7 Best Sailboat Watermakers For Liveaboards 2024

If you’re a liveaboard sailor looking for the best sailboat watermaker then you’ve come to the right place. In this blog post, we’ll take a look at some of the best watermakers on the market and show you how they can help make your sailing experience more enjoyable.

There’s nothing quite like the freedom of sailing on the open water. If you’re a liveaboard sailor, though, you know that keeping your boat stocked with fresh water can be a challenge. That’s where sailboat watermakers come in handy.

Not only do they produce fresh water for drinking and cooking, but they also help keep your boat clean by providing water for showers and dishes.

In this blog post, we’ll take a look at the best sailboat watermakers available on the market today. We’ll discuss the pros and cons of each model so that you can make an informed decision before purchasing one for your boat.

So, whether you’re looking for a compact unit that is easy to install or a high-performance model that can handle large volumes of water, we have something for you. Keep reading to learn more.

How do marine watermakers work?

What are the benefits of having a watermaker on your sailboat.

- How do I choose a sailboat watermaker?

How big a water maker do I need?

How much does a sailboat watermaker cost, how much power does a watermaker use, how much space does a marine watermaker take up, maintaining your sailboat watermaker, the best sailboat watermakers for liveaboards.

As an Amazon Associate, we earn from qualifying purchases. We also earn from other affiliate programs. This means we may receive a small commission on products purchased through our links at no extra cost to you.

Marine watermakers are devices that convert salt water into fresh water, making them an essential tool for sailors and boaters. But how do they work?

At the heart of every marine watermaker is a reverse osmosis membrane. This is a thin, semi-permeable film that allows water molecules to pass through, but blocks out larger molecules like salt.

To create freshwater, salt water is forced through the membrane under high pressure. This process is known as reverse osmosis, and it leaves the salt behind in the brine stream. The freshwater that comes out of the other side is then collected and stored in tanks.

Marine watermakers are powered by either electricity or a diesel engine, depending on the size of the unit. Some small portable units can even be powered by a car battery.

You will probably want a pretty decent battery bank and solar or wind setup to power your watermaker. By far the easiest solution is to get a reliable, drop in battery. We highly recommend BattleBorn’s lithium batteries which is what we use to power our watermaker.

⚡ Check out BattleBorn batteries here

If you’re thinking of outfitting your sailboat with a watermaker, you’re in for a treat. Adam and I put off buying one for two years, as we weren’t sure it would be worth the big investment. But after a year in the Cyclades where finding free town quays with water was near impossible, we decided to bite the bullet and commit.

It’s the one thing we wish we’d done sooner. A sailboat watermaker has literally changed our lives at sea and we couldn’t be without one now.

Not only will you have a reliable source of fresh water, but you’ll also be able to enjoy extended stays at sea. Here are just a few of the benefits we’ve found of having a watermaker on your sailboat:

Perhaps the most obvious benefit of having a marine watermaker is that you’ll never have to worry about running out of fresh water. Whether you’re sailing around the world or just spending a few weeks cruising the coast, a watermaker will give you the peace of mind that comes with knowing you have an unlimited supply of fresh water.

Obviously, fresh drinking water from the watermaker is great, but it also means we don’t worry about taking a shower or the huge amounts of washing up caused by certain meals or having people over for dinner!

In addition to providing an endless supply of fresh water, a watermaker can also help extend your cruising range. By making your own water, you won’t have to make as many stops to restock your tanks. This means you can stay out on the open water for longer periods of time and explore more distant ports. It also saves a lot of money on marinas and a lot of trips to beach showers!

Finally, having a watermaker onboard can be a real lifesaver in an emergency. If your boat is disabled and you’re stuck at sea, having a way to make fresh water can mean the difference between life and death.

How do I choose the best sailboat watermaker?

There are a few things to keep in mind when choosing a watermaker for your sailboat. There is no one size fits all when it comes to choosing the perfect watermaker for you, so take some time to read the pros and cons of each model before you commit!

If you’re just cruising around the local waterways, you can get away with a smaller unit and top up your tanks with water from the dockside. But if you’re planning on venturing out into the open ocean, you’ll need a larger unit that can produce more water.

You’ll want to take into consideration the amount of people you’re likely to have onboard. Adam and I find out Rainman naked 12V system keeps up with our needs just fine, but after taking on two more members of crew we quickly ran out of water and struggled to keep up with the new demand.

You should also track your water usage habits for a bit to see how much water you use on a daily basis. If you can’t live without daily long showers, or you need fresh water to wash down the boat regularly, or you have fresh water flushing toilets then you’ll obviously be using a lot more water than others.

The amount of water you use when you have a watermaker is likely to increase a little from your needs now, as you’ll be a little less careful with it. Factor this into your decision!

Like everything in sailing, you can spend as much or as little as you want on a watermaker. There are even some people who have successfully made their own watermaker and only spent money on the parts (some of which you can source second-hand).

If you aren’t a wizard with things like that though, you’re going to be looking at spending a decent amount of money on a sailboat watermaker. On average, they cost around £3000-£5000 for a watermaker for a cruising sailboat (around 40ft).

You can spend more like £10,000 on a watermaker for a larger boat, and you can spend less on a second-hand marine watermaker or a DIY one.

We’ve put together a guide to help you work out your needs based on what you use aboard.

Different brands of watermakers are more efficient than others, but from our own experience and that of others we’ve talked to, it takes around 10 Watt-hours to make a litre of water – i.e. about 0.8 Amp-hours from a 12-volt battery.

Things like the chemistry of your battery bank, the length of your cable runs, and even the temperature of the sea, can all make a difference to the amount of power you’ll need to make a certain amount of water, but this is a rough average.

We’ve got a guide on working out how much power you’ll need.

A marine watermaker is a very useful tool, but it’s not exactly small. In fact, depending on the model, a watermaker can take up quite a bit of space.

The average unit is about the size of a small freezer, and some models are even larger. Given that most boats are fairly limited in terms of space, this can be a bit of a problem.

The good news is that there are now several manufacturers who offer compact watermakers that are designed to take up less space. These units are often smaller than a standard coffee maker, making them much easier to find a spot for on your boat.

We’ve included some great options for smaller boats below.

Like any piece of equipment, a watermaker requires regular maintenance. Fortunately, there are some simple steps that you can take to keep your watermaker in good working condition.

First, be sure to check the filters on a regular basis. Not only will this help to ensure that your water is clean, but it will also help to prolong the life of your watermaker.

Second, be sure to check the seals and o-rings for leaks. These are essential for keeping your watermaker operating efficiently, and any leaks can lead to costly repairs.

Finally, be sure to perform a yearly “spring cleaning” by flushing the system with fresh water.

By following these simple tips, you can keep your watermaker in good working order for years to come.

You should also account for the fact that parts are bound to break and need fixing or replacing. Most watermakers come with proprietary parts which make them a pain to fix in remote places, but there are a few that take non-proprietary parts. We would recommend these to anyone planning a larger cruising ground.

#1 Rainman naked 12V Marine Watermaker

The Rainman naked 12V watermaker is a great option for anyone looking for a compact, efficient way to produce fresh water.

The unit is simple to set up and use, and it produces up to 30 litres of fresh water per hour for a smaller unit, or up to 140 litres per hour for a larger one.

One of the main reasons we were drawn to Rainman watermakers is that they use all off-the-shelf, standardised parts. If your Rainman breaks down, it almost doesn’t matter where in the world you are – you’ll likely be able to get standardised spares in the nearest major city. For any liveaboards hoping to circumnavigate this should be an important consideration.

Installation was really very straightforward. End-to-end it took two days to install and test the unit, plus an extra day to get the autoflush set up.

We were pleasantly surprised to find that the unit came with almost everything we needed to install it. We were expecting to supply our own hoses, sundries, etc. but Rainman supplies everything you need.

Whether you’re sailing around the world or just weekends on the lake, the Rainman naked 12V watermaker is a great way to ensure you have access to fresh, clean water.

Check out our full Rainman watermaker review for everything you need to know.

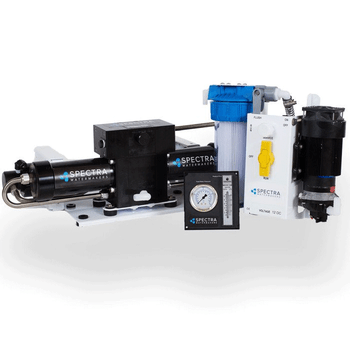

#2 Spectra Newport 400c Watermakers for Sailboats

Spectra watermakers have an excellent reputation among the sailing community and you can’t go wrong with one of their marine watermakers for your sailboat.

They make a range of different sailboat watermakers to suit different needs and sizes of boat, from hand-operated desalinators that can make 6 gallons a day to their largest system that produces 20,000 gallons of fresh drinking water per day.

The Newport 400c model operates on as little as 4 watts per liter, so you can run it on a small generator, solar, wind, or even just straight off the batteries. It’s a great option

The Spectra Connect system means you can operate and monitor your watermaker from a remote device, and it has lots of other clever features including a fill tank mode and suggested maintenance intervals.

You can choose the speed operation on this sailboat watermaker for maximum flow or maximum efficiency depending on your power management onboard. This is a great ‘all bells and whistles’ watermaker that takes the guesswork out.

#3 Spectra watermaker Ventura Series

As with the Newport 400c, Spectra ensure these watermakers are built to last and they have a really great reputation.

The Spectra watermaker Ventura series is designed to be energy-efficient and lightweight and is the perfect watermaker for smaller spaces.

It produces 24 litres an hour, which is less than the Rainman model but still enough for a couple living aboard a small sailboat if you’re conservative with water usage.

You can also opt for a warm water model that will produce slightly more water per hour and is the same size (but you’ll need to be sure your cruising area is only warm water!)

#4 The Ultra Whisper

The Ultra Whisper by Sea Recovery is one of the best watermakers out there for smaller boats, or boats not set up with adequate power to run one of the larger units.

It can run on either AC or DC and claims a 75% reduction in power consumption compared to the other products listed here. It’s also super quiet, which if you’ve run a watermaker before, is actually a huge bonus!

This is a small but perfectly formed piece of equipment that will enable you to make water with the smallest power setup, but obviously, on the downside, you won’t produce as much water so you’ll need to be careful with your consumption onboard.

Sea Recovery has more watermaker models on offer in a wide variety of size and capacity options. There’s even a really tiny version that measures only 2-3 cubic feet for sailboats that can’t compromise on space.

#5 Village Marine – Little Wonder series

Village Marine is another of the most popular marine watermaker brands and has a reputation for making reliable and efficient sailboat watermakers in a range of different models to suit different needs.

The Little Wonder series is one of the smallest (the reason for the name) and weighs only 69 pounds with the ability to produce 180 gallons of freshwater per day.

It has a low RPM high-pressure pump in a modular design, which means you can install it in different parts of the boat to maximise your space. This is really handy for smaller sailboats.

Installation is quick and easy, and a competent DIYer can do it. It is anti-corrosive and as a bonus, is also quiet to run!

This is one of the best watermakers on the market for smaller sailboats, and should last a long, long time.

#6 Village Marine – LW Watermaker Series for bigger boats

For anyone out there looking for a serious sailboat watermaker for a bigger boat, Village Marine has something suitable. The LW watermaker series caters to boats up to 100 feet in length.

This watermaker can produce up to 1800 gallons of freshwater a day, which is a crazy amount and will give you complete water independence on board.

It’s a much larger unit, obviously, so you’ll need to make sure you have space on board. It’s also a lot more expensive so it really is only suitable for larger boats and commercial vessels.

#7 Rainman Portable Sailboat Watermaker

Rainman make a portable watermaker that has many benefits over an installed version. it won’t suit all sailboats but it’s a great option to have for the following reasons.

- You don’t need to install the system. You can cut out a lot of the faff and make fresh drinking water within minutes of receiving the product.

- You don’t need any extra holes in your hull to use the watermaker.

- If you race your sailboat you can store the watermaker ashore to save on weight.

- It’s a great option for smaller sailboats as it can be moved to accommodate for extra guests.

- You can take it with you from boat to boat.

- You can share the watermaker and potentially the cost!

- You can use it for all your trips away from water supplies. Take it on road trips, fishing trips etc.

A portable sailboat watermaker might make a lot more sense for your needs, and it’s great to have the option to choose between the two. This watermaker comes with all the benefits of the Rainman installed version, so you can check out our Rainman review to help with your decision.

Conclusion for the best sailboat watermakers

If you’re in the market for a watermaker, we hope our review has helped you narrow down your choices. We believe that the best sailboat watermakers are those that are reliable, powerful enough for your needs, and easy to maintain. So if you’re looking for an efficient and durable watermaker, be sure to check out the options on this list.

If you’re looking for more liveaboard tips or want help with planning your move onto a boat then check out our ‘ How to run away to sea ‘ guidebook for everything you could possibly need to know about living on the ocean.

Similar Posts

How Much Do Sailboats Cost 2024? The Average Prices

Gill OS2 Jacket Review: Tried And Tested Offshore Gear 2024

12 Tips For Restoring an Old Boat: Costs, Time, And Expert Advice

7 Large Cockpit Sailboats: When Size Matters

What Is A Catamaran? All Your Questions Answered 2024

Liveaboard Marinas: What’s It Like To Live In A Marina

- Search Search Hi! We’re Emily, Adam and Tiny Cat, liveaboard sailors travelling the world on our 38ft sailboat and writing about it as we go. We hope we can inspire you to live the life you’ve always dreamed, whether that’s exploring the world or living a more simple way of life in a tiny home. Find out more. Patreon

- Privacy Policy

Yachting Monthly

- Digital edition

Everything you need to know about watermakers

- February 24, 2023

An onboard watermaker will free you from ever worrying again about where your next freshwater stop will be. Andy Pag looks at the latest models available for your yacht

The feeling of autonomy that a watermaker gives a yacht is unique. It transforms that weekend-only cruiser into a go-anywhere, life-on-the-hook, adventure craft, breaking the tether to marinas.

Filling your water tanks at the fuel jetty will always be a cheaper alternative to the eye-watering cost of buying and installing a watermaker, but there will be times when your plans are limited by having no access to a tap or if the only source available doesn’t look particularly appetising. And in the event of a burst pipe or accidentally draining your tank mid-passage, it means you’ll be able to keep sailing at the flick of a switch, rather than having to reroute to refill.

Watermaker desalination process

Watermakers – technically known as desalination units – use a process called reverse osmosis (RO) to make drinking water. By forcing salty water at a high pressure against one side of an RO membrane, fresh water will slowly seep through, leaving the salt and bacteria behind. The output is notably devoid of minerals, but the taste can be a little strange at first. Think of the membrane as a filter so fine that even bacteria and salt molecules can’t get through it.

But as well as the pressure, a membrane also needs to have the water flowing over it to flush away all the stuff that didn’t pass through as it would otherwise block the membrane’s pores. In this way it’s different to a filter because a membrane has a salty inlet, a freshwater output, and a saltier discharge outlet.

Much of the cooking done onboard needs fresh water. Photo: Tor Johnson

High pressure pumps

Creating high-pressure water, which is also flowing at speed, takes a lot of energy, and there are two methods watermakers use to achieve this. One is simple: a high-pressure pump. This can draw a lot of current but it creates the speed of flow needed, and the forceful pressure too. The saltwater is directed to the membranes and the pressure is created by closing down a tap, called a needle valve, at the discharge to build up pressure on the membrane while still allowing water to flow out through the needle valve at the required speed.

High-pressure pump watermakers are fast, but they aren’t the most energy- efficient way of creating clean water. They are usually tuned to produce 60 litres per hour or more but can draw upwards of 500W and while there are 12V versions, they typically use mains voltage pumps and are better suited to being run from a generator than a battery bank.

They’re designed to fill your tanks quickly so you don’t have to run the generator for long. Mechanically, they’re simple, and apart from the high-pressure pump there are no moving parts to go wrong.

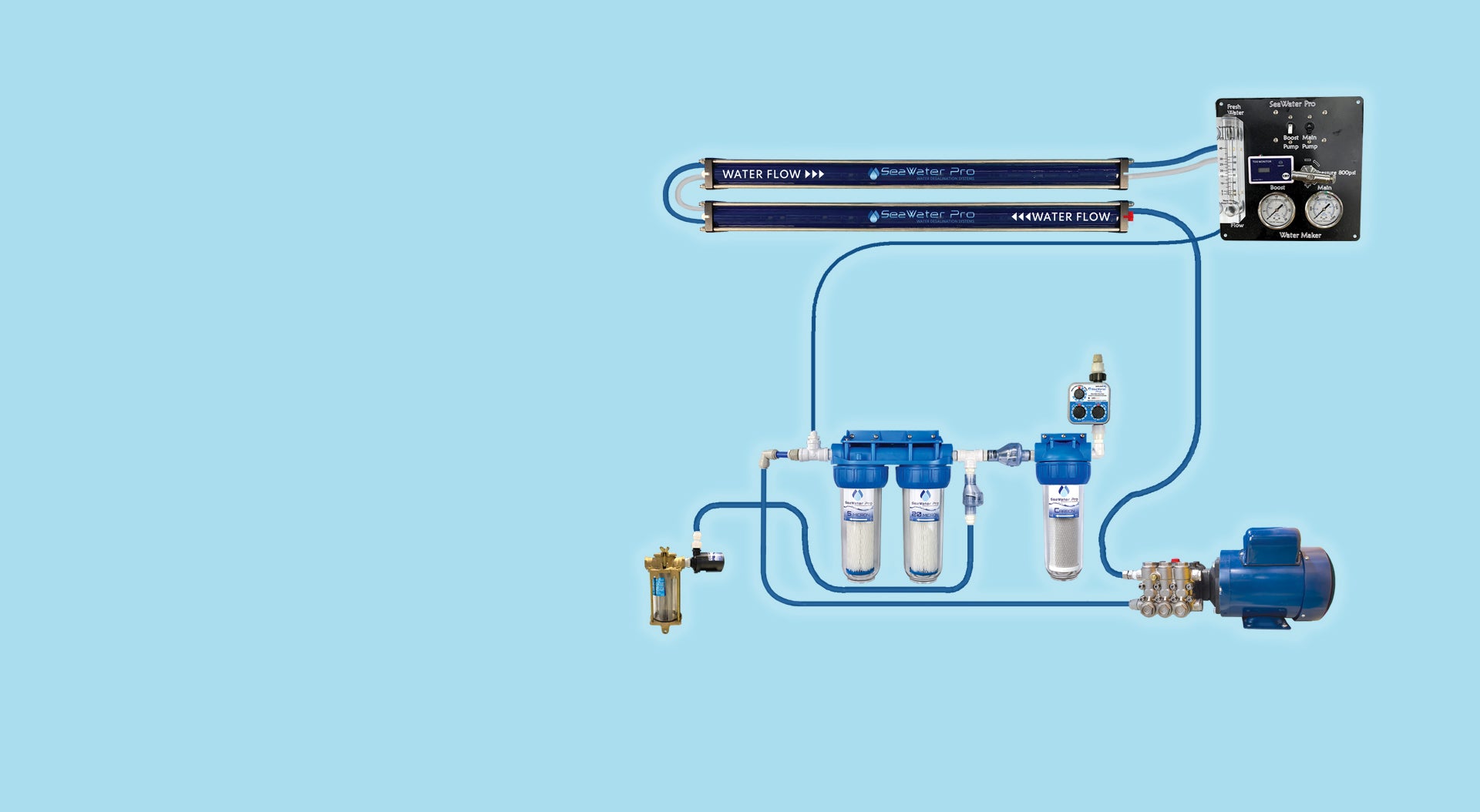

A watermaker and its many parts.

Energy recovery

The alternative method is a Clark pump watermaker, also known as an energy recovery device (ERD). This uses a fast-running but much lower-pressure pump which needs less power. To obtain the high pressure required, the pressure in the discharge water is harnessed by a couple of reciprocating pistons and used to boost the inlet pressure. It takes a few minutes to build up pressure and during that time the output is slow and not very clean.

Watermaker running costs

An ERD unit will typically produce 20-60 litres per hour. The lower demand on the pump means it can be reasonably powered by 12V with as little as 9A, and can produce a litre of water with just 4-5Wh of energy. High-pressure units need between two and three times that energy per litre. If you run your boat from solar panels or don’t have a generator, this is the type of watermaker to go for.

Devoid of minerals, the taste can be a little strange at first

In fact, your boat’s power source is the first thing to look at when considering which type of watermaker to get. But it’s also worth remembering that the extra complexity of ERD units make them expensive to buy and more prone to breakdowns.

When choosing an ERD watermaker it’s therefore really important to consider the availability and costs of spare parts because sooner or later they will need servicing.

Most manufacturers have a dealer network that can provide advice, but don’t count on them stocking parts or offering servicing. These machines are notoriously fiddly to repair, and one dealer told me discreetly it’s not financially viable for him to offer a repair service as the time it takes can spiral into hours. That leaves you with the option to send the machine back to the manufacturer at great expense, or do it yourself.

Article continues below…

How it works: The diesel engine: The 4-stroke cycle

Understanding how your diesel engine works is key to knowing how to look after it, and fix it when it…

How it works: Looking after fuel: diesel, hoses and filters

Looking after fuel is essential for keeping your engine running smoothly. Callum Smedley shares his top tips

After-sales service

Spectra has one of the best reputations for after-sales service. In most places you’re more likely to find Spectra and Schenker dealers, but that doesn’t guarantee they’ll have parts in stock, and all manufacturers will ship parts to you. Spectra also offers rebuild kits which come with step-by-step instructions and special tools to get to those hard-to-reach O-rings. They feel like a lot of money for a bag of O-rings, but are a cheaper option than sending the unit back to the factory.

If you’re buying new, a warranty is highly valuable but once it runs out you’ll find out how pricey the parts really are. Some manufacturers give longer warranties if a certified technician installs the system.

Most ERD units are made out of engineering plastics such as Delrin which can split around fittings if over-tightened or if warm water is used during cleaning.

One leading UK dealer who sells all brands told me that since Spectra changed the type of plastic used a few years ago he’s had no returns, unlike rival brands. Spectra were tight-lipped on the material they use when Yachting Monthly asked them for details.

An average-sized watermaker will easily squeeze into the space under a bunk

Watermaker instillation tips

A bad installation can render a good machine useless, so there are a few key points to know. Use dedicated through-hulls for the saltwater intake and brine discharge. Make sure the intake is low enough that it won’t be exposed when heeling or in big waves to prevent air bubbles entering the system. Don’t install the intake where there will be turbulent flow, behind the keel, for example, or near the props and rudders. The discharge should be above the waterline.

To give the pump the best chance of producing the pressure needed, install it as low as possible in the boat. Follow the manufacturer’s recommendations on hose diameters and avoid long hose runs and tight turns that restrict flow.

Finally, use correctly sized wiring as the 12V pumps will underperform if there are voltage losses in the wiring.

Monitoring quality

A Total Dissolved Solids (TDS) meter measuring impurities in the output water coupled to a diverter valve can automatically protect the purity of your tank. Anything under 500ppm is fine to drink but a well-installed system should deliver 200-300ppm.

You can buy inline TDS meters, or stick meters that you dunk into a sample cup to monitor it manually. You’ll see it slipping over time if there’s a problem developing with the pump or membrane.

It’s important to flush or ‘pickle’ your watermaker if you decide to not use it for any period of time

Membrane care

The membranes will produce more output and cleaner output in warmer and less salty seas. For the best lifespan, use them every few days. Drying them out, or running chlorinated water through them will do irreparable damage.

According to Dupont, which makes the widely used Filmtec membranes, they should not be left unused for more than 24 hours, but in practice they can be left for around five days before organic growth risks building up on the membrane, which blocks it and reduces performance. This can sometimes be remedied with an alkaline flush if caught early.

The other thing that can block them is carbonate deposits. In this case, an acid flush will restore some of the membrane’s performance.

If idle for a few days, it’s worth flushing the membrane with fresh water. Some manufacturers recommend doing this after every use, but that’s to protect other components in their systems.

If the machine is going to go unused during the off-season, the membrane can be pickled in propylene glycol. Most manufacturers offer branded pickling solutions and restorative solutions which conform to their warranty and don’t react with other materials in the system.

Avoid using the watermaker in anchorages where other boats aren’t using holding tanks. Although the membrane will sift out e.coli, the pre-filters will become a nasty Petri dish of bacteria.

Pickling tablets will be less aggressive on internal metal components

Don’t leave me this way

Different manufacturers have different recommendations, but, as a general guide, here’s what to do if leaving your watermaker unused for any period of time.

1-5 days: In practice, leaving the membrane sitting in saltwater won’t do too much harm, even though the membrane manufacturer warns against more than 24 hours. Check your watermaker manufacturer’s recommendation though. For instance, Spectras suffer from dramatic internal electrolysis if left soaking in sea water.

1-2 weeks: Definitely flush it through with fresh unchlorinated water. Use a carbon filter to remove chlorine if you are flushing with tap water.

More than a month: Pickle it.

They used to recommend using acid (hence the term pickling) but now manufacturers recommend propylene glycol, which is less aggressive on O-rings and other metal components. Buying the branded solution for your machine will give you peace of mind.

If your boat lives in relatively clean water, think about setting a timer so the machine runs automatically every few days for 10-15 minutes. That’s long enough to flush the membrane and prevent organic build-up.

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

Sailboat Watermakers

It is not uncommon for people that want to take part in the sailing lifestyle to spend a lot of time out at sea. Since these boats are powered by renewable energy sources, they do not have the limitations of boats powered by fossil fuels. However, if a sailor is going to be out at sea for an extended period of time, they are going to need desalination appliances. Desalination is the process of making salt water drinkable. If you are looking for a sailboat watermaker, our marine desalination systems are the best option for you. Continue reading below to learn more from our experienced professionals.

What Are the Best Watermakers for Sailboats?

Sailboats come in many shapes and sizes, which means that there is no one correct sailboat desalinator for sale. In fact, when choosing a watermaker for your sailboat, consider factors such as capacity, energy efficiency, ease of installation and maintenance, and compatibility with your boat’s electrical system. It’s also important to choose a reliable and reputable brand like ECHOTec Watermakers with a good track record of customer support and service. Some of our most popular options for sailboat watermakers include the following:

- 12/24v DC Economy Watermakers

- 12 – 180v DC Watermakers

- Belt-Driven DC Watermakers (Modular)

- 115/230v AC Economy Watermakers

What Are the Benefits of Desalinators for Sailboats?

If you are wondering what exactly the benefits of using desalinators for sailors are, we are here to answer your questions. These include the self-sufficiency it would give sailors that want to take part in the liveaboard lifestyle. Our products are designed to be as easy to use and convenient as possible. Perhaps one of the most pertinent benefits of using a desalinator of this kind is that it provides a virtually unlimited supply of water. On the other hand, sailors that do not have a watermaker will need to rely on buying bottled water whenever they run out. This allows them to enjoy sailing without having to go to shore to buy new bottled water. Even if the person aboard the sailboat is not exactly living on the sailboat, a watermaker for yachts or sailboats maximizes the amount of time that sailors spend on the water.

How Does Sailboat Desalination Work?

The way that a watermaker works is quite interesting. The steps are the following:

- Seawater is taken in from the ocean through a pump or gravity system.

- The seawater is passed through a pre-filter to remove large particles such as sand, sediment, and other debris.

- The seawater is passed through a high-pressure pump where it passes through the RO membrane.

- The RO membrane allows water molecules to pass through while blocking salt and other contaminants. The resulting fresh water is collected on one side of the membrane, while the concentrated brine solution is discarded on the other side.

More About ECHOTec Watermakers

ECHOTec Watermakers is one of the top suppliers of boat watermakers and desalination systems. Our full selection of products includes both onboard watermakers and on-shore watermakers, and home desalination systems. If you are interested in purchasing one of these products, do not hesitate to contact our watermaker for boats supplier to learn more about what we could offer you today when it comes to sailboat watermakers.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Ericson 34-2 Finds Sweet Spot

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Solar Panels: Go Rigid If You have the Space…

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Belowdecks & Amenities

- Marine Electronics

- Systems & Propulsion

Test of Six 12-volt Watermakers

While at first blush all appear about the same size, we find important differences in output and current consumption. the spectra 180 is amazingly efficient but expensive. of the six, village marine tec's little wonder seems the most tried and true..

Last month we took an overview of the pros and cons of 12-volt watermakers. This month, we look at high-output machines from five manufacturers, ranging from systems from industry giants such as Village Marine to small shops such as SK Engineering. All of the watermakers we looked at were production models, although the Spectra 180 we tested had been re-configured to serve as a demonstration model.

As we began our market survey and field testing, we discovered that a number of other manufacturers are jumping into the fray, realizing that 12-volt watermakers constitute a small but growing segment of the market. Most notable among these new players is HRO-another industry giant-which has been promising a state-of-the-art, computer-controlled, self-contained 12-volt watermaker for more than a year. We saw the literature a year ago at the Miami Boat Show. We saw a non-operational mockup last fall at the Southampton, England boat show. We have yet to see a functional machine in the flesh.

With the assistance of Andy Cortvriend of Ocean Link, a knowledgable Portsmouth, Rhode Island, marine servicing company, we tested product output, water quality, and electrical consumption of all the watermakers. Electrical consumption was measured with a Cruising Equipment amp-hour meter, using gel cell batteries maintained at full capacity by a Heart inverter/charger between tests.

Saltwater was pulled from lower Narragansett Bay into a large storage tank maintained at a constant temperature during the tests. The waters at our Little Harbor test facility are not as clean as open ocean waters, but are closer to the reality of the watermaking most cruisers will experience. This was not a pure laboratory test with manufactured sea water of exactly the right total dissolved solids (TDS).

We then examined each machine carefully on the bench, looking for weak points, strong points, potential installation or maintenance hang-ups, and general quality of construction.

The quality of output water was tested with a TDS meter and all machines easily met standards for potability.

The real test of any watermaker is how it performs over time-not just months, but years. Because maintenance is a key factor in longevity and trouble-free operation, the owner/operator will bear a large portion of the responsibility for the long-term success of any watermaker installation.

Here are our findings.

Village Marine Little Wonder When Village Marine Tecs Little Wonder was introduced almost a decade ago, it was the first 12-volt watermaker that actually had the capacity to supply the water needs of a medium-sized cruising sailboat without almost continual running. More than 1,500 of these compact, well-made machines have been produced, and there have been virtually no changes to the design or components over the entire production run.

Both 12-volt and 24-volt models are available, with the higher voltage model producing slightly more product flow.

The standard model is totally self-contained in a well-designed package, with all components bolted to a heavy aluminum chassis, topped off with a removable aluminum cover. Mounting requires drilling through the chassis for suitable through-bolts.

The three plumbing connections-feed water, product water, and brine discharge-are pre-plumbed through one end of the case. The wiring junction box also contains connections for an optional feed water boost pump, and an internal 25-amp breaker to protect the electrics.

Although the package is tightly plumbed, there is reasonable space between components for service.

Power for the high-pressure pump is provided by a continuous-duty 1/4-hp. Pacific Scientific motor, rated at 21.5 amps at full power. The motor is connected to the high-pressure pump by a lightweight cogged belt.

The heart of the Little Wonder is its proprietary high-pressure pump, specially made by Village Marine for this machine. It features a titanium pump head with ceramic plunger-a combination which should be corrosion-proof for the life of the watermaker. All wetted parts in the pump are titanium, type 316 stainless steel, or ceramic. High-pressure plumbing and connectors are type 316 stainless.

Monitoring includes a high-pressure gauge and product flow gauge. System pressure can be adjusted if necessary using an open-end wrench, although the factory pre-set pressure of 800 psi should be correct for most watermaking situations. The pressure regulator is a high-quality regulator, rather than the more commonly seen needle-valve adjuster.

The fiberglass pressure vessel and the standard-sized 2521 membrane are both manufactured by Village Marine, although they are industry-standard in size.

In our tests, the Little Wonder produced a product flow of 5.8 gph at 13 volts, drawing 16.7 amps-about 37.4 watts per gallon. This does not include the 1-amp current draw of the small optional booster pump, which is required for above-the-waterline installations, long feed water runs, or installations containing multiple pre-filters.

The water produced by the machine we tested was very high quality. The noise level of 79 dB, with the cover removed, was louder than the two quietest machines tested, but was not loud enough to be objectionable.

The self-contained unit is 25.5″ long, 11″ wide, and 9.25″ high, and requires a slightly larger mounting space to accommodate plumbing connections and allow access for removal of fastenings holding the cover. For tight installations, a modular version is available, which does away with the mounting chassis and uses flexible high-pressure hoses rather than rigid stainless steel tubing. Obviously, installation of the modular unit requires slightly more time, but offers a lot of flexibility-very desirable in field installations aboard the typical cruising sailboat, in which locker or shelf space is at a premium.

Documentation is excellent, with a 35-page manual covering installation, operation and maintenance.

The warranty is somewhat complex. The membrane has a three year warranty, the pressure vessel a lifetime warranty, the high pressure pump a one-year warranty-although some of its internal components have only a 90-day warranty-and the electric motor 12 months. You need a flow chart to keep it straight.

The Little Wonder comes with pre-filter, three-way cleaning valve, basic plumbing connectors, and a membrane cleaning kit. You supply PVC hose, hose clamps, and the wiring connection. Options include the boost pump (standard with the modular version, $144 for the self-contained version), a three-way sampling valve ($38), a pre-plumbed fresh water flushing system ($150), hand-held salinity meter ($49), and spares kit for extended cruising ($199). For long-range cruising, all of these options are nearly essential for any properly installed watermaker.

List price of either the self-contained or modular 12-volt Little Wonder is $3,195. It is available at slight discounts through some mail-order catalogs, and there are periodic promotions at boat shows featuring special prices and thrown-in options.

Weight of the self-contained system is 63 lb. (The modular system weighs 48 lb.)

Village Marine will soon introduce a higher-output version of the Little Wonder, a 1/3-hp. watermaker in almost the same package size. Current draw, however, will be about 26 amps, requiring heavier wiring and perhaps a look at your battery capacity and charging capabilities.

Bottom Line: There are quieter 12-volt machines, more efficient ones, cheaper ones, and others that put out more water. The Little Wonder, however, has a combination of features-ease of installation, relatively low current draw, high quality components, and a 10-year track record-that is hard to beat. You can’t go wrong with this watermaker.

SK Engineering DC 150 SK Engineering is a small watermaker manufacturer based in Ft. Pierce, Florida. They do virtually no advertising, go to few boat shows, and have a very low-overhead operation geared to the Florida market. While most of their units are AC-powered, their DC 150 is a 12-volt model with a nominal output of 6 gallons per hour.

The DC 150 is powered by a 1/3-hp. continuous-duty Pacific Scientific motor rated at 26 amps. This is a larger version of the motor that powers the Village Marine Little Wonder.

The membrane is a standard 2521, and the pressure vessel appears identical to that used by Village Marine. All high-pressure fittings are type 316 stainless, as is the rigid high-pressure plumbing.

A Giant high-pressure pump provides pressure for the system. This is a standard industrial pump with a stainless steel pump head. A complete servicing manual for the pump is provided.

This is an open-frame system, with the components mounted on a heavy aluminum chassis. The footprint is 18.5″ x 12.5″, with a height of 8.5″. The pressure vessel is mounted on the outside of the chassis, increasing overall dimensions to about 25″ long outside the footprint of the mounting frame. Rubber vibration mounts are provided to isolate the chassis, reducing noise and vibration.

System pressure is user controllable via a knob-operated valve on the panel. Monitoring capabilities include system pressure and product water flow.

In operation, the DC 150 was one of the quietest machines tested, producing a maximum of 72 dB of noise. Product flow of the test machine was 6.5 gallons at 800 psi, with the motor drawing 21.3 amps at 13 volts. This translates into electrical consumption of 42.6 watts per gallon of water produced. As with other systems, adding a booster pump for above-waterline installations would add to total current draw. SK states that the system will operate without a booster pump in installations up to 2′ above the waterline.

One of the nicer features of this machine is the availability of a remote operating panel. This option allows routine operation of the system without direct access to the watermaker itself, which greatly increases installation flexibility.

The system is supplied with a pre-filter with a vacuum gauge, allowing you to monitor the condition of the filter without opening the housing. A freshwater flush kit-highly-desirable in any installation-is a $125 option. The 12-volt booster pump, drawing 1 amp, is a $120 option. An extensive cruising kit, including 12 pre-filters, rebuild parts for the high-pressure pump, cleaner, preservative, and other spares, costs $330.

SKs pricing is very competitive. The self-contained DC 150 has a list price of $2,740, but has a discount price-which we suspect would be available to most sailors who approach the manufacturer directly-of $2,350. The remote panel version has a discount price of $2,450, although the list price jumps to $3,140.

The system documentation is basic, but adequate. Total system weight is 74 lbs.

Being a small manufacturer, SK has a limited network of regular servicing dealers, but since all the system components are essentially off-the-shelf items, any good watermaker technician could repair the unit if necessary.

This is a quiet system with high-quality components and a great deal of installation flexibility when coupled with the optional 8″ x 8″ remote panel. Its open-frame design is easily serviced, although the package is not as neat as a totally enclosed package like the Little Wonder.

Bottom Line: With its 1/3-hp. motor, electrical installation will require careful thought, and you will need to look at your entire charging system and battery capacity a little more closely than you would with a 1/4-hp. machine.

The low price makes this system worth looking at. It is simple, soundly engineered, and utilizes good quality, standard components that are easily serviced. The only potential drawback is the small size of the manufacturer, which might limit long-term support.

PUR PowerSurvivor 160E The PowerSurvivor 160E is PURs entry into the high-output 12-volt watermaker market. It is the latest in a long line of machines that dates back to the PowerSurvivor 35, the first practical small 12-volt watermaking system.

The 160E uses a standard 2521 membrane in a proprietary housing. It is a dead-simple modular system, utilizing a Leeson 1/3-hp. motor directly coupled to a proprietary stainless steel high-pressure pump. Flexible high-pressure hose between the pump and the pressure vessel allows a great deal of mounting versatility, including bolting the entire system to a bulkhead. All high-pressure fittings are 316 stainless steel.

At 54 lbs. for the entire system, this is one of the lightest high-output watermakers we tested.

When we say dead-simple, we mean it. Other than the pressure bypass valve and the on-off switch-which you provide-there are no gauges to monitor, no product flow meter, and no means of adjusting system pressure, which is pre-set at the factory and is not intended to be user-adjusted. You would still, of course, install the product sampling valve, cleaning valve, and pre-filter, just as with all other units.

The 160E is a gravity feed system, and can only be installed below the waterline.

Our test machine produced 6.5 gallons of water per hour, drawing 17.3 amps at 13 volts-less than we would expect for a 1/3-hp. system. This yields an energy consumption of 34.6 watts per gallon of water-more efficient than average for the watermakers in our tests.

There are several drawbacks to the PowerSurvivor 160E. First, the system is the noisiest of any we tested, putting out 80 dB at our standard test distance of 1′. Furthermore, the reciprocating drive system of the high-pressure pump produces not a steady noise, but one punctuated by a loud popping sound at one stage of the piston stroke. We would recommend mounting this watermaker in a sound-insulated compartment if possible.

The reciprocating pump also produces pulsing in the systems hoses, which should be well-secured to prevent fatigue over time.

This is one of the more expensive watermakers we tested, with a list price of $4,440. Several discount marine catalogs sell the 160E for as low as $3,800. Options include a repair seal kit ($80), an extended cruise kit ($200), and an extensive preventative maintenance package ($420).

On the plus side, routine service of the system, including replacement of high-pressure pump seals-a requirement every 1,000 hours of operation-is simple and well-documented in the excellent instruction manual.

We also looked at two other units from PUR, the PowerSurvivor 80II modular and the newly-designed PowerSurvivor 40E. The 80II is very similar to the 160E, simply scaled down. We did not test it, but since all the other PUR machines met the manufacturers specifications, we expect this one to do the same. The smaller-diameter membrane of the 80II limits you to membranes from the machines manufacturer. It lists for $3,330, and is routinely discounted to about $2,950-about the same as the higher-output Little Wonder.

The PowerSurvivor 40E is the totally re-designed successor to the PowerSurvivor 35, the original high-output 12-volt watermaker. In our tests, its 1/18-hp. motor drew 4.8 amps, producing about 1.6 gallons per hour, consuming 39 watts per gallon of water. It is very compact, and like all PUR watermakers, easy to service and operate.

At 72 dB, its noise level was the equivalent of the quieter large 12-volt machines.

With its light weight (25 lbs.) and tiny footprint-about 15-1/2″ x 15″ x 6″ high-the 40E would be the most suitable watermaker for a single sailor or a couple cruising on a small or very light boat-a multihull, for example-with limited electrical generating capacities, perhaps just a few solar panels and small batteries.

In an emergency, the motor can be disconnected from the 40E, and it can be operated manually by a handle, just like its Survivor 35 predecessor. Because virtually all the parts of the 40E are proprietary, including the pressure vessel, membrane, and pump, you will only be able to service the units with parts from PUR.

List price of the 40E is $2,220/$1,900 discount, with options analogous to those available for larger PUR machines.

Bottom Line: All three of these smaller watermakers are actually the core business for PUR, and fill specific niches where there is no competition. Although the 160e is an easily serviced watermaker, and is more efficient than average, its high price and noisy operation are drawbacks. If the installation flexibility of the 160E is not essential to you, we think there are other 12-volt watermakers of similar capacity and quality of construction that offer better value.

Caribbean Technology The Caribbean Technology YM-200 DC 12 made by Great Water is the highest-capacity 12-volt watermaker we tested. Its rated output of 10.2 gph at 800 psi significantly exceeds that of most of the watermakers in our test.

In many ways, this modular system mimics both the output and sophistication levels of more mainstream engine-driven or 110-volt systems, including a direct drive high-pressure pump, high and low pressure automatic shutoff, and a sophisticated remote operating panel including power switch, pressure regulator, and gauges for system pressure, product water flow, and brine flow.

Power is provided by a 1/2-hp. continuous-duty motor directly coupled to a stainless steel Wanner Hydracell industrial pump. An instruction manual for the pump leads you through the periodic maintenance required. A new oil venting system in the pump claims to have eliminated an earlier tendency of Wanner pumps to weep oil.

A Codeline pressure vessel holds a standard 2521 membrane. Because this is a modular system, high-pressure plumbing includes flexible hose rather than rigid tubing. All fittings are 316 stainless steel.

A Flojet boost pump is standard, allowing the system to be mounted above the waterline. This pump-actually designed as a shower drain pump-adds 3.6 amps to the current draw of the system.

A product flow rate of 10.2 gph is pretty much the absolute capacity of a 2521 membrane, and our test system had no trouble achieving that rate of flow. The downside is that to achieve this flow, the electrical demands of the system are much higher than any other watermaker we tested: 38 amps at 13 volts, or 48.4 watts per gallon.

You would never run this system without running the engine at the same time. The current draw is high enough to drop system voltage down instantly. In all fairness, for maximum efficiency none of the systems drawing 15 amps or more should be operated without running the engine at the same time.

Because of the high current draw, your charging system should be equipped with a big alternator if you choose this watermaker. To take advantage of the big alternators capacity, youll want a big bank of batteries. The system will probably need a 50-amp circuit breaker separate from the main panel, as many main panels do not have service wiring that is really heavy enough for this type of load.

You will also need heavy wiring between the circuit breaker and the systems electrical relay box. The manufacturer recommends 4-gauge wiring, which is heavy and may in some cases be difficult to run.

Obviously, a great deal of planning and thought is required before installing a system of this capacity and with these electrical requirements.

On the plus side, the fully modular design allows the system to be mounted in a surprisingly small space, essentially little more space than is required by a modular 6-gph system.

Weight of the YM-200 is 83 lbs.

The manual includes excellent system schematics, and reasonably thorough instructions for installation, operation, and maintenance of the watermaker.

As you might expect, the size of the pumps and motors result in a fairly noisy system: 80 dB at a distance of 1′ from the high-pressure pump-the big noisemaker in any system. Due to its weight, electrical needs, and noise, the best location for this watermaker is a sound-insulated engine room or compartment, as close as possible to the ships electrical supply.

Bottom Line: The best application for this system is a larger boat with existing electrical capacity, and lacks a genset or a means of installing an engine-driven watermaker.

With a list price of $3,500-which is sometimes discounted through dealers-this is not an expensive system. In fact, on a dollar cost per gallon of water produced per hour basis, this is the cheapest system of the entire lot to purchase. It is not an electrically efficient system, but if the maximum output in the minimum time is your primary criterion in a 12-volt watermaker, the Caribbean Technology is definitely worth considering.

Spectra 180 The Spectra 180, and a few variations on its basic version, are the only watermakers produced by Edinger Marine Services. It is radically different from other 12-volt watermakers, extracting a lot of freshwater with astonishingly low power consumption.

When you first see the Spectra 180, your first impression is that one component-a big DC motor to power the high-pressure pump-has been left out. In fact, the entire system is powered by a small 12-volt pump and motor-about 1/8-hp.-no larger than the water pressure pump on a 35-footer. This is possible due to the unique design of the Clark pump, a remarkably energy-efficient pump created specifically to power this watermaker.

The Clark pump is totally unlike any other high-pressure pump used in watermakers. To oversimplify, the Clark uses two opposing pistons and cylinders with a single connecting rod. System pressure is created by the connecting rod driving the piston into the opposite cylinder. Without a detailed technical explanation of exactly how any why this works, it is fair to say that compared to other methods of creating adequate pressure for reverse osmosis, this is a remarkably energy-efficient system.

The Spectra 180 is also different from other watermakers in that it uses a standard full-size membrane whose pressure vessel is just over 44″ long-almost twice the length of the pressure vessel containing the 2521 membrane used by all the other high-capacity systems in out tests. Mounting this much longer pressure vessel may present problems in some boats. The Clark Pump housing itself is almost as long as the pressure vessel for a 2521 membrane.

According to the manufacturer, they have torn down Clark pumps after 3,000 hours of operation and found no significant wear. In any case, the pump is easy to overhaul in the field by a reasonably proficient owner. An overhaul manual for the pump is part of the system documentation, which is basic but adequate.

This is a modular system, with a remote control panel that can allow basic operation without direct access to the other system components. Total weight is about 51 lbs.

Our test system was a factory demonstrator, configured as a self-contained frame system with some performance compromises compared to the correct, conventional modular installation. Instead of a single large membrane, our test system utilized two 2521 membranes, similar in flux area to the larger membrane.

From a pure electrical efficiency perspective, the Spectra 180 was the most impressive watermaker we tested. With a current draw of 8.6 amps at 13 volts, our test unit pumped out fresh water at the rate of almost 9.5 gph–almost as much as the Great Water system, which draws almost five times as much power. Thats only 11.8 watts per gallon, by light years the most electrically efficient machine in our test.

In addition, at a noise level of 65 dB, this was the quietest system.

The Spectra 180 is not perfect, however. The system runs at low pressure compared to other systems-just 600 psi with our 70F water temperature-and the product water, although perfectly acceptable, had the highest total dissolved solids in our tests. Since product water quality can vary with different membranes, we are reluctant to attach much significance to this slightly lower water quality, which was still well within standards for drinking water.

We have some concerns about the relatively low feed water flow rate through the big membrane. The more water that passes over a membrane, the better it likes it, according to most manufacturers. The Spectras flow rate of about 90 gph is quite small for the large membrane, and we do not know how the longevity of the membrane might be impacted by this.

The ends of the main block of our systems Clark pump were machined from bronze, and showed some signs of surface oxidation at the interface to the Delrin main block. According to the manufacturer, future editions of the Spectra will have stainless steel components in place of bronze.

Likewise, the pressure relief needle valve on our test system dribbled when it was barely cracked open. We were told that this component has also been re-designed.

Our test system utilized brass high-pressure fittings, rather than the type 316 stainless used by every other manufacturer. Some manufacturers claim that the only reason to use brass is to save money, while others admitted to us, a bit reluctantly, that they had never seen a brass high-pressure fitting with significant corrosion, and stainless was generally used for appearance and galvanic compatibility as much as for longevity purposes.

Given the cost of the Spectra 180, we think you should get type 316 stainless fittings, and type 316 pump block components. The price of the Spectra 180 is $4,650, the highest of any machine we tested. You pay a significant premium for a major increase in electrical efficiency. Service, parts, and options prices are similar to those of other manufacturers: $350 for a long-term offshore service kit, for example. The price of the installation kit-$275-strikes us as a bit high for such parts as the three-way servicing and diverting valves that some other manufacturers include in the price of the basic system.

According to the manufacturer, although the system is fully functional and in production, they are still looking at further developments, including a composite Clark pump that would have no metal components. Relatively few of these machines are in use in the field at this time, as the product is quite new to the market.

Bottom Line: The most attractive feature of this system is its energy efficiency. We are less impressed by its price, and by the fact that it would appear to be a system with some room for refinement. However, if being able to run a watermaker without running the engine at the same time is important to you, and if price is less important than electrical efficiency, the Spectra 180 would be the choice among the systems we tested.

Conclusions/Recommendations Because virtually every cruising boat has different needs, priorities, and installation requirements, no single high-capacity 12-volt watermaker is going to fit the bill for every sailor. These are all well-designed, fully functional machines. Each has specific advantages and disadvantages, which we have described.

All meet their manufacturers performance specifications in terms of electrical consumption and product water output. Variances of +/- 10% to 15% from the manufacturers specifications for performance are normal.

The variations in product water quality we found are not significant. All the watermakers produce water that meets international standards for potability. The quality of the water will vary over time with any watermaker and with any membrane. A simple hand salinity tester-available from most watermaker manufacturers-is all that is required for routine checking of water quality. Most owners who use their watermakers daily don’t even bother testing salinity. They start the machine, let it run for a few minutes, taste the water, and if it tastes good, divert it to the tank.

All watermakers have similar maintenance requirements, and all we tested are reasonably easy to service. Your choice of a specific system will be largely the result of specific requirements for your boat and your cruising. The key questions are the amount and shape of space you have for the watermaker, the existing or planned electrical generating and battery storage capacity of your boat, and the amount of water you must make in a specific time frame.

All watermakers are maintenance-intensive. To a large extent, the long-term, hassle-free operation of a watermaker is a function of where and how it is used, and how religiously routine maintenance is performed. None of these machines will stand abuse.

A freshwater flushing system is an important component of a watermaker installation. Of the machines tested, only Village Marine and SK Engineering offer a ready-made freshwater back flush system as an option. While it is an easy system to design and build for anyone capable of installing a watermaker, it should be offered and recommended as an option by other manufacturers as well.

None of these systems is beyond the installation capabilities of a reasonably handy boat owner. If space permits, a totally self-contained system such as Village Marines Little Wonder will be slightly easier to install, but the total difference in installation time between self-contained and modular systems should not be more than a few hours unless there are vexing component mounting problems to solve. Plumbing and wiring connections are essentially the same for modular and self-contained systems, although a modular system with a remote panel will certainly take the longest time to install because of the number of individual components that must be placed.

All installations require attention to detail, particularly when it comes to wiring. We would not recommend you install a watermaker as the first major project you undertake on your boat, since it will require putting in a through-hull, installing heavy-duty wiring, and completing some plumbing that may in some boats be more difficult than it may first appear.

While all watermakers are covered by manufacturers warranties, all specifically exclude damage due to abuse in operation, poor maintenance, or improper installation.

A watermaker is not a use-it-and-forget-it product. Its for those who live aboard. If you don’t use it regularly and maintain it properly, you are wasting your money, and you shouldnt own one. On the other hand, if you are willing to accept the responsibility of maintaining a fairly demanding piece of equipment, a 12-volt watermaker can give you-particularly if you are a cruising sailor who desires long-term independence from shore-a degree of freedom you may not otherwise find.

Contacts- Edinger Marine Service, Inc., 298 Harbor Dr., Sausalito, CA 94965; 415/332-3780, fax 415/332-8527. Great Water, Inc., 5148 Peach St. Erie, PA 16509; 814/838-0786, fax 814/838-8700. Ocean Link, 52 Maritime Dr., Portsmouth, RI 02871; 401/683-4434. PUR, Recovery Engineering, 9300 75th Ave. North, Minneapolis, MN 55428; 800/845-7873, fax 312/315-5505. SK Engineering, 4256 N. US 1, Suite 1, Ft. Pierce, FL 34946; 800/489-0852, fax 561/489-0808. Village Marine Tec., 2000 West 135th St., Gardena, CA 90249; 800/421-4503, fax 310/538-3048.

RELATED ARTICLES MORE FROM AUTHOR

Excellent article, thank you for the research and detailed info.

Agree! Thank YOU

I really appreciated reading your recommendation, especially power consumption from one manufacturer to the other.

I am some how confused with Spectra manufacturing and Katadyn. I thought it was all Katadyn for some time now. When was this test done?.

Great review, except it would have been helpful to have specific TDS figures for the output in each case.

The contact information for SK engineering is wrong. Went to some health insurance company that sounded like a scam.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

What’s The Best Vinyl Window Cleaner for Your Boat?

40-Footer Boat Tours – With Some Big Surprises! | Boat Tour

Electrical Do’s and Don’ts

Bahamas Travel Advisory: Cause for Concern?

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

How to Install a Watermaker in a Sailboat

- By Ellen Massey Leonard

- Updated: March 26, 2018

Fresh water is one of the few things the human body cannot do without. A person can survive several weeks without food but only three or four days without water. This is why the logs of explorers such as James Cook are filled with references to anchorages where rivers were found, descriptions of long days working to replenish the ship’s water supply and worried remarks about the number of casks found sour in the hold midocean. The tales of voyaging yachts, such as John Guzzwell’s Trekka and Frank Wightman’s Wylo, also devote paragraphs to rain catchment and refilling the tanks in port. This was our situation when my husband, Seth, and I set off as cash-strapped college kids to circumnavigate aboard a vessel much more akin to the home-built Wylo than anything on the market today. We tried catching rain, we took seawater showers and we spent long days in remote anchorages hauling buckets of fresh water from shore to our boat.

In spring 2014, however, as we were preparing for our current voyage to the Arctic on our new-to-us boat, Celeste , Seth and I learned of Katadyn’s PowerSurvivor 40E, an efficient, low-draw watermaker. We’d been worried about our water supply for this journey because Celeste carried only half the water capacity of the heavy-displacement vessel on which we’d circumnavigated and yet the Arctic is a desert — water would be expensive or even impossible to obtain there. We debated filling the bilge with gallon jugs, à la cruiser Annie Hill, but didn’t want the extra weight pushing down our waterline. So, we approached Katadyn (now called Katadyn Group, with watermakers branded under the name Spectra) with a sponsorship proposal for our Arctic voyage and were soon the owners of a new 4 amp, 1.5-gallon-per-hour desalinator that we could operate manually in the event of a power failure.

Compact and relatively lightweight, the PowerSurvivor was simple and straightforward to install. Seth and I decided to fit it in a locker in the head, and we found that we could still stow the locker’s previous contents (mostly toilet paper and paper towels) without any trouble. We chose the head locker for several reasons: It was a convenient location for installation and servicing; it provided easy access to a saltwater intake and a drain; and it was a dry area free of fuel vapors or excessive heat, as stipulated by the owner’s manual. Our classic cutter was on the hard when we performed the installation, although it would be simple enough to do in the water; the only difference is that you would have to close the seacocks.

As with many boat projects, the key to a hassle-free installation is the preparation: It’s important to configure as many of the hoses and electrical connections as possible before affixing the watermaker itself. The PowerSurvivor came with everything we needed that was not specific to Celeste , including valves, hoses and hose clamps. Our first step was to fit a strainer and T-valve on the saltwater intake hose. This allowed us to use the intake either for its original function of flushing the head or for the reverse-osmosis system (though you wouldn’t want to do both at the same time!). The through-hull had the advantage of being at a low point on our hull, minimizing the chance of air intake while heeling or in rough conditions. It was also ¾ inch wide, satisfying the requirement of at least ½ inch for the desalinator, and of course, it had a seacock for safety.

We then cut our sink’s drain hose and fit another T-valve for the briny waste to exit the boat. We also mounted a three-way valve for the fresh water coming out of the desalinator. This let us run the fresh water either through a ¼-inch-inner-diameter tube to test the water or to fill jerry jugs, or — once we’d tested the desalinated water’s quality — through a 3⁄8-inch reinforced plastic hose to a T-valve we inserted into our starboard tank’s vent.

Next came the electrical connections. Using 14-gauge tinned, stranded copper wire, we ran power from our main circuit-breaker panel to a terminal bar in the locker with the watermaker. Once we had hooked up the wires that came with the PowerSurvivor to that terminal bar, the watermaker had its own switch on the breaker panel to turn it on and off.

We then mounted the pre-filter below the pump intake, as recommended by Katadyn’s engineers, to allow air bubbles to pass easily. There was plenty of room for it alongside our pressure-water hoses, and even room to mount a silt-reduction filter if we needed it for brackish or shallow water, inland waterways or areas of glacial runoff, this last being the most likely on our present voyage. The pre-filter should be mounted vertically and through-bolted with stainless-steel hardware. Its three-way valve — which allows you to choose between seawater intake for regular operation and another hose for membrane-cleaning solution — should be sealed with nonhardening paste, such as Loctite 5331, for an airtight seal. We also mounted the pre-filter in a part of the locker that’s easily accessible for maintenance, which includes inspecting and emptying the housing, cleaning the filter regularly and treating the membrane any time we won’t be using it for a week or more. In the tropics, this time frame is closer to three days, but in higher latitudes, the cold water and air keep algae growth down a little longer.

With all that completed, it was time to mount the drive assembly/pump/membrane unit. The trickiest part was holding the 25-pound device in place while Seth marked its position. Seth then drilled the holes in the bulkhead, after which I held up the PowerSurvivor while he fitted the first two ¼-inch stainless-steel bolts. With the desalinator firmly in place, the second two bolts were easy. We made sure to mount the desalinator with the long axis of the membrane in a horizontal position; to do otherwise would risk ruining either the drive assembly (if the pump developed a seawater leak) or the pump (if the drive assembly developed an oil leak).

Because we had installed all the hoses in advance, the only thing that remained was to plug in the unit. We connected the 3⁄8-inch saltwater intake hose from the pre-filter, the 3⁄16-inch freshwater hose from the end of the membrane canister to its three-way valve, and the 3⁄8-inch briny-waste hose out to the T in the sink drain. Then, we attached the electrical wires from the drive unit to the terminal bar (with the breaker switched off, of course). The owner’s manual recommends either leaving enough hose coiled next to the desalinator so that you can pull it out for manual operation without undoing your installation, or assembling a separate set of hoses so you can move it to any location for manual operation. We originally left lots of hose coiled up but decided after the first operation to shorten our hoses to decrease the distance the intake water had to travel. We opted for assembling a separate set of hoses for emergencies.

Treating the membrane to prevent biological growth had been a mystery to Seth and me before owning a watermaker, but as it turns out, that too is easy. First, we lifted the lever on the pump’s cleaning valve. According to the manual, you are supposed to use 2 quarts of desalinated water from the PowerSurvivor for the preserving process in order to avoid using chlorinated (city) water that could damage the membrane. We had neglected to keep enough water from our last use of the desalinator (and were now in the marina where we planned to keep Celeste for the winter and where we didn’t want to run the unit), so we bought a gallon of distilled water. We prefer to use more than 2 quarts to ensure that plenty makes it through the unit, since some stays in the pre-filter. Into this we mixed — according to its instructions — the membrane preservative solution that had come with the PowerSurvivor. We positioned the three-way valve so that the product water would run through the testing hose rather than into our starboard tank. Then we turned the lever on the pre-filter’s three-way valve so that it would use the membrane cleaning intake hose rather than the saltwater intake. This intake hose has a small strainer attached at the end; we put this into our container of distilled water and membrane preservative. Then it was a simple matter of running the desalinator until all the preservative solution had been drawn through and foamy water was coming out the reject-brine hose. Because we were leaving Celeste in the Aleutian Islands, we continued to run the watermaker until air was coming through the brine hose as a precaution against freezing conditions.

The PowerSurvivor has been a big success for us so far. It takes up hardly any storage room, it’s easy to operate and maintain, the water is as pure as it should be and the desalinator produces its promised 1.5 gallons per hour at an average of 4 amps. The manufacturer warns that it might require more power upon first operation (we found that it did not) and that its output might decrease in water below 57 degrees Fahrenheit. The chart in the owner’s manual shows capacity dropping to about 90 percent at 55 degrees and 60 to 80 percent in water below 40 degrees. In our first summer with the desalinator — during which the coldest water temperature we experienced was 49 degrees, in the Bering Sea — we did not see any noticeable drop in output or increase in current draw, and thus found the watermaker to be very reliable in normal circumstances. In summer 2015, we tested the machine at the edge of the polar pack ice, at 71.4 degrees N in the Arctic Ocean above Barrow, Alaska. With the sea temperature at 37 degrees, we did find a modest decrease in output: 5 liters per hour instead of the usual 6, which equates to 83 percent of normal and thus better than the engineers’ predictions. In other words, the PowerSurvivor has more than lived up to our expectations.

Having sailed long distances both with and without a watermaker, I’m now convinced that the half-day project of installing the PowerSurvivor and the minor task of servicing it when needed is well worth it. We no longer spend our first day after a passage hefting buckets of water. During our summer in the Arctic, we didn’t refill our tanks from shore for seven weeks and yet we never rationed ourselves — in fact, we took frequent freshwater showers. Now, if we want to anchor and avoid tying up to a dock, we can. If we doubt the quality of the shore water, we don’t have to fill up with it. And all this with only the power produced by our solar panels. Capt. Cook would have loved it.

Ellen Massey Leonard and her husband, Seth, have circumnavigated the globe and cruised extensively in Alaska and the Arctic. Ellen chronicles her adventures at gonefloatabout.com .

- More: How To , Living Aboard , watermakers

- More How To

How to Protect Your Spars from Corrosion

Sailing totem refit series: the forward head makeover, fatty goodlander: dealing with chafe while cruising, how to rig everything in your favor, route planning in the face of climate change, new to the fleet: pegasus yachts 50, imtra named employee-owned company of the year.

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Our products are proudly manufactured here in Fort Lauderdale, Florida USA!

- Afghanistan (USD $)

- Åland Islands (USD $)

- Albania (USD $)

- Algeria (USD $)

- Andorra (USD $)

- Angola (USD $)

- Anguilla (USD $)

- Antigua & Barbuda (USD $)

- Argentina (USD $)

- Armenia (USD $)

- Aruba (USD $)

- Ascension Island (USD $)

- Australia (USD $)

- Austria (USD $)

- Azerbaijan (USD $)

- Bahamas (USD $)

- Bahrain (USD $)

- Bangladesh (USD $)

- Barbados (USD $)

- Belarus (USD $)

- Belgium (USD $)

- Belize (USD $)

- Benin (USD $)

- Bermuda (USD $)

- Bhutan (USD $)

- Bolivia (USD $)

- Bosnia & Herzegovina (USD $)

- Botswana (USD $)

- Brazil (USD $)

- British Indian Ocean Territory (USD $)

- British Virgin Islands (USD $)

- Brunei (USD $)

- Bulgaria (USD $)

- Burkina Faso (USD $)

- Burundi (USD $)

- Cambodia (USD $)

- Cameroon (USD $)

- Canada (USD $)

- Cape Verde (USD $)