- Perfecting Your Model’s Sails: The Art of Rigging | Seacraftclassics

- Blog Seacraftclassics

- Boats and ships

- September 10, 2023

Mastering the Art of Rigging: Enhancing the Authenticity of Your Model’s Sails

When it comes to creating a realistic and authentic model of a sailboat, one of the most crucial aspects is perfecting the rigging, particularly the sails. The art of rigging involves setting up the sails in a way that accurately represents the real-life counterpart, capturing the essence and beauty of sailing. In this article, we will delve into the secrets and techniques of sail rigging that will elevate the realism of your model to new heights.

Unveiling the Secrets of Rigging: Techniques to Perfect Your Model’s Sail Setup

Rigging a sailboat model requires attention to detail and a deep understanding of the principles of sailing. Here are some techniques that will help you achieve impeccable sail rigging:

1. Research and Reference

Before starting the rigging process, it is essential to conduct thorough research on the specific sailboat model you are replicating. Study photographs, blueprints, and even real-life sailboats to understand the intricacies of the rigging. Pay close attention to the arrangement of the sails, the types of rigging lines used, and the tension applied to each line.

2. Use High-Quality Materials

Investing in high-quality rigging materials is crucial for achieving a realistic look and ensuring the longevity of your model. Opt for materials such as fine thread or fishing line for the rigging lines, and choose appropriate fabrics for the sails, such as cotton or silk. These materials will provide the necessary strength and flexibility to accurately represent the tension and shape of the sails.

3. Rigging Techniques

There are several rigging techniques that can enhance the authenticity of your model’s sails:

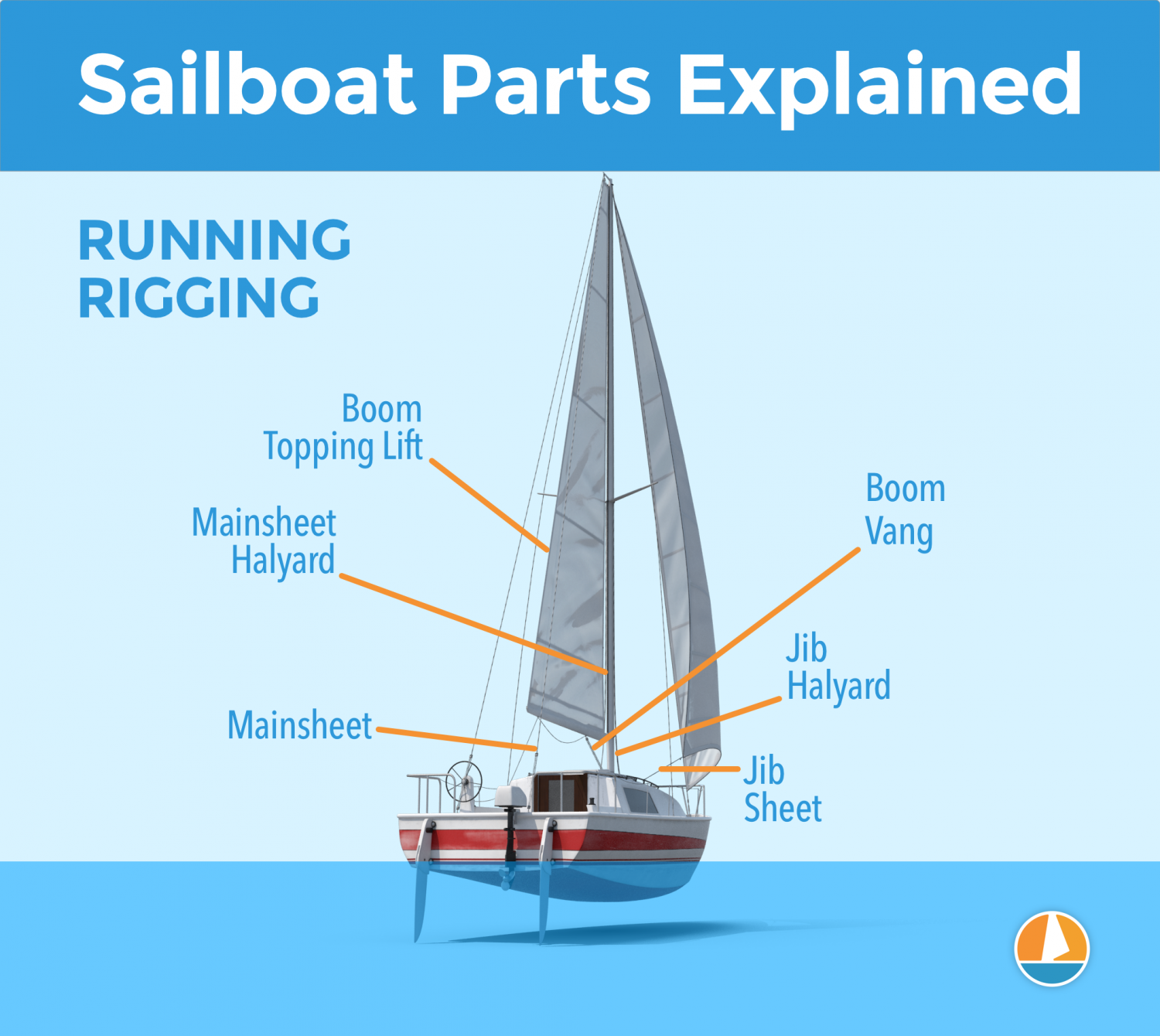

- Running Rigging: Use thin thread or fishing line to create the running rigging, such as halyards, sheets, and control lines. Ensure that the lines are properly tensioned and secured to the appropriate points on the mast, boom, and deck.

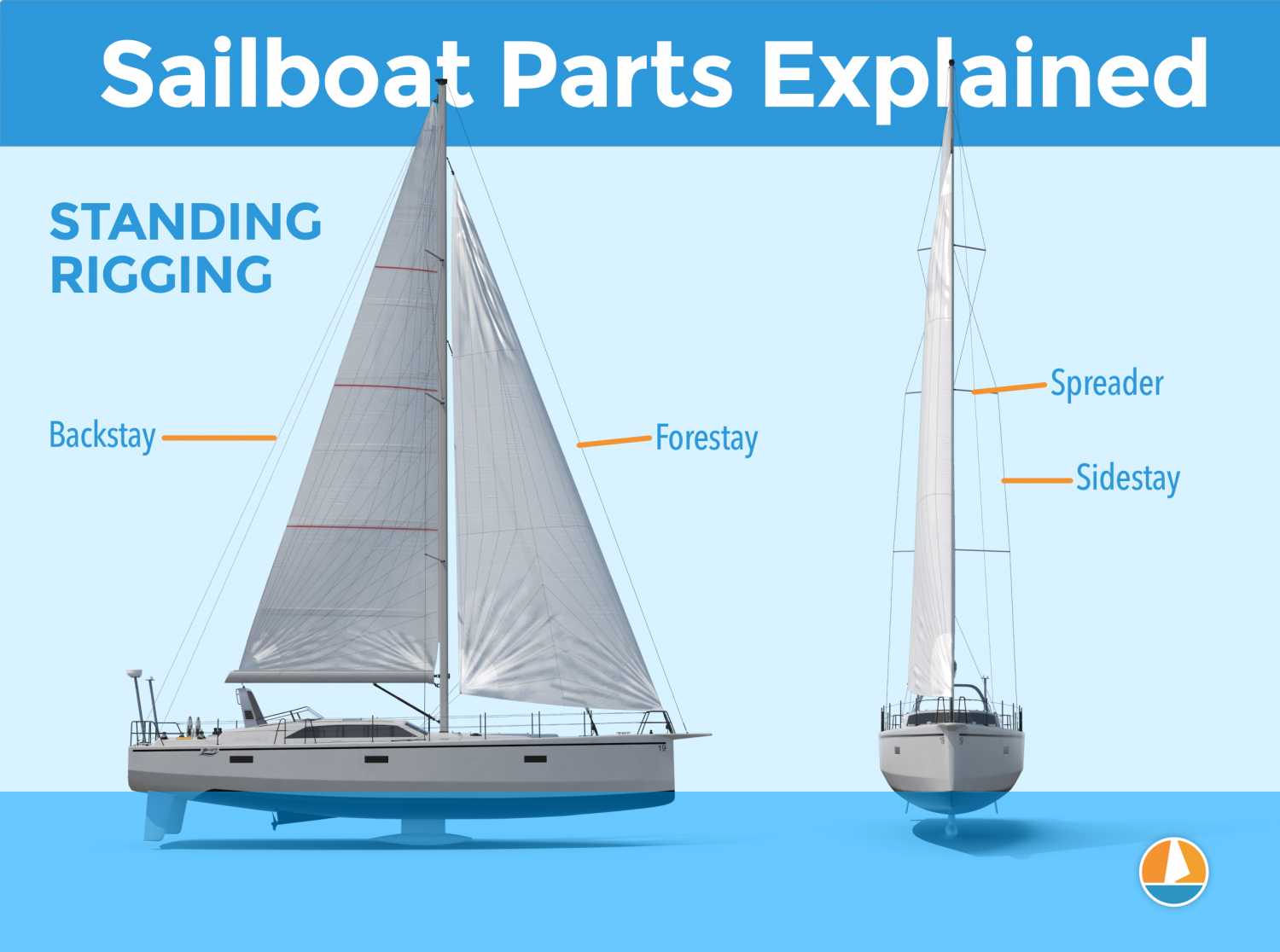

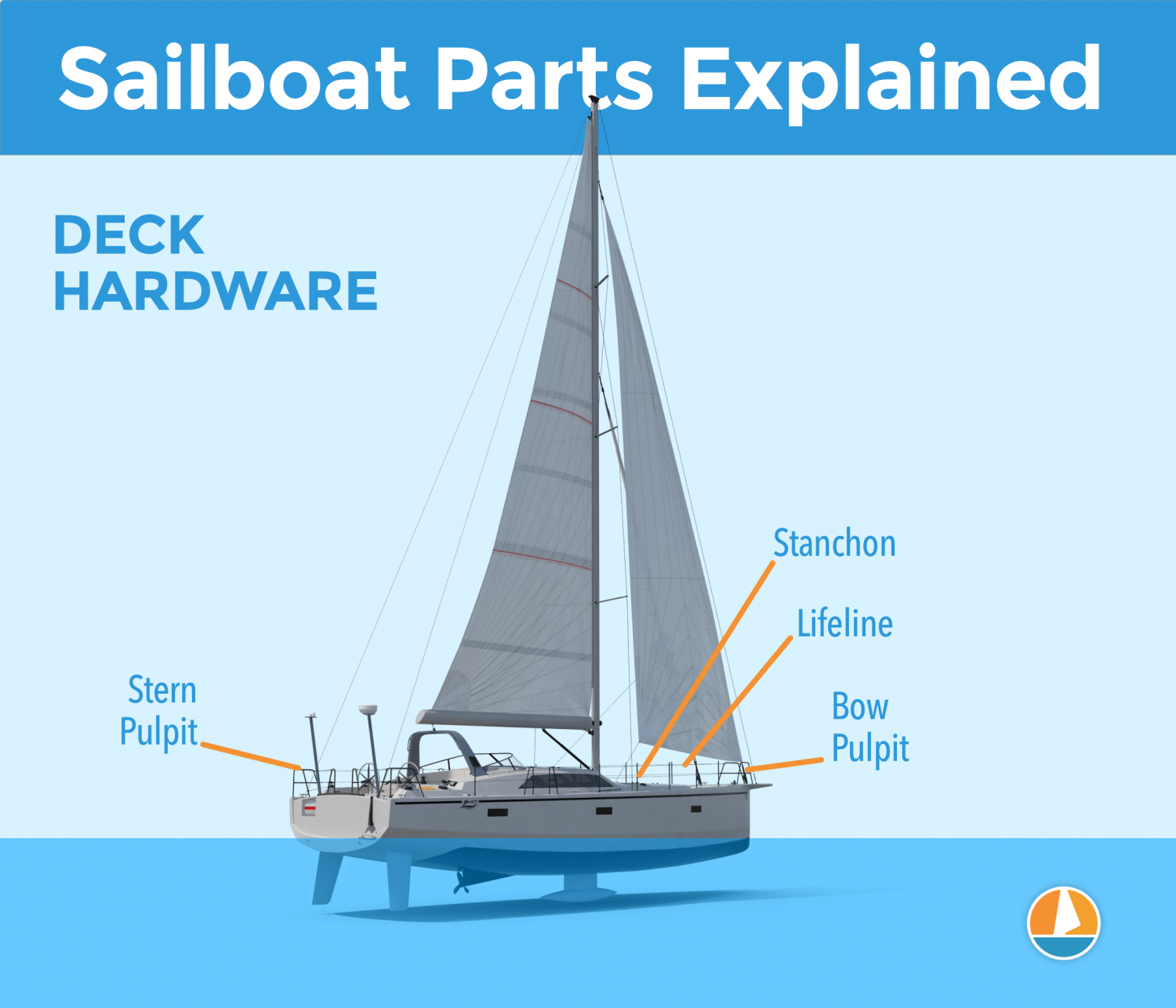

- Standing Rigging: The standing rigging, including shrouds and stays, provides the necessary support for the mast. Use fine thread or wire to create these lines, ensuring they are accurately positioned and tensioned to maintain the correct shape of the mast.

- Sail Attachment: Attach the sails to the mast and boom using small eyelets or hooks. Pay attention to the proper alignment and tension of the sails to achieve a realistic appearance.

Elevate Your Model’s Realism: Tips and Tricks for Achieving Impeccable Sail Rigging

Here are some additional tips and tricks that will take your sail rigging to the next level:

1. Weathering and Aging

To add a touch of realism to your model, consider weathering and aging the sails. Use diluted acrylic paints or fabric dyes to create subtle discolorations and stains that mimic the effects of sun, saltwater, and time. Be sure to apply these effects sparingly and strategically to maintain a natural appearance.

2. Scale Accuracy

Pay close attention to the scale accuracy of your model’s rigging. Ensure that the size and proportions of the rigging lines and hardware are appropriate for the scale of your model. This attention to detail will greatly enhance the overall realism of your sailboat replica.

3. Practice and Patience

Perfecting the art of rigging takes practice and patience. Don’t be discouraged if your first attempts are not flawless. Take the time to learn from your mistakes, refine your techniques, and experiment with different approaches. With each model you build, your skills will improve, and your sail rigging will become more refined.

Mastering the art of rigging is essential for creating a realistic and authentic model of a sailboat. By conducting thorough research, using high-quality materials, and employing the right techniques, you can achieve impeccable sail rigging. Additionally, incorporating weathering and aging effects, ensuring scale accuracy, and practicing patience will elevate the realism of your model’s sails even further. So, set sail on your next model-building adventure and let your rigging skills shine!

Sign up for speacial offers

Subscribe our newsletter.

[mc4wp_form id="806"]

Most Viewed Posts

- Talk about a venue with a view! This Quebec couple had the absolute wedding of …

- Everything You Need to Know About Trading in Your Boat

- Happy 4th of July! Wishing you all a happy holiday weekend on the water with you…

- Wishing all the IMOCA Globe Series teams and skippers competing in the Vendée-Ar…

- The training continues for Alex and the crew. In case you missed it, we won’t b…

Our latest custom models

- model 1329 1329 products

- Custom Sail boats 218 218 products

- Custom Power Boats 399 399 products

- Custom Half Models 532 532 products

- Custom Desk Models 92 92 products

- Join Newsletter & Get 10% Off Your First Order

Join / Login

Rigging tips for building a model ship.

- Updated on: 25th January 2021

- Written by Gary Renshaw

Introduction

Rigging is a significant part of the process of building a model ship. It can be tedious and time-consuming however putting the effort in adds to the beauty of your finished model.

In general, the instructions on rigging provided by the manufacturers of model ship kits are fairly sparse. Whilst there are several specialised and very detailed books on masting and rigging, they are more concerned with matters of historical and technical accuracy than with the sort of advice that might help the beginner to understand the best way of going about what might appear to be quite a daunting task.

Highly recommended is a 3 DVD set available from Modellers Shipyard on Masting and Rigging . This is a comprehensive set which shows all aspects of preparing the masts, spars and yards and the rigging for a period model. For further information call our office or visit our website.

We do strongly recommend “Ship Modelling Simplified” by Mastini – it contains excellent advice on ship modelling in general and has a good section on rigging. Modeller’s Shipyard has produced the following information as an introduction to the Rigging of a model ship. The following points should be noted:

- This is a general guide only and is to be used in conjunction with any instructions and plans provided by the kit manufacturer. In particular, it must be emphasised that any illustrations used in this leaflet are purely for the purpose of example and may not relate to your specific model.

- The approaches described are not the only way of doing things and the order in which the various processes are carried out may be varied, within reason, to suit the individual modeller.

Building a model ship is as much an exercise in using the mind as it is in using your fingers and hands. In this small leaflet, we can’t hope to cover all the problems and queries that may be encountered in the construction of your model. It is necessary to spend as much time thinking about the task at hand as actually doing it. If having thought about it, you still have a problem then contact us. We’ll either be able to advise you ourselves or refer you another modeller in your area who’ll be happy to help you with “hands-on” assistance.

TYPES OF RIGGING

The rigging of a ship can be divided into two main parts:

- “Standing” or “Fixed” rigging, which is used to support the Masts and Bowsprit.

- “Running” rigging, which is used to manipulate spars and sails.

On an “actual” ship any Rigging which didn’t pass through a pulley block was coated with tar to help prevent it rotting. For this reason, standing rigging is often, although not always, black on ship models.

If you do want your standing rigging black, and black cord is not supplied in the kit then you can consider these options:

- You can purchase Black cord.

- The use of black rigging “wax” gives a very authentic tarred look but it is difficult to do well.

- The cord supplied with the kit can be coloured using black dye or “Raven Oil” as used by leatherworkers/saddlers.

- Black felt-tipped “Texta” is an easy way to colour the cord.

- Black “Padawax” shoe colour is also very satisfactory.

When any liquid dye has been used it will be necessary to stretch the cord by hanging it on a clothesline, with weights, to prevent it going slack after installation on the model. It will also probably be necessary to use clear wax to eliminate any furry look in the cord.

STANDING RIGGING

This includes the rigging of the Stays, Backstay, Bowsprit and Gammoning. This is fairly straightforward and should present few difficulties. Work from the centre of the ship out and try to avoid difficult and confined spaces. A Rigging Tool presented in the Tools section of our Catalogue will be helpful when rigging. The various names for the standing rigging are presented below.

- Fore topmast stay

- Fore topgallant stay

- Flying-jib stay

- Fore royal stay

- Fore skysail stay

- Main topmast stay

- Main topgallant stay

- Main royal stay

- Main skysail stay

- Mizzen stay

- Mizzen topmast stay

- Mizzen topgallant stay

- Mizzen royal stay

- Mizzen skysail stay

- Mizzen topmast backstay

- Mizzen royal backstay

- Mizzen skysail backstay

- Main topmast backstay

- Main topgallant backstay

- Main royal backstay

- Main skysail backstay

- Fore topmast backstay

- Fore topgallant backstay

- Fore royal backstay

- Fore skysail backstay

- Bowsprit shrouds (bobstays)

Source: “Ship Modeling Simplified” by Mastini Pages 143 –144

FITTING OF BLOCKS, EYE PINS & CLEATS

Before proceeding further fit all the eye pins and rigging blocks to the bowsprit, masts, yards, and deck – also to the insides of the bulwarks if required. Cleats may be required on the lower masts, deck or bulwarks. Pay particular attention to any area which will be relatively inaccessible once the shrouds and other standing rigging ropes are in place.

It is as well to drill out the holes in the blocks and deadeyes to facilitate the threading of the rigging cord when the time comes.

For the most inaccessible blocks, insert a short piece of thin rigging cord through the hole and glue it to itself forming a loop. Later, when you wish to insert the permanent running rigging you cut the loop, glue the new cord to one end and pull it through the hole using the other end of the pilot cord. No awkward threading

DEADEYES (LOWER) AND CHAIN STRAPS/ DEADEYE STRAPS

In most models, the lower deadeyes are fitted into “deadeye loops” which are inserted into gaps in the outer edge of the “Channel”. Once the complete row of deadeyes are installed a capping strip is fixed along the front.

From the bottom of the deadeye loop either a straight ”Deadeye Strap” or a “Chain Strap” goes to the side of the hull at a lower level. The style of this fitting will depend on the period to which the particular ship belongs and also the price/ quality of the ship being built.

There are several points to keep in mind when setting up these “deadeye assemblies”

The deadeye strap (or chain strap) is rarely, if ever, perpendicular. Rather, it should be at an angle which is an extension of the angle of the shroud which will eventually be attached to the deadeye above it. The diagram on the left of this page should make that mouthful clearer!!

The lower deadeyes, the ones being attached at present, should be placed so that the three holes are positioned with the lowest one being the centre of the three. When at a later stage the upper deadeye is fitted, it is equally important that the centre hole is the highest of the three. Refer to the diagram on the right-hand side of this page.

These together with the “forestays” and “backstays” are the ropes that support the masts. Shrouds, which are the group of ropes to which the ratlines are attached, are made up in pairs with a deadeye at each end of a single rope.

First cut a piece of cord to an appropriate length and with the help of an alligator clip or a small clamp glue one end around a deadeye. This deadeye should then be temporarily connected to the front portside (left hand) lower deadeye using a wire jig. This jig will provide the correct spacing between the upper and the lower deadeye.

The loose end of the rope then goes up, around the mast and down to the position of the lower deadeye immediately behind the first. Using glue, alligator clip and another wire spacer, the upper deadeye is attached to the shroud. At a latter stage, the double thickness of cord immediately above the upper deadeye will be bound with fine thread as shown as shown in some of our diagrams. The “Lanyards”, made of the thinnest rigging cord, are then installed as shown in the adjoining drawing. Because on the “real thing” the lanyards were constantly used to take up tension on the shrouds they were never tarred and should not be black.

Once the first pair of shrouds has been completed, the exercise is repeated on the other (starboard) side, then, back to the port side and so on.

If, when the others have been done there remains a single lower deadeye on each side then the final pair of shrouds goes from one side of the ship to the other with a large seized eye around the masthead. In all of this, it is important to ensure that the deadeyes are in straight rows parallel with the channels and with each other.

SEQUENCE OF SHROUDS

The forestays should now be fitted paying attention to the particular fittings used. Quite commonly “heart deadeyes” and lanyards will be used for tensioning purposes.

These are always rigged with a large seized eye around the masthead as with the “odd” shrouds (if any). As with the shrouds they are rigged with deadeyes and lanyards but the upper deadeye will normally be at a higher level than that of the shroud deadeyes.

The colour of the ratline cord is grey or fawn. The tying of ratlines can be fairly tedious but it is worth going to some trouble to ensure that it is done well. Among the points to keep in mind are:

- They should not be too tight otherwise they will pull the shrouds together.

- They should be parallel to the waterline.

- On the “real thing” the spacing between each row was about 400mm so, on a model at a scale of say 1:50, the gap would be approximately 10mm.

- Avoid tying knots tightly until all the ratlines are in place. This will allow some “fine tuning” before placing a tiny dab of glue on each knot. Placing a sheet of white plain paper behind the shrouds will assist with gaining contrast to make the tying of the ratlines a tad easier on the eyes.

ATTACHING RIGGING LINE TO BELAYING PINS

The adjacent diagram demonstrates clearly the method best used to attach the cord to the belaying pins.

If you have any difficulties determining which belaying pin a rope is intended to go to, a good rule of thumb is that the higher up the mast it starts then the further back it finishes.

ROPE COILS

Plenty of rope coils draped over the belaying pins provide a finishing touch. These can be made from odd lengths of offcuts. If placed into the shapes you require they can be (fixed) permanently by using hair lacquer or nail polish.

WHAT SIZE ROPE TO USE

In the plans or in the instructions there should be a key or description of the size of cord to be used for various purposes. In the unlikely event that no indication is given, then the following can serve as a guide:

Forestays & Anchor ropes – Heavy cord

Shrouds & Backstays – Medium cord

Ratlines & Running Rigging – Lightest cord

RUNNING RIGGING

Once the standing rigging has been completed you can now start the Running Rigging. You will have enlarged the holes in the blocks which are already in place. Do the same with all other blocks as you come to use them.

When threading cord through blocks, you will find that a needle threader (available from sewing shops) will be very handy. Also, a smear of super glue on the end of the cord can stiffen it and make it easier to thread. Work from the centre of the ship out and try to avoid locking yourself into difficult positions. A Rigging Tool presented in the Tools section of our Catalogue will be helpful when rigging.

The various names for the Running Rigging are presented below.

- Fore brace

- Fore lower topsail brace

- Fore upper topsail brace

- Fore lower topgallant brace

- Fore upper topgallant brace

- Fore royal brace

- Fore skysail brace

- Fore yard lift

- Fore topsail yard lift

- Fore topgallant yard lift

- Fore royal yard lift

- Fore skysail yard lift

- Main lower topsail brace

- Main upper topsail brace

- Main lower topgallant brace

- Main upper topgallant brace

- Main royal brace

- Main skysail brace

- Main yard lift

- Main topmast yard lift

- Main topgallant yard lift

- Main royal yard lift

- Main skysail yard lift

- Mizzen yard brace

- Mizzen lower topsail brace

- Mizzen upper topsail brace

- Mizzen lower topgallant brace

- Mizzen upper topgallant brace

- Mizzen royal yard brace

- Mizzen skysail yard brace

- Mizzen topmast yard brace

- Mizzen topgallant yard lift

- Mizzen royal yard lift

- Mizzen skysail yard lift

Source: “Ship Modeling Simplified” by Mastini Pages 145 –146

TYPICAL RUNNING RIGGING APPLICATIONS

NAMES OF MASTS & SPARS

- Fore lower mast

- Fore topmast

- Fore topgallant mast

- Fore royal and fore skysail mast

- Main lower mast

- Main topmast

- Main topgallant mast

- Main royal & main topgallant mast

- Mizzen lower mast

- Mizzen topmast

- Mizzen topgallant mast

- Mizzen royal & mizzen skysail mast

- Fore topsail yard

- Fore upper topsail yard

- Fore lower topgallant yard

- Fore upper topgallant yard

- Fore royal yard

- Fore skysail yard

- Main lower topsail yard

- Main upper topsail yard

- Main lower topgallant yard

- Main topgallant yard

- Main royal yard

- Main skysail yard

- Crossjack yard

- Mizzen lower topsail yard

- Mizzen upper topsail yard

- Mizzen lower topgallant yard

- Mizzen upper topgallant yard

- Mizzen royal yard

- Mizzen skysail yard

- Gaffsail boom

- Flying-jibboom

- Martingale boom, dolphin striker

Source: “Ship Modeling Simplified” by Mastini Pages 142 –143

Learn The Art Of Building A Model Ship

Get started in wooden model ship building today

Join 18,543 other modelers to hear about specials, new products and modeling tips

- Become a Member

- Modeling Hub

- Model Ship Building

- Maritime History

- Affiliate Program

Information

- Terms & Conditions

- Privacy Policy

Copyright © 2023 Modelers Central. ABN: 31 114 830 732

- Claim 10% Off First Order

- Get 5% off ALL orders with a Membership

- Gift Vouchers

- Help & Advice

Modelers Central. 2023, All rights reserved.

- Claim 10% Off Your First Order

- Get 5% Off All Orders With A Membership

Get 10% off

Your first order.

10% off applies only to full-price items. By providing your email address, you agree to our Terms & Privacy Policy

10% off applies only to full-price items. By providing your email address & mobile number, you agree to our Terms & Privacy Policy and consent to receive marketing messages from Modelers Central at the addresses provided. You can unsubscribe at any time by replying STOP.

- Vanquish 65

- Mini Maniac

- RG65 Appendages

- Maniac MK II

- IOM Appendages

- Marblehead Class

- Marblehead Appendages

- RT65 Ragnarok

- RT65R Armageddon

- RC65 Adrenaline

- ST65 Sowelu

- Mini40 / F48 Class

- Nightmare X

- Nightmare MK VIII

- MultiOne Class

- FireDragon 1000

- DIY Sail Winch

- Rig Building

Rig building

Fast Shipping or local PickUp

Potter solutions, the one stop model yacht shop.

Sails, rigs, boat stands, accessories and fittings, including the new range of DF65 and DF95 complete packages.

Email Address

the history of the future

At the age of fifteen David Potter started sailing model boats at the world famous Birkenhead Model Yacht Club.

In 2012 he decided to turn his passionate hobby into a business and launched Potter Solutions.

As a qualified engineer, with a good eye for detail, he produces a range of equipment for the majority of radio controlled model yacht classes.

David has competed in this thrilling sport for over Thirty years at both national and international events and is fully aware of the need for products that can deliver in the field at a competitive price.

Whatever your requirements, including information and advice, David is always available for a chat.

featured products

Complete DF95 Package

Complete DF65 Package

DF95 Alloy Boat Stand

Pierre Gonnet Mast 11.1mm

Everything in one place.

30 Years of experience in radio sailing means we know what’s required to produce competitive and reliable parts .

Order before 3pm for UK next day delivery *

Most products can be shipped same day. Some products like sails * are made to order unless they are from our standard range. Products that can be dispatched same day will be indicated on the product description.

Secure Ordering online

You can place an order online. Once we receive the order we calculate the shipping cost and send you information on how to make payment. Your personal information is protected and encrypted by Secure Socket Layer (SSL) technology. Our website is ecommerce PCI Compliant .

Customer Service

Excellent customer service is one of the key areas where we can truly make a difference, which is why we work hard to keep our customers happy and make it easy to do business with us. A quick response matters and we aim to reply promptly and professionally.

some of our reviews

A history of trust and service.

“Fast shipping and exactly the parts I needed to complete my new IOM. Highly recommended”

“Bought a boat stand for my Marblehead. Arrived in a couple of days and very happy with the quality.”

“Bought some new sails for my DF95. Potter’s service is excellent. The sails are top quality.”

- Shop Notes, Ship Modeling Tips, Techniques and Research

- Remember me Not recommended on shared computers

Forgot your password?

Masting, rigging and sails

- Start new topic

1,746 topics in this forum

- Recently Updated

- Most Viewed

- Most Replies

- Solved Topics

- Unsolved Topics

Seven-Ten-Seven (7-10-7) template for making masts from square stock

- Nunnehi (Don)

- August 8, 2021

Making your own rope? Want to know how? See these tutorials and topics....

- February 6, 2021

Making an 1.00mm block

- modeller_masa

- Sunday at 05:18 PM

Finding authentic rope looking line for New Bedford Whale boat.

- Sunday at 12:11 AM

At A Loss On How To Rig

- Keith Black

- Saturday at 09:40 PM

jack stay rat lines?

- Roger Pellett

- Friday at 11:53 PM

Need a source for a "how to" all the needet basic knots, best with diagrams/photos

- Thursday at 03:01 AM

Stepping masts on Revell Cutty Sark 1:96

Help with translation of rigging term, instructions for rigging cutty sark, rigging cutter square sail sheets and tack.

Securing yards to masts

Securing the yards

Tiny Spar on 17th Century English Yacht

jack stay on 1850s clippers

HMS Sphinx Bowsprit Rigging

Heller Shroud Loom

Block Tumbler Help

- February 27

Flying fish

- February 24

Lift lines on cutty sark ,Revell 1/96

- February 23

lines to the fife rails?

- February 22

- February 19

how to secure a rope hank to the sheer poles?

- February 15

Topgallant Storm Rig

Tagged with:

- rwiederrich

- February 14

Help with understanding the rigging diagram

- February 10

mast top holes

Question on mayflower rig, black rigging wax, chain plates, member statistics, forum statistics, who's online 53 members , 2 anonymous, 122 guests (see full list).

- Rik Thistle

- Noctavigant

- Knocklouder

- Blue Ensign

- Gaetan Bordeleau

- JacquesCousteau

- Long John Silver

- myMADNESS78

- realworkingsailor

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild 237 South Lincoln Street Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful links.

- Articles Database

- NRG Home Page

- NRG Online Store

- Important: Our Guidelines

- Terms of Use

- Buildlog Index

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

Our Emblem ®

Nautical Research Guild ® and the NRG logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,999,236 & No. 6,999,237, registered March 14, 2023)

- Existing user? Sign In

- Latest Posts

- All unread content since my last vist

- Unread topics I have posted in

- Create New...

Nylet. Fine Sails & Quality Products ~ 92 Years

Welcome to the 2024 nylet website: everything for the model yachtsman. world-wide mail order service since 1958., welcome to the 2024 nylet website. nylet 92 years . the oldest established international master sailmakers, since 1932. everything for the model yachtsman. creating the very finest sails. tradition - craftsmanship - innovation. established 1932. 92 years since our firm's founding ethos "fine products, quality first". nylet racing sails are used the world over. makers of model sails to the national maritime museum cornwall. sails made by special commission for collectors & museums. every sail suit carefully made to your special order either in synthetic sailcloth, or for the vintage or classic yacht we make fine sails in cotton. large range of yacht fittings, wires, screws, tools etc. our fast world-wide mail order service (since 1958) is open for business. scroll down for more, or go to top toolbar to click on other pages. thank you for visiting our website, we hope you will find our product listings useful. iom sail rig kits, plus other class rig kits. replacement kit sails such as fairwind, seawind, victoria, etc. sails made for 200 different designs (see the "150 sails" list) and which include the classic - vic smeed's starlet and star baby, also wild duck (plan sold by sarik hobbies) and the recent eventide. prompt despatch from stock of large range of mast & deck fittings, aluminium tubing (incl stiffer 7075), wires & cordage, screws, tools, booklets & other quality products for model yachts, see price list (over 500 items). nylet racing sails with our "wind catching" shape - all sails cut specially to order and designed to enable your yacht to respond to varying *wind conditions, sails you can be proud of to compliment your model racing or cruising yacht. the very finest cotton sails manufactured for sailing yachts and display models. sails with wind catching shape and that extra sparkle. cross-reference listings of fittings in section e of our price list with the online "fittings & photos" page. full size sailmakers and contractors to the admiralty 1932-1966. 1772. silk mercers established in high holborn, london - 8 generations - 252 years of working with fine cloths. model & miniature makers spanning 4 centuries and 12 generations, with an example of our early 18th century work held in the british museum, london. slide & click on any of the 7 links below, or click any link on top bar. this is just one of 35 pages on our website., product & price list.

PRICE LIST - your first stop - approx. 500 items (fully searchable pdf file).

Quick guide to Sails

IOM, M-class, Ten Rater & other sails. Replacement kit sails - Fairwind, Voyager 2, Victoria, Seawind (over 150 other standard sail suits available).

Our Sailmaking Service in detail

Fine 'vintage' style cotton sails.

Creating the Finest Sails for Vintage & pond model yachts, Nylet cotton sails are specially made to order.

IOM rig carry bags & IOM carbon-fibre fin sets, ballast.

Sail rig carry/stowage bags; lead ballast; high quality c.f. fins/rudders.

Nylet 'How To' booklets

A range of 'How to' booklets, the BB3 aspects of fitting out model yachts.

Rig & deck fittings, wires etc.

Prompt despatch on our large range of quality rig & deck fittings (see photos), cordage, wires, stainless steel screws & nuts, brass wood screws, tools, etc.

Vintage yacht restoration

Your vintage model yacht can be carefully restored in our workshop.

Mast & boom tubing

Range of aluminium mast & boom tubing (incl 7075 grade).

Yacht sail winches

Sail winches to suit 36 inch, IOM, Marblehead, 6M, 10R & A-class.

Nylet. Master Sailmakers - Quality First. Established 1932. Click the "contact us" button to email your enquiry and for phone numbers/email/business hours & other/holiday dates.

View more photos of nylet sails, download our order form here., welcome - accueil, bienvenido, velkommen, welkom, tervetuloa, willkommen, benvenuto, velkommen, bem-vindo., nylet ~ master sailmakers ~ "quality first". 2 generations, 108 years of experience. 92 years of model sailmaking (including 35 years full size sailmaking). at nylet we don't just 'make' sails, we create sails, we breathe life into the sailcloth in order that they might be shaped by the wind. using technological advances in materials coupled with innovation, expertise and tradition over 92 years to bring you the very finest model sails. all sails are made specially to your order; please phone us and/or email sail plan, drawing for a quotation. see price list for 'standard' racing sails, iom sails and replacement kit sails (plus three sail pages with full info)., everything for the model racing yachtsman since 1932. world-wide mail order service since 1958. prompt despatch on fittings and stock items. quality mast & deck fittings, sails of all types, screws & nuts etc. accessories, aluminium tubing, iom rig bags and more. fast world-wide mail order service. please click on our price list before enquiring (500 items). over 200 sail designs available. makers of model sails to the national maritime museum cornwall., a warm welcome to our customers and new visitors to our website. if you have logged on recently then please refresh your browser to enable updated pages to be displayed correctly. this website contains approx 35 pages including help/info/tips files. clickable links also on top bar. we are working to bring you nylet products via our long established prompt world-wide mail order service. full details on our dedicated mail order page. we wish all our customers good health and happy sailing., about us; also making your order..

We hope you will find our services and products useful in your model yachting hobby. Our mail order service commenced in 1958 and we have been despatching our products world-wide since then.

Our PRICE LIST gives you instant access to almost 500 items so please refer to this firstly before enquiring. And please note there is no VAT tax (we do not charge VAT). Having firstly visited the list of products to see what we offer, the other dedicated pages on this site are to assist you with further info on sails, aluminium mast/boom tubing, rig & deck fittings (with photos), wires & cordage, screws & bolts etc., sail winches, tools & accessories. To access all other pages and products as well as our "help" pages either click on the individual (sliding) carousel links "read more" or via the top bar. There are some 35 pages on this website (including help files with useful tips). All other pages can be accessed using the drop down menus at the very top of each page.

Nylet are the longest established professional model sailmakers in the world, manufacturing full size sails from 1932 to 1965, and also model yacht sails in cotton from the early 1930's onward. 108 years of experience - 2 generations. We have been exporting our products world-wide since 1958 and offer a comprehensive model sailmaking service including yacht sails made in white Dacron, also racing scrim, and IOM sail rig kits, plus replacement kit sails, also Dacron Heritage sewn sails in 1950's/60's style. For some 35 plus years we have again manufactured finely finished Premium 'vintage' style cotton sails. We offer a large range of rig & deck fittings, wires & cordage, a huge selection of screws, nuts etc, sail numerals, accessories and hardware for modern racing yachts. Also sail winches, and much, much more. For products and prices click on (top bar) "all pages" and select from the drop down list. Please also see customers comments on the various pages. News - Range of sail winches for most yachts, see dedicated winch page; for prices refer to our products & price list in section M (prices start at around £100). Just a note about our sails. As it says on the "sail" pages Nylet sails are finished and are complete with batten stiffeners (where necessary) and all eyelets etc etc. A few customers ask if they are complete - seems some Chinese "kit" sails are not fully finished (I use the word "sails" loosely here!). We are Master Sailmakers and have been for 92 years , so you are purchasing the best. Please read our 3 sail pages for fuller details.

NYLET, a family business (since 1832), has moved with the times over 3 centuries and for many years been run on a mail order basis. We are thus able to focus on orders from home and abroad enabling us to effect a brisk turnaround on stock items. On a personal note, a milestone - in 2024 I celebrate 58 years of model sailmaking (taking over from my late father in 1981) and am pleased to say that I take great pleasure in my work, every sail I make is given equal attention to detail. Our skills represent some 108 years of sailmaking experience when taken together with my late father, who taught me most of what I know. It might actually be 118 years if I reckon his early years working for his father (a keen yachtsman) and making sails for the dinghy he constructed in the mid 1920's (before making sails commercially). Our family firm (originally known as J.Parsons) was established in 1832, 5 generations ago and originally being chandlery supplies and manufacturing canvas goods, sheeting, tilts etc. for narrowboat hauliers as well as farmers, then later in the marquee trade and in turn manufacturing full size sails as well as model sails from the early 1930's. We are proud that in our family business we can say this is some 192 years of manufacturing.

How to order and pay . VISA, MASTERCARD & PayPal accepted, or electronic bank transfer (BACS). Please email or phone with your order. FOR DELIVERY times and making/putting up your order please see relevant info pages.

Les visiteurs de la France s'il vous plait cliquer sur "bienvenue". Los visitantes procedentes de Espana, por favor haga clic en "bienvenue".

Today - Racing sails in scrim and film, Dacron sails & Heritage sewn Dacron sails. Nylet Finest 'Premium' cotton sails, fittings etc. 2016 - Frank Parsons marked his 50th year of model sailmaking. 1966 - Coloured Terylene racing sails. 1932 - Commencement of full size and model sailmaking. 1834 - Founding of the family firm, J.Parsons (canvas goods manufacturers). 1772 - My 4th gt grandfather, Michael, a Silk Mercer in High Holborn, London, working with fine cloths. 1738 - My 5th gt grandfather, Michael Compigné, Goldsmith, London, a specialist miniature maker for private customers, items made in gold & silver. 1620 - My 8th, 7th & 6th gt grandfathers, Clockmakers in Normany, London, and Winchester. From 1620 to 2022, over 400 years of the finest craftsmanship. 400 Plus Years of Tradition

Sails made by Special Commission for Collectors & Museums. Nylet IOM racing sails finely manufactured in racing scrim, white Dacron and satin film. Also replacement kit sails; Classic Varnished Terylene sails, also "Heritage" 1960's style sewn white Dacron sails made exclusively by Nylet. Also Premium 'Vintage' style cotton sails. Any size sails, of any type, made to your drawings or templates. Just a note, sail suits are often wrongly referred to as "sets". In nautical parlance sails are a "suit" whether that be 2, 3 or 4 sails (or more) for a yacht or a working boat, or a ship of the line such as HMS Victory where a dozen or more sails may be involved. All our sails are priced as a suit.

Makers of model sails to the National Maritime Museum Cornwall.

*Note: Wind conditions within sail type & design parameters.

Please note, we are not a "shop" (we have been asked). Phone us to chat, always happy to help.

The Nylet website is often updated weekly; updated March 2024

SOME Testimonials

Thank you for the BB3 booklet - a mine of information.

Thank you for such excellent service again, quality goods sent at lightning speed. A credit to how things should be done.

I had various recommendations of who to get sails from but the other day I saw a yacht with your sails and it just shone out, the shape looked beautiful, so I decided there and then to contact you.

Thanks Frank, sails arrived, what a work of art! They are incredible!

The fittings arrived in record time and I am really grateful to you for such a superb service.

I was pleased to receive my new IOM sails today, they are very good indeed just what I wanted, possibly the best I have ever had, good workmanship.

Many thanks for the superb Seawind sails that arrived this morning. I really appreciate the speed of processing of the order, and the precision of the finished sails.

Sails received with thanks. Great quality and great fit!

The M-class sails arrived and absolutely fantastic, really pleased and more than happy to recommend your workmanship.

The Voyager sails arrived in perfect condition and look beautiful. Thank you very much for the nice work!

Just to let you know that the new IOM sails work very well, thank you. I had 2x1st, 2x2nds,2x3rds, and 1 fourth. So I came first overall after 7 races.

I live on the coast of NSW in Australia. Some time ago I bought Spirit No.2751 (the one featured on your site). I am currently racing the boat here in Australia in several IOM fleets. The elliptical rudder works perfectly and the boat is at full potential now, points higher than the TS2 and the Topiko. Neither are faster off the wind.... Thanks for a great boat, I have never felt another IOM that glides to windward like the Spirit 3. All your efforts are appreciated here.

I just wanted to say a really big thank you for the lovely suit of Dacron Heritage (sewn) sails you have made for my vintage 4 foot model J Class sloop. I have put the sails on the spars and they look superb! They are beautifully made as I expected them to be, but in all fairness it is actually better than I had even hoped for.

Sails have arrived safely and look fantastic. Very many thanks.

Many thanks, order arrived today, superb service as always.

Just a note to thank you for phoning me with the expected delivery of the Dragon sails. They came the same day! I have to say that they look stunning and beautifully made with lovely details.

Safely received! Thanks for the great service.

Hope you are doing well, again, thank you for the (cotton) sails. They turned out beautifully.

I immediately rigged my 36"-class and was happy about the perfect fit of the (cotton) sails. They are wonderful and I am happy. Thank you very much!

Sails arrived this morning, as promised; they are a work of art - the real thing! Whatever else people say about the barge, they will say "who made her sails?"

Sails have arrived safely. But what a superb job, my old girl will be the best dressed yacht at any of our VMYG meetings. Wonderful work of the very highest standard as always from you, I cannot thank you enough.

I've never won anything before with my One metre (IOM) yacht but with your sails newly fitted I won the series of races. An excellent job, marvellous, thank you.

Hi. Sails arrived today, very impressed. Thank you.

I received my sails today....PERFECT...arrives safely. Perfect fit and I look forward to sailing with the new sails!!!!!! THANKS,

Received the sails, many thanks - as usual, quality better than expected!

Hi Frank, The One Metre sails are looking great.

Hi Frank thanks for another great (sail) job.

Thank you for your most attentive service, my best regards.

Dear Frank, the sails arrived safely on time, as promised. Superb quality and workmanship, as ever.

more comments from satisfied customers

Just a quick email to let you know the J class sails arrived in perfect condition and look amazing. I will of course send you some pictures when the boat is finished.

Hi Frank. The sails arrived today - they look great. I very much look forward to getting them rigged and tried out. I've already taken trophies with the sails you made for my 10 rater so hoping for more of the same.

The (Seawind) sails have arrived, the only thing I can say is - WOW. What a difference compared with the standard sails.

Absolutely magnificent (cotton) sails!

Congratulations for your sails! They look perfect and the belly looks fine and regular. Many thanks for the high quality of your work.

Many thanks for the most efficient service.

Sails received with thanks. You are a true craftsman.

Looking forwards to receiving the (Mascotte) sails, your workmanship always gives me pleasure.

Many thanks for the first class service you always give, items arrived this morning so that's my bank holiday weekend sorted!

Sails arrived this morning, superb as usual, thanks again.

Beautiful suit of sails arrived safe this morning, thank you.

Hello Frank, the sails arrived yesterday and are super thanks. I attach a photo of them fitted to my yacht.

Thanks for the BEAUTIFUL (cotton) SAILS which arrived today. What fantastic work. Amazing. Well worth the wait! I've fitted the sails to the spars. Fantastic. My goodness you are a skilled and talented man. I saw the shape you had made before fitting and understood why you did so, but only when rigged did it all make sense. Amazing. And those tiny brass eyelets... I took the yacht to my sister this morning. What a thing of beauty, was the unanimous cry. Forgot to get a picture for you in all the excitement... watch this space. I am so grateful to you, and will be coming back for more!

Thanks for your great service and friendly advice.

Order arrived this morning (next day), all OK, excellent service.

Just arrived, perfect delivery! Thank you Frank, and have a nice Weekend!

Many thanks for the prompt reply (directing me to the price list). Lots of goodies there!

The items arrived in the post today, all Ok. Thank you for the quick and excellent service, its nice to know that small orders like mine are given the same service as larger orders.

Hi Frank, (cotton) sails have arrived, they are perfect, you did a lovely job, will send you a pic when on the boat.

Just received my glorious suit! Magnificent! The tablings..... marvellous!!!... the stitching lines, the overall shape, every detail, all very beautiful indeed! I can't tell you how delighted I am. You must understand, the wind has always held a magical place in my heart and the thin membrane with which we apply our feeble human attempts to have it do our way over an equally mysterious sea..... alchemy indeed. I hold this suit in my hands and it all comes alive again. You sir, are a Wizard of Dacron. Thank you for your brilliant work, I raise a glass to you Sir,

Really thanks again for your great products and service!

The sails arrived safely yesterday and look amazing. I am very pleased with the result and they will make the yacht look smarter than she has ever done.

Hello Frank. Thank you for all your help, the sails, mast and fittings are all first class and Starlet is sailing beautifully.

Amazing. I wish all British businesses ran on your lines!

Hi Frank, sails (Nottingham J) arived safely this morning, very pleased, they are very well made and look beautiful. Merry Christmas.

Thanks Frank, wonderful service.

- Table Dolly Car

- Super Hornet X650

- Build Your Own

- Parts & Accs.

- News/Events

The Victoria R/C Sailing Yacht allows you to enjoy the simply pleasure of sailing on gentle summer breezes on a sunny afternoon....or the intensity of racing in the America's Cup. Ideal for the first-time skipper or beginning R/C enthusiast, the Victoria is a highly prefabricated, easy-to-assemble kit with detailed instruction manual. Recognized by the American Model Yachting Association (AMYA) as a racing class, Thunder Tiger's Victoria has become synonymous with maximum yachting pleasure.

Highly prefabricated with a blow-molded ABS hull/deck, sails, mast, deck fittings and rigging hardware.

The realistic sail and rigging details combine to result in a model that you will be proud to own.

The impressive Victoria stands over 4ft. tall, making it ideal for sailing or display your yacht proudly in home or office.

High performance Plus Tear Resist Racing Sails.

File download.

- VICTORIA v2017 Racing Yacht Manual Size: 4.66MB

THUNDER TIGER / About Us News | Download | Video | Terms and Conditions | Privacy Policy | Contact Us

Copyright © 2019 Thunder Tiger All rights reserved.

Pond Sailboat Rigging

by L. Novak (Houston, TX)

Click here to add your own comments

Return to Model Boats Q&A.

Would you prefer to share this page with others by linking to it?

- Click on the HTML link code below.

- Copy and paste it, adding a note of your own, into your blog, a Web page, forums, a blog comment, your Facebook account, or anywhere that someone would find this page valuable.

- Plans Store

- Model Boat Books

- Model Boats Intro

- Building Materials

- Make a Hull

- Plastic Kits

Radio Control

- US Battleships

- Torpedo Boats

- Model Boats Q&A

- Model Ship Gallery

- What's New?

- Privacy Policy

By Petter Blix

Copyright 2009-2018 Building-Model-Boats.com

Trademarks belong to their respective owners

All Rights Reserved

Yachting Monthly

- Digital edition

Expert advice: sails and rigging

- Katy Stickland

- December 22, 2021

Keeping sails and rigging in tip-top shape are of key importance to sailors. Read our tips and tricks from experts to improve their longevity

Sails and rigging are the engine room of any sailing boat from small dinghies up to giant superyachts. No matter how big or how new your boat, the sails and rigging need to be checked regularly and will need intermittent updating.

Updating of rigging on a yacht in particular will often be a requirement for insurance purposes so any owner will want to be mindful of that and make sure they upgrade often enough for those purposes – usually 10-15 years, but check your policy.

But you don’t need to focus on buying new to make improvements to your boat. Sure brand new sails will give you a performance boost, but there is plenty to be done with your old sails and rigging to improve performance and their longevity.

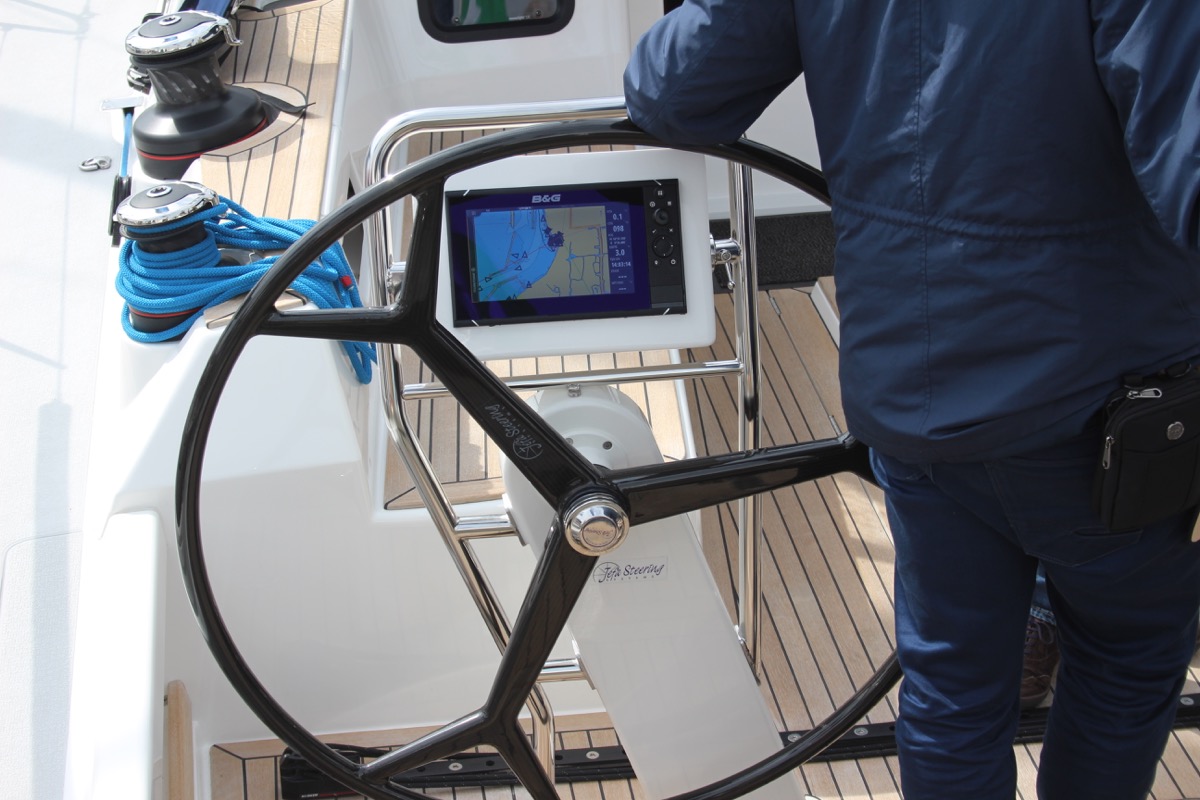

Tidy up your rigging – Dr Nick Bamford

Keeping lines shorter will help keep a clear cockpit. Credit: Dr Nick Bamford

When changing your standing rigging, look at your running rigging too.

The hi-tech, non-stretch polyester with which we just replaced our old wire and rope halyards has massively reduced the friction and now makes hoisting the mainsail a joy.

And this prompted another review. The advantages of all halyards and reefing lines led back to the cockpit, in terms of ease of operation as well as safety, are well known.

But the price you pay is that mountain of spaghetti cluttering up the cockpit!

I realised that a lot of mine was simply not needed. The lines were the length they were because they always had been! It was time for a rethink.

I treated myself to a £20 butane rope knife and set to work, and the result is a joyfully tidy cockpit.

I do have one other rigging tip, which I discovered when I lost a reefing line in the boom.

While specialist mousing devices are not cheap, curtain wire is! And it works a treat

Carabiner at your boom – Harry Dekkers

Carabiners will make it easier to reef. Credit: Harry Dekkers

How often did you try to hook the reefing eye of the mainsail at the forward end of the boom only to find that it has fallen out before you are able to hoist the halyard?

I have overcome this issue by welding carabiners on the existing ramshorn hooks on both sides of the gooseneck.

Secure every inch of your sails – Jonty Pearce

Sails and rigging advice: Ensure genoas are well secured on their roller reefing forestay before leaving the boat. Credit: Theo Stocker

When wandering around marinas, moorings, and boatyards, I am always dismayed by the number of yachts left with a triangle of genoa unfurled on their roller reefing forestay.

Not only does this engender potential weakness as a result of exposure to damaging solar ultraviolet, but that small handkerchief of unrolled sail can be worried by strong winds until it risks a catastrophic unfurling with consequential ripping and destruction of the flogging material.

It seems that every winter I spot a tattered rag of an unfurled sail that could have been properly protected by secure tight rolling.

My habit is to roll my genoa away with at least two turns of overlying sheet to trap the sail; the sheets are then tightened and securely tailed on the winches. This protects against unwanted unfurling and also provides an extra handhold.

When leaving the boat for any time, those more obsessional than I might back the sheets up with a safety lashing around the sail/sheet combination, as well as tying a preventer onto the roller reefing drum so that any damage to its furling line does not result in the sail unwrapping.

Homemade mast steps – Tony Curphey

Tony’s homemade mast steps are still going strong after two circumnavigations of the world. Credit: Tony Curphey

Mast steps are invaluable when you are cruising. They don’t have to be expensive. Mine cost me about £100, which was the price of a flat aluminium bar and Monel pop rivets. It’s necessary to have a good large pop riveter like the trellis one I have.

I used my small, onboard vice to bend them into shape. Make sure each step is wide enough for your foot with hard shoes on.

Start from the deck and put as few on as possible, spacing them apart as far as you can step up. You can use your bosun’s chair to drill and rivet, using 4x 6.4mm rivets per step.

Finish off with two together at the top so that you can stand on them and work at the very top of the mast.

I finished mine off with gold spray paint to match Nicola Deux ’s 1970s mast.

The mast steps have been there for five years and two circumnavigations, and are as firm and strong as when first fitted.

The mast has 14 steps, but I have long legs.

DIY quick-release soft shackles – Duncan Wells

Soft shackles are just the business these days; easy on the hands, no chafe to worry about and no pin to drop in the drink.

Soft shackles made from Dyneema are lighter and stronger than stainless steel, they are also kinder to your boat and your hands.

But a soft shackle, such as the one above does still present and issue in that getting them undone does require you to pull the inner core to open the loop end and allow the diamond knot through. This is why a quick-release system is a good idea.

Tie off the ends once you have passed your quick release lanyard through the shackle. Credit: Duncan Wells

Pull the inner core of the shackle out so it makes a loop sufficient to get the diamond knot through comfortably.

Then make your hole. Use a fid (a pen or screwdriver will do) to separate the 12-strand rope, pass the lanyard through and tie in a knot. Now set the shackle and smooth the outer core from the diamond knot end to the loop end and nip it up tight.

To release, pull on the lanyard.

Preventing chafe on sails and rigging – Julian and Patricia Morgan

Sewing on anti-chafe covers to lines ahead of a passage. Credit: Patricia and Julian Morgan

Chafe and rubbing damage is an ongoing enemy and it is surprising how quickly small rubs can lead to considerable damage to sheets, sails, halyards, lines and equipment.

On long-distance passages we do a detailed boat inspection, using a checklist, at least twice a day, including looking for signs of chafe.

We have installed tough anti-chafe covers on halyards and reefing lines where damage is likely, for example where ropes pass around sheaves or blocks.

We carry a bag full of short lengths of plastic pipe, which we use to pass over mooring and other lines when wear is likely to be an issue.

We also have plenty of readymade Dyneema soft shackles and loops, and have replaced many of our shackles with Dyneema equivalents, again reducing wear and damage.

Sails are very susceptible to chafe on long passages.

We have to be careful that our mainsail does not rub on our spreaders and shrouds when sailing downwind and have had covers sewn over our batten pockets where chafe has arisen.

We put one reef in the main when running to stop the sail touching the upper intermediate shrouds.

The ideal Genoa sheet attachment – Vyv Cox

Sails and rigging advice: A soft shackle makes an ideal genoa sheet attachment. Credit: Vyv Cox

There are many different ways in which genoa sheets may be attached to the sail, ranging from the simple but inelegant cow hitch, via bowlines or other knots, to some quite sophisticated methods.

In most cases they may be much of a muchness but there is one particular case that complicates the issue, and this is the presence of a baby-stay.

On our boat the combination of a large overlapping genoa and baby-stay has probably led to more sailing foul-ups than anything else on the boat.

Over the years we have tried most common methods of attachment but in every one there is a good chance that the knot or join will catch when tacking.

The only answer, short of going forward to unhitch it is to let the boat’s bow fall away until the sail blows free, not conducive to efficient tacking and doubling the effort of sheeting the sail home on the new tack.

We have tried most types of bearing on the stay itself, large and small diameter plastic tubes in various order, but none was truly satisfactory.

Then, soft shackles came onto the market. This seemed like the perfect solution to the problem, and so it proved.

I spliced loops into the end of each sheet, not quite as easily as it might have been as I was using a welding rod as a fid, and working with rope that was several years old.

Nonetheless, after an afternoon’s work we had a new system to try and the transformation was remarkable.

I cannot claim that the sail never hangs up on tacking but the occasions are pretty rare.

We have now used this same original shackle for 10 years and it continues to give excellent service.

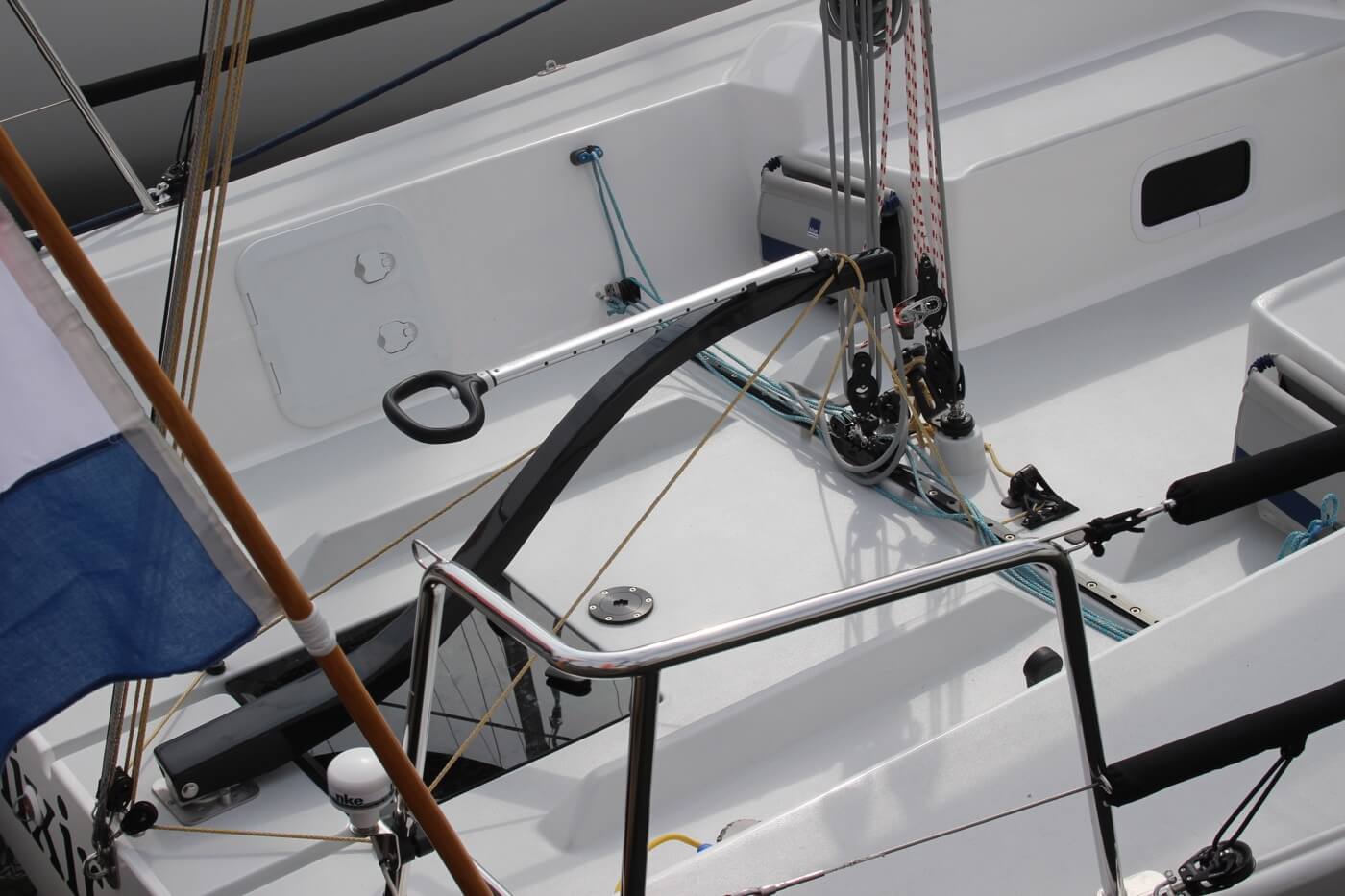

Permanent boom preventer – Helen Melton

A permanent preventer attachment makes sailing easier. Credit: Helen Melton

Our Westerly Ocean 43 has a large, fully battened mainsail.

In light winds, or in anything less than flat seas, we have found it is essential to pin the main into place to curb any unnecessary flogging and hence prevent an accidental crash gybe.

Having a dedicated preventer line and pulley blocks in the cockpit locker ready for such conditions was helpful, but attaching it to the end of the boom in a centre cockpit boat whilst at sea felt like a needlessly hazardous manoeuvre that I wasn’t comfortable with.

We solved the problem by rigging a permanent line along the underside of the boom, one end with a hard eye splice and the other with a snap shackle.

From the relative safety of the mast foot, the preventer can now be secured and winched into place.

Wash your turning blocks with warm water – Graham Walker

Sails and rigging advice: Salt crystals and other debris can prevent turning blocks and clutches from running smoothly. Credit: Graham Walker

Before we set off on our Atlantic passage from Las Palmas, we had an expert rigger do full rig inspection for us.

At the same time he gave us a lot of valuable advice about maintenance.

One thing he recommended was to wash all of our turning blocks and clutches with warm, fresh water to remove all the salt crystals and other debris ingrained in the blocks and their bearings.

We took his advice and used a lot of warm water to wash everything down thoroughly.

It was eye-opening to see how much friction we were able to remove from the system by getting everything really clean.

That then translated directly into less effort on sail handling and sail changes.

Think like a climber – Helen Melton

Using an ascender and climbing hardness has made it easier for the crew of SeaEye to climb the mast. Credit: Helen Melton

After a few years of taxing work winching a crew member, sat in a bosun’s chair, up the mast we rethought how to lighten the load, (literally) and bought ourselves two ascenders and a climbing harness.

Also known as jumars, they clip and lock to a rope – we use the spinnaker halyard on our boat – sliding freely in one direction but clamping firmly when pulled in the opposite direction.

By using them in pairs, one with a foot loop affixed, the climber can alternate taking weight through their harness whilst easily manoeuvring the other upwards, then stepping up on the foot loop.

In an emergency, the mast can be ascended alone without support whilst if crew are available, a second halyard can be used as a safety line.

This brings about an added advantage when descending in that they can be lowered away efficiently on the winch.

A rigger, who has recently worked on our boat, works alone and always uses this technique, mousing his own halyard to be 100% certain of the condition of the line bearing his weight.

It is recommended that you wear a helmet when climbing the mast.

Check furling line fairleads – Harry Dekkers

A worn furling line fairlead can make hauling lines heavy work. Credit: Harry Dekkers

Do you sometimes wonder why your headsail furling line is not running freely? Is it the wind, the furling system itself or is it a problem with the furling line fairlead?

I found out that mine was 50 pert cent worn out, as you can see in the picture.

No wonder it took me a lot of effort.

It is also worth remembering that when unfurling your headsail, always control the furling line because if a strong wind makes the headsail run out too fast, the furling line will be tangled in the furling drum and you will only notice it once you need to furl the sail again

Practice working aloft – Graham Walker

Sails and rigging advice: Make sure every crew member has experience going aloft. Credit: Kate Walker

Who normally goes aloft when the need arises?

Depending on the task and the situation it may not always be appropriate for this to be the most experienced person (possibly the skipper) or the lightest member of the crew.

On a long passage it makes good sense for all members of the crew to have experience going aloft and putting other crew members aloft.

Before our transatlantic we made sure that everyone on board had the opportunity to go aloft and experience working on the mast.

Cost-effective mainsheet horse – Tony Curphey

Tony’s mainsheet horse has stood up well to a circumnavigation of the world. Credit: Tony Curphey

Most of the changes I make to my Nicholson 32 are for economic and simplistic reasons.

When I built the new large stern locker to reduce the volume of my cockpit, I had to move the mainsheet horse.

The new mainsheet horse was very simple and cost only the price of four new long 12mm stainless steel ringbolts.

It is also better than the old one because it’s higher so doesn’t chafe on the top guardrail when sailing off the wind.

I used the original four bolt holes for the new long ringbolts but raised them with hardwood by 5 inches.

A single length of 3-strand pre-stretched 10mm polyester rope (the boltrope from an old sail) was passed through all four ringbolt eyes and the ends tied together.

The sliding part of the horse is a 12mm stainless steel bow shackle, over all four parts of the rope. All ringbolts have equal strain.

The rope horse did a complete circumnavigation via the Southern Ocean with very little sign of wear.

Put chafe guard on your genoa sheet – Graham Walker

Chafe guard will make your sheets last longer. Credit: Graham Walker

When we started sailing longer passages we read about the problem of chafe, particularly on genoa sheets when poled out downwind.

The junction between the jaw on the pole and the section of sheet just behind the bowline seemed to be a particular area of wear.

\We learnt that rigging the pole so as to minimise movement between the jaw and the sheet makes a massive difference.

To try to eliminate any possible chafe we put Dyneema chafe guard on the first 2m of the genoa sheets, covering the area that would be in contact with the pole jaw.

After 12 years we’ve replaced a few metres of chafe guard, but we still have our original genoa sheets.

Enjoyed reading Expert advice: sails and rigging?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

- standing rigging

- rope and line

- cams, cleats and clutches

- head sail gear

- roller furling

- main sail control

- mast hardware

- eye straps and pad eyes

- fairleads and bulls eyes

- anchor and docking

- miscellaneous hardware

- Alexander Roberts

- My Wishlist

We will be closed Friday, March 29th in observance of Good Friday.

Rigging Only is a full service rigging shop. All running rigging, standing rigging, life lines, wire splicing, and custom hardware are assembled right here in our shop. We know our products, and we deliver that expertise with every job we do.

N ote: Some orders may incur additional shipping costs, particularly those with heavy or long items.

All prices are subject to change without notice.

Location & Hours

- Customer Service

- Order Tracking

- Your Account

- Store Policies & Info

- Privacy Policy

- Helpful Links

- Payment Methods

Shopping Cart: 0 Items

Rig Sails: A Comprehensive Guide to Sailboat Rigging

by Emma Sullivan | Aug 19, 2023 | Sailboat Gear and Equipment

Short answer: rig sails

Rig sails refer to the various types of sails used in sailing rigs. They include mainsails, jibs, spinnakers, genoas, and more. Rig sails play a crucial role in harnessing wind power to propel boats and are designed for different wind conditions and sailing purposes.

How to Rig Sails: A Step-by-Step Guide for Beginners

Title: Mastering the Art of Rigging Sails: A Step-by-Step Guide for Novice Sailors

Introduction: Sailing, with its mystique and undeniable allure, has been captivating hearts for centuries. As a beginner sailor, understanding the process of rigging sails may seem like venturing into uncharted waters. Fear not! In this comprehensive guide, we will take you through the ins and outs of sail rigging, ensuring smooth sailing experiences ahead.

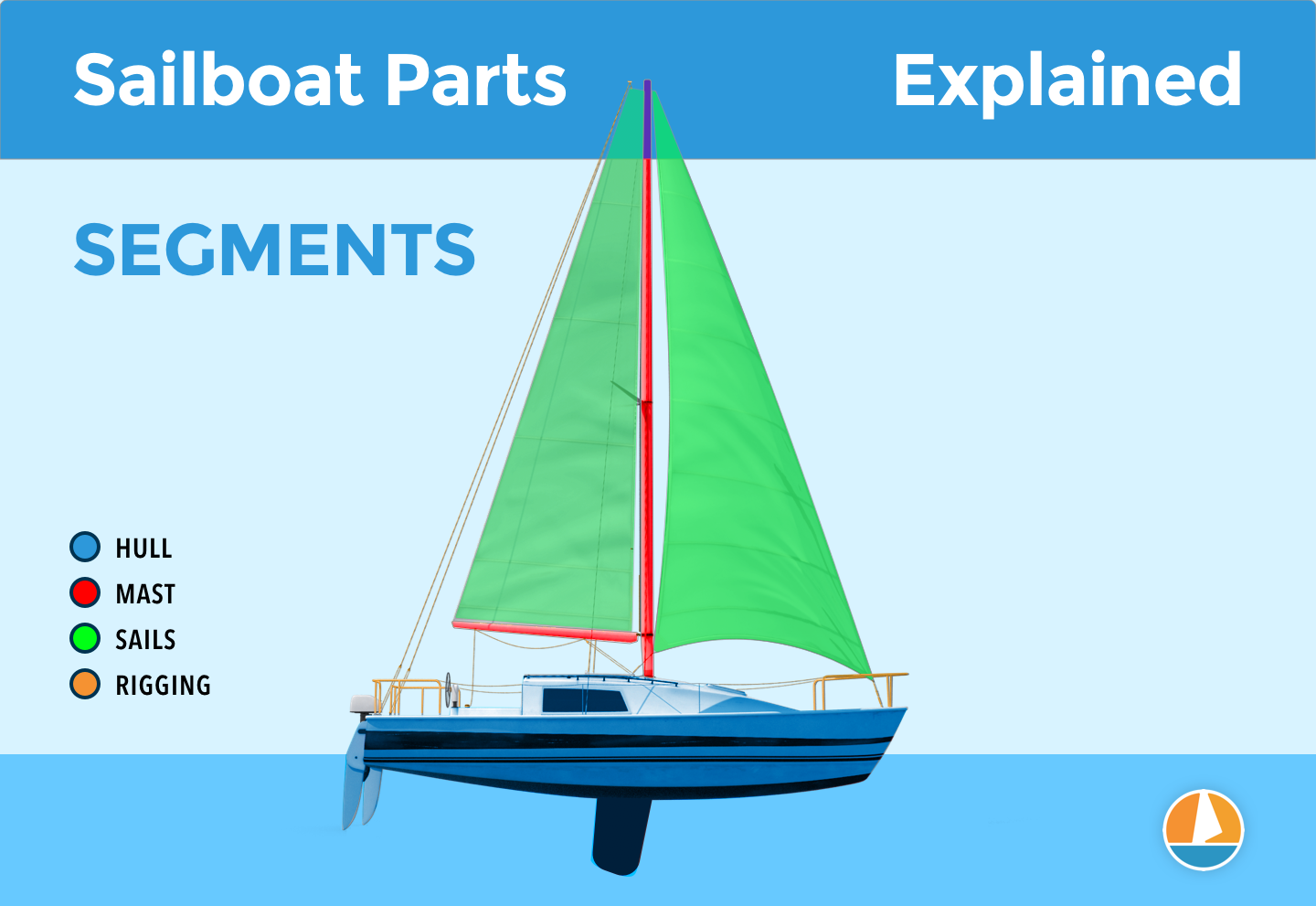

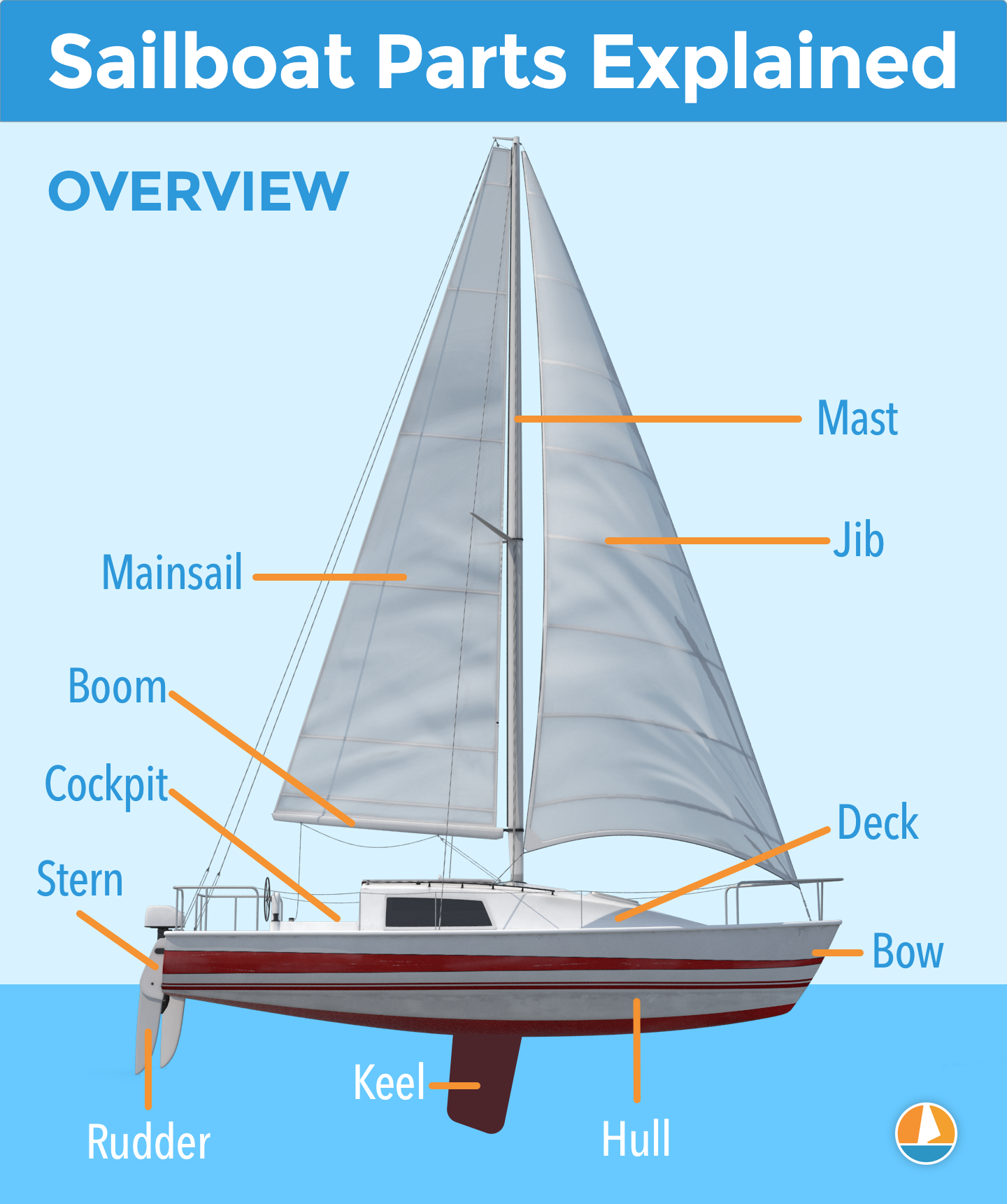

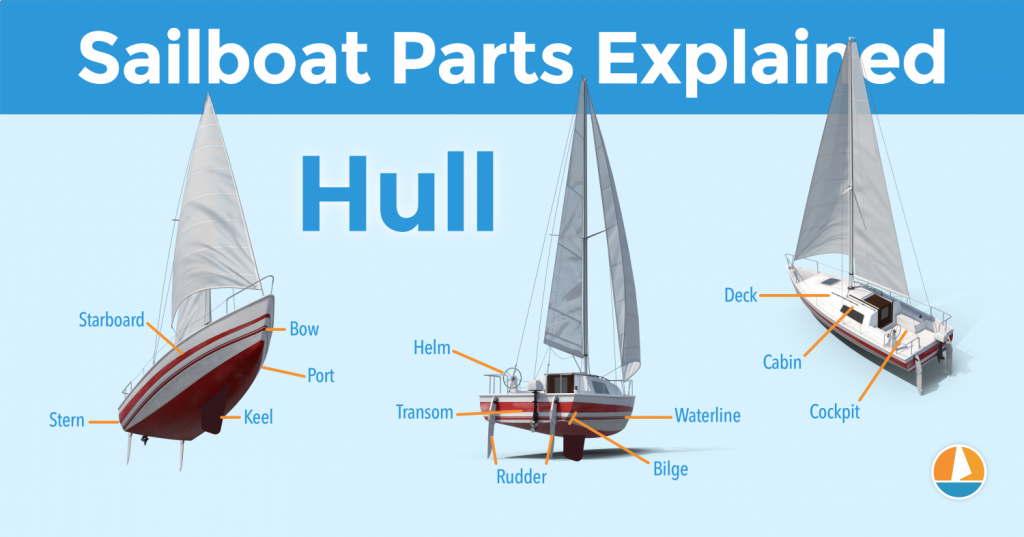

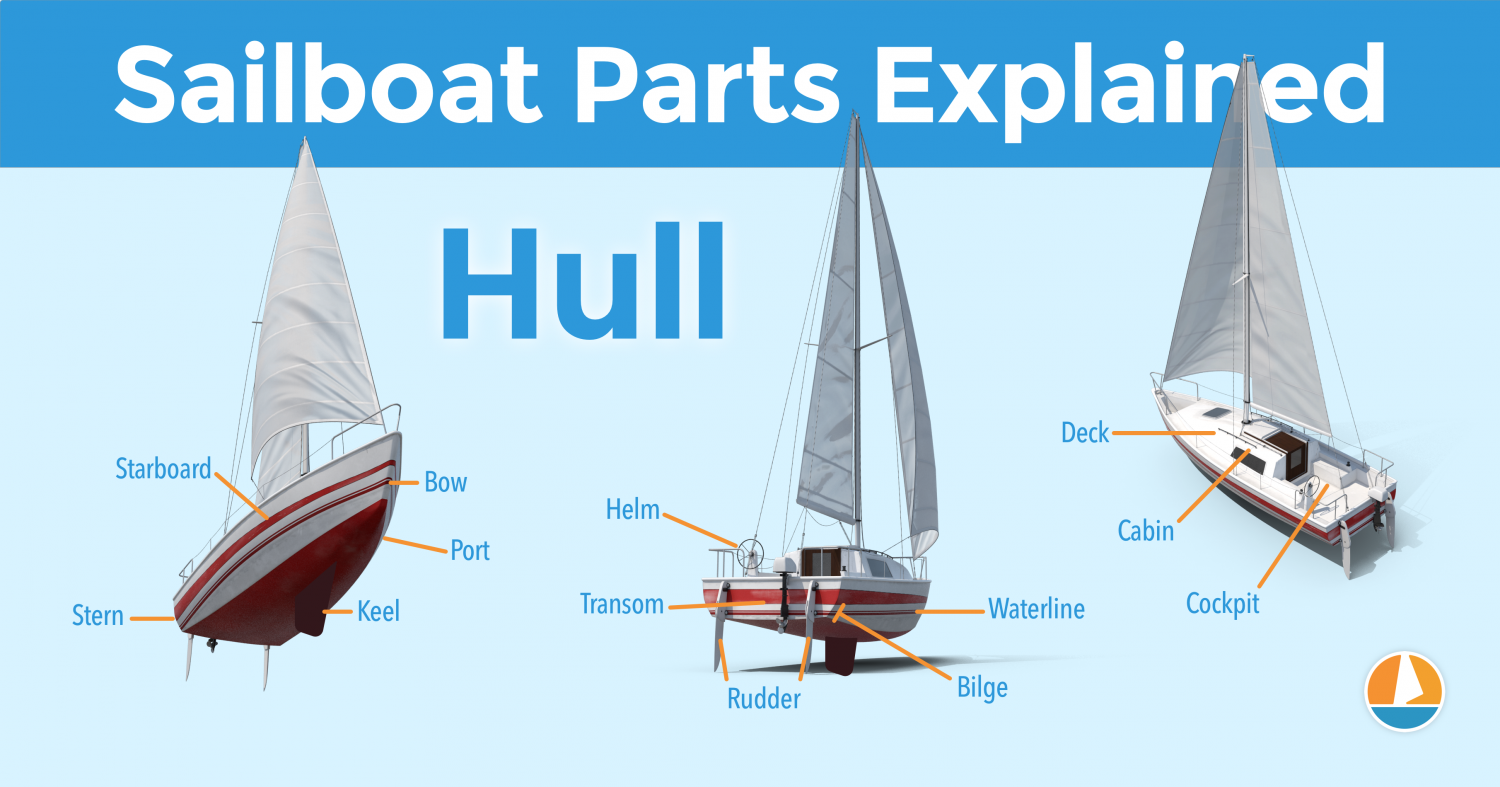

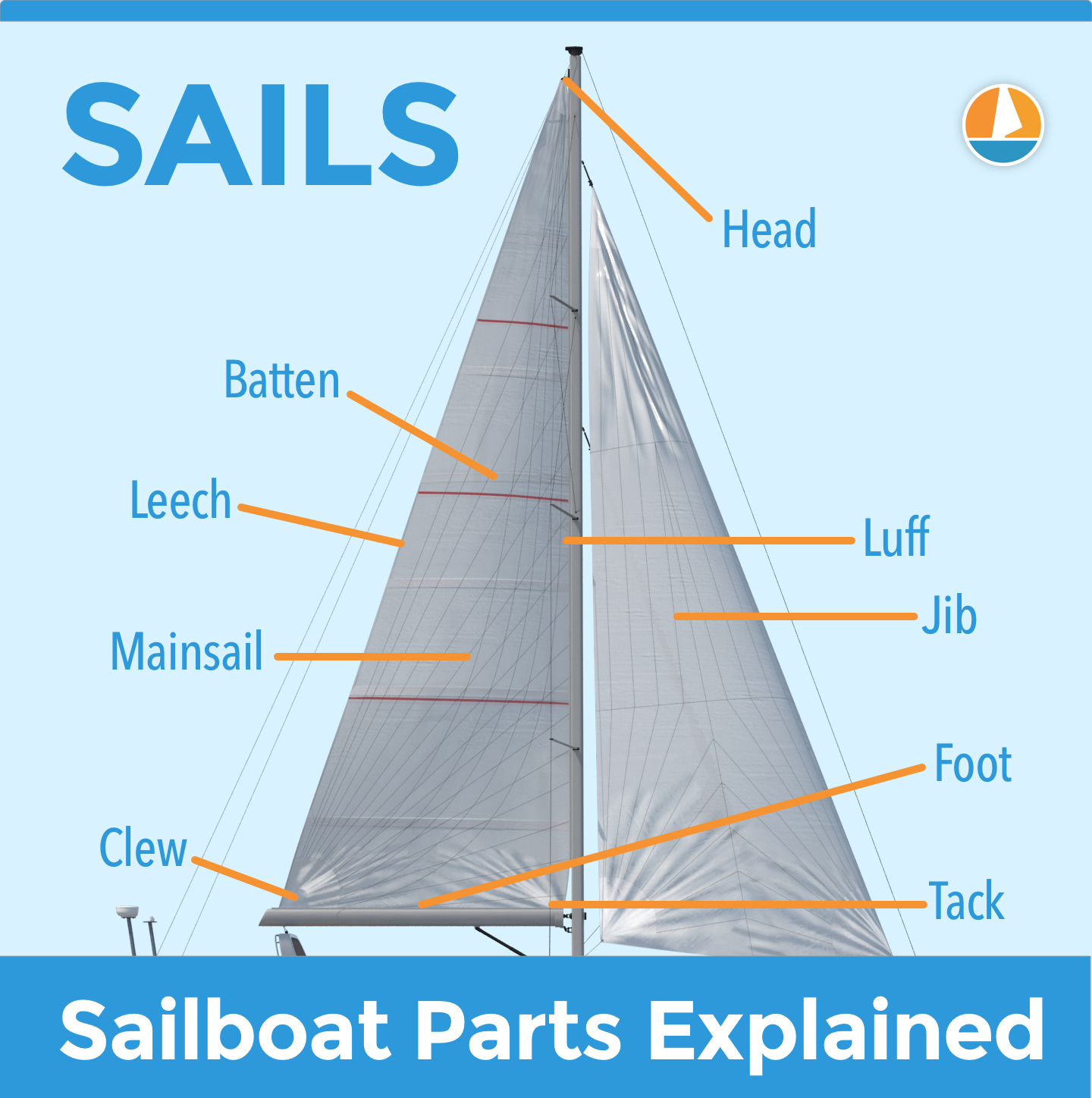

1. Unveiling the Anatomy of a Sailboat: Before delving into rigging sails, it is essential to familiarize yourself with the fundamental components of a sailboat . From mast to boom, stays to shrouds, each part plays a crucial role in successfully setting up your sails for optimum performance .

2. The Art of Preparation: Preparing your sailboat before embarking on your adventure is akin to an artist priming their canvas before creating a masterpiece. This section covers key pre-rigging steps such as inspecting your equipment for wear and tear, verifying weather conditions, and readying necessary tools.

3. Setting Up the Mast: The mast serves as the backbone of your sailboat’s rigging system. We will guide you through erecting and securing this towering structure with precision and ease while emphasizing safety measures that should never be overlooked.

4. Attaching Shrouds and Stays: Once the mast is securely in place, attaching shrouds (cables supporting vertical stability) and stays (supporting lateral stability) work together harmoniously to maintain balance during sailing maneuvers. Our step-by-step instructions ensure these crucial elements are properly adjusted for optimal sail performance .

5. Hoisting Your Sails Before Hoisting Anchor: This exciting moment marks when all previous efforts culminate into tangible forward momentum on water! Guided by our expert advice, we’ll walk you through hoisting main sails or jibs sequentially while highlighting commonly overlooked details that impact sail trim and efficiency.

6. Fine-tuning Sail Trim: As any seasoned sailor will attest, the art of sail trim can transform a seemingly average voyage into an exhilarating, breeze-filled escapade. Gain insights into adjusting sail controls, such as halyards and sheets, to optimize sailing performance in various wind conditions.

7. Navigating Nautical Knots: A sailor’s toolkit is incomplete without proficiency in tying essential knots . In this segment, we’ll showcase a selection of nautical hitching marvels, from the versatile bowline to the secure figure-eight knot . Master these knot-tying skills for security and confidence when rigging sails .

8. Deploying Safety Measures: While embracing the excitement of setting out on your sailing adventure, it is paramount to prioritize safety precautions that protect you and your crew on the water. We’ll share vital tips regarding life jacket usage, weather awareness, emergency protocols, and more.

9. Practice Makes Perfect: Troubleshooting Common Issues: Even with meticulous planning and execution during sail rigging, occasional mishaps may occur while on the water. Fear not; this section unravels common troubleshooting scenarios a novice might face along their journey while providing practical solutions to keep any minor setbacks from dampening spirits.

Conclusion: With this all-encompassing guide to rigging sails designed exclusively for beginners like you, embark on your maiden voyage with confidence! By understanding each step intricately and embracing best practices in safety and knot-tying techniques, you’ll master the art of rigging sails—a critical stepping stone towards becoming an adept sailor capable of navigating endless seascapes with grace. So hoist those sails high as you venture forth into a world brimming with endless possibilities—it’s time to set sail!

Mastering the Art of Rigging Sails: A Comprehensive FAQ

Are you ready to take your sailing skills to the next level? Look no further! In this comprehensive FAQ, we will dive into everything you need to know about mastering the art of rigging sails . From understanding the different types of rigging systems to troubleshooting common issues, we’ve got you covered. So grab a cup of coffee and let’s set sail on this knowledge-filled adventure !

1. What is Rigging and Why is it Important? Rigging refers to the system of ropes, wires, and other devices used to support and control the sails on a boat . It plays a vital role in harnessing the wind’s power effectively, allowing sailors to maneuver their vessels with precision. Proper rigging ensures optimal sail shape, enhances speed and stability, and improves overall performance on the water.

2. Different Types of Rigging Systems There are several types of rigging systems commonly used in sailing:

– Fractional Rig: This type employs a forestay that attaches below the masthead, making it highly versatile for various wind conditions. – Masthead Rig: In this traditional rig setup, both the headstay and backstay attach at the top of the mast. – Cat-Rigged: A single mast positioned well forward in the boat characterizes cat-rigged vessels . – Slutter Rig: Combining elements from both sloop and cutter rigs, slutter rigs use more than one headstay.

Understanding these different rig configurations allows sailors to choose what best suits their intended use and sailing conditions.

3. Essential Knots for Sail Rigging Knot tying is an essential skill for any sailor . Here are a few crucial knots for sail rigging:

– Bowline Knot: This versatile knot creates a secure loop that won’t slip under load. – Cleat Hitch: Used for securing lines onto cleats without tying knots . – Reef Knot: Ideal for tying two ends of a line together, especially when reefing sails . – Taut-Line Hitch: Perfect for adjusting the tension of a line under load.

Mastery of these knots will make sail rigging both efficient and effective.

4. Troubleshooting Common Rigging Issues Rigging problems can arise even for seasoned sailors. Here are some common issues you may encounter and how to tackle them:

– Excessive Mast Bend: This can lead to inefficient sail shape. Adjust the backstay tension to correct it. – Loose Shroud or Stay: A loose shroud affects mast stability and ultimately, sail performance. Tighten the appropriate stay using a turnbuckle or other tensioning mechanisms. – Slipping Halyards: Prevent halyards (ropes used to raise sails) from slipping by tying a stopper knot at the end. – Snapped Masthead Sheave: Replace the damaged sheave with a similar-sized one before it compromises your sailing experience .

Remember that regular inspections and maintenance are crucial for preventing major rigging mishaps.

5. Tips for Efficient Sail Rigging To maximize your sail rigging efficiency, consider these valuable tips:

– Label Your Lines: Invest time in labeling your lines according to their function or purpose; this saves time during set-up or troubleshooting. – Use High-Quality Hardware: Investing in top-notch pulleys, blocks, and shackles ensures reliability during critical moments on the water . – Practice Kaizen Methodology: Continuously seek small improvements in your rigging setup over time to enhance overall system performance gradually.

By adhering to these tips, you’ll be well on your way to becoming a seasoned sailor who consistently achieves peak rigging proficiency.

Mastering the art of rigging sails is an exciting journey filled with endless learning opportunities. Understanding different types of rigs, essential knots, and troubleshooting common issues will empower you as a sailor. Remember to prioritize regular maintenance, practice efficient rigging techniques, and continuously seek improvement. So go ahead, hoist your sails, catch the wind, and embark on unforgettable nautical adventures !

Exploring the Different Types of Rig Sails: Which One is Right for You?

Title: Exploring the Different Types of Rig Sails: Which One is Right for You?

Introduction: When it comes to sailing, one crucial element that determines the performance and maneuverability of your boat is its rig sails. Designed to harness the power of the wind, rig sails come in various types, each offering unique characteristics and advantages. In this blog post, we will delve into the different types of rig sails available, helping you navigate through your options and choose the perfect one for your sailing needs.

1. The Classic Mainsail: Starting off with a timeless choice, the classic mainsail remains a popular option due to its versatility and easy handling. Its triangular shape offers excellent efficiency in directional stability and steering upwind. This traditional sail design allows sailors to adjust settings swiftly in response to changing wind conditions, making it ideal for both cruising enthusiasts and racing warriors alike.

2. The Genoa: For those seeking enhanced speed and performance, look no further than the genoa sail. As an overlapping headsail that extends beyond the mast’s leading edge, this type of sail maximizes surface area exposed to wind pressure, translating into increased momentum while sailing close-hauled or reaching. With impressive light-air capabilities and superb pointing ability when partially reefed, genoas are a favorite among competitive sailors chasing buoy-to-buoy supremacy.

3. The Jib: Similar to a genoa but with less overlap on the mast’s leading edge, jibs find favor among sailors seeking greater balance between speed and manageability. Their reduced surface area generates reasonable power without compromising control during gusty conditions or tighter maneuvers . Overall, jibs make excellent companions for cruisers embarking on long journeys where varying wind conditions may be encountered.

4. The Spinnaker: Enterprising thrill-seekers looking to catch downwind winds with flair will undoubtedly appreciate spinnakers’ gossamer elegance and exhilarating potential for acceleration. Often employed during downwind sailing or racing, these large, billowing sails can capture even the slightest zephyr, propelling your boat to impressive speeds. Spinnakers come in a wide range of cuts and sizes, from traditional symmetrical designs to asymmetrical versions that simplify handling for solo sailors.

5. The Code Zero: When it comes to reaching faster than the wind itself or making significant headway at low wind angles, using a Code Zero sail is an ingenious choice . This specialized sail combines the characteristics of both a genoa and a spinnaker, tingling your competitive instincts with remarkable speed possibilities in light air conditions. Its projecting bow-sprit allows effective sheeting angles and creates lift while minimizing drag, ensuring you triumph over calmer waters .

Conclusion: Choosing the right rig sails involves assessing various factors such as your sailing style preferences, your boat’s design and size, and the prevailing weather conditions you typically encounter. Whether you opt for the time-honored mainsail or revel in the adrenaline rush provided by spinnakers or Code Zero sails, understanding their strengths will enable you to select the most suitable sail for maximum performance on your voyages. So weigh anchor , hoist your chosen rig sail high and confidently set course towards endless nautical adventures!

Pro Tips and Tricks for Efficiently Rigging Sails to Enhance Performance

As sailing enthusiasts, we understand the importance of harnessing the power of the wind to maximize performance on the water. Rigging your sails efficiently is not only key to enhancing your boat’s speed, but it also improves maneuverability and overall control. In this blog post, we’ll delve into some professional, witty, and clever tips and tricks that will take your sail rigging skills to the next level.

1. Choose the right materials: The choice of materials for your sail rigging can greatly affect its performance . Opt for high-quality lines that ensure minimal stretch, such as Dyneema or Spectra. These are not only lightweight but also provide excellent strength and durability.

2. Tension is everything: Proper tensioning of your rigging lines is crucial for optimal sail shape and control. Too loose, and you risk losing power; too tight, and you may hinder maneuverability. Experiment with different tensions until you find the sweet spot that maximizes both speed and responsiveness.

3. Know your angles: Understanding how wind interacts with your sails at different angles is a game-changer in sail rigging efficiency. Adjusting your sheets based on wind direction allows you to fine-tune sail shape and trim effectively. Keep in mind that small tweaks make a big difference!