert engineers and craftsmen. The use of aluminium is key to this success as it provides enormous flexibility in the design and construction. Working by hand, the aluminium specialists at the Vanquish yard in the Netherlands work tirelessly for owners who embrace non-traditional thinking, with no request too crazy if technically feasible.

Only in alu…

In essence, the choice for aluminium comes down to these simple facts:

If you’re looking for a fast boat between 45 and 80 foot it needs to be light in weight. Our aluminium hulls weigh up to 40% less than their composite equivalent and as much as 55% less than steel yachts

If you’re looking for a fast boat that you can fully customise to your wishes, only aluminium has the flexibility to make such changes. Composite doesn’t offer this option (unless you make an expensive one-off mould) and steel cannot be shaped in the same way.

In addition to offering the ability to adapt countless aspects of your Vanquish to individual preferences, aluminium (marine alloy 5083) has many other benefits in terms of strength, durability, ease of repair/maintenance and more. Let’s explore these assets together…

Safety first

Vanquish yachts are mostly used on blue water so the safety of owners and their guests is central to everything we do at Vanquish. Aluminium has a far better strength/weight ratio than the vast majority of shipbuilding materials and is very difficult to deform. Moreover, the effects of any impact on an aluminium hull are only felt locally, with the rest of the body retaining its shape (and safety for passengers).

The exceptional properties of strength and resistance mean that aluminium hulls are far more resilient to damage than their GRP equivalent. Moreover, aluminium absorbs its own energy in collisions over a larger surface area than steel and is twice as good at absorbing shocks.

This marvellous metal also doesn’t burn in the atmosphere and nor will it fuel a fire. Using aluminium also allows us to incorporate any specific safety considerations you might have for taking the kids out to sea. Let’s get thinking together…

Powerful performance

No-one buys a Vanquish to cruise around at low speeds – there’s a reason they’re called driver’s boats. The incredible performance of our yachts is a key factor in our success and the fact that aluminium is lighter than composite plays a critical role herein.

The weight savings offer you an acceleration that make the most of our power-packed VQ hull designs. You’ll save on the fuel bill too and have a reduced draft, allowing you to go places other boats cannot reach. All in all, creating your boat in aluminium ensures you maximum manoeuvrability, blistering speeds and supreme comfort.

Made to last

Vanquish owners are happy to invest in their pleasure and expect a premium product in return that will stand the test of time. Aluminium offers an incomparable longevity compared to other boatbuilding materials. Maintenance requirements are very low and aluminium structures deteriorate very little over the years.

Aluminium boats are also far cheaper to repair. Dents can often be beaten out with a hammer and, if needed, parts can easily be cut out and replaced. Aluminium is remarkably resistant to corrosion, osmosis and structural fatigue. The only possible source of galvanic corrosion on aluminium hulls is contact with stainless steel parts but the expert builders at Vanquish will ensure this cannot happen with your VQ boat

Redefining comfort

The word ‘comfort’ has a different meaning to us all depending on what we find important. At Vanquish we define comfort by our ability to create a boat that meets the owner’s specific needs. And the use of aluminium plays a huge role in this as we modify the layout and accommodations in countless bespoke ways such as:

- Extra ceiling height for taller guests

- Building in beds of appropriate lengths

- Creating seats and sofas of various sizes in the lounge and on deck

- Adjusting or removing obstacles to easy on-board movements such as steep stairs or low chairs

- Opting for specific populsion system that require a custom interior

- Arranging your sleeping quarters and bathrooms in a way you enjoy… or dispensing with both and creating the ultimate day boat

The list is endless and purely revolves around how you see, feel and experience comfort.

Looking good

Aluminium is more elastic so allows for easier shaping and more unusual designs. From straight lines to curves, the style is all yours.

Resale value

Because aluminium boats are exceptionally durable, barely deteriorate over time and are easily repaired, they can attain a lifespan of 50 years. This means their resale value holds up far better than any equivalent yacht in steel or polyester.

Greener future

Vanquish owners love life and are keen to do their part to protect our planet. Aluminium is a more environmentally friendly material and fully recyclable at the end of its product lifecycle. Building in aluminium results in much less waste and what is left over can be reused in other applications. There is no more future-compatible and eco-conscious way to justify owning a boat than to have it made in aluminium.

Information request .

Our website uses cookies to optimise our services. Moreover, we would like to show you personalised ads on the internet based on your use of www.vanquish-yachts.com. If you agree to the latter, please click ‘I agree’. For more information, read our Cookie Statement and our Privacy Statement .

2019 - jachtbouw folmer - [email protected] - makke troch Roeloffopma.nl

- Stageplaatsen

- Open Day 2024

- Introduction event Hutting 46

Exclusive aluminium sailing yachts

Hutting 52 hutting 46 explorer hutting 40 hutting 45 hutting 50.

The sailing yacht that reflects your personality. Optimized for your sailing style and destinations, wherever you go in the world. An exclusive sailing yacht that fully meets your desires. Specially designed for the sailor who goes beyond the beaten paths and has a unique vision of the ideal yacht.

Choose the model that suits you and initiate the development process with our team and the architect. There is freedom of choice for the keeltype, deck layout and rigging. There are additional options to create the layout of the interior with a range of colours and materials available.

Explore the endless possibilities for creating your exclusive Hutting yacht. Our team of specialists is ready to advise you on these choices, based on over 45 years of knowledge and the experience of our team of Hutting sailors.

Hutting Yachts has over 45 years of experience in building custom-built aluminum sailing yachts. 55 yachts have been built from the ‘Hutting line,’ designed by Dick Koopmans senior. Read more about the Hutting 40 , 45 , 50 , the Hutting 52 by Hoek Design and the Hutting 46 Explorer.

Or discover the possibilities to create a 100% custom-built yacht here.

Our advice: schedule a viewing and step aboard various Hutting sailing yachts; each one a unique, exclusive sailing yacht. And discover the added value of a custom-built sailing yacht yourself.

“Hutting Yachts are like the Rolls Royce of the Ocean”

K. bartels – welt am sonntag.

Stay informed:

ELEVATE YOUR EXPERIENCE

BEST OF BOTH WORLDS, HYBRID SOLUTIONS, FUEL SAVINGS

This equilibrium maintains speed when needed, ensuring secure passages, optimal operational economy, unwavering reliability, and zero-fuel serenity at anchor.

The ocean connection bestows tranquility, adventure, and sustenance, fostering personal well-being and a vibrant lifestyle.

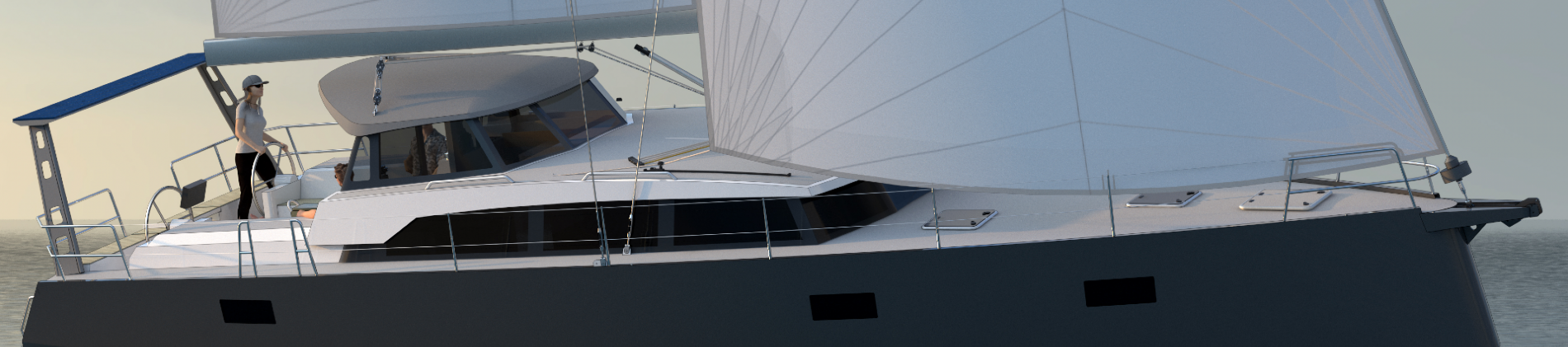

CUSTOM CATAMARAN ALUMINIUM YACHTS

Discover the ultimate in custom catamaran aluminium yachts with Cosmopolitan Yachts. Our passion for excellence shines through in every detail, from the cutting-edge hybrid diesel/electric propulsion system to the meticulous construction using top-grade materials and state-of-the-art technologies.

At Cosmopolitan Yachts, we take pride in delivering superior build quality and attention to every detail, ensuring unmatched durability, performance, and luxury. Our custom catamaran aluminium yachts are designed to excel in any environment, with marine-grade aluminium construction that provides strength, sturdiness, and resistance to corrosion for sailing in any water conditions.

Whether you’re looking for a silent electric boat or speeds of over 26 knots, our custom catamaran aluminium yachts offer ultimate flexibility in power and fuel efficiency. And with advanced hull forms and superior bow height, you’ll enjoy comfortable sailing even in seas exceeding 1.75m.

Embark on a journey of a lifetime with a custom catamaran aluminium yacht from Cosmopolitan Yachts. Let us help you bring your dream yacht to life with our superior build quality, attention to detail, and passion for excellence. Contact us today to start creating the perfect yacht for your needs and make unforgettable memories on the water.

HYBRID-ELECTRIC, HYDROGEN AND FUTURE BIOFUEL AND BIOGASES

At Cosmopolitan Yachts, we’re committed to creating custom catamaran yachts with the latest in propulsion technology. Our hybrid diesel/electric propulsion system offers ultimate flexibility in power and fuel efficiency,but we don’t stop there. We’re also exploring the use of hydrogen and biofuels as a more sustainable alternative for yacht propulsion and all our yachts are classified as “Hydrogen-Ready”. Hydrogen yachts or the use of biofuels and biogas could be the future of yachting, offering an even cleaner and more sustainable, self-sufficient energy source for powering your yacht.

Our dedication to sustainability and innovation means that we’re always looking for ways to reduce our impact on the environment while still delivering unparalleled performance and luxury. With the combined integration of the most advanced electric and hybrid technologies and, with the use of the next generation of fuels such as hydrogen, solar, biogas or biofuels,we can offer the perfect propulsion system to meet todays.

DISCOVER OUR YACHTS

New journeys await.

Discover the ultimate in durability and performance with our catamaran yacht range, designed to excel in any environment. with a robust aluminium construction and hydrid diesel/electrical propulsion system to make the most of the best technological advancements without any compromises.

THE WAY FORWARD

Equipped with either a conventional diesel or a hybrid diesel/electric propulsion system installed in both hulls, each with dual power inputs. This grants Cosmopolitan Yachts the ability to operate silently and emission-free as an electric boat at lower speeds, while still achieving speeds of over 26 knots. Complete redundancy and future proof.

A MAJOR IMPROVEMENT

To create the ultimate catamaran yacht, we have meticulously crafted every aspect with a keen eye for detail, to provide unparalleled performance and luxury. Our yachts are constructed using top-grade materials and state-of-the-art technologies, ensuring durability, comfort, and efficiency.

SUPERIORLY BUILT

The use of high-quality marine aluminium in our yachts not only provides strength and sturdiness but also ensures resistance to corrosion, making it perfect for sailing in various water conditions.

EXCEPTIONALLY DESIGNED WHIT A MAJOR IMPROVEMENT

We believe that every yacht should be a masterpiece, crafted with passion and dedication. Our commitment to quality and attention to detail is reflected in every yacht we build.

UNMATCHED COMFORT

The most spacious interiors, complete with luxurious to create an unforgettable sailing experience. The modern exterior design pays meticulous attention to every detail, including the placement of windows and other features that provide maximum comfort and offer breathtaking views of the surrounding water.

The yacht’s advanced hull form and superior bow height work in tandem to ensure comfortable sailing, even in seas exceeding 1.75m.

- KM Yachtbuilders

- The Shipyard

- - Aluminium

- - The People of KMY

- - Custom Yacht Builders

- - Design Process

- - Building Process

- The Services

- - Brokerage

- - Painting Service

- - Customer Care

- - Build Your Own Yacht

- - Bestevaer

- - Sailing Yachts

- - Motor Yachts

- - Visit the Shipyard

- - Partnerships

- - Careers (Dutch)

Home › News › How it’s made; Aluminium yachts

How it’s made; Aluminium yachts

Typical long-distance vessels are often made of aluminium and are designed for the high seas, the tropics or the Arctic Ocean. Many of these yachts are sailed for tens of thousands of miles and their structure is usually as firm as on the first day, even after hard continuous use. Why are they particularly suitable for these extreme applications?

How are they built, and what do old models look like? Ralf Weise gives us some insights.

Read the whole article here: How it’s made; Aluminium Yachts

More stories to read

Altena 53 happy hours – a successful refit by km yachtbuilders, bestevaer 36 nominated for three awards, turning dreams into reality: a yacht refit.

Yachting World

- Digital Edition

First look: Ovnicat 48 aluminium multihull

- Rupert Holmes

- April 26, 2022

The inevitable combination of both the trend for aluminium yachts and towards multihulls, the Ovnicat 48 is a new go anywhere catamaran, Rupert Holmes reports

It’s easy to assume that all rugged metal yachts are very heavy. While that was the case at one time for steel designs, it’s a different matter for aluminium which, before carbon fibre became feasible, was frequently used for competitive racing yachts and from which the Ovnicat 48 is built.

This means it was almost inevitable that two of the biggest trends in cruising yacht design – expedition yachts and multihulls – would merge at some stage. The Garcia Explocat 52 , launched late in 2020, wasn’t the company’s first aluminium catamaran, but it brought the concept to a bigger audience.

At the same time Ovni, which has built 1,500 shoal draught aluminium monohulls over the past 50 years, was also developing a multihull concept with a 48 design. The first two have already been sold, with one scheduled to launch in 2024.

We don’t yet have many details, but it looks like an enticing design by Mortain and Mavrikios, with more of an emphasis towards warm water sailing and temperate climates than the other yachts in this selection.

Despite the boat’s rugged nature, laden displacement is lower than that of most cruising catamarans of similar size, giving the promise of brisk and enjoyable sailing without the worries of a more fragile fibreglass construction.

Ovnicat 48 specifications

LOA: 14.50m / 47ft 6in Beam: 7.75m / 25ft 6in Draught: 1.35m / 4ft 5in Base price: €1,200,000 ex VAT Builder: alubat.com

If you enjoyed this….

Yachting World is the world’s leading magazine for bluewater cruisers and offshore sailors. Every month we have inspirational adventures and practical features to help you realise your sailing dreams. Build your knowledge with a subscription delivered to your door. See our latest offers and save at least 30% off the cover price.

Alubat » OVNI

ALUBATS’s experience in centreboarders and the Mortain/Mavrikios and CBA design offices reputation bring together a fantastic model in terms of comfort and performances. Upwind or downwind, on long trips or just coastal cruising, the OVNI 370 will satisfy the most demanding of skippers.

Building on our experience and expertise in blue water sailing yachts, we have collaborated with the MORTAIN & MAVRIKIOS and CBA agencies to upgrade the OVNI 400 to the OVNI 430.

The OVNI 450 is the new version of the OVNI 445, of which already 46 units have been built since the first one in 2008.

With her pilot house and her deck saloon, the OVNI 490 will take you very far on the seas.

These constructions require a great capacity for adaptation and quality finishes that the shipyard reveals in each of its units produced.

A desire? A project?

Tel. Beratung vereinbaren

Aluminium als Werkstoff

Für den Yachtbau kommen ganz unterschiedliche Materialien zum Einsatz - von Holz über Glasfaser, Carbon bis zu Stahl und Aluminium. Wir hatten die Werkstoffe schon kurz in einem Blogbeitrag vorgestellt, als wir uns während der Planung für unsere Viator Explorer 42 DS damit beschäftigt haben. Doch warum ist Aluminium der ideale Werkstoff im Yachtbau?

Leichtbau ist bei Segelyachten enorm wichtig, da nur eine leichte Yacht die verfügbare Segelfläche in gute Segeleigenschaften umsetzen kann. Ein leichtes Boot verbraucht auch bei Motorfahrt weniger Treibstoff bzw. kommt mit einem kleineren Motor aus. Über die Lebensdauer senkt Leichtbau daher auch die Betriebskosten.

Bis ca. 40 Fuss Länge hat GFK Gewichtsvorteile, da die Aluminiumbleche eine Mindeststärke brauchen, um verzugfrei geschweißt werden zu können. Aber bei größeren Yachten kann Aluminium die Vorteile ausspielen.

Aluminium wiegt etwa 35% von Stahl, benötigt aber ungefähr die 1,5 fache Blechdicke. Der verwindungsfreie und selbsttragende Aluminium-Rumpfbau führt dann im Endergebnis zu einer 29% höheren Zugfestigkeit und zu einer 12,5% höheren Dehnbarkeit im Vergleich zu Stahl. Daher ist Aluminium beim Gewicht und Festigkeit Stahl weit überlegen.

GFK hat zwar eine hohe Zug- und Bruchfestigkeit, allerdings sehr abhängig von der Faserrichtung. Eine Belastung in Querrichtung führt sehr schnell zum Bruch eines Laminats. Typische Belastungen sind Grundberührungen oder Kollisionen oder auch Stöße gegen eine Betonpier bei Wind und Welle. Es kommt dann unweigerlich zu einem Leck und Wassereinbruch.

Ein GFK-Rumpf ist zudem nicht selbsttragend, sondern erhält erst durch die Schoten eine ausreichende Steifigkeit. Dennoch wird er sich bei schwerer See immer verformen. Das "Knarzen" eines Rumpfes ist eine typische Begleiterscheinung. Oft klemmen dann auch Schränke oder Türen. Ein Aluminiumrumpf wäre auch ohne Einbauten absolut stabil und verwindungsfrei. Und natürlich gibt es kein "Knarzen".

Hier ein Beispiel von zwei ähnlichen Schadensfällen. Links der GFK-Rumpf eines Luxuskatamarans, der mit einem Riff kollidiert ist. Rechts der Rumpf einer Aluminiumyacht, die über Stunden von der Brandung auf die Steine am Strand geworfen wurde. Der Katamaran war ein Totalschaden, die Aluminiumyacht ist trotz erheblicher Verformung dicht geblieben.

Hier zum Vergleich der von einer Kollision des Ruders zerstörte Koker einer eigentlich sehr stabilen Malö 46 und der Ruderkoker unserer Viator Explorer 42 DS. Bei solchen Belastungen wird GFK immer versagen, zumal die neuesten Yachtmodelle immer weniger Material verwenden und die GFK-Rümpfe immer dünner werden.

Zum Bau einer Fahrtenyacht ist GFK daher ein völlig ungeeigneter Werkstoff, da eine Kollision oder Grundberührung in abgelegenen Gegenden sehr schnell zum Totalverlust der Yacht führen würde.

Wenn man Argumente gegen Aluminium hört, dann steht Elektrolyse bzw. galvanische Korrosion immer ganz oben. Das ist nicht unbegründet, da es in der Tat einen Aluminiumrumpf in wenigen Wochen zerstören könnte.

Eigentlich ist Aluminium korrosionsfrei, da es mit dem Sauerstoff in der Luft sehr schnell eine dünne Schicht aus Aluminiumoxid ausbildet, die das darunterliegende Aluminium schützt. Die von uns verwendete seewasserfeste Aluminiumlegierung ist zu 100% resistent gegen Salzwasser und wird auch nach Jahrzehnten keinerlei Korrosion zeigen - ganz im Gegensatz zu Stahl, der durch Seewasser komplett zerstört werden könnte. In den Marinas erkennt man Stahlyachten schon von Weiten an den Rostschlieren.

GFK ist hier eher unproblematisch, da es vom Salzwasser nicht angegriffen wird. Allerdings nimmt GFK immer Feuchtigkeit auf und das kann zu Osmose führen. Diese kann über die Jahre erhebliche Schäden im Laminat verursachen.

Doch zurück zur galvanischen Korrosion von Aluminium. Sind zwei Metalle elektrisch leitend verbunden, so wird sich das unedlere Metall langsam im Elektrolyt (bei uns eben Salzwasser) auflösen. Leider ist Aluminium ein recht unedles Metall und steht in der Oxidationsreihe unter Eisen oder Stahl. Fließt nun unbeabsichtigt ein Strom (z.B. bei einer fehlerhaften Verkabelung an Bord), so wird sich das Aluminium recht schnell zersetzen. Die Fotos unten zeigen typische "Ausblühungen" von Aluminium durch Elektrolyse (links) und den Lochfrass im Aluminiumrumpf, wenn man die Ausblühungen entfernt hat (rechts).

Dem kann man natürlich durch eine fachgerechte Elektrik vorbeugen. Der Landstromanschluß ist über einen Isolationstransformator galvanisch vom Bordstrom getrennt. Bei einem fehlerhaften Landstromanschluß kann das also keine Auswirkungen auf das Bordnetz haben. Außerdem ist ein Testschalter eingebaut, mit dem jederzeit geprüft werden kann, ob es Blindströme im Rumpf gibt, die eine galvanische Korrosion verursachen könnten. Zusätzlich schützen sog. "Opferanoden" aus Zink den Rumpf, da sich diese zuerst auflösen, bevor das Aluminium angegriffen wird.

Das Gefahrenpotential ist also beherrschbar, wenn professionell gearbeitet wird. Die zahlreichen Aluminiumyachten, die auch nach Jahrzenten noch wie neu aussehen, sind der Beweis.

Zum Vergleich noch eine typische Korrosion bei einem Stahlrumpf. Der Eigner wollte nur etwas Rost entfernen und hatte gleich ein Leck im Rumpf. Stahlrümpfe rosten von Innen und können daher bei einer Begutachtung von Aussen noch tadellos erscheinen.

Von Aussen kann sich dann nach dem Abschleifen der schadhaften Stelle ein massiver Schaden ergeben, der eine umfangreiche Sanierung notwendig macht. Oft wird so ein Rumpf nur noch durch die Lackschichten zusammen gehalten.

Auch bei GFK-Yachten kann es zu einer galvanischen Korrosion der Metallteile kommen, wenn diese elektrisch leitend verbunden sind. Bei dieser Yacht waren die Kabel der Solarpaneele am Geräteträger durchgescheuert, was den Geräteträger und die Reling unter Strom setzte. Als Folge kam es zu einer massiven galvanischen Korrosion des Edelstahls innerhalb kürzester Zeit.

Aluminium kostet zwar das Dreifache von Stahl (aktuell ca. 1500 EUR vs. 500 EUR je Tonne), was bei den 3,7 Tonnen, die wir für eine Viator Explorer 42 DS benötigen, kaum ins Gewicht fällt (auch unter Berücksichtigung der höheren Preise für die verwendete Legierung und von Blechen). Entscheidender ist aber die einfachere Verarbeitung. Die Bauteile werden automatisch geschnitten und kommen dann als "Puzzle" in die Werft. Aluminiumrümpfe lassen sich schneller schweißen und daher spart man viel (teure) Arbeitszeit ein. Der Rumpf unserer Viator Explorer 42 DS war z.B. in nur 3 Monaten fertig. Insofern ist ein Aluminiumrumpf kostenmäßig mit einem Stahlrumpf vergleichbar.

Für einen GFK-Rumpf muß zuerst eine Negativform erstellt werden. Bei einem Einzelbau lohnt das daher nicht, weil sich die hohen Kosten einer Negativform erst im Serienbau wirtschaftlich darstellen lassen.

Grundsätzlich kann gesagt werden, dass ein Aluminium-Werftbau nicht teurer als eine hochwertige GFK-Serienyacht sein muß. Allerdings bekommt man dann für das gleiche Geld eine ungleich stabilere Yacht mit einem viel besseren Werterhalt.

Wartungskosten

Aufgrund seiner Beständigkeit gegen Seewasser muß ein Aluminiumrumpf nicht lackiert werden. Im Gegenteil, ein fein geschliffener Alurumpf wird auch nach Jahren noch wie neu aussehen. Kleine Kratzer steckt er weg, da sich sofort wieder eine schützende Aluminiumoxidschicht bildet. Man spart sich also die erheblichen Kosten für eine Lackierung. Sollte es mal zu einer Beule kommen, so kann Aluminium gut repariert oder geschweißt werden.

Aluminiumyachten erfreuen sich einer steigenden Nachfrage, der allerdings eine sehr begrenzte Werftkapazität gegenüber steht. Es sind meist kleine Betriebe, die Aluminiumyachten bauen. Die Wartezeiten werden also länger, die Preise steigen. In Verbindung mit der extremen Langlebigkeit und einer hochwertigen Verarbeitung im Werftbau sowie dem sehr überschaubaren Angebot am Gebrauchtmarkt bleiben die Yachten sehr wertstabil. Der Kauf einer Aluminiumyacht ist ein Investment, zumal Bargeld in heutiger Zeit mit seinen Negativzinsen nicht mehr als Wertspeicher dienen kann. Eine gute Aluminiumyacht kann daher als Sachwert verstanden werden, der zudem noch viel Freude bereitet.

Bei den meisten GFK-Yachten sieht es durch ein extremes Überangebot eher schwierig aus. Bei einer typischen Serienyacht verliert man schon bei Unterzeichnung des Kaufvertrages ca. 30% des Wertes. Nach 5 Jahren erfährt man ca. 50% Wertverlust.

Stahlyachten sind eher unverkäuflich. Hier wird man nur über den Preis einen Liebhaber finden. Ein Grund ist eben der sehr hohe Wartungsaufwand, da es ein ständiger Kampf gegen den Rost ist. Ein anderer Grund ist die Bauqualität. Oft sind es Eigenbauten (z.B. die Reinkes), da kann man als Käufer nicht einschätzen, welcher Stahl verwendet wurde, wie die Qualität der Schweißnähte ist oder ob schon beim Bau an einen guten Rostschutz gedacht wurde. Natürlich gibt es auch sehr professionell gebaute Stahlyachten, aber das ist dann eher die Nadel im Heuhaufen. Echter Stahl-Werftbau ist sehr selten geworden und man findet ihn vielleicht noch bei Motoryachten in Holland.

Ein hochwertiger Aluminium-Werftbau hingegen behält seinen Wert. Ein gutes Beispiel mag die rote "Marlin" sein, die 2006 bei Jachtbouw Folmer geschweißt wurde - wie auch unsere "VOLT". Sie lag jahrelang im Surinam-River in Südamerika und rottete im tropischen Klima vor sich hin. Aber nach einer liebevollen Behandlung durch den neuen Eigner sieht sie jetzt wieder aus wie neu. Inzwischen steht sie zum Verkauf . Der aufgerufene Preis von 1,25 Mio. Euro dürfte etwa dem Neuwert entsprechen.

- Buying and Selling Boats

- Before You Buy: 17 Pros And Cons Of Aluminium Boats

Before You Buy: 17 Pros and Cons of Aluminium Boats

Fiberglass and aluminium (known as aluminum in North America) are two of the most commonly used materials when building boats. If you're in the market for a new vessel, you'll need to decide between the two.

What are the pros and cons of aluminium boats? And how can you tell if an aluminium boat is right for your needs?

The Pros of Aluminium Boats

We'll start by taking a look at the benefits of aluminium boats, when compared to their fiberglass counterparts:

- Lower weight. One of the biggest and most universally recognised advantages of aluminium is its low weight. When compared to the same volume of fiberglass, aluminium is 30 to 40 percent lighter. It’s also 45 to 55 percent lighter than steel , though steel is a less popular material for constructing boats. There are several reasons why it's beneficial to have a lighter boat; in addition to having an easier time towing the vessel, you'll enjoy higher fuel efficiency, so you ultimately save money on fuel. These vessels can also have smaller, lighter engines, and they can run faster, all other factors being equal.

- Overall lifespan. If you're looking for a boat that will last you as long as possible, aluminium may be the best material for you. Aluminium has an incredible tensile strength that makes it ideal for whole durability. As we'll see, it's also resistant to many forms of damage and is relatively easy to maintain. Generally, aluminium boats last longer than fiberglass boats.

- Resale value. Because aluminium is easy to maintain and capable of preserving its integrity for longer, it has a tendency to preserve its resale value better than its competing materials. If you're thinking about reselling the boat in the future, aluminium may be the best choice.

- Hull integrity and energy absorption. Are you heading to rough waters? If so, you should know that aluminium is an ideal material for absorbing energy. Compared to fiberglass, aluminium is resistant to impact and much more flexible, allowing it to prevent hull damage in even the worst conditions. As an added bonus, because aluminium is highly ductile, it's relatively easy to repair – so even if it does get damaged, the damage will be temporary.

- Easier maintenance. If you want to maintain a fiberglass boat properly, you need to wax and buff the fiberglass gel coat on the outside. If it ever suffers significant damage, you'll also need to spend an excessive amount of money on a fiberglass specialist to repair it. In contrast, you won't have to do much to maintain your aluminium boat – and repairs are relatively inexpensive.

- Solar radiation resistance. Hopefully, you'll enjoy bright, sunny days when taking your aluminium boat on the water. All materials can suffer from sun damage, but aluminium is particularly resistant when compared to fiberglass. If you overexpose your fiberglass boat to solar radiation, the gel coating can degrade – and even the hull can suffer damage.

- Recyclability (and eco friendliness). The process of creating an aluminium boat is more environmentally friendly and less resource intensive than creating a fiberglass boat. This makes aluminium an eco-friendlier option from the outset. Aluminium is also easily recyclable, meaning it can find new life if the boat is ever retired or destroyed.

- Corrosion and fire resistance. Aluminium can corrode, but it's much more corrosion resistant than other materials. Modern aluminium boats are capable of handling seawater without issue, accordingly. Aluminium is also resistant to fire, while fiberglass is highly flammable without the proper fire-retardant resins to reduce the chance of ignition. Overall, these properties make aluminium a safer choice.

- Flexible options. There are some issues with aluminium from a construction perspective, which we'll explore in the next section, but because aluminium boats are constructed from many different parts welded together, it affords boat owners significant customisability.

The Cons of Aluminium Boats

Of course, there are some downsides of aluminium boats, as no material is perfect.

- Excessive noise. Aluminium is highly durable, but this property also makes it noisier, especially during rough conditions. The sound of the metal slapping the water may interfere with your ability to relax – and scare away the fish if you're not careful.

- Unsteady handling. The lightness of aluminium is a major advantage, but it also has some drawbacks. Because there's little resistance and light weight, rides on the water tend to be bumpier and handling tends to be somewhat more difficult.

- Welding and riveting requirements. Boat manufacturers prefer fiberglass because it can be easily moulded to any shape. With aluminium, boats need to be constructed from individual parts, using intensive welding and riveting processes. This also makes aluminium boats more expensive in some cases.

- Susceptibility to corrosion (in some conditions). While aluminium is corrosion resistant, it's not totally inert. If you neglect your boat, or if you leave it in seawater for too long, it could end up experiencing corrosion.

- Anti-fouling difficulties. If you're thinking about applying anti-fouling paint to your aluminium boat, you may need to reconsider. While this coating can help your boat remain resistant to barnacles and other forms of marine life, it's also much more expensive and complicated to apply to aluminium.

- Aesthetic preferences. Some people simply prefer the look and feel of fiberglass to aluminium.

- Vulnerability to cold weather. Since aluminium is a metal, it's highly conductive. It also attracts condensation. Because of this, aluminium boats are notoriously cold during cold seasons.

- Historical perceptions. Historically, aluminium has been a cheap and unreliable material for boats. Despite the fact that modern aluminium is far superior, it still has a questionable reputation in some circles.

Whether you're looking for a fiberglass boat, an aluminium boat, or you're undecided on the matter, you've landed in the right place. At TheYachtMarket, we list thousands of vessels from all over the United States and Europe so you can find the new or used boat you've always wanted. Browse our selection today if you're ready to get started!

Share this article

You might like.

Sign up to our newsletter

By submitting this form, you agree to our Privacy & Cookie Policy

Change units of measure

This feature requires cookies to be enabled on your browser.

Show price in:

Show lengths, beam and draft in:

Show displacement or weight in:

Show capacity or volume in:

Show speed in:

Show distance in:

IMAGES

VIDEO

COMMENTS

Brought to you by KM Yachtbuilders, the leading builder of aluminium expedition yachts up to 100ft. Learn more. We are KM Yachtbuilders . We build aluminium yachts. Starting out with three people and about as many yachts. A few decades later we are a team of 45 with more than 100 builds under our belt and our yachts are sailing the seven seas ...

Explore Bestevaer yachts. Designed by one of the world's most legendary sailors as his private yacht. Brought to you by KM Yachtbuilders. We make custom aluminum sailing yachts and aluminum motor yachts: lightweight, strong, stiff, low maintenance and infinitely customisable.

Welcome to Hutting Yachts. Since 1975 Hutting Yachts has stood for quality, craftsmanship and performance that has come from a passion for sailing and yacht building. Start to find your exclusive aluminum sailing yacht, meticulously crafted according to your preferences within our semi-custom range, with sizes up to 55 feet.

Vanquish yachts are mostly used on blue water so the safety of owners and their guests is central to everything we do at Vanquish. Aluminium has a far better strength/weight ratio than the vast majority of shipbuilding materials and is very difficult to deform. Moreover, the effects of any impact on an aluminium hull are only felt locally, with ...

OVNI 430. Since 1973, ALUBAT have been designing, building and commercializing 100% aluminium boats for blue water sailing. 100% aluminium means that the hull, the deck, the coachroof and the cockpit are all made in aluminium. Everything is welded together with an inside and outside weld, because your safety is priceless.

We are known the world over for our custom build aluminium sailing yachts. Home › Your Yacht › Sailing yachts. About our sailing yachts From the arctic or mediterranean seas to the pacific and the atlantic oceans as well as closer to our home on the IJsselmeer. Our yachts are found all over the world.

Explore Bestevaer yachts. Designed by one of the world's most legendary sailors as his private yacht. Brought to you by KM Yachtbuilders. We are a Dutch shipyard with aluminum yachts. Experience, expertise and an eye for detail are what make all the difference in yacht building.

welcome, Welcome to the website of Jachtbouw Folmer, a dutch shipbuilder with more than 30 years of experience in yacht building. We specialize in custom designed aluminum sailing yachts between 30 and 60ft. We also build motor yachts or parts for luxury super yachts, such as chimneys, helicopter decks and radar masts.

Hutting Yachts has over 45 years of experience in building custom-built aluminum sailing yachts. 55 yachts have been built from the 'Hutting line,' designed by Dick Koopmans senior. Read more about the Hutting 40, 45, 50, the Hutting 52 by Hoek Design and the Hutting 46 Explorer.

Whether you're looking for a silent electric boat or speeds of over 26 knots, our custom catamaran aluminium yachts offer ultimate flexibility in power and fuel efficiency. And with advanced hull forms and superior bow height, you'll enjoy comfortable sailing even in seas exceeding 1.75m. Embark on a journey of a lifetime with a custom ...

Continuing with our project to build a custom aluminum boat, we begin a feasibility study with KM Yachtbuilders in the Netherlands by going through a series ...

How it's made; Aluminium yachts. Typical long-distance vessels are often made of aluminium and are designed for the high seas, the tropics or the Arctic Ocean. Many of these yachts are sailed for tens of thousands of miles and their structure is usually as firm as on the first day, even after hard continuous use. ...

The inevitable combination of both the trend for aluminium yachts and towards multihulls, the Ovnicat 48 is a new go anywhere catamaran, Rupert Holmes reports ... which has built 1,500 shoal ...

Sailboats The Garcia Exploration range brilliantly renews the concept of the aluminium centreboarder monohulls with pilot saloon, allowing you to explore ever new horizons. The Garcia Exploration range. Nowhere you can't go. Aluminium centreboarder sailboats with deck saloon, as robust as they are comfortable

Garcia Yachts is a French shipyard building high-end blue water cruising aluminum sailing boats, monohulls or catamaran, from 45 to 60 feet.

Allures Yachting is a French shipyard specializing in the construction of blue water cruising aluminum sailing boats using a centreboard.

OVNI 650. These constructions require a great capacity for adaptation and quality finishes that the shipyard reveals in each of its units produced. OVNI - "THE" lifting keel aluminium yacht. OVNIs have been designed for experienced, demanding customers keeping in mind that they are built for intensive use. They are the ideal boats for ...

Aluminium im Yachtbau - der perfekte Werkstoff. Beim Bau einer hochwertigen Yacht hat die Wahl des richtigen Werkstoffs eine entscheidende Bedeutung. Wir erklären die Unterschiede.

2024 Veranda 22 Vista Biew RC. Find Aluminum boats for sale in your area & across the world on YachtWorld. Offering the best selection of boats to choose from.

Conrad Shipyard. - Poland, company Conrad S.A. Boat models/ranges: Conrad. Manufacturer: powerboats (sailing yachts/cabin boats, luxury sailing yachts (> 20 m), aluminium sailboats), (motor yachts/cabin boats, luxury motor yachts (> 20 m), aluminium boats) built since 1989. » Conrad Shipyard boats for sale. » Boat builder web.

2022 Custom 21 m Aluminum Sailing Catamaran. US$3,602,852. YMB YACHTING LLC | Limasol, Cyprus. Request Info. <. 1. >. * Price displayed is based on today's currency conversion rate of the listed sales price. Boats Group does not guarantee the accuracy of conversion rates and rates may differ than those provided by financial institutions at the ...

Lower weight. One of the biggest and most universally recognised advantages of aluminium is its low weight. When compared to the same volume of fiberglass, aluminium is 30 to 40 percent lighter. It's also 45 to 55 percent lighter than steel, though steel is a less popular material for constructing boats.