- Practical Boat Owner

- Digital edition

Antifouling: Everything you need to know

- October 31, 2023

Our all-inclusive guide to preparing for, choosing and using antifouling paints

Choosing the right antifouling and applying it well is essential for your boat’s performance. A serviced engine , new sails and carefully tensioned rigging are all worthless if you have a coral reef growing on the bottom of your boat.

Even moderate fouling can easily lose you a knot or more of boat speed. But how much preparation does your boat need? Which paint is best and what’s the best way to apply it?

After a few years the thickness of paint on your boat’s bottom will inevitably have built up to the point where it has to be stripped back to the bare hull to start from scratch.

We test DIY methods for scraping, stripping, peeling and blasting old antifouling off the hull. But not all boats will need to do this!

It’s generally recommended that you do this every four to five years with self-eroding antifouling. The good news is that the more antifouling there is on the boat, the easier it is to remove, so it pays to wait a few years between attempts.

First of all, take a good look at the surface of the old paint. Self-eroding antifouling should, as the name suggests, gently remove most of itself during the year – but hard antifouling and many layers of eroding antifouling will eventually build up.

When to scrape off old antifouling There are craters where layers of old paint mean the boat’s bottom resembles a moonscape. There is flaking where patches of paint have peeled off to leave ragged edges. There are blisters where water is trapped under a bubble of paint – usually diagnosed by it being easy to pop. If you suspect the blisters are osmosis, get them checked out by an expert.

If the bottom isn’t too bad, you can probably leave taking it all off for another year and just do some minimal preparation this year, preparing the surface and keying it, to take the new paint.

Article continues below…

Removing antifouling – the job I’ll never do again!

After a season on the water and two years in a boatyard, Maximus’s antifouling was old and flaky. We’d been…

How to antifoul a boat: What we learned from antifouling Maximus

As we’d scraped back the hull and were starting afresh, the idea of releasing biocides into the water, albeit very…

Removing antifouling

If the bottom’s in a bad way, it’s clearly time to take the paint off. First, a warning: removing antifouling is not a pleasant DIY job. You’ll rarely meet a boat owner who has enjoyed the experience, and some pay a professional blasting company to come and do the job for them.

But for most of us, economy dictates that doing it yourself is the only way. PBO tested the various methods out on the bottom of Gallant a Sigma 38. The bottom wasn’t too bad, but 21 years of paint had left it pitted in some places, and the performance of the antifouling left a lot to be desired.

Owner Paul Fenner, with plans for a season of racing this year, wanted to know the best method to remove the old paint.

We headed to the Elephant Boatyard on the Hamble River armed with the three main DIY removal methods available:

- Dry scraping

- Chemical stripping

- DIY soda blasting

We taped out a test grid halfway down Gallant ‘s port side and set to work, dressed to the nines in overalls, gloves, eye protection and face masks. It’s a lovely job!

It’s worth repeating: afterwards, you’ll need to key the surface before painting.

After six hours, the RemovAll had bitten through the top layer of paint

Removing antifouling – Method 1. Dry scraping

Scraping is the cheapest way to take paint off. But which is the best scraper to use? We tried three – a traditional flat-bladed ‘push’ scraper, a triangular paint scraper and a Bahco ‘pull’ scraper with tungsten-carbide blades.

Flat-bladed scraper

Sharpened on a grinding wheel and with the corners ground off, the flat-bladed scraper was good for lifting flakes of paint off.

But for heavy-duty scraping it had a tendency to dig in and try to gouge the gel coat.

Triangular scraper

Sharpened on a grinding wheel and with its pointed corners ground off, the triangular scraper made light work of 21 years’ worth of paint.

An advantage is that you have three scraping surfaces to work with, which gives you extra time before it needs sharpening with a file. But it still needed frequent sharpening.

Bahco scraper

The Bahco scraper uses a reversible tungsten-carbide blade. It was so sharp it shaved the paint off unless you got the blade right underneath the paint layer, and its uber-sharp edges had a tendency to bite into the paint.

But it was probably the most effective. Larger versions have a knob on top for two-handed work that allows you to put a lot of force into it. The tungsten-carbide blade stayed sharp for longer than those of the triangular scraper.

Hi-tech scrapers

PBO reader Philip Stevens uses a Bosch PSE180E electric scraper with the blade’s corners rounded off. It’s no longer made by Bosch but can still be found for sale online.

Cheaper alternatives are sometimes available in discount stores like Lidl and Aldi.

‘It takes a while to get a feel for the correct angles of use but is much easier and cleaner to use than a manual scraper,’ says Philip. ‘A friend did the bottom of his 11.3m (37ft) Moody in a few days.’

Buy it now on Gael Force Marine

Note: We may earn a commission when you buy through links on our site, at no extra cost to you. This doesn’t affect our editorial independence.

PBO VERDICT: Best dry scraper on test

Scraping is quick but very labour intensive. The Bahco was the best, but the triangular scraper was effective – just keep those blades sharp!

TIPS FOR DRY SCRAPING

Round the corners off the blades with a file or on a grinding wheel. This will stop them digging into the gel coat.

Keep the blade sharp with a file or change the blades regularly. Hacking away with a blunt blade is just a waste of your energy.

Yards like you to clean up after yourself. Lay garden fleece, as used for protecting plants from frost, on the ground first. Water drains through, but dust and scrapings are left behind. At the end of the day you can bundle everything up and throw it away.

Removing antifouling – Method 2. Chemical stripping

An option which takes some of the effort out of scraping is to use chemicals to strip the paint.

You can’t just use any old paint stripper though – it has to be one safe for use on GRP.

We tried the three most readily available recommended products: International Paint’s Interstrip AF, Owatrol’s Marine Strip (formerly called Dilunet) and Removall 620 from Cirrus Systems.

Interstrip AF

PRICE: £23.99 for a 1 litre tin

This product is specifically formulated for removing antifouling. The tin’s instructions recommend leaving the product on for 10 minutes before scraping it off with a blunt wooden scraper.

‘This is fine if the antifouling being removed is thin,’ says International’s Richard Jerram, ‘But for thicker layers I would recommend that the Interstrip is left on much longer, even overnight’.

He goes to say that if leaving it overnight a covering of cling film stops the solvent from evaporating and keeps it moist overnight.

We tried scraping after 10 minutes, and the Interstrip had eaten away at the first two layers of paint. We found the best tool was in fact a plastic scraper of the type used to apply filler.

Leaving the stripper to work for 10 minutes each time, we got down to the primer after three applications. The Interstrip will leave the primer untouched, ready for the new coat of antifouling.

The tin recommends cleaning up any remaining antifouling with Thinners No3 – which worked but also started to remove the primer underneath. Finally a quick wet sand prepared the surface for the new antifouling.

PBO VERDICT: Quick but messy, and the fastest-acting of all the strippers we tried. Left the primer intact beneath the paint.

Buy it now on Amazon

RemovALL 620

PRICE: £36.60 for a 3.8 litre tub

Removall is environmentally friendly and safe on your skin. Depending on temperature, youleave it to work for 1-6 hours.

After four hours it had softened the top layer of paint, but nothing underneath, so we applied more and left it overnight. In the morning, the paint had begun to lift, so we scraped it off with a plastic scraper. It took off all the paint down to the primer.

A further application would have revealed the epoxy coating on top of the gel coat. It was viscous enough to not drip when applied.

The instructions say it can be simply blasted off with a pressure- washer. This worked for a few layers, but in our case would have needed another application if we weren’t to resort to a scraper.

PBO VERDICT: Slower acting than Interstrip. Environmentally friendly. Left the primer intact beneath the paint.

Owatrol Marine Strip

PRICE: £17.95 for a 1 litre pot

Marine Strip is sold in most chandleries. It requires 12 hours at least to eat through antifouling, so we applied it and came back the next day.

When applying, it was viscous enough not to drip. The instructions say to wait until the paint changes colour.

After a few hours, it had darkened and had softened the top layers of paint, but 12 hours later, it was really dark. With a plastic scraper we could then remove all the paint layers down to the primer.

It left the primer dry, which would need wet sanding, or another coat of the stripper, before more paint could be applied over the top.

It came off as easily as the Removall, in soft strips. Like the Removall, it can be pressure-washed off, though this was not as effective as scraping.

PBO VERDICT: Slower working and dried the primer out more than Removall, but the paint came off in bigger sheets.

A blunt wooden scraper removed the paint – but a thin plastic one proved more effective

TIPS FOR CHEMICAL STRIPPING

If leaving for extended periods, ie overnight, cover applied areas with cling film to stop the chemical drying out.

Wear eye, hand and body protection. Chemical strippers can burn!

Use synthetic-bristled brushes

Especially where there are many layers of antifouling, you may need a number of applications. Chemicals work better in warmer weather.

The kit comprises a ‘pot’ of soda, and you’ll need to hire a compressor

Removing antifouling – Method 3: DIY Soda blasting

PRICE: SODA POT £159.95 £29.95 per bag of soda

COVERAGE: 1sq m per bag

Most people bring in the experts to blast off their old stuff, but one way to keep costs down is by doing it yourself.

Yorkshire-based company Millar Soda Blasting supply soda ‘pots’ and the accompanying soda which, when coupled with a suitable compressor, lets you do your own blasting.

Company owner Michael Millar made the trip down south to demonstrate the unit. We had a relatively low-powered 13cfm compressor, which meant that the unit’s nozzle had to be small. A larger compressor would mean you could use a larger nozzle.

The soda explodes on contact with the hull, removing antifouling without damaging the GRP. It ate effortlessly through the layers of paint and primer, leaving the epoxy coating intact, and was by far the least labour-intensive of all the methods we tried.

The DIY soda blasting option was slow but effortless. A compressor with a bigger capacity would speed things up significantly

Using the small nozzle it took Michael five minutes to strip a rectangle 15cm x 25cm. We also tried it on another boat’s keel, which was brought back to bright metal quickly and easily, with a residual layer of soda that will protect the metal for up to six weeks.

Hard medium can also be added to the soda mix if you need to blast away more than paint.

PBO VERDICT: A slow but easy way to remove antifouling. You could save money by grouping together with fellow boat owners to share a blasting unit. Hiring a large compressor (30-40cfm) would make the job much quicker.

Buy it now on eBay

Overall verdict: Best DIY method for removing antifouling

Scraping was by far the cheapest and quickest way – but it’s labour-intensive, creates lots of dust and you run the risk of scratching the underlying gel coat.

The chemical strippers were messy and expensive, but did the job well. The ability to paint on and leave overnight makes the job of scraping the hull next day far easier than dry scraping.

And finally, soda blasting is the least labour-intensive – but was extremely slow. A bigger compressor would sort that out.

It’s cheaper than getting someone else to do it – but takes time. If you can afford it, paying someone else to blast it off might not be a bad idea!

For a more in-depth look at removing antifoul , read James Wood’s account of removing the antifoul from the PBO Project Boat, Maximus.

Antifouling preparation

If your boat’s bottom has a half-decent finish, you may be able to postpone the job of removing the old antifouling, but you will need to key the surface to ensure that the next layer of antifouling sticks to it.

Note: Even if you’ve removed your paint, you still need to key the surface.

A coarse, 40- or 60-grit wet/dry sandpaper (used wet to keep dust down) should do the trick. Use plenty of water to avoid clogging the sandpaper and, if it’s cold, consider using warm water and household washing-up gloves.

Change sandpaper regularly – as soon as it begins to lose its bite. Barnacle remains need very thorough treatment, as their cement contains a hormone which encourages young barnacle ‘spat’ to settle nearby. So sand off all this cement until none is left.

If you can organise it, cleaning off the hull like this is actually a job best done soon after the boat comes out of the water.

Old antifouling and marine growth is easier to remove before it hardens out of the water over winter and it saves time in the springtime.

Should I prime my hull?

Whether you’ve had to remove all the old antifouling or are just putting more on this year, you should consider priming the hull. A tie-coat primer ensures the antifouling will stick properly.

If simply overcoating the existing paint, you’ll probably get away without it – but you need to check that the new and old paints won’t react with each other. Most modern paints should be compatible with each other.

If you’ve taken the existing antifouling back to the yacht’s gel coat or epoxy coating, it’s recommended that you paint the hull with primer to ensure good adhesion.

If your existing paint is flaking, you need to prime any bare or flaky patches. Scrape away until all the flaky paint has come off, then feather the edges by wet sanding them.

Generally speaking, self-eroding antifouling can be safely applied over the top of hard, but applying hard on self-eroding should be avoided.

Specialist racing antifoulings, especially those containing Teflon, are generally incompatible with other coatings – it’s worth checking the tin and data-sheets carefully.

If in any doubt, apply a tie-coat of the recommended primer – it’s a lot cheaper and quicker than scraping everything off afterwards and having to buy a new tin of paint!

Which antifouling is best?

When choosing your antifouling you need to find out what will work best on your type of boat and which will be most effective in your sea area.

As a starting point, there are three main types of paint to choose between:

- Copper-based

Eroding antifoulings use the water’s friction to reduce the thickness of the paint and expose fresh layers of biocide. This erosion releases biocides in a controlled manner, providing a longer and more consistent performance throughout the season. It also helps to reduce long-term build-up of antifouling.

It’s important that the correct film thickness is applied to get the right concentration of biocides.

High-speed vessels, boats on drying moorings and racing boats require a hard film antifouling rather than an eroding one. This stops the increased pressure on the hull, whether from high speed, silt and mud or scrubbing, from removing the paint film too quickly. These antifoulings work because the biocide leaches out of the paint without the paint film eroding away.

Another variety with a dedicated following is copper-based paints, such as Coppercoat. These use particles of copper suspended in an epoxy coating and can last up to 10 years, saving you the annual ritual of antifouling.

Copper-based paints are significantly more expensive than standard antifoulings, but will last a great deal longer. Their application is not covered in this article, but they’re worth looking at as a long-term solution to fouling.

So which paint should you choose? That depends not only on where you go boating but also the type of boat you have. Here’s a quick guide to the products available from four of the UK’s leading brands (prices and brands correct as of April 2021):

Cruising yacht

Most cruising yachts will at most scrub off once per season, and many go from launch to haul-out without mid-season attention. To cope with this, manufacturers recommend using eroding antifouling paints, which will continually refresh the surface and biocides exposed to the water throughout the season.

| Micron 350 | Micron 300 | Cruiser 250 | |

| Mille NCT | Tiger Extra | Cruising Performer | |

| 033 Shogun | 033 Shogun | 031 Samurai | |

| NonStop Supreme | NonStop | Mare Nostrum | |

Racing yachts

Serious racers need a smooth antifouling finish to reduce friction with the water. This is traditionally achieved with a hard antifouling that can be burnished with a light abrasive.

However, both Hempel and International now offer products with a Teflon component to reduce friction, which they say can be maintained by regular scrubbing. For club racers who keep their boats afloat for long periods, International suggests Micron 350, which although an eroding antifouling is designed to self-smooth.

| Micron 350 | Ultra 300 | VC Offshore | |

| Mille NCT | Tiger Extra | Hard Racing | |

| 035 Hard Racing | 035 Hard Racing | 035 Hard Racing | |

| Racing | Racing | Racing | |

Displacement powerboats

Displacement power vessels have similar requirements to cruising yachts, but pay carefulattention to the manufacturer’s specification for the maximum speed allowed with your chosen antifouling. The rate of erosion of eroding antifoulings increases dramatically at high speeds and will need to be compensated in the amount you apply.

| Micron 350 | Cruiser 250 | Cruiser 200 | |

| Mille NCT | Cruising Performer | Hard Racing | |

| 033 Shogun | 037 Coastal | 035 Hard Racing | |

| NonStop Supreme | NonStop | Mare Nostrum | |

Planing powerboats

Eroding antifoulings will typically not survive speeds above 25 knots, although Seajet claim 40 knots for many of their products. To combat this, hard paints are typically applied to planing powerboats.

Usually, high speeds will dislodge fouling from the hull of a regularly-used boat, but if you only go afloat occasionally you may need to scrub the hull. As with racing sailing boats, you can choose between an antifouling with or without Teflon.

| Ultra 300 | VC Offshore EU | VC Offshore EU | |

| Hard Racing | Hard Racing | Hard Racing | |

| 035 Hard Racing | 037 Coastal | 037 Coastal | |

| Racing | Racing | Racing | |

Over the winter of 2021/22, we teamed up with our sister magazine Motor Boat & Yachting to test 8 of the antifouling paints side-by-side. Read our best antifouling paint group test feature to find out what we learned.

How to antifoul a boat

This is the fun part. Ideally apply it in the late morning or early afternoon in calm, dry weather to avoid the risk of dampness or overnight dew. Sometimes you may need to put a plastic sheet down to protect the ground, or wet the surrounding area to prevent dust rising onto your paint surface.

If you’re painting on a cold day, keep the tin in a warm place before use, or in a bucket of warm water to help make the paint flow more easily. How much you need to apply varies – but most paints require at least two coats.

- Using a wide stick, stir the paint well. Biocides are heavy and will sink to the bottom of the tin, so stir vigorously and for longer than you think is probably necessary.

- It’s best not to mix old and new batches of paint in a tin. If you do, use a roller tray, with small amounts at a time. But be warned. One reader writes on our web forum: ‘I mixed the contents of my stock pot with a couple of litres of another paint. There was an odd reaction, not unlike a stormy sky, and the stuff seemed to thicken up. Being a cheapskate I applied it to the boat PDQ. It dried looking rather like flock wallpaper.’

- Pour a small quantity at a time into your roller tray – that way if you drop it you won’t lose too much. Replace the lid on the tin, too.

- Apply the paint in a logical fashion. One PBO reader told us of his way of remembering which bits he’d painted. He drew chalk lines at roughly one foot intervals, which disappeared under the new paint so he always knew where he’d got to.

- Use a brush for fiddly bits around transducers and stern gear. For a really smooth finish, someone can follow you with a pad to smooth ridges and remove dribbles.

- If you have enough paint, apply an extra coat along the waterline and leading edges of keels and rudders – all areas that are high wear.

- Paint around the cradle pads – we’ll come to what to do to those later on

For a more in-depth look at how to antifoul a boat , read James Wood’s account of antifouling the PBO Project Boat, Maximus.

Keels can be primed, filled and faired to create the best finish

Keel antifouling

Once a steel keel has started to corrode and become pitted it can be hard work to restore its smooth finish. The trick is to remove the paint first. Then you can begin to tackle any rust.

Use a wire brush, angle grinder, drill attachment or soda blasting to begin to take the keel finish back to bright metal. Apply a rust converter such as Fertan to get rid of the rust.

Once you’ve done that, fill any major voids with solvent-less epoxy filler (this is preferable to using polyester filler as it’s below the waterline). It’s a slow process. If there’s any damage to the leading edge from grounding, you can build that back up with solvent-less epoxy filler as well.

Once you’ve got the keel to an acceptable finish, it’s time to prime it with epoxy primer, to seal it, before proceeding to prime and antifoul it.

An area most likely to show signs of corrosion is the keel root. On many boats this is marked by rusty dribbles, although in many cases this is just an irritation rather than being symptomatic of a deeper problem.

To be sure, give the keel a side-to-side wiggle when the boat is in the slings to make sure it isn’t moving – if it is, consult a professional to have your keel bolts checked . If, as is most likely, the rust is just cosmetic, you can take the visible bits of keel back to bright metal before priming them with rust- remover.

You can them prime them with epoxy primer to stop any water ingress, before sealing the gap with Sikaflex or another flexible underwater sealant. Before you antifoul, consider a further coat of a tie coat primer like Primocon before you paint on the antifouling.

Which roller to use for antifouling

It’s best to use a short mohair or sponge roller suitable for gloss paint. Rollers designed for emulsion will disintegrate very quickly, leaving bits of fluff all over the newly painted surface.

Some people find that smaller radiator-size rollers with long handles are easier to use with such thick paint, but coverage will take longer with these.

Paint around the pads, then wait for the yard to shore the boat up and lower the support

How to paint under cradle pads

Painting under the cradle supports is a common problem for boat owners. The time-honoured solution is to paint around the support, then get the yard to move it before painting the bare areas.

If they won’t do that, you can slap some paint on while the boat is in the slings – but this won’t give you the required two coats or, with most paints, the correct drying time.

I keep my boat on a trailer over the winter and, impatient to get the job done, I chocked the boat up with a hefty fence post, plywood squares and wedges, before gingerly lowering and removing the pad. I painted underneath the pad, ran out of time and wound it back up too soon.

Mistake! When it came to launching, the pad had stuck to the wet paint and left an imprint of itself on the antifouling. This year I’ll take my time!

How to paint a boot-top line

A boot-top line really adds to the look of a boat. What’s more, it ensures the hull will stay free of fouling and contaminants. If your hull is always stained yellow at the end of the season, consider raising the boot top and antifouling level by a few inches.

You have a number of options when it comes to paint. Some people prefer to use a hard antifouling, like International’s Trilux, which will keep the line free from fouling but which, unlike most antifoulings, contains no copper oxide so won’t oxidise at the waterline.

Others use standard gloss paint, which looks better when dry and shiny, but will run a greater risk of fouling. Bear in mind that gloss paint that spends any significant amount of time below the waterline is likely to bubble up.

Use a number of bits of masking tape to ensure a fair curve around the stem

How to mask a straight line

We’ve all seen boats with a wobbly boot-top. The trick to getting it straight is to take your time. First of all, use a good quality tape to ensure paint doesn’t ‘creep’ underneath it. Try to get a stepladder or a low scaffolding at a height so the stripe to be masked is at eye level.

Even better, have someone else look along the line while you stick it on. Pull out a long length of tape, and gently lower it to the hull while looking along it. This will give you a much fairer, even line than if you stick it down at short intervals.

Stand back every now and again to check. When you get to the bow, use a number of pieces of tape to keep the line straight and level as it goes around the curve.

A word about propellers and stern gear

There are a number of options when it comes to stern gear.

Some people like a highly polished finish to the metal so fouling can’t get a grip, others prefer to paint it with a hard antifouling or specialist propeller paint, like Seajet’s Peller Clean, while some coat it in lanolin or similar grease, such as Propshield or Dr Barnacle.

I’m sending mine off to a machine shop to be polished to a high gloss.

What is antifouling paint?

How does antifouling work?

This magnified image (supplied by International Paints) is a cross-section of a self-eroding antifouling paint. The yellow bit on the left hand side is a control section which shows the paint as it is when applied new.

The gap between the horizontal red dotted line and the pale cream section (leached area) is where the paint has eroded when the boat moves. The leached area is the part of the antifouling film which has lost all its biocide through leaching, but because the boat has not been used enough, the dead paint has not been eroded away.

This area dries out and becomes brittle and unstable. You can see a small crack in the film on the left side next to the yellow section which highlights how brittle the film can become.

The leached area needs to be wet sanded away to go back to the stable biocide-rich remains of the old paint (orange section) before a new season’s antifouling is applied on top.

If the wet sanding is not done, it is likely that the old antifouling would flake off on the roller as the new paint is applied or the new paint will fall off underneath the water when the boat goes back in – neither of which are desirable!

One option is to antifoul your propeller with a special coating

Antifouling biocides

Antifouling paints are expensive for good reason – they’re a complicated formula designed to work in very testing conditions. But what actually goes into them? Here, as an example, is the contents of one popular paint, Micron 350 (formerly known as Micron Extra).

GUM ROSIN A natural product harvested from various species of pine trees around the world, gum rosin is used as a binder when dissolved in solvent. It’s soluble in seawater, which allows a controlled release of the biocide mixed with it.

ACRYLIC is used as an insoluble binder when dissolved in solvent. A high acrylic/ low rosin ratio is used in hard, slow-release paints, whereas a low acrylic/ high rosin ratio is used in high eroding paints.

PLASTICISERS are added to increase the flexibility of the paint – gum rosin is a very brittle material, which on its own can cause the paint to crack.

THIXATROPES , normally clay and fumed silica, are added in small quantities to ensure the product does not settle in the tin, to maintain optimum viscosity and to minimise runs and drips.

COPPER OXIDE is a biocide which is effective against both animal and weed fouling.

ZINC OXIDE is slowly soluble in seawater which allows it to help control the polishing rate. It also absorbs UV which can attack the sensitive biocides, especially at the waterline.

EXTENDER PIGMENTS , which include talc, China clay, gypsum (plaster of paris) and barium sulphate are used to adjust the binder-to-pigment ratio, which in turn affects the paint film properties, such as permeability of water and blistering. Careful selection of the extender pigments is particularly important as their particle size and shape greatly affects their performance.

SOLVENT XYLENE and NAPHTHA these are used to dissolve components of the paint. The evaporation of the solvents causes the paint to dry and form a film.

Further reading on antifouling

Ultrasonic antifouling.

Antifouling that reduces the need for regular stripping, sanding and repainting has broad appeal. But is ultrasonic antifouling the answer?

Back in 2015, PBO editor Ben Meakins donned his diving gear to put four options to the test. You can read his findings in our feature on ultrasonic antifouling .

Propeller antifouling

Getting antifoul to stick to your propeller can be a tricky task and we’re often asked for the best way to do it.

In this article on propeller antifouling , PBO expert Vyv Cox shares his best advice.

Copper antifouling

A popular option on the market, copper antifouling boasts a 10-year lifespan, but some have raised concerns about whether it could cause damage to your hull.

But as marine surveyor Colin Brown explains in this article on copper antifouling , that needn’t be a worry if you prepare the surface properly.

Taking your time masking the boot-top will give a better finish

Why do we need antifouling?

You might even be wondering if it’s worth all the hassle and if you could skip antifouling altogether. As PBO editor Alison Wood explains, that’s not a good idea!

Here’s her piece explaining how antifoul works , what it contains and why we need it.

3 top tips for antifouling your boat

- Keep a rag and some thinners handy for the inevitable splashes and drips. That way you can remove them easily and quickly.

- As soon as the final coat feels tacky, remove the masking tape. It will be difficult to get off later on. Dispose of it quickly unless you want it to make fancy patterns on your topsides as it blows in the wind.

- Don’t apply the antifouling too vigorously or try to stretch it too far – if you do that you will run the risk of disturbing the primer below.

And finally, sail more!

Unfortunately, no antifouling is going to keep your boat completely slime free. But the more you use your boat, the better the antifouling works, as International Paint’s Richard Jerram reminds us:

‘Antifouling paint always works best when the boat is well used as they are developed to work when in motion. So if you want a completely clean hull then choose the most appropriate antifouling and get out onto the water. Do you really need an excuse?’

- Search for:

No products in the basket.

- Base Layers

- Technical T-Shirts

- Sailing Jackets

- Sailing Trousers

- Dinghy Footwear

- Sweatshirts

- Holebrook Samples

- Pelle Samples

- Changing Robes

- Cleaners & Proofers

- Scarves / Snood

- Dinghy Equipment

- Hi-fits / Trousers

- Hiking Equipment

- Hiking Shorts

- Spray Tops / Smocks

- Full Wetsuits

- Shorty Wetsuits

- Long John Wetsuits

- Wetsuit Tops

- Wetsuit Shorts & Trousers

- Summer Wetsuits

- Winter Wetsuits

- Children’s Wetsuits

- Men’s Wetsuits

- Women's Wetsuits

- Wetsuit Sale

- Technical Clothing

- Casual Clothing

- Hats, Gloves, Socks & Scarves

- Watersports

- Accessories Sale

- Amazing Bundle Deals

- Cables & Accessories

- Fixed GPS/plotters

- GPS Antennas

- Handheld GPS/Plotters

- Marine Cameras

- Mounting/Brackets

- Radar Scanners

- Sailing Watches

- Thermal Cameras

- Waterproof Cases

- Accessories

- Fish Finder Sonar

- Depth Instruments

- Multifunction Systems

- Speed Instruments

- Weather Instruments

- Wind Instruments

- Autopilot Accessories

- Cockpit Autopilots

- Onboard Autopilots

- Navigation Charts

- Plotting Aids

- Entertainment Accessories

- Entertainment Systems

- Speakers & Subs

- Electronics

- 4G and WIFI

- Handheld VHF Radio

- Mounted VHF Radio

- VHF Antennas

- Walkie Talkies

- Buoyancy Aids

- Lifejackets

- Children’s Life Jackets

- Commercial Lifejackets

- Harnesses/Bosuns Chair

- Lifejacket Accessories

- Safety Knives

- Safety Lights

- Safety Lines

- PLB & AIS

- Satellite Communicators

- Fire Safety Stick

- Fire Extinguishers

- GPS Tracker

- Liferaft Accessories

- Recovery Devices

- Survival Suit

- Cones & Balls

- Dye Markers

- Horns & Whistles

- RADAR Reflectors

- Bungs & Bailers

- Battery Management

- Chargers & Alternators

- Electrical Other

- Leisure Batteries

- Plugs & Connectors

- Shore Power

- Wind Generator

- USB & Phone Chargers

- Blocks & Terminals

- Circuit Breakers

- Seals / Outlets / Plugs

- Switches & Panels

- Wires & Cables

- Deck Lights

- Interior Lighting

- Navigation Lights

- Searchlights

- Head Torches

- Freshwater Pumps

- Macerator Pumps

- Service Kits

- Toilets/Waste

- Spray Guns & Connectors

- Toilet Accessories

- Toilet Parts

- Waste Tanks

- Ball Valves

- Inlet & Skin Fittings

- Metal Plumbing Fittings

- Plastic Plumbing Fittings

- Diverter Valves

- Non Return Valves

- Deionised Water

- Filters & Purification

- Taps & Sinks

- Water Heaters

- Water Tanks

- Gas Connectors

- Gas Fittings

- Bow Thruster

- Bungs And Self Bailers

- Cleats and Fairleads

- Deck Filler

- Deck Flooring & Protection

- Eye Bolts & U Bolts

- Grab Rail / Handles

- Hooks and Clips

- Latches & Catches

- Shackles & Swivels

- Tiller Extenders & Joints

- Track & Cars

- Winch Handles

- Fans & Windscoops

- Hatch & Inspection Covers

- Hatch Shades

- Hatches & Portlights

- Plastic Hatches

- Yacht / Keelboat Rope

- Dinghy Rope

- Dockline / Mooring Rope

- General Purpose Rope

- Watersports Rope

- Fender Rope

- Rope Accessories

- Furling & Reefing

- Mast, Spars & Sails

- Pins & Rings

- Rigging Screws, Adjusters & Tensioners

- Splicing & Whipping

- Thimbles & Stoppers

- Galvanising Paints

- Thinners & Solvents

- Paint Brushes

- Glue & Adhesives

- Mixing Pots & Accessories

- Resins & Epoxy

- Sealants & Caulking

- Boat Cleaner

- Cleaning Equipment

- Fabric Cleaners & Proofers

- General Cleaners

- Metal Cleaners

- Onboard Cleaner

- Polishes & Waxes

- Vinyl Cleaner

- Teak Cleaner

- All Zinc Anodes

- Zinc Shaft / Prop

- Zinc Engine / Outdrive

- All Aluminium Anodes

- Aluminium Hull

- Aluminium Shaft / Prop

- Aluminium Engine / Outdrive

- All Magnesium Anodes

- Magnesium Hull

- Magnesium Shaft / Prop

- Magnesium Engine / Outdrive

- Bow Thruster Anodes

- Hanging Anodes

- Bolts & Fixings

- Backing Pads

- Lubricants & Grease

- Power Tools

- Marine Prepacks

- Dehumidifiers

- Blowers & Exhaust

- Engine Oil & Additives

- Oil Extractors & Filters

- Shaft Bearings

- Pumps & Inflation

- Tender Accessories

- Petrol Engines

- Boat Fender

- Dock Fender

- Edging Strip

- Hooks & Pumps

- Mooring Buoy

- Step Fenders

- Anchor Bags

- Anchor Connectors

- Anchor Lines

- Anchor Windlass

- Compensators

- Personal Craft

- Engine Covers

- Fuel Tanks & Lines

- Fuel Connectors

- Kill Switches

- Propeller Bags

- Straps & Ratchets

- Flag Staff & Holder

- Lighters & Matches

- Cabinet Fridges

- Cooling Kits

- Portable Fridge/freezers

- Chandlery Misc

- Cup Holders

- Sail Knives

- Seats & Cushions

- Games & Toys

- Gift Vouchers

- Nautical Gifts

- Novelty Hats

- Anemometers

- Clocks & Barometers

- Teak Fittings

- Weather Stations

- Galley Equipment

- Tumblers & Glasses

- Water Bottles & Flask

- Inflatable Paddleboards

- Hard Paddleboards

- Inflatable Kayaks

- Handles / Bridles

- Throw Lines

- Swim Accessories

- Sea Scooter

- Free Delivery on UK mainland orders over £100 excl. Highlands / rural areas

FREE Next Working Day or Saturday delivery on orders over £150 - Choose option in basket (UK mainland, excludes Highlands rural areas, order before 3pm. Saturday delivery option available from 3PM Thursdays.)

Boat Antifouling Paint and Self Polishing Antifoul

Antifouling paint protects your boat from barnacles, algae and marine organisms using biocides released by the paint, including copper, organotin compounds and other agents. Coating the hull with antifoul preserves its performance including top speeds and fuel consumption. We stock a full range of premium hard and self-polishing antifoul paints from top brands such as International , Hempel and Seajet .

Need help selecting the right antifoul? Check out our useful guide to antifouling paint . Or how much antifoul you need? Check our coverage guide HERE

Showing all 26 results

International Micron 350

Hempel Tiger Xtra Antifoul

Hempel Classic Antifouling – 2.5 Litre

Seajet 033 Shogun Antifouling 2.5 Litre

International Cruiser 250

Hempel Silic One Topcoat Antifoul Paint – Biocide Free

Hempel Hard Racing Antifoul

International Ultra 300

International Trilux Prop-O-Drev

Seajet 037 Coastal Hard Antifoul

Hempel Ecopower Prop Antifoul – Biocide Free

Hempel Cruising Performer – 2.5 Litre

Seajet 031 Samurai Antifoul Paint

International VC Offshore EU – 2 Litre

International Hard Antifouling

Hempel Hard Racing Boottop 375ml

International Micron 300 Dark Grey 2.5L

Hempel Mille NCT Antifouling Paint

Seajet Emperor Anitfoul

Hempel Silic One Propeller Kit

Hempel Alu Prop NCT

International Cruiser 200 Antifouling

Polymarine SP54 PVC Antifoul

International Micron 350 750ml

Seajet 035 Hard Racing Antifoul

Polymarine sp54 Hypalon Antifouling Paint

Username or email address *

Password *

Remember me Log in

Lost your password?

Email address *

A password will be sent to your email address.

- EU STORE, IRELAND BASED | WORLDWIDE SHIPPING | FREE DELIVERY TO IRL & NI FOR ORDERS OVER €80

Antifoul - Bottom Paint

- BOAT CARE & MAINTENANCE

At CH Marine we stock a wide range antifoul paint and bottom paint for both commercial and leisure applications. Our range includes top brands such International and Jotun. These antifouls come in self-polishing and hard racing versions and there are is a bottom paint for all types of uses from general sailing or high performance. Popular brands include, Cruiser, Micron, VC Antifoul, Mare Nostrum, Boat Guard and Seaforce are all in the range

International Ultra 300 Antifoul for High Speed Craft - 2.5L

- International

International Micron 300 Antifoul - Dark Grey 2.5L

International Micron 350 Antifoul - 2.5L

International Prop Primer Red - 250Ml

International Cruiser 200 Antifoul - 375ML

International Cruiser 200 Antifoul - 2.5L

International Cruiser 250 Antifoul - 3L

International Micron 350 Antifoul - 750ml

International Cruiser 250 Antifoul - 750ml

International Primocon Antifoul Primer - Grey - 2.5L

International Primocon Antifoul Primer - Grey - 750ml

International Ultra 300 Antifoul for High Speed Craft - 750ml

International VC Tar 2 Part Epoxy Primer White - 1L

International Trilux Prop-O-Drev Spray Antifoul - Grey - 500ml

International VC Offshore EU Antifoul - 2L

Jotun Seaforce 30 Antifoul 5L

Jotun Jotun Vinyl Primer Grey

Jotun Nonstop Antifoul 2.5L

Jotun Mare Nostrum SP Antifoul - 5L

Jotun Mare Nostrum SP Antifoul 2.5L

International Boatguard 100 Freshwater Antifoul - 2.5L

International VC General Thinners - 1L

International VC Tar2 Part Epoxy Primer - Black - 2.5L

International Interprotect Epoxy Primer - 750ml

International VC Prop-O-Drev Primer - Grey - 300ml

Owatrol Marine Strip - Paint & Antifouling Stripper - 2.5L

Owatrol Marine Strip Paint & Antifouling Stripper - 1L

International VC Offshore EU Antifoul - 750ml

Owatrol Oil Paint Conditioner and Rust Inhibitor 500ml Tin

Owatrol Oil Paint Conditioner and Rust Inhibitor 1L Tin

- Nautic House Marsh Rd Skibbereen Co. Cork Ireland P81 R230

- Call us on 021 4315700

About CH Marine

- Stores & Hours

- About Xtra Loyalty

- Join Xtra Loyalty

- Xtra Dashboard

Customer Service

- Brexit Notes

- Privacy Policy

- Returns Policy

- Terms & Conditions

- Shipping & Delivery Times

- Gift Certificates

- WEEE Recycling

Popular Brands

- See all brands here

- Subscribe to our newsletter

International

Interswift 6600, antifoulings-tbt free antifouling, find out more.

Speak with one of our experts to discuss how we can get the best results for your area of application.

Characteristics

Application guidelines, support & advice.

Guidance for the application of our marine coatings

Cargo Resistance Guide

Designed for vessels engaged in transportation of bulk liquid cargoes

MED Declaration of Conformity

Approved for application in accordance with MED & MRA requirements

Our most popular colour shades displayed and are available worldwide

Technical Service

Our highly qualified and experienced Technical Service team are on hand

Safety Datasheets (SDS)

Search for Safety Data Sheets (SDS) for Marine Coating products

We are here to help

Marine Paint: A Comprehensive Guide for Owners

Marine paint is a specialized type of coating designed specifically for use in marine environments. Its primary purpose is to protect marine vessels, structures, and equipment from the harsh conditions.

Marine paint is formulated to provide superior protection to boats, yachts, ships, and other watercraft. It is available in a wide range of colors and finishes, including gloss, semi-gloss, and matte.

Some of the key characteristics of these coating systems include:

- Resistance to saltwater, UV radiation, and temperature fluctuations

- High durability and abrasion resistance

- Resistance to fading and chalking

- Resistance to marine fouling, such as algae, barnacles, and other organisms

Marine paint is formulated with special additives and resins that provide these properties. Some of the most common resins used in boat paint include epoxy, polyurethane, and alkyd. These resins provide high durability, adhesion, and chemical resistance.

When selecting marine coating systems, it is important to consider the specific needs of the vessel or structure being painted. Factors such as the type of watercraft, the intended use, and the environmental conditions will all impact the choice of coating. It is also important to follow proper surface preparation and application techniques to ensure the best possible results.

Overall, marine coating is an essential component of any watercraft maintenance program. By providing superior protection against the harsh marine environment, it helps to extend the life of boats and other marine structures and equipment.

Types of Marine Paint

When it comes to marine paint, there are several types to choose from. Each type of paint is designed for a specific purpose, and it is important to choose the right one for your boat. Here are the most common types of marine coatings:

Topside Boat Paint

Topside boat paint is designed to be used above the waterline of a boat. This type of paint is used on the hull, deck, and interior of a boat. Topside paints come in a variety of options, including one-part polyurethane, two-part polyurethane, and alkyd marine enamel. One-part polyurethane is the easiest to apply, while two-part polyurethane provides a more durable finish. Alkyd marine enamel is a budget-friendly option that is easy to apply, but it is not as durable as polyurethane.

Boat Bottom Paint

Boat bottom paint is used on the hull below the waterline. This type of paint is designed to protect the hull from the harsh marine environment, such as barnacles, algae, and other marine growth. There are two types of boat bottom paint: hard bottom paint and ablative bottom paint. Hard bottom paint is a durable option that provides long-lasting protection, while ablative bottom paint slowly wears away over time, releasing biocides to prevent marine growth.

Antifouling Paint

Antifouling paint is a type of boat bottom paint that is specifically designed to prevent marine growth. This type of paint contains biocides that prevent barnacles, algae, and other marine growth from attaching to the hull. Antifouling paint is available in both hard and ablative options.

Marine Deck Coatings

Marine deck coatings are used on the deck of a boat to protect it from the harsh marine environment. This type of paint is designed to be slip-resistant and to provide a durable finish. Marine deck coatings come in a variety of options, including epoxy, polyurethane, and acrylic. Epoxy is the most durable option, while acrylic is the most budget-friendly. Polyurethane provides a balance between durability and cost.

Choosing the right marine paint for your boat is important to ensure that it is protected from the harsh marine environment. By understanding the different types of paint available, you can choose the right one for your boat’s needs.

Application of Marine Paint

Here are some guidelines on how to apply marine paint effectively.

Surface Preparation

Before applying marine paint, it is essential to prepare the surface properly. The surface should be clean, dry, and free of any contaminants such as oil, grease, or rust. The following steps should be followed for surface preparation:

- Remove any loose paint, rust, or other debris using a wire brush or sandpaper.

- Clean the surface thoroughly using a solvent or detergent.

- Rinse the surface with clean water and allow it to dry completely.

- Sand the surface to create a rough surface for better adhesion of the paint.

Paint Application

Once the surface is properly prepared, it is time to apply your coating. The following steps should be followed for paint application:

- Stir the paint thoroughly to ensure that it is well mixed.

- Apply the paint using a brush, roller, or spray gun, depending on the size and shape of the surface being painted.

- Apply the paint in thin, even coats, and avoid over-applying the paint to prevent runs and drips.

- Allow each coat to dry completely before applying the next coat.

Drying Time

The drying time of marine paint depends on several factors, such as temperature, humidity, and the thickness of the paint layer. Generally, these coatings take about 24 hours to dry completely. However, it is recommended to wait for at least 48 hours before exposing the painted surface to water or other harsh conditions.

In conclusion, proper surface preparation, paint application, and drying time are crucial for the effective application of marine paint. By following these guidelines, one can ensure that the painted surface is protected from the harsh marine environment.

Marine Paint Brands

When it comes to marine paint, there are several reputable brands to choose from. Each brand has its own unique features and benefits, so it’s important to do your research and choose the one that best fits your needs. Here are some of the top brands:

Interlux is a well-known brand in the marine industry, offering a wide range of high-quality paints and coatings. Their products are designed to provide long-lasting protection against the harsh marine environment, including resistance to fading, chalking, and abrasion. Interlux offers both topside and bottom paints, as well as varnishes and primers.

Pettit has been a trusted name in marine coatings for over 150 years. Their products are known for their durability and long-lasting protection against the elements. Pettit offers a wide range of bottom paints, topside paints, varnishes, and primers, as well as specialty coatings for specific applications.

Awlgrip is a premium paint brand, known for its high-gloss finish and superior durability. Their products are designed to provide long-lasting protection against UV rays, saltwater, and other harsh marine conditions. Awlgrip offers a range of topcoats, primers, and specialty coatings, as well as custom color matching services.

TotalBoat is a newer brand in the marine industry, but they have quickly gained a reputation for offering high-quality products at an affordable price point. Their products are designed to be easy to use and provide long-lasting protection against the elements. TotalBoat offers a range of paints and coatings, including topside paints, bottom paints, and varnishes.

Overall, there are many great marine paint brands to choose from. Whether you’re looking for a premium product or something more affordable, there is a brand out there that can meet your needs. It’s important to do your research and choose a product that will provide the protection and durability you need for your specific application.

Environmental Impact of Marine Paint

Marine paint is a coating applied to the exterior of ships and boats to protect them from corrosion, fouling, and other environmental factors . However, the environmental impact of marine paint has been a growing concern in recent years.

One of the main issues with marine paint is that it can contain toxic chemicals such as copper, lead, and tributyltin (TBT). These chemicals can leach into the water and harm marine life, including fish, shellfish, and other aquatic organisms. TBT, in particular, has been linked to reproductive problems in marine mammals and has been banned in many countries since 2008.

Another environmental issue these coatings is the release of microplastics and paint particles into the ocean. These particles can be ingested by marine life, leading to potential health problems and even death. Estimates suggest that paint particles may contribute up to 35% of the synthetic micro-debris input in the ocean.

To address these environmental concerns, many countries have implemented regulations on the use of marine paint. For example, the International Maritime Organization (IMO) has developed guidelines for the use of antifouling coatings, which are designed to prevent the growth of marine organisms on the hulls of ships. These guidelines limit the use of harmful chemicals and require the use of environmentally friendly alternatives.

In addition to regulations, there has been a growing trend towards the use of eco-friendly marine coatings. These coatings are made from natural materials and are designed to be biodegradable, non-toxic, and sustainable. While these coatings may be more expensive than traditional marine paint, they offer a more environmentally friendly solution to protecting ships and boats from the harsh marine environment.

Overall, the environmental impact of marine paint is a complex issue that requires careful consideration and regulation. While there have been efforts to reduce the use of harmful chemicals and promote eco-friendly alternatives, more work needs to be done to ensure the long-term sustainability of the marine industry.

Frequently Asked Questions

What is the difference between marine paint and regular paint.

Marine paint is specially formulated to withstand the harsh marine environment. It is designed to provide a durable, long-lasting finish that can protect the boat from corrosion, fading, and other forms of damage. Regular paint, on the other hand, is not designed to withstand these conditions and can quickly deteriorate when exposed to the marine environment.

What kind of paint is used in marine painting?

There are different types of marine paints available, including antifouling paint, topside paint, and bottom paint. Antifouling paint is used to prevent marine growth, such as barnacles and algae, from attaching to the hull. Topside paint is used above the waterline and can be used to paint the deck, cabin, and other areas. Bottom paint is used below the waterline to protect the hull from marine growth and other forms of damage.

What is a good brand of marine paint?

There are several good brands of marine coating available, including Interlux, Pettit, and West Marine. These brands offer a range of products, including antifouling paint, topside paint, and bottom paint, that are designed to provide durable, long-lasting protection for boats in the marine environment.

How long does marine paint last?

The lifespan of marine paint can vary depending on several factors, including the type of paint, the quality of the application, and the conditions of the marine environment. Generally, a high-quality coatings can last for several years, but it may need to be reapplied every few years to maintain its protective properties.

Does marine paint need primer?

In most cases, marine paint does require a primer. The primer helps to ensure that the paint adheres properly to the surface and provides a smooth, even finish. However, there are some types of paint that are self-priming, so it is important to read the manufacturer’s instructions carefully before applying the paint.

Can you use marine paint on fiberglass boats?

Yes, marine paint can be used on fiberglass boats. However, it is important to use a paint that is specifically designed for use on fiberglass surfaces. These paints are formulated to adhere properly to fiberglass and provide the necessary protection against the marine environment.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

You are using an outdated browser. Please upgrade your browser to improve your experience.

International Boat Paints & Antifouling

As one of the world’s largest manufacturers of high-performance boat paint and marine protection, International has been at the forefront of innovation in yacht coatings for decades. Trusted by boat owners and professionals globally, International offers a comprehensive range of solutions to protect, beautify, and enhance the performance of all types of boats.

No matter where your adventures take you, International has you covered with high-performance coatings for both above and below the waterline. From antifouling paints to undercoats and yacht varnishes.

Explore our range of International marine paint and products today at Force 4 Chandlery.

- Anti-Osmosis Treatments

- Antifouling Paint

- Cleaners, Polish & Teak Care

- Cleaning & Polishing

- Deck & Bilge Paints

- Gelcoat & Paint Cleaners

- Glosses & Topcoats

- Hard Antifouling

- Hull Polish

- Maintenance

- Maintenance & Repair

- Paint & Varnish

- Paint Strippers

- Primers & Undercoats

- Propeller & Stern Gear

- Resins, Glues & Fillers

- Self-Eroding Antifouling

- Spray Antifouling

- Tapes & Sail Repair

- Teak Cleaners & Treatments

- £4.00 - £24.00

- £24.00 - £44.00

- £44.00 - £64.00

- £64.00 - £84.00

- £84.00 - £104.00

- £104.00 - £140.00

- International Marine Coatings

- International Protective Coatings

A division of AkzoNobel, Interlux® is one of the world’s largest manufacturers of high performance boat paint, yacht coatings and marine protection. Formed in 1881, the Interlux brand has become synonymous with the highest standard of care for all kinds of vessels and is an integral part of boat building and maintenance. For over a century, Interlux has been creating the most innovative coating solutions to protect, beautify and improve the performance of all types of boats. No matter where you are, in whichever waters around the globe, you’ll find Interlux offers high performance yacht coatings for both above and below the waterline including antifouling, undercoats, yacht varnish and many more solutions. The success of our business has been built on two things: an on-going commitment to understanding the needs of our customers, and, in turn, providing quality product and service solutions that consistently perform for the boat owner, boatyard professional or boat builder anywhere in the world. Scientific expertise is at the heart of our business. We dedicate more people, technology and investment to our research and development programms than any other yacht paint manufacturer in the world. With our dedicated yacht laboratories and our customer-integrated testing programms, we have become the first choice partner for the world’s most demanding customers. Interlux is devoted to providing proven solutions that protect, beautify and reduce boat maintenance. We strive to ensure that the work we do not only makes a difference – it becomes a critical element of support for our customers. Whether we’re in the lab researching and developing new products, or at sea putting our products to the test, we’re in our element. Getting the chemistry right is critical to us, as is knowing the subtle differences between people and water all over the world. Wherever there are boats, we’re right at the heart of the matter, making connections, solving problems and sharing knowledge.

About AkzoNobel

AkzoNobel has a passion for paint. We’re experts in the proud craft of making paints and coatings, setting the standard in color and protection since 1792. Our world class portfolio of brands – including Dulux, Interlux, Sikkens and Interpon – is trusted by customers around the globe. Headquartered in the Netherlands, we are active in over 150 countries and employ around 35,000 talented people who are passionate about delivering the high performance products and services our customers expect.

For more information please visit www.akzonobel.com .

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise

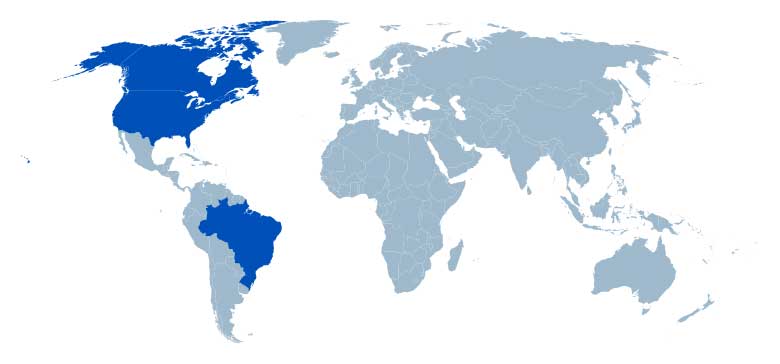

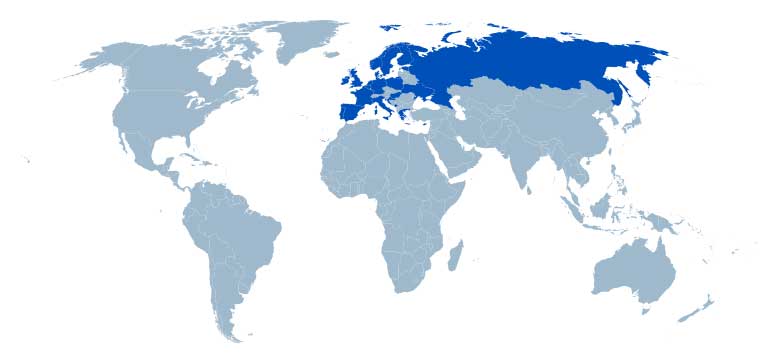

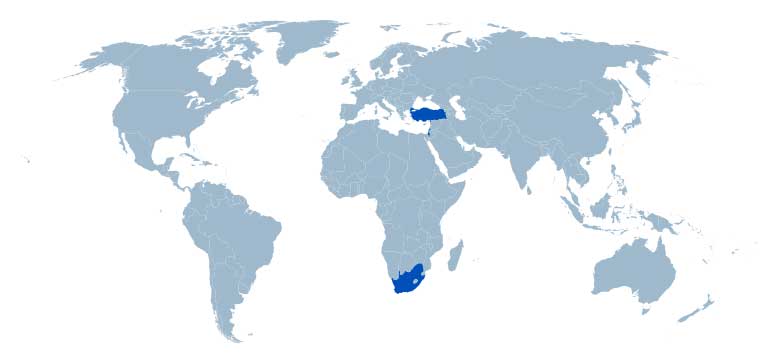

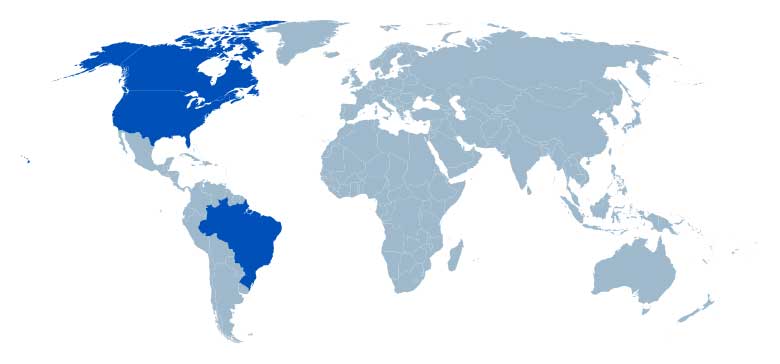

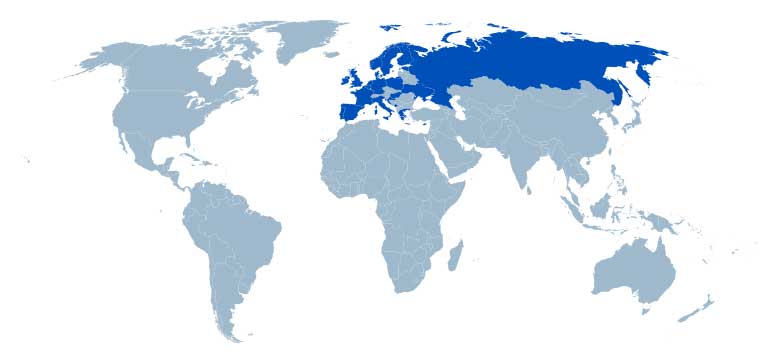

Select your country

Our products and guidelines are customised for each country. Please select yours below.

- Canada Canada

- United States United States

Asia Pacific

- Australia Australia

- New Zealand New Zealand

- Singapore Singapore

- België Belgium

- Hrvatska Croatia

- Danmark Denmark

- Suomi Finland

- France France

- Deutschland Germany

- Ελλάδα Greece

- Ireland Ireland

- Italia Italy

- Nederland Netherlands

- Norge Norway

- Portugal Portugal

- España Spain

- Sverige Sweden

- United Kingdom United Kingdom

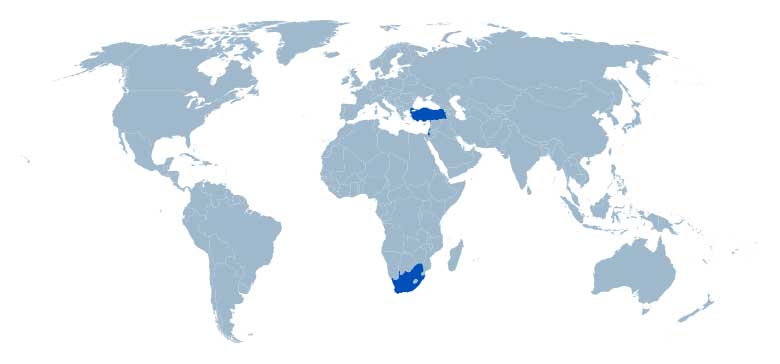

Middle East & Africa

- South Africa South Africa

- Türkiye Turkey

Who's painting?

Choose one of the following to tailor the site to your needs.

- International Marine Coatings

- International Protective Coatings

Please note: this product is labelled for Professional use only Learn more

A premium antifouling for use on aluminium craft, Trilux 33 contains Biolux® for extra antifouling protection. Such strength makes it suitable for boats in all waters. Trilux 33 is available in several bright colours.

Use antifouling paints safely. Always read the label and product information before use.

Find an applicator

This product is for professional use only and may only be bought and applied by a professional applicator. Find an applicator that's near you.

Find a distributor

There are many distributors of International products throughout Great Britain. Find a distributor that's near you.

Good to know

- Biolux® Technology for long-lasting antifouling protection

- Slow polishing formula suitable for use on aluminium craft, outdrives, outboards and any substrate

- Available in bright colours, including bright white

Available colours

Download technical datasheet.

Contains detailed information on everything from the substances used to the application method.

- Technical datasheet - EN (PDF 178KB)

Technical data excerpt

* Method for professional use only

Safety information

The safety datasheet contains detailed information for the current formulation of this product such as hazardous ingredients, first-aid measures, fire-fighting measures, handling and storage. To make sure you have the right datasheet, please find the corresponding colour and formula on your can. The formula is usually on the bottom. We provide safety datasheets for each latest formula.

- Sales code YBA064

- Revision Date 20220805

Flammable liquid and vapour. Harmful if inhaled. Causes serious eye damage. Causes skin irritation. May cause an allergic skin reaction. May damage fertility. May damage the unborn child. May cause respiratory irritation. May cause damage to organs through prolonged or repeated exposure. Very toxic to aquatic life with long lasting effects.

- Sales code YBA065

- Sales code YBA067

- Sales code YBA069

Tributyl-tin (TBT) Free Certificate

You can use this certificate to confirm that the paint system used in this product is compliant with the IMO International Convention Standards.

TBT Certificate

Trilux 33 tbt certificate, suggested protective equipment.

- Protective equipment overview

Advice on how to avoid problems

- Solve common problems

Check if this product is compatible with your current antifouling product

Simply use this tool to check compatibility with the antifouling product you already have on your hull. If you need any assistance, feel free to contact us for support.

Related products

Gelshield 200

A quick drying and easy to apply epoxy primer, that protects GRP against osmosis.

Interprotect

Interprotect is a high performance two pack primer/undercoat. Suitible for above and below the waterline.

Fast drying, anti-corrosive primer for timber, steel, aluminium, cast iron keels and lead keels

Thinner No. 3

Thinner No.3 is suitable for thinning antifouling paints, but also to help spray on our one-part varnishes and finishes.

Although every effort has been made to ensure the colours on screen are as close as possible to actual paint colours, we cannot guarantee an exact colour match. Paint swatch colours will vary depending on your screen settings and resolution. The manufacturer cannot be responsible for slight variations.

- White YBA064

- Navy YBA065

- Black YBA067

Paint needs

Calculate how much paint you need

For professional use only

Because of the application method required for this product, it is labeled for professional use only. This product is only for use by boat paint industry professionals.

How much paint do I need?

We'll help you calculate how much paint is needed.

What product do you want to paint

What type of boat.

Full bodied craft

Fin keeled racing craft

Medium draft racing craft

What is the underwater area?

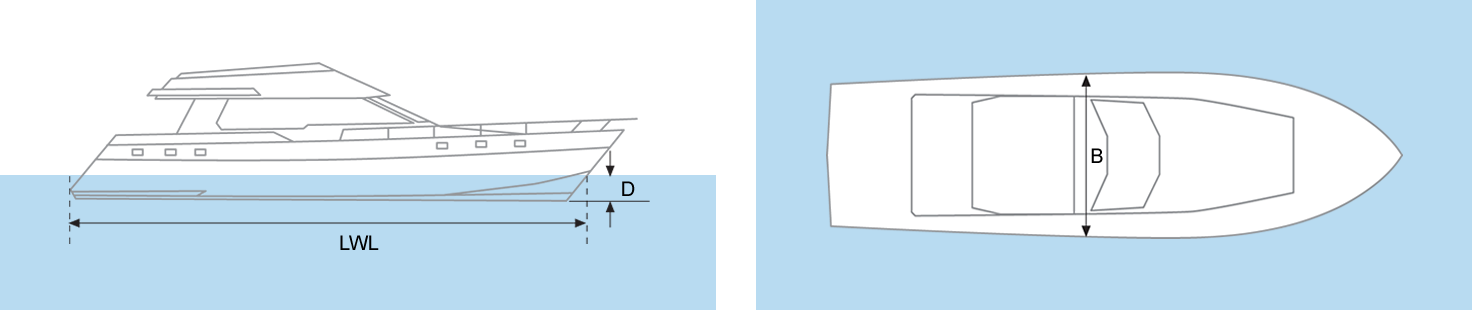

1 x LWL x (B+D) = Underwater Area (m 2 )

0.5 x LWL x (B+D) = Underwater Area (m 2 )

0.75 x LWL x (B+D) = Underwater Area (m 2 )

Abbreviations LOA = Length Overall LWL = Length Waterline B = Beam D = Draft F = Freeboard

Length waterline (Meters) (Feet)

Draft (Meters) (Feet)

Beam (Meters) (Feet)

Total boat area (Meters) (Feet)

What application method?

* For professional use only

Recommended no. of coats: ?

How many coats do you want to apply?

If you put less than the minimum recommended numbers of coats, it may affect the performance of the coating.

To paint a ? x ? x ? ?? , with ? coats

You'll need ? litres of

Warning that this tool is an estimator only

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise

Select your country

Our products and guidelines are customised for each country. Please select yours below.

- Canada Canada

- United States United States

Asia Pacific

- Australia Australia

- New Zealand New Zealand

- Singapore Singapore

- België Belgium

- Hrvatska Croatia

- Danmark Denmark

- Suomi Finland

- France France

- Deutschland Germany

- Ελλάδα Greece

- Ireland Ireland

- Italia Italy

- Nederland Netherlands

- Norge Norway

- Portugal Portugal

- España Spain

- Sverige Sweden

- United Kingdom United Kingdom

Middle East & Africa

- South Africa South Africa

- Türkiye Turkey

Who's painting?

Choose one of the following to tailor the site to your needs.

IMAGES

VIDEO

COMMENTS

International offers a range of antifouling products for different boat types, regions, substrates and conditions. Compare colours, features and prices of 12 products and find the best one for your boat.

Find the right paint solution for your boat with the International Product Guide. Explore categories such as antifouling, primers, fillers, varnishes and more.

Find the right products and helpful advice for painting your boat or yacht with International Yacht Paint. Browse antifouling, undercoats, topcoats and colours for different types of boats.

A high performance Self-Polishing Copolymer (SPC) antifouling coating, Intersmooth 7476Si SPC is proven to deliver 1.4% speed loss over the docking cycle.It delivers guaranteed fuel savings using next generation silyl methacrylate polymer technology with an enhanced biocide package when compared to other products.Intersmooth 7476Si SPC is supported by the long term customer trust of ...

A high performance, TBT free, polishing antifouling. Enhanced biocide release mechanism. Prevents coating build-up. At subsequent drydockings, it is only necessary to top up the system.

International-marine is a brand of AkzoNobel that provides high performance coating solutions for vessels operating in diverse and challenging environments. Learn how International-marine can help you optimize your vessel performance for decarbonization goals and download a whitepaper on the topic.

Learn how to prepare, choose and apply antifouling paints for your boat. Compare different methods of removing old paint, from scraping to soda blasting, and find out the best products and tips.

Learn how to calculate the area and coverage of your hull for antifouling paint. Use the Paint Estimator tool or the reference chart to find the right amount of paint for your boat.

Interlux offers a range of products for painting your boat, including antifouling, finishes and non-skid. Find helpful guides, support and problem solvers for your boat paint job.

Learn what antifouling is, how it works, and which type is suitable for your vessel. Compare different brands and products of antifouling paint and get free delivery on UK orders over £100.

Learn the difference between hard and eroding antifoulings and how to choose the right product for your boat. Find out how much paint you need and get expert support from International, a leading brand of boat paint.

Boat Antifouling Paint and Self Polishing Antifoul. Antifouling paint protects your boat from barnacles, algae and marine organisms using biocides released by the paint, including copper, organotin compounds and other agents. Coating the hull with antifoul preserves its performance including top speeds and fuel consumption.

Once you've identified the Interlux® antifouling that's most suitable, if you have an existing coating on your hull you will need to establish the compatibility of the two products. Antifouling Compatibility Chart. Use this simple table to check compatibility. If you need further assistance, please contact our Technical Helpdesk.

At CH Marine we stock a wide range antifoul paint and bottom paint for both commercial and leisure applications. Our range includes top brands such International and Jotun. These antifouls come in self-polishing and hard racing versions and there are is a bottom paint for all types of uses from general sailing or high performance.

Patented, TBT free, self polishing antifouling system incorporating unique Copper Acrylate SPC (Self Polishing Copolymer) technology. Characteristics Volume Solids 58

Hard bottom paint is a durable option that provides long-lasting protection, while ablative bottom paint slowly wears away over time, releasing biocides to prevent marine growth. Antifouling Paint. Antifouling paint is a type of boat bottom paint that is specifically designed to prevent marine growth. This type of paint contains biocides that ...

Premium marine stockists of popular antifouling & boat paints from International paint. Check out the great prices on antifouling paints and products. ... Explore our range of International marine paint and products today at Force 4 Chandlery. Read More £ £ £ Relevance. Showing Items 1 - 24 of 63. 1 2 3 Next. Page 1. Show All. Shop By: ...

Hard Antifouling is an antifouling product effective against fouling organisms; slime, aquatic plants and animals. A Hard Antifouling suitable for professional and consumer application onto vessels in fresh and salt water. The hard scrubbable coating is suitable for burnishing to provide a smoother finish.

A division of AkzoNobel, Interlux® is one of the world's largest manufacturers of high performance boat paint, yacht coatings and marine protection. Formed in 1881, the Interlux brand has become synonymous with the highest standard of care for all kinds of vessels and is an integral part of boat building and maintenance.

Ultra 300 is a hard antifouling paint that provides 1-year protection for powerboats or any streamlined yacht, even in harsh fouling conditions. It allows scrubbing and polishing, maintains protection after hauling, and is suitable for various substrates and water types.

Many years ago, tributyltin (TBT) and triphenyltin (TPT) were developed as antifouling coatings but turned out to be toxic and non-environmentally friendly to the marine environment .In the year 2008, the International Maritime Organization (IMO) banned the use of TBT for antifouling coating .Then, copper is used as the main biocide ingredient in antifouling paint, and it also results on ...

Trilux 33 is a slow polishing antifouling paint with Biolux® technology for long-lasting protection. It is suitable for all waters and substrates, including aluminium, and available in bright colours.