The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Pricing Plan

- Superyacht Insight

- Product Features

- Premium Content

- Testimonials

- Global Order Book

- Tenders & Equipment

Gas turbines and generator systems for yachts

Gas turbines offer the most concentrated source of power in the marine world. With a turbine it is possible to pack 5,000hp into the same space that would be occupied by a 500hp diesel engine.

They are very light in weight for the power they produce; their maintenance requirements are much lower than a diesel engine because they just have one or two moving parts; they don’t need a vulnerable cooling water system; and they can produce full power immediately from start up.

Navies of the world love them, so why are gas turbines still seen as an exotic power source for motor yachts?

Cost of gas

The main answer is cost. A turbine will cost perhaps four times as much as comparable diesel power. Their fuel consumption also is higher than a diesel and tends to remain high even at intermediate speeds.

As far as motor yachts are concerned, gas turbines are generally used as a way to boost power rather than as the main means of propulsion. In this role they will be found installed with a pair of diesel engines, with each engine coupled to a water jet. The wing diesels provide the normal cruising power, perhaps taking the speed up to 35 knots, then the turbine can be switched in on the centreline jet, perhaps adding another 10 or 15 knots to the top speed.

Gas turbines are generally used as a way to boost power rather than as the main means of propulsion

This is the engine package offered on the Pershing 115, where an owner can choose between having just a pair of MTU diesels producing around 5,500hp for speeds of around 35 knots, having three of these diesels, or replacing the centre diesel with a 5,000hp gas turbine that will provide a top speed close to 50 knots.

Danish Yachts offers a similar package on its very lightweight 38m Aerocruiser, where the addition of a 5,000hp turbine can take the speed to over 60 knots.

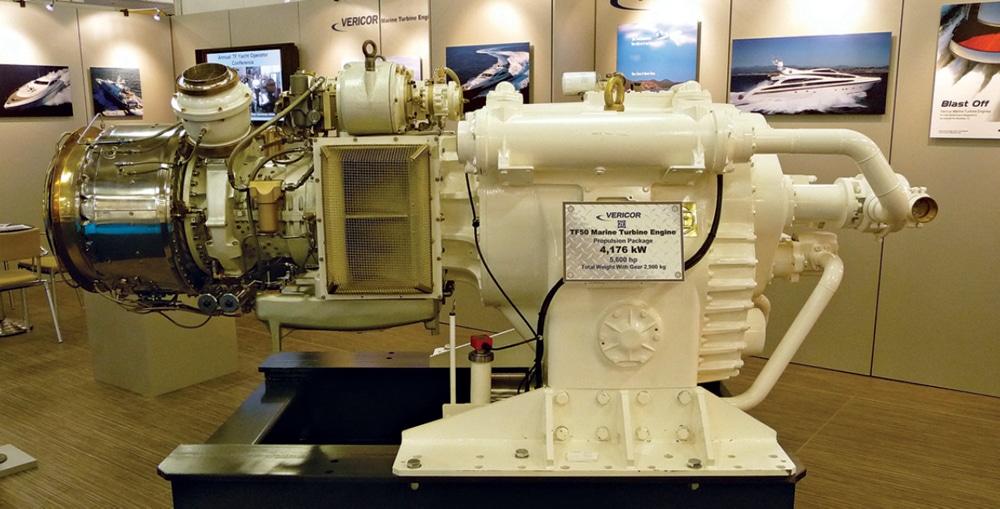

The favoured turbine for these applications is the TF50 from Vericor, which is a tried and tested unit that comes in two other versions: the TF40, and the new TF60. The same turbine unit can be configured to produce various power outputs. These units are the most popular in the yacht sector.

The high-performance 118 WallyPower used three TF50s for main propulsion – one of the few all-turbine installations on a motor yacht. The high speed of the basic turbine of around 20,000rpm had to be geared down considerably to match the requirements of the water jet units, typically to around 1,000rpm. There are specialised lightweight gearboxes to meet this requirement.

With all three turbines in operation, the _118 r_eached speeds close to 70 knots. For harbour manoeuvring, the turbines were a bit fierce, so a pair of 500hp Cummins diesels could be coupled into the wing water jets for more gentle progress.

The Aga Khan’s gas-powered yachts

While the 118 was a complex installation, but even more complex was a yacht built under considerable secrecy at Devonport Dockyard. Reportedly built for HH the Aga Khan, this 42m yacht was powered by no fewer than six gas turbines coupled in pairs to three water jets. The smaller turbines were thought to be Eurodyne units, each producing about 3,000hp.

The smaller turbines were for relatively low speed cruising and harbour manoeuvring. When high performance was required, the second batch of turbines – each delivering around 10,000hp – could be coupled in. The yacht was designed for speeds of up to 80 knots, and the result was one of the most complex machinery installations ever. She was plagued by considerable delays mainly caused by the machinery and its final speed potential has never been revealed.

When high performance was required, HH the Aga Khan’s yacht could use a second batch of turbines – each delivering around 10,000hp

HH the Aga Khan was no stranger to high performance, with his involvement in the Destriero project, a 67m vessel built to challenge for the trans-Atlantic record. Powered by three General Electric LM1600 gas turbines, she had around 52,000hp on the throttles and averaged 53 knots across the Atlantic, burning fuel at the rate of 10 tonnes per hour.

On board the 86m Estasea , built for Roman Abramovich, there was one General Electric LM2500 gas turbine. This turbine produced around 30,000hp and was supplemented by four MTU diesels totalling over 12,000hp.

The diesels allow a variety of flexible cruising speeds and when the turbine is coupled in the speed could reach 28 knots – fast for a superyacht of this size – although the fuel consumption obviously shoots up resulting in a drastically reduced range.

Gas turbines are at the exotic end of the fast motor yacht market, but they continue to attract attention from owners and builders who want a vessel that will stand out from the crowd. When money is no object, the gas turbine can still be an attractive power source for propulsion systems.

However, the possibility of using gas turbines to power a superyacht’s other electrical systems is now being explored.

Gas turbine generators

A pioneering installation on board an inland waterways tanker operating on the River Rhine is showing how gas turbines can be used as efficient and clean electricity generators.

This 110m barge has two gas turbine-powered generators that not only supply the vessel’s electrical power, but also can provide the domestic hot water, heating and air-conditioning – and they do this while generating very low emissions that can exhaust without any treatment to meet stringent regulations.

It opens the door to a new generator concept for superyachts and Pon Power of Holland, who developed the system, is keen to explore this market sector.

The barge’s system uses a pair of US-built Capstone C30 30kW gas turbines coupled to the vessel’s generators. They not only provide the electrical power, but the hot exhaust gases are passed through a heat exchanger, which in turn provides the hot water for domestic use and heating. Part of this exhaust heat is also fed to an absorption chiller for the air conditioning, making the most of energy that would normally be lost.

The exhaust from the turbine shows a significant reduction in harmful emissions compared with a normal diesel, and smooth running and low noise levels improve the on-board environment, reducing the need for insulation.

The age of gas

This particular vessel uses natural gas for both main and auxiliary engines. The turbines operate very happily on this gas as well, but they also can be programmed to use most common fuels such as diesel and jet fuels, which makes them suitable for superyachts.

Capstone currently offers three models producing 30, 60 and 200KW, which would meet most generator requirements. They are used on many land-based applications and have been approved by Lloyd’s Register of Shipping. The turbines are equipped with special bearings that require no lubricating oil, eliminating another possible source of contamination.

There is obviously considerable potential for superyachts, particularly high-performance yachts, where the low weight and compact size of the units could create a performance bonus. The available sizes of the turbines should meet the auxiliary requirements of most yachts and the quiet and absence of vibration could lead to peaceful nights in the marina.

Originally published in Superyacht Owners’ Guide to Propulsion 2012 .

More about this yacht

More stories, most popular, from our partners, sponsored listings.

- THE PRINCESS PASSPORT

- Email Newsletter

- Yacht Walkthroughs

- Destinations

- Electronics

- Best Marine Electronics & Technology

- Boating Safety

Turbine Engines Revealed: Benefits of Gas

- By Dudley Dawson

- Updated: January 25, 2011

The Benefits of Gas-Turbine Engines

First, let’s dispel the myth that you need your own oil well to operate a boat powered by gas turbine engines. Yes, turbines can be a bit pricey and they’re generally not as fuel-efficient as diesel engines , but you don’t have to belong to OPEC to have a turbine.

Gas turbine engines are now offered by at least one production boatbuilder. Pershing Yachts ( www.pershing-yacht.com ), part of the Ferretti Group, completed its third 115-footer fitted with a turbine engine in 2011. The Vericor TF50 engine, built by a division of MTU, is linked to a centerline Kamewa waterjet and boosts the speed from the 35 or so knots achieved with twin MTU diesels into the rarified air north of 50 knots.

Among the more well-known custom yachts with a turbine is the 153-foot Feadship Detroit Eagle , delivered to Roger Penske in 2001. Her second owner has rechristened her Sea Racer and intends to use the turbine on a regular basis. Like the Pershing yacht, the Sea Racer also has a centerline TF50 employed in a configuration known as CODAG, an abbreviation for combined diesel and gas turbine. Such installations use diesel engines for normal cruising, and kick in the turbine to provide additional boost power for the occasional high-speed sprint.

Another configuration, CODOG, short for combined diesel or gas turbine, is best illustrated by the Wally Power 118 . She has not one but three turbines, as well as two small diesels. When maneuvering in the harbor or puttering along at displacement speed, the Wally is under diesel power only. For planing operation, including both cruising and top speed, the diesels are shut down and the turbines provide the sole power — so the or in CODOG operation is what sets it apart from the and in CODAG.

What these three yachts have in common, besides the gas turbines, is consultant Tom Keefer, the principal at T3 Automation ( www.t3automation .com ), a company that specializes in gas turbine controls. His first response when I asked about the pros and cons of gas turbines was, “No vibration!” but he was quick to follow with the advantages of weight versus power. The TF50 package, he explained, with the new, more compact reduction-gear configurations now available specifically for coupling turbines to water jets or surface-piercing propellers, provides 5,600 horsepower and weighs in at around 5,400 pounds.

There are, of course, downsides to gas turbine engines — in their initial cost, their sensitivity to salt air and their specific fuel consumption when compared with diesels. Tom mentioned that, for some applications, smaller gas turbine engines are often available at bargain prices as surplus from military applications. And salt-air intrusion has been addressed by improved filtering systems in recent years, so it is not the concern it once was.

The problem of fuel consumption remains. The specific fuel rate for the TF50, for example, is about 0.064 gallons per horsepower-hour, compared with 0.050 to 0.055 for diesel engines, a penalty averaging about 20 percent. This is mitigated by two factors, however. First, the turbine weighs only a fraction of what a diesel engine providing the same power weighs, so there’s a bit of inherent savings there. Also, a turbine-powered yacht typically operates at top speed no more than 10 percent of the time, so the overall fuel premium will in all likelihood run less than 2 percent of the total fuel cost. And since fuel cost is only a fraction of overall operating costs, what looks at first blush to be a substantial penalty becomes insignificant in the total picture. In other words, we may see more gas turbine engines in the near future.

How to Swing a Compass on a Boat

Onboard Ambience with Prebit’s Thoa Lamp

Spring Commissioning Your Boat

Seakeeper Unveils Two New Models

Power Catamaran Popularity Rising

For Sale: Sunseeker Predator 68

For Sale: CL Yachts CLB 72

10 Yachts Under $500,000 You Can Have Today

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Feb 10, 2022

Is The Turbine Engine Coming to Boating?

By: Scott Way

The internal combustion engine may be at a crossroads. It has been the backbone of economics and industry for over a hundred years, and it has served us well. Even more, the marine industry is still developing exceptionally powerful engine platforms with more horsepower with less maintenance than we ever thought possible. It's not that the internal combustion engine doesn't work, it's just that some new competitors have arrived.

Now, that's not to say gas-powered engines are going to disappear tomorrow. We're simply in a transition between reliance on the old system and the potential of a new one. As far as boating is concerned, the turbine engine has the potential to not only exceed the performance of piston-driven engines, but also offer lower emissions, better fuel economy, and in a perfect world, a lower price point.

A small company out of Wichita, Kansas named Astron Aerospace has developed a small turbine engine called the Omega 1. It still burns fuel like a traditional internal combustion engine, but it operates in a way that's unlike anything the marine world has seen. The company claims it can serve as a viable alternative for cars, trucks, planes, and boats, and that certainly seems to be the case.

Now, a quick clarification. Yes, a turbine engine is technically an internal combustion engine. However, the two most popular combustion engines in history are the spark ignition gasoline engine and the compression ignition diesel engine. Most of these are four-stroke cycle engines (two-stroke engines are being phased out), meaning four piston strokes are needed to complete a cycle. The cycle includes four distinct processes: intake, compression, combustion and power stroke, and exhaust. For example, the Chevrolet V8 small block is one of the most popular engines in history. Both the spark ignition and compression ignition engine have been the foundation of boating since it ditched sails in favour of propellers.

A turbine engine , meanwhile, operates by compressing air to high pressure, then combusting fuel inside the air stream to increase pressure and temperature. Then the expanding high-pressure exhaust gases through a turbine to produce work. You've seen turbine engines in commercial aircraft, natural gas pipelines, and various industrial applications.

How is this relevant to boating? I'll explain.

Turbine engines are extremely lightweight. The Omega 1 weighs only 35 pounds but produces 160 horsepower. For comparison, a 150 horsepower marine outboard engine weighs about 450 lbs. That's 13 times heavier than the Omega 1. The weight savings on a small vessel, like say an 18' aluminum fishing boat, would create noticeable performance improvements and better fuel economy simply due to the weight reduction. Acceleration, holeshots, getting on plane, and the physics of hull shape would all be affected. A standard outboard engine with 150 hp running at 4000 RPM produces about 190 lb-ft of torque. The Omega 1 produces a comparable 170 lb-ft of torque.

And therein lies the second factor. RPMs.

Piston driven engines and turbine engines have vastly different RPM ranges. The Omega 1 idles around 1000 RPM and red lines at 25,000 RPM, which creates a wider range of performance from low to high speed. Most marine outboard engines cruise around 3000-4000 RPM redline around 5000-6000 RPM. With the ability to run at higher RPM, turbine engines can produce faster acceleration while simultaneously 'working' less (burning less fuel and producing fewer emissions) than their piston-driven counterparts due to less friction inside the engine.

Turbines like the Omega 1 can also be stacked, which means you can add multiple units together to increase power. To match the 450 lbs of engine weight from a 150 hp outboard, you could conceivably stack 13 Omega 1 turbine engines, which would generate 2,080 horsepower. Even if you ran a single turbine, the weight savings relative to a single outboard would produce better fuel economy. Couple that with the fact a turbine itself burns less fuel, and you get considerable savings.

The combustion cycle of a turbine is also mechanically less destructive than a piston engine. It uses a rotation setup, and Astron claims that the loss of power through friction, like you see with a piston engine, is minimal. This means the cross-contamination of oil like you see in a piston engine doesn't occur, which potentially means lower maintenance costs and longer service intervals.

Now, of course there are downsides. If you've ever been on a plane, you know how loud a turbine engine is. The idea of a high RPM turbine without major sound dampening on a transom is problematic. Turbines are also often air cooled, which presents another set of issues for a water vessel. But, if a turbine can be encased inside an engine bay while still having access to air-cooling, the possibilities are almost limitless.

The Astron turbine is already making waves in the automotive industry , and the company claims it is applicable for boats as well. It's not that new of a concept either. The first turbine car was the Chrysler Turbine Car in 1964. Modern companies like Jaguar have also tinkered with the idea in the C-X75 Concept .

Perhaps a boat is next.

You can get an in-depth look at how the Omega 1 works in the video below:

#news #culture #products

Recent Posts

One of the World's Most Famous Boat Rides Struggling Under $1.2 Billion Debt

Intrepid Powerboats Marks New Era with 50 Evolution

5 Engines Primed to Disrupt the Marketplace in 2024

- Dec 7, 2023

Yamaha to Reveal Hydrogen-Powered Outboard Prototype at Miami

- Nov 3, 2023

FLIBS Recap- 7 Boats You Gotta See in 2024

- Nov 1, 2023

First Drive – Brunswick's Autonomous Docking System

- Oct 25, 2023

Why the Vertical Bow is Making a Comeback

- Oct 6, 2023

Formula Announces Massive 457 Center Console Models for 2024

- Sep 27, 2023

This Is It - The Coolest Catamaran Ever Built

- Sep 13, 2023

#WeirdBoats - Historic 'Flying Boat' that Led Amazon Expedition is Up For Sale

Marine Turbine Engines - How Does a Steam Turbine Work on Ships?

- Categories : Marine machinery, engines & controls

- Tags : Marine engineering

Marine steam turbine engines have largely been replaced by the more economical marine two stroke diesel engine, mainly for commercial reasons as the diesel engine is much more economical. Notwithstanding this there are still a few about, running like clockwork- their one big selling point along with reliability, little maintenance, and high speed- pushing large cruisers and battleships along at forty knots, but they are very thirsty. Let’s find out how steam turbines work in the context of marine turbine engines.

The Cross Compound Double Reduction Turbine

For marine applications, the cross compound double reduction steam turbine was a popular choice because it was more compact, taking up less space in the ships engine-room . It also had the advantage of a built-in astern turbine giving easier astern movement, with up to 50% astern output power as that of the ahead turbine.

This was a big advantage when the first oil super tankers were built – they took half a mile to stop from full ahead!

In operation, the steam is supplied from the ship’s boiler as high pressure, high temperature superheated steam and passes into the high pressure turbine, (HP) expanding through the blades and exiting into the low pressure turbine through a large bore insulated pipe.

From here the low pressure steam passes through LP turbine blades, exiting from these and then being drawn by vacuum from the last few stages into main condenser.

The high pressure and low pressure turbines are really separate turbines having their own drive shafts, which are coupled to a double reduction gearbox that decreases their revolutions from several thousand to about 100 RPM, the normal operating propeller shaft speed.

The high pressure turbine rotor also has several rows of blades that are used as an astern turbine, which enables the ship to maneuver when arriving or departing ports. Also the astern turbine can be used in an emergency to avoid collision at sea, and although I have had to emergency stop and put astern a large marine main diesel engine, I have thankfully never had to carry this operation out on any steamships that I served on as marine engineer, as they were all tankers, so I cannot comment on its viability.

Both the high pressure and low pressure steam turbines have glands at each end which stop the steam from escaping into the engine-room from the high pressure stage and which stop the loss of condenser vacuum through the low pressure stage. These glands are known as labyrinth type and, as the name suggests, are made up of a series of three rings and are supplied with two different pressures, which effectively seals both turbines shafts and end covers, with the supplied steam exiting to the gland cooler.

A common lube oil system is used to lubricate the various components and keep them cool by pumping the oil through a cooler. The oil is drawn from the drain tank a through a set of magnetic strainers by the lube oil pump into a set of duplex filters, then onto the main lube oil cooler before supplying oil under pressure to the turbine white metal bearings, gearbox, gearbox sprays, and thrust block. There is also a secondary back-up lube oil pump driven by the turbine shaft supplying oil to gearbox and thrust.

An overhead tank, usually positioned at the top of the engine-room, is also supplied by the pump through a bleed off orifice. From the tank there is a vertical overflow pipe incorporating a circular glass window, usually illuminated from behind, from which the oil can be observed flowing back down into the system.

The reason for the header tank is in the event of a black-out or loss of a lube-oil pump, the header tank has the capacity to keep the turbine bearings supplied with oil until the turbine stops rotating, with the auxiliaries being supplied by the secondary pump. It is usual to have a lube oil purifier or centrifuge located within the system to remove any ingress of water or impurities from the oil.

There is also another lube oil system known as gravity feed whereby the lubrication of all the components is by the overhead tank; this system is shown in the sketch.

Warming Through

After the turbines and steam supply/exhaust have being idle in port, about two hours before standby, the turning gear should be withdrawn and the steam supply and exhaust system slowly warmed through. This is carried out firstly by raising a full vacuum about 28-29” Hg, and once this has been achieved, the ahead steam valve should be slowly opened a few notches rotating the shaft a few revs only, holding for one minute before shutting again, the astern turbine also being operated similarly. This should be continued to ensure all the pipe-work, turbine covers and rotors, expansion plates and condensate returns to boilers are all well warmed through and expanded up to working temperature.

Remember any water in the system will damage the turbines so only superheated steam should be used, and operate the steam drains and check the steam traps if applicable

A typical steam turbine layout in a ship’s engine room is shown below.

- Author’s Experience

- Drawing by Author

- Motorcycles

- Car of the Month

- Destinations

- Men’s Fashion

- Watch Collector

- Art & Collectibles

- Vacation Homes

- Celebrity Homes

- New Construction

- Home Design

- Electronics

- Fine Dining

- Baja Bay Club

- Costa Palmas

- Fairmont Doha

- Four Seasons Private Residences Dominican Republic at Tropicalia

- Reynolds Lake Oconee

- Scott Dunn Travel

- Wilson Audio

- 672 Wine Club

- Sports & Leisure

- Health & Wellness

- Best of the Best

- The Ultimate Gift Guide

Boat of the Week: This Speedy 153-Foot Superyacht Has Its Own Turbo Boost

Push a button and the turbine kicks in, which is yachting's equivalent of light speed., julia zaltzman, julia zaltzman's most recent stories.

- This Boatmaker Builds 1960s-Inspired Cruisers With a Modern Twist. Here’s How.

- This 150-Foot Fishing Trawler Was Transformed Into a Rugged Explorer Yacht

- These 3 Miniature Explorer Yachts Are Ready to Take You Off-Grid

- Share This Article

What do you get if you have two friends with a passion for boats, high-profile automotive careers and cash to burn? The answer is the 153-foot superyacht Excellence , a vessel that oozes speed, has brand pedigree and captures the hearts of all who own it.

Built in 2001 by Formula One racing car driver and automobile entrepreneur Roger Penske, who named her Detroit Eagle , the yacht combined Feadship ’s Dutch craftsmanship with Penske’s own brand of engine. (Disclosure: Roger Penske is the father of Jay Penske, who owns this publication, as well as its sister publications in the Penske Media portfolio.)

Meet Spear, an Epic 460-Foot Trimaran Concept That Looks Like It’s From the Year 3000

- First Drive: Radical’s New Track-Only Racecar Is Brutally Quick and Responsive

- Rossinavi Just Launched a Custom, Full-Aluminum 164-Foot Superyacht

“At the time [Roger] Penske owned a company called Detroit Diesel that made diesel engines for boats, and he was also involved with a company that built turbine engines,” current owner and Penske’s longtime friend, Herb Chambers, told Robb Report . “So, he went to Feadship and built a lightweight aluminum yacht with a shallow draft to demonstrate the capability of his engines.”

The Feadship was originally built and owned for years by Roger Penske, who wanted a very fast, very luxurious superyacht. Penske installed his own Detroit Diesel-branded engines and then added a 5,600-hp turbine to give the yacht a 10-knot pop at the top end. Courtesy of Burgess Yachts

The immaculate, polished-chrome engine room, with the diesels painted in fire-engine red, has always been a symbolic indicator of the type of impressive speeds the yacht can reach. The engines are 16-cylinder 4000 series, which generate 3,650 horsepower each. Penske then added something the superyacht world had never seen before–a Lycoming TF-50 gas turbine for an additional 5,600 horsepower.

“The boat can cruise at about 23 knots on diesel engines,” Chambers says, “but if you really want it to go fast, you push a button and the turbine kicks in taking the boat from 23 knots up to around 33 knots. It really is a remarkable vessel.”

Serial boat builder Chambers grew up in the Boston area, spending long summers on the water at his grandmother’s cottage. “I always had the desire to have a boat,” he says, a goal he realized at 24 with a 30-foot Trojan flybridge motoryacht. The Trojan would be the first of five yachts called A-Copy , named after his successful copy-machine business.

“After I sold the copy company and had this windfall of money, I ordered a 127-foot Feadship. The name A-Copy wasn’t of any significance to me anymore so I tried to think of a name that I would like,” Chambers says. “I’m not an avid reader, but I read Tom Peters’s book In Search of Excellence and loved it. It’s about running a good business. I thought Excellence , that is a great name for a boat.”

Launched last summer, Chambers’s newest 262-foot Abeking & Rasmussen “Excellence” has a futuristic hull shape, with an eagle-beak bow and large glass panels on the exterior. Courtesy Abeking & Rasmussen

To date, Chambers has owned more than 40 yachts of many sizes. Some were even sold before he took delivery. The name “Excellence” serves as a constant reminder to his 30-year-long captain for the need to maintain high standards on board, he says. It has also carried through to Chamber’s six most recent yachts. This includes his largest yacht to date, a striking 262-foot Abeking & Rasmussen launched in 2019, on which he enjoys cruising the European waters of Croatia, Greece, Italy and St Tropez. That Excellence won Robb Report ’s 2020 Best of the Best award for interiors.

With its “eagle” reverse bow and triple-height glass atrium, the Winch-designed yacht turns heads wherever it goes. But that’s hardly surprising considering Philip Starck’s opinion-dividing Motor Yacht A was the design inspiration this latest Excellence .

“When I first saw Motor Yacht A , I said, ‘That looks like a submarine. Who would ever want to have a boat like that?’ And the second time I saw it, I said, ‘That boat is pretty nice. I kinda like that bow.’ And the third time I saw it, I thought, ‘I absolutely love that.’ So, that’s where the idea for Excellence ’s bow came from.”

While he has recently listed the Feadship “Excellence,” Chambers plans to enjoy the yacht for while he still owns her. He has often owned two yachts—the newer one that is often under charter, and a smaller, faster one that is at his disposal for his “personal use.”

While Chambers’s appreciation of Feadship has long endured after his first foray with the Dutch shipbuilder, it wasn’t until a 2018 visit to Fort Lauderdale Boat Show that Penske’s 153-foot yacht caught Chamber’s eye. Prized by Chambers for its flexible speed and six-foot Bahamas-friendly draft, it is one of the few yachts that he hasn’t put on the charter market.

“I view the Feadship as a very personal boat,” says Chambers. “It’s only a four-stateroom boat, but you can bring three other couples or family members with you. When I told Roger Penske that I had bought the boat, he said his family was mad at him when he sold it because they loved it so much.”

An extensive 2019 refit of the yacht includes a full paint job, an updated sound system and refurb of the original John Munford interior. Chambers bought the yacht for his own personal use. “Because my boats get chartered, I always love to have a boat that’s available just for me,” Chambers says. “I built a 94-foot Mangusta for that purpose and used it in America when my big yacht was on charter in the Mediterranean or Caribbean. The Feadship can do pretty much what the Mangusta did, but it’s a bigger, more comfortable boat, so I sold the Mangusta at the start of 2020.”

The 2001 build has undergone a complete refurbishment of the interior.

Being a serial owner, Chambers also recently listed the updated Feadship. He plans to enjoy the yacht while she is still available. Will he miss this Excellence ?

“I really don’t know,” Chambers says, pausing. “I would maybe look to build a similar boat, around 150 feet, something that would be fast. But the Abeking & Rasmussen Excellence is still new to me. The time for me to sell a boat is when I still like it.”

That creates a great opportunity for a buyer who wants a piece of superyacht history–a very fast superyacht history.

Excellence is co-listed for sale with Burgess and Merle Wood & Associates for $16,900,000. Here are more views.

Images Courtesy of Burgess Yachts

Read More On:

- Abeking & Rasmussen

More Marine

This New 131-Foot Aluminum Catamaran Concept Can Take on a Transoceanic Expedition

This New 150-Foot Superyacht Can Cruise Through Shallow Waters in Florida and the Bahamas With Ease

Open Space, Eco-Friendly Tech: What a Rising Class of Millennial Superyacht Owners Is Looking For

Culinary Masters 2024

MAY 17 - 19 Join us for extraordinary meals from the nation’s brightest culinary minds.

Give the Gift of Luxury

Latest Galleries in Marine

8 Fascinating Facts About ‘Nero,’ a 295-Foot Superyacht Inspired by a 1930s Classic

Palm Beach Vitruvius in Photos

More from our brands, diane von furstenberg, lo bosworth, rupi kaur and more, celebrate the official launch of breadwinner, james madison’s record $53m in student fees tops all public schools, kim kardashian and emma roberts kiss in first trailer for ‘american horror story: delicate’ part 2 (tv news roundup), documenta 15 diary: beyond borders, the best yoga blocks to support any practice, according to instructors.

MARINE SPECIAL PROJECTS

This is where MTT started: Turbine engines used in boats and for marine special projects.

Why use turbines in boats? The clear choice for power in the aviation industry, turbine engines are a viable multi-fuel power option for the demanding marine industry. Why? Interestingly, the friction created by wetted opposing surfaces on boats is very similar to the friction of air and the force of gravity on planes.

Weight and space efficiency are also factors in marine installations. Turbine engines are unparalleled in this regard because they have a greater power-to-weight ratio than reciprocating engines. Their power is better used to propel the boat, whereas diesel engines expend up to 20% of their power simply to move themselves due to their high weight.

Finally, in turbine engines, all moving parts spin centrifugally around a central shaft, eliminating the “grenade” effect all too familiar with experienced boaters. This occurs when a reciprocating engine blows as a result of running at high RPMs for prolonged periods of time.

Custom manufactured MTT boats are treated on a case-by-case basis. MTT is most interested in large scale production runs for specialized watercraft, whether civilian or military.

320hp MILITARY OUTBOARD

SEAL DELIVERY VESSEL 1

SEAL DELIVERY VESSEL 2

SEAL DELIVERY VESSEL 3

SEAL DELIVERY VESSEL 4

AIRBOAT IN SWAMP

AIRBOAT FROM WATER TO LAND

INFLATABLE w/ 320 HP TURBINE

WATER STREAMS

FROM WATER TO LAND

AIRBOAT FOR RECON

ELIMINATOR POWER

1,400 HP TURBINE AT 680 LBS FOR 33′ ELIMINATOR

42′ FOUNTAIN

22′ ELIMINATOR

25′ TALON

31′ WARLOCK

43′ BLACK THUNDER

50′ NORTECH

92′ SPORTFISH

TWIN 700 HP TURBINES

CUSTOM COCKPIT

CUSTOM FOR THE U.A.E.

Jean Lafitte Project – Remediation of Marsh Buggy Damage to Wetlands – Case Study 2 – MTT SOLUTIONS

By Ted McIntyre II – CEO and Owner – Marine Turbine Technologies, LLC – Franklin, Louisiana With the recent success of our land bank mitigation projects, the local Louisiana utility (Entergy) called MTT about a new project in the Jean Lafitte Wildlife Refuge. ...

Excavation of Levees for a Land Bank Mitigation Project – Case Study 1 – MTT SOLUTIONS

2016 was busy for MTT’s twin engine Super Turbine Airboat. Among other things we were contracted to excavate levees surrounding a land bank for a large mitigation project in Louisiana. This project had started two years ago with dredging in Lake Borgne east of New...

MTT Develops Turbine Technology to Save Louisiana’s Eroding Coast – MTT SOLUTIONS

Marine Turbine Technologies in Franklin, Louisiana has developed a state-of-the-art Super Turbine Airboat which does not harm the fragile ecosystem of our state like traditional marshland transport equipment. The MTT Turbine Airboat skims across water and land...

420RR and 3 Wheeled Trike Superbikes – MTT MOTORCYCLES

Check out the Video on our latest 420RR (Race Ready) and 3 Wheeled Trike Turbine Superbikes.

Y2K Superbike Video – MTT MOTORCYCLES

Check out the MTT Y2K Superbike Video.

Super Airboat Video – MTT SOLUTIONS

Check out MTT’s video on the Super Airboat.

Historic Cuba Powerboat Rally Provides an Adventure of a Lifetime

Ted McIntyre and his crew featured on speedonthewater.com for participating in this year's historic Cuba Powerboat Rally. From speedonthewater.com... "Expecting nothing less, members of the Florida Powerboat Club were treated to the adventure of a lifetime as...

1MW and 2.5MW Distributed Turbine Power Generation – MTT SOLUTIONS

Distributed turbine power generation is the alternative to grid power. With distributed turbine power generation the electrical power package is brought to a customer site versus reliance on grid power. MTT is a manufacturer of 1MW and 2.5MW turbine power generation...

Flood Control and FiFi Fire Fighting with Turbines – MTT SOLUTIONS

MTT is the premier provider of turbine powered FiFi fire fighting packages used by offshore vessels in the Gulf of Mexico and throughout the world. The MTT turbine powered FiFi fire fighting packages have a water flow volume range between 5,285 Gallons per Minute...

Turbine Powered Airboats for Sensitive Wetland Work – MTT SOLUTIONS

MTT is the innovative leader of turbine powered airboat technology. These turbine powered airboats are specifically designed to operate in sensitive coastal wetlands that suffer destruction from marsh buggies and are otherwise inaccessible to conventional watercraft....

KEYSTONE PIPELINE PUMPING STATIONS FOR SALE [Click Here]

Gas Turbine Boost Power: Higher Speed for Naval and Commercial Vessels

The challenge.

Increasing vessel speed without making dramatic design changes or increasing vessel weight.

Vericor's Solution

A single Vericor TF50 center boost marine gas turbine package

The Results

Additional 5000 hp of installed power and higher speed with addition of one shaft line. Power switched on when high speed is desired. Minimal added weight.

Advantages of the Center Boost TF Gas Turbine Package.

The vericor difference, product spotlight, marine gas turbine.

Vericor Success Stories

View more of our success stories..

- North America

- South East Asia

- United Kingdom

- Global contacts

- Climate-tech centre

- Small modular reactors

- Micro-Reactor

- Digital Platforms

- Digital Twin

- The Aletheia Framework ®

- Sustainability

- Purchase Parts & Services

- Other Customers

- Aircraft Transitions

- Capable & Versatile

- RB211-524G/H & -T

- RB211-535E4

- Tay 620 / 650

- M250 turboshaft

- M250 turboprop

- Future products

- Access our testing capabilities

- Testbed facilities

- Net Zero for Future Combat Air Systems

- Developing the Next Generation

- Digital FIRST

- Energy Transition for Defence

- LibertyWorks

- Rolls-Royce LiftSystem®

- M250 Turboshaft

- Trent 700 MRTT

- M250 Turboprop

- T56 3.5 Enhancement

- Distributed Generation Systems

- MT30 Marine Gas Turbine

- AG9160 Generator Set

- AG9140 Generator Set

- MT7 Marine Gas Turbine

- Power Systems

- Naval Handling Systems

- Naval Support & Services

- TwinAlytix®

- Power Generation Solutions

- Governmental

- Power Systems Sustainability

- Our Electrical power & propulsion portfolio

- Our Capability

- Our Strategy

- Executive Team

- Corporate governance

- Where We Operate

- Advanced Manufacturing Research Centres

- Research and University Technology Centres

- Rolls-Royce Cybersecurity Technology Research Network

- Our Businesses

- Our History

- Our Heritage Centres

- Heritage Trust – Bristol

- Heritage Trust – Coventry and Ansty

- Heritage Trust – Derby and Hucknall

- Heritage Trust – Indianapolis

- Heritage Trust – Scottish branch

- Become a member

- Learn and explore

- Contact the Trust

- The Magazine

- News & Insights

- Members’ events

- R-RHT Documents

- Inventors & technology licensing

- Defence aerospace business team

- Defence team

- Corporate sustainability team

- Heritage team

- Helicopters team

- Pensions team

- Rolls-Royce no Brasil

- ロールス・ロイスについて

- country-landing-navigation

- Történeteink

- Támogatott kezdeményezések

- Nachrichten

- Geschichten

- Werde Teil des Teams in Dahlewitz bei Berlin

- Talent Community

- Direkteinstieg

- Praktikanten und Werkstudenten

- Karriere bei Rolls-Royce Electrical

- Schülerpraktika

- Tag der Ausbildung

- Engineering

- Manufacturing & supply chain

- Civil Aerospace

- Our approach

- Our community programmes

- MT30 함정용 가스터빈

- MT7 함정용 가스터빈

- 전기, 자동화 및 제어

- Our stories

- The wider South East Asia

- قطاع الطيران المدني

- أنظمة الطاقة

- رولز-رويس التكنولوجيا والفضاء

- رولز-رويس إس إم آر

- معامل بيانات آر2

- تواصلو معنا

- Our emissions footprint

- Decarbonising complex and critical systems

- Creating an enabling environment

- Materiality

- Ethics and compliance

- Engineering and innovation

- Operations and facilities

- Our Stakeholders

- Cyber Security

- Reporting approach

- Target progress

- Data charts

- Share price

- Analyst consensus

- Small Modular Reactors

- Why Rolls-Royce?

- 2023 Full Year Results

- Regulatory news

- Financial Results

- Annual Report 2023

- Annual Reports archive

- Financial calendar

- General Meetings 23 May 2024

- General Meeting archive

- Payments to shareholders

- Manage your shareholding

- Shareholder fraud warning

- Debt Securities

- Rights issue

- Investor contacts

- Company announcements

- Trade press releases

- Press releases

We develop and deliver complex power and propulsion solutions for safety-critical applications in the air, at sea and on land.

Our products and service packages enable our customers to connect people, societies, cultures and economies together.

Products & Services

We develop and deliver complex power and propulsion solutions.

For more than 100 years we have been at the forefront of innovation. Helping to power, protect and connect the modern world.

Create your future with us

Help us deliver better power for our changing world.

Doing more with less

We have a fundamental role in meeting the environmental and societal opportunities and challenges that the world faces.

Capital Markets Day 2023

We will announce new strategic and financial priorities on 28 November 2023 at our Capital Markets Day. We are inviting investors and stakeholders to hear our new priorities and objectives from our leadership team via a livestream.

Rolls-Royce announced Full Year Results on 22 February 2024.

View results

News centre

Updates and news from around the Rolls-Royce businesses.

Sign up to get the latest news

“Mighty” MT30 Marine Gas Turbine successfully achieves full power at highest rating yet

The Rolls-Royce MT30 Marine Gas Turbine has achieved its full power, exceeding 40MW, as part of JS Kumano’s Power and Propulsion system commissioning milestone. JS Kumano is the second ship in the Japan’s 30FFM programme, the 22-ship Mogami-class frigates being built for the Japan Maritime Self-Defense Force (JMSDF).

JS Kumano, launched in November 2020 at Mitsui Shipyard, is the first ship in the 30FFM programme to commence sea trials. Masaru Mizuno , Defence Business Development Manager in Japan, said, “We are proud to help achieve this milestone for the 30FFM program and remain committed to supporting this important period in preparing for JS Kumano’s successful entry into service. Furthermore, MT30 has achieved its highest power rating yet making it the most powerful MT30 running in any ship to date. This successful commissioning means the JMSDF will have the power needed to vigorously test the ship’s performance and systems as part of the important sea trials".

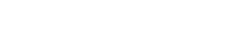

The FFM programme continues at a pace with the commissioning of the MT30 in JS Mogami now well underway ahead of her imminent sea trials. Rolls-Royce has currently delivered five MT30 engines for the Mogami-class programme to KHI and is contracted to deliver a further three engines over the next year. KHI is responsible for manufacturing the specialised compact gas turbine enclosure at its Kobe works and conducting the shore trials prior to delivery to the shipyards. The 22-ship Mogami-class frigates for the JMSDF are initially intended to replace the Abukuma-class frigates and Asagiri-class destroyers, both powered by the Rolls-Royce Marine Spey. The introduction of MT30 into the JMSDF future fleet continues the strong relationship between Rolls-Royce, KHI and JMSDF. The MT30 is the world’s most power-dense marine gas turbine in service today. Designed for 21st century platforms, it entered service with the U.S. Navy’s Freedom-class Littoral Combat Ship in 2008. Since then, in just over a decade, it has gone on to be selected for 11 of the world’s next generation naval programmes and become fondly referred to as the “Mighty” MT30 amongst parts of the naval community.

You can learn more about MT30 here

Rolls-Royce develops and delivers complex power and propulsion solutions for safety-critical applications in the air, at sea and on land.

© Rolls-Royce plc 2024. All rights reserved.

© Rolls-Royce plc . All rights reserved.

- Products & Services

- Country sites

- Electrical Aviation

Vulnerability Reporting

Disclosure Policy

- Use of cookies

- Cookie Settings

- Legal information

- Data privacy

- Anti-slavery statement

- Accessibility

The T58 turbine engine and other high-performance equipment discussed here is very dangerous and is intended to be installed, operated and maintained by experienced, qualified personnel only.

Personal safety is paramount. The requirement to follow proper, established procedures while operating any turbine engine cannot be overemphasized. We are not responsible for any injury or damage that may occur.

By visiting this web site you acknowledge and agree to these terms and specifically agree to hold us harmless from any and all liability. Do not try this at home. The images, text, photos, and code on is web site is copyrighted. Reproduction of this web site in whole or part is expressly prohibited.

This web site is dedicated to turbine engines and turbine powered projects.

Surplus military turboshaft engines (helicopter engines) can easily be adapted to create turbine boats, jet cars, and many other turbine powered vehicles a few of which are showcased within www.TurbineFun.com

The menus and "pop-ups" on this web site are powered by JavaScript. Ensure you have 'JavaScript enabled' in your browser. We've completed successful, cross-platform testing in the latest versions of Internet Explorer, Netscape Navigator, and Mozilla.

If you are still having problems, you may also need to 'loosen up' your browser security settings just a little. Software firewalls (blackice, zone alarm) and 'pop-up' blockers may also cause problems.

You are welcome to add your T58 turbine powered boat or gas turbine project story or related information to my web site. Just e-mail it in and be sure to include lots of photos to show all the details.

You can contact me by e-mail.

As I post new content describing my turbine powered boat, I usually add it to the bottom of the page (so the story flows naturally from top to bottom).

This story begins with My Turbine Dream

T58 powered Jet Bike lights off

We have Gas Turbine engines and parts for your project

All about the Cobra Terminator offshore race boat

Boating the San Juan Islands in northern Puget Sound

Flying my Dynafoil around the lake

My 26ft by 44ft Boathouse is now 'hard at work'

Applying the topcoat on my 30ft Cobra Terminator

Here's a movie of a Gnome H1200 turbine engine running on the cart

My Turbine Powered Boat Project is powered by a T58-GE-8F gas turbine.

A closer look inside the ASD8 Arneson Surface Drive

The Rolls Royce Gnome gas turbine engine is a cousin to the GE T58 Gas Turbine

Here's some really wild Turbine Powered Projects

The T-58 Turbine Engine has been powering helicopters for over 50 years

Repairing the composite transom on my Kevlar Race Boat

A tour of the Speed Decreaser Gear (SDG) for the T-58 gas turbine engine

A closer look at the T58-GE-3 Turbine Engine

I reworked my triple axle 'South Florida Trailers' and tow vehicle

Checkout this unusual Aqua Car

My Kevlar Cobra Terminator 30' offshore race boat

Gas Turbine Engine Fuel and Lube Oil Requirements

We have T-58 starters, instruments, manuals and gearboxes available

Gathering parts for my T58 Turbine Powered Boat conversion

This is the Special Tool used for torquing the T58 turbine gearbox mounting studs

Turbine boat Stainless Braided Hose Assembly tips

Some High-performance Boating and Marine Supply links

Really wild Offshore Racing crashes: Dialup and Broadband

Inexpensive Powder Coating unit setup and tips

Updated: Turbine Powered Honda CRX added hydraulic drive

A look at the Garrett GTP30-67 Gas Turbine

Useful welding and metalworking links

A TIG Welding Cabinet for my Lincoln TIG185 welder

Check out the The Power of Vacuum

It's nice to have hobbies to keep our minds occupied, but let's not forget those who may not be as fortunate. You may find satisfaction in volunteering at your local food bank , or (if you don't have the time) you may prefer to donate to a disaster relief fund or give to help fight hunger or homelessness . Contact your church, look in you local newspaper: there are plenty of worthwhile ways YOU can volunteer . Together, WE CAN MAKE A DIFFERENCE.

I keep my computer humming with free SpyBot and free AVG Antivirus products. I find that Mozilla Firefox picks up a lot less spyware than other browsers. You may want to try a web search with Dogpile as an effective alternative to Google .

- What's My Car Worth?

- Buyer's Guide

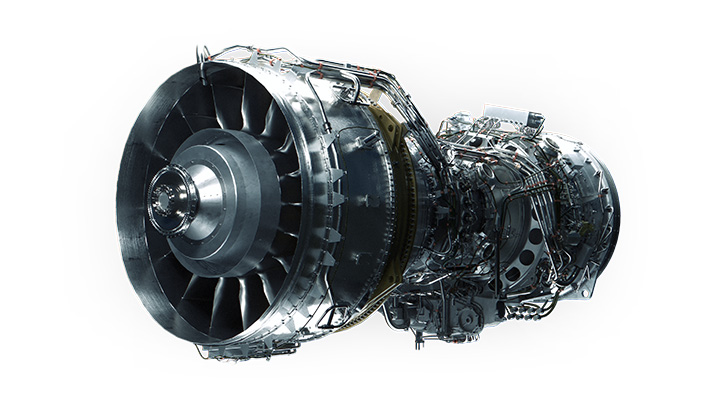

Yamaha's Got a New 7600-RPM, 200-HP Four-Cylinder Engine

We'll take our new engine debuts where we can get them these days. Even if they're in boats.

But the marine industry is a different story, and in recent years some of the coolest new engines— Mercury's V-12 , Honda's V-8 —were designed for boats. Which is also the case for Yamaha's new 1.9-liter four-cylinder, which makes 200 hp at 7600 rpm and can be found powering high-output WaveRunners and jet-drive boats. It's not designed for cars, but the Lemons racers among us can dare to dream.

The 1.9-liter four replaces Yamaha's 180-hp 1.8-liter mill and blurs the performance line between the company's naturally aspirated and supercharged engines. Yamaha's supercharged 1.8-liter makes 255 horsepower, but in a WaveRunner there's not a huge practical difference between the boosted 1.8 in a SVHO model and the naturally aspirated 1.9 that powers HOs. Personal-watercraft manufacturers adhere to an agreement that's something like the old German pact to limit top speeds to 155 mph, except on the water the target is 65 mph. That spec includes a 2-mph fudge factor, which naturally means that PWCs of sufficient horsepower top out at an electronically limited 67 mph. Since a 200-hp WaveRunner can hit that limit, the only difference is how quick you get there.

The 1.9-liter, as a new design, enjoys a bundle of changes aimed at durability and refinement. One example: There's an extra bolt connecting the cam chain housing to the block—a little tweak that makes a big difference. "The cam chain room is a thin aluminum casting," says Mark Sagers, senior watercraft factory service technical specialist (in other words, the guy who knows all the engines inside out). "That great big straight piece of aluminum is like a sound board, amplifying the noise of the cam chain. But if you run a fastener from that to the main casting, it knocks that noise way down. That's important when you're sitting right on top of the engine and it's bolted to a guitar body, basically."

Performance-enhancing upgrades include a new exhaust manifold with dedicated pipes for cylinders one and four, a bore increase from 86 mm to 88 mm, and a channel to route cooling water between the exhaust valves to cool the valve seats. The 1.9 even uses about a half-quart less oil than the 1.8, because Yamaha determined that it could cut windage losses (read: increase horsepower) without sacrificing durability. And durability versus performance is always a tradeoff, whether on land or not. "In a 250-cc motocross bike, the maintenance schedule calls for a new piston every nine hours and it's putting out specific power like a NASCAR engine, or almost Indy," says Sagers. "Boats are more on the lower end of high performance, so we can make them last thousands of hours."

A car engine might well make its horsepower peak beyond 7000 rpm, but it isn't expected to spend much time there. An engine destined for a WaveRunner is a different story. "A lot of the durability testing is done fully loaded at wide open throttle," Sagers says. "These will run a very long time at WOT. Waverunners are often idling or WOT, and there's no middle ground. But I've seen Waverunner engines with more than 1500 hours and no major mechanical work. It's staggering that these mechanical things can live through this."

Still, 200 hp isn't enough for everyone. Logically, it would seem inevitable that this engine will get a supercharger and the 1.8-liter will be retired. Boost prognosticators might find a clue at the 1.9-liter's Coast Guard–mandated intake flame arrester—the intake manifold is cast around it so it can't be sucked into the engine. Which is the kind of thing that would probably only happen if said intake was huffing some major boost. Perhaps soon, it will be.

In the meantime, you can break the 200-hp barrier without forced induction. And for twin-engine boats, that means Yamaha is packing 400 horsepower into some of its 22-footers, which we imagine would mean 50-plus-mph top speeds given that the 210 FSH hit 48.0 mph with the 1.8s and their 360 total horsepower.

Yamaha has built some nice automotive engines—most famously, the Ford Taurus SHO's —but those of us dreaming of 200-hp Yamaha-powered Miatas will probably have to wait a while for these latest ones to hit the salvage yards. (You can spend that interim figuring out how to adapt a closed-loop cooling system, since the jet drive on these engines doubles as a water pump.)

Calling a powerplant a "boat motor" is traditionally a pejorative, meaning a low-revving hunk of iron, an outdated castoff better suited as a mooring. But motors are electric, and that's where things are heading on the highways. So if you appreciate the mechanical complexity and cleverness of engines, boats are the new—and maybe last—frontier.

Ezra Dyer is a Car and Driver senior editor and columnist. He's now based in North Carolina but still remembers how to turn right. He owns a 2009 GEM e4 and once drove 206 mph. Those facts are mutually exclusive.

.css-190qir1:before{background-color:#000000;color:#fff;left:0;width:50%;border:0 solid transparent;bottom:48%;height:0.125rem;content:'';position:absolute;z-index:-10;} News .css-188buow:after{background-color:#000000;color:#fff;right:0;width:50%;border:0 solid transparent;bottom:48%;height:0.125rem;content:'';position:absolute;z-index:-10;}

2025 Nissan Kicks Glows Up, Now Offering AWD

How Cupra Plans to Sell EVs in America by 2028

335-HP VW ID.Buzz GTX Coming to U.S. as AWD Model

Stylish 2025 Kia K4 Sedan Set to Replace Forte

Mercedes Recalls 116,000 SUVs with 48-Volt Issue

Ford Starts Ranger Raptor Off-Road School

BMW's Neue Klasse X Concept Is a Big Tease

New QX80 Drops Jaws with Bold Design, $100K+ Price

Feds Tighten Emissions Rules to Encourage EVs

2025 Mercedes-Benz GLC350e Plug-In Hybrid Revealed

$101K Wrangler V-8 Final Edition Drops the Mic

Six innovative ways to float skyscraper-sized wind turbines

Career Development Fellow in Engineering, University of Oxford

Disclosure statement

Emma C. Edwards has received funding through the Cornwall FLOW Accelerator, funded through the European Regional Development Fund. Her other research has been funded by the US Office of Naval Research and the UK Research & Innovation council.

University of Oxford provides funding as a member of The Conversation UK.

View all partners

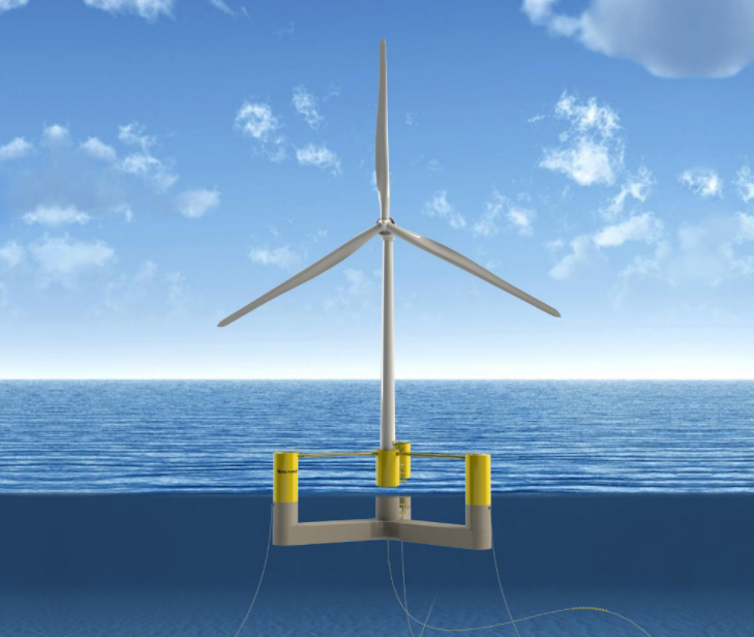

Yes, you read that right – float. You may have seen a wind turbine in the sea before, but chances are you were looking at a “fixed” turbine – that is, one that sits on top of a foundation drilled into the seabed. For the new frontier of offshore wind power, the focus is on floating wind turbines. In this case, the turbines are supported by floating structures that bob and sway in response to waves and wind and are moored with chains and anchored to the seafloor.

This is becoming the focus of the sector for the simple reason that most wind blows above deep water, where building fixed platforms would be too expensive or simply impossible. Designing these new floating platforms is a true engineering challenge, and is a focus of my academic research .

These wind turbines are enormous, reaching up to 240m tall – about the size of a skyscraper. Since they are so tall, strong winds far above the sea surface tend to make the turbine want to tilt, so platform designs focus on minimising this tilt while still being cost-competitive with other forms of energy.

There are more than 100 ideas for platform designs, but we can broadly group them into the following six categories:

Spars are narrow, deep platforms with weight added to the bottom to counteract the wind force (this is called “ballast”). They are usually relatively easy to make because they normally consist of just one cylinder.

However, they can extend 100 metres or more underwater, which means they can’t be deployed in normal docks which are not deep enough. Specialist installation procedures are required to install the turbine once the platform has been towed into deep water.

Barges are wide, shallow platforms that use buoyancy far from the centre of the structure to counteract the wind force on the tower. As they usually extend less than 10 metres underwater, they do not need any specialist deep-water docks or installation vessels.

However, they can be difficult to make because the platform is usually a single, large unit with a complex shape.

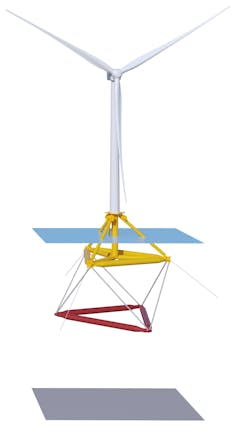

3. Tension-leg platform

Tension-leg platforms, or TLPs, use taut mooring lines to connect the platform to the seabed and stop the turbine from tilting in the wind.

These platforms are usually smaller and lighter than the other types, which makes them easier to fit at a standard port. Also, their seabed “footprint” is small due to the taut lines.

However, the platforms are usually not stable until attached to their mooring lines, meaning that a special towing and installation solution is required.

4. Semi-submersible

Semi-submersibles consist of three, four or five connected vertical cylinders, with the turbine in the middle or above one of the columns. The platform utilises buoyancy far from the centre (similar to the barge) and ballast at the base of each column (similar to the spar).

Like barges, semi-submersibles do not require specialist tow-out equipment and work for a wide range of water depths. Manufacturing is again a challenge.

5. Combination-type

The four categories above are the more “traditional” platforms, influenced by their predecessors in the oil and gas industry. Since the 1960s, floating platforms have meant huge oil rigs can access deeper water sites (the deepest is over 2,000m). Most of these oil rigs in deep water are either semi-submersibles, anchored to the seabed with chains, or TLPs, connected to the seabed with taut cables.

More recently, there has been a trend towards platforms more specialised to floating wind. Specifically, some use a combination of the stability mechanisms, taking advantages from each of the previous designs.

For example, “lowerable ballast” platforms look like traditional semi-submersible or barge platforms, but with a weight hanging from from taut cables.

During turbine installation at the port and tow-out, the weight is raised, so that a traditional (non-deep) dock can be used and no specialist equipment is needed. At the site of installation, the weight is lowered and the platform gets extra stability from a low centre of mass.

Other designs use the benefits of stability from taut mooring lines (similar to a TLP) but are designed to be stable during tow-out and so don’t need a special installation vessel. For example, the picture below shows the X1 Wind platform:

The taut mooring lines are attached to a single column, which is installed initially. The rest of the platform, which is self-stable, is then towed out and connected to the pre-installed column with the taut mooring lines. The platform uses the extra stability from the mooring lines but without the tow-out instability typical of TLPs.

6. Hybrid platforms

These platforms add another type of renewable energy, most commonly a wave energy converter. This increases the overall amount of energy generated, and reduces costs as power cables, maintenance and other infrastructure can be shared.

A wave energy converter also reduces platform motion, which in turn increases the power performance from the turbine.

Room for improvement

Four floating offshore wind farms have already been built, the largest of which was opened in 2023 off the coast of Norway . Two of these farms use the Hywind spar design and two use the WindFloat semi-submersible .

There have been 18 other platform designs to reach at-sea testing, including at least one of each of the categories described above. Some have plans to build floating farms in the next few years, and additional early-stage designs have plans to deploy their own prototype devices in the near future.

Interestingly, platforms are actually diverging in design. After many years, wind turbines have mostly converged on the three-bladed design that you see today, but there has been no such convergence yet on a consensus “best” floating platform. This suggests significant improvements are still possible, especially in terms of reducing motion and decreasing cost.

Don’t have time to read about climate change as much as you’d like? Get a weekly roundup in your inbox instead. Every Wednesday, The Conversation’s environment editor writes Imagine, a short email that goes a little deeper into just one climate issue. Join the 30,000+ readers who’ve subscribed so far.

- Renewable energy

- Offshore wind

School of Social Sciences – Public Policy and International Relations opportunities

Partner, Senior Talent Acquisition

Deputy Editor - Technology

Sydney Horizon Educators (Identified)

Deputy Vice-Chancellor (Academic and Student Life)

IMAGES

VIDEO

COMMENTS

The same turbine unit can be configured to produce various power outputs. These units are the most popular in the yacht sector. The high-performance 118 WallyPower used three TF50s for main propulsion - one of the few all-turbine installations on a motor yacht. The high speed of the basic turbine of around 20,000rpm had to be geared down ...

Rolls-Royce Marine Spey, a gas turbine developed by Rolls-Royce Holdings in the 1960s for marine propulsion.. Marine propulsion is the mechanism or system used to generate thrust to move a watercraft through water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of an electric motor or internal combustion engine ...

The Vericor TF50 engine, built by a division of MTU, is linked to a centerline Kamewa waterjet and boosts the speed from the 35 or so knots achieved with twin MTU diesels into the rarified air north of 50 knots. Among the more well-known custom yachts with a turbine is the 153-foot Feadship Detroit Eagle, delivered to Roger Penske in 2001.

By: Scott WayThe 160 HP turbine from Astron Aerospace weighs only 35 lbs / Photo- Astron AerospaceThe internal combustion engine may be at a crossroads. It has been the backbone of economics and industry for over a hundred years, and it has served us well. Even more, the marine industry is still developing exceptionally powerful engine platforms with more horsepower with less maintenance than ...

The LM2500+G4 gas turbine provides 47,370 shp, and is the most powerful and efficient member of the LM2500 family. The 40,500 shp LM2500+ marine gas turbine is based on the design and precedent-setting reliability of GE's popular LM2500. The 33,600 shp LM2500 is GE's most popular marine gas turbine, powering more than 400 ships in 33 world navies.

The Rolls-Royce MT7 marine gas turbine features the very latest in gas turbine technology, sharing proven common core architecture with the AE 1107C-Liberty aero engine that powers the V-22 Osprey tilt-rotor aircraft. Delivering power of up to 4.6MW, it's a compact power plant with excellent fuel efficiency and performance retention.

Marine turbine engines have mostly been replaced by large two stroke diesel engines as a means of ships propulsion. This was mainly because of the great difference in fuel consumption, even modern oil-fired steam boilers consumption was up to 30% more than that of today's big diesels. The superheated steam enters the high pressure (HP) stage (the astern turbine is on the same shaft) and ...

The U.S. Navy's DDG-51-class, the longest production program for surface warships in the history of the U.S. Navy, has received over 200 Rolls-Royce AG9140 generator sets (three sets per ship, each delivering 3MW of power). The AG9140s are powered by the 501-K34 engine, an upgrade of the original 501-K17 model delivered to the Spruance-class.

The ST40M marine turboprop gas turbine [7], whose constructive diagram is presented in Fig. 1 below, is an aeroderivative engine, based on a three-shaft, two-spool aircraft engine design [10] [11 ...

SUBMIT. Vericor's marine propulsion systems provide faster vessel speed, enable greater payloads and deliver more power per square foot of machinery space than comparable solutions. When vessel speed is critical and space is a premium, our marine gas turbine engines are an ideal solution.

Rolls-Royce plc. First run. 2000s. Developed from. Rolls-Royce Trent 800. The Rolls-Royce MT30 (Marine Turbine) is a marine gas turbine engine based on the Rolls-Royce Trent 800 aero engine. The MT30 retains 80% commonality with the Trent 800, the engine for the Boeing 777. The maximum power rating is 40 MW and minimum efficient power 25 MW.

Penske installed his own Detroit Diesel-branded engines and then added a 5,600-hp turbine to give the yacht a 10-knot pop at the top end. ... of impressive speeds the yacht can reach. The engines ...

Marine Turbine Technologies, LLC (MTT) is a design, engineering and manufacturing company. We specialize in the packaging of gas turbine engines for unique industrial applications. All of the MTT products involve a gas turbine engine that generates mechanical energy to drive the turbine's output shaft. The output shaft then becomes the power ...

The Vericor TF50B marine gas turbine provides propulsion power for fast naval vessels, mega yachts and other high performance applications. ... The TF Series marine gas turbine engines offer the ideal solution for marine power where compact size and light weight can be translated to faster vessel speed, greater payload, or simply more power per ...

TURBINE ENGINE DOMINANCE. Turbine engines have a power-to-weight ratio that is without equal. For example, the turbine used in the MTT Y2K Superbike produces 420 HP but weighs only 160 lbs. Our 1,400 HP turbine weighs 680 lbs. compared to its diesel counterpart weighing between 8,000 and 10,000 lbs. MTT's larger turbines produce 3,850 HP but ...

In this article, the performance assessment of two-shaft gas turbine engines topped with a four-port through-flow wave rotor as a prime mover for naval ships was performed. Integration of wave rotor technology in marine gas turbines can moderate the fuel consumption and increase the specific power of the engine.

This is where MTT started: Turbine engines used in boats and for marine special projects. Why use turbines in boats? The clear choice for power in the aviation industry, turbine engines are a viable multi-fuel power option for the demanding marine industry. Why? Interestingly, the friction created by wetted opposing surfaces on boats is very similar to the friction of air and the force of ...

MT30 Marine Gas Turbine. Designed with approximately 50 per cent fewer parts than other aero-derived gas turbines in its class, to minimise maintenance costs, the MT30 has a twin-spool, high-pressure ratio gas generator with free power turbine. It maintains operating efficiency down to 25MW and can be configured in either mechanical, electrical ...

For the naval architect and the operator, the advantages are numerous: • Vericor marine gas turbines operate on diesel fuel and are controlled from the bridge just like conventional diesel engines. • Gas turbines operate waterjets or props just like diesel engines. • The gas turbine can be brought on line once underway and only.

Examples of gas turbine configurations: (1) turbojet, (2) turboprop, (3) turboshaft (shown as electric generator), (4) high-bypass turbofan, (5) low-bypass afterburning turbofan A gas turbine, gas turbine engine, or also known by its old name internal combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power ...

The Rolls-Royce MT30 Marine Gas Turbine has achieved its full power, exceeding 40MW, as part of JS Kumano's Power and Propulsion system commissioning milestone. JS Kumano is the second ship in the Japan's 30FFM programme, the 22-ship Mogami-class frigates being built for the Japan Maritime Self-Defense Force (JMSDF).

The turbine boat is a remarkable innovation in the world of marine transportation.Unlike traditional boats that rely on internal combustion engines, turbine boats utilize gas turbines to generate power. These turbines are highly efficient and provide a significant amount of thrust, allowing the boat to achieve high speeds.The turbine boat is known for its smooth and quiet operation, making it ...

The T-58 Turbine Engine has been powering helicopters for over 50 years. Repairing the composite transom on my Kevlar Race Boat. A tour of the Speed Decreaser Gear (SDG) for the T-58 gas turbine engine. A closer look at the T58-GE-3 Turbine Engine. I reworked my triple axle 'South Florida Trailers' and tow vehicle.

But the marine industry is a different story, and in recent years some of the coolest new engines—Mercury's V-12, Honda's V-8—were designed for boats. Which is also the case for Yamaha's new 1 ...

PelaFlex by Swansea-based Marine Power Systems. Marine Power Systems. Tension-leg platforms, or TLPs, use taut mooring lines to connect the platform to the seabed and stop the turbine from tilting ...