DIY Cruising Catamaran: Complete Building Guide

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

A brand-new cruising catamaran can set you back a hefty amount of money. However, a DIY cruising catamaran provides a more affordable way to own your own boat. While building a large boat can be an extremely challenging and time-consuming experience, nothing beats the pleasure of bringing your own boat to life.

To build a DIY cruising catamaran, buy good design plans, determine your budget and find a working space. Next, choose your hull material, buy supplies and start building the mast beam. Build and sheathe the hull, install bulkheads, the interior, and finally, launch the catamaran boat.

In this article, you will find a complete guide to building your own catamaran. You will also find detailed information on why you may want to consider building your catamaran and approximately how much this project would cost. Finally, we will explore the advantages and disadvantages of building a catamaran from scratch.

Why You Might Want To Build Your Own Catamaran

Most people might think that purchasing a used boat to repair and fix it up would be cheaper than a DIY cruising catamaran. But while building your own catamaran could be an enormous undertaking, it also comes with many advantages over buying something used.

Other than the unique opportunity to create beautiful memories and experiences while cruising, sailing, and exploring beautiful coastlines, there are a number of benefits that come along with the DIY approach.

Knowing Your Boat

Building your own catamaran provides you with intimate knowledge of your boat. You will know every corner, including where to find every bolt, wire, bulkhead, rib, hose, and support as you installed them yourself. This knowledge will enhance your confidence while at sea since you will have entrusted your life to a boat whose history you are aware of and deeply connected to.

Pride of Ownership

The satisfaction you get from crafting something with your own hands is immense. As a result, the knowledge that you built your boat from scratch will fill you with absolute pride and an immense sense of achievement. Furthermore, as an owner-builder, you get to keep and enjoy the boat for as many years as you wish.

Substantial Cost Savings

Building your catamaran will work out cheaper than buying a new or even gently used boat. Though you will likely require some additional labor since doing some things will require an extra pair of hands, if you are particularly good at DIY, you will save a significant amount of money on labor costs as a whole.

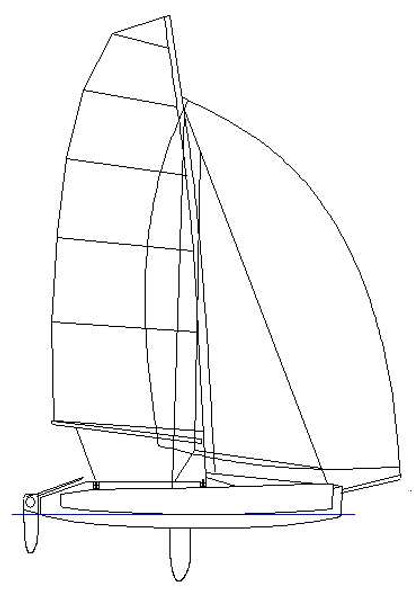

Freedom To Create Your Own Designs

If you decide to buy a catamaran boat, it might not be easy to find one that meets your unique needs. However, instead of choosing from production boats that bear traditional and outdated designs, you can come up with an ultra-modern design or style for your catamaran. You also get to pick your layout, size, and equipment based on your taste and budget.

Great Learning Experience

Building your own boat will help you pick up numerous skills that will come in handy later when sailing your boat. As much as you might still require an expert to help you with specialized skills like carpentry or wiring, your new skills will serve you well. This will also be beneficial when it comes to your boat’s maintenance and fixing things for yourself.

What To Look For in Catamaran Boat Designs

When deciding on the type of catamaran boat to build, you may want to choose a design that’s simple and easy to build. This is because doing so will allow you to spend a shorter time building the boat.

You also need to have a set of requirements to guide you in choosing your design or what you might call an ideal cruising catamaran wish list. This is essential because, ultimately, you want to build a boat that offers outstanding qualities such as:

- Delivers good speed

- Affordable to own and operate

- Agile, strong, and easy to maintain

- Has a high resistance to capsizing

- Great for sailing and cruising

- Delivers a comfortable and easy motion underway

- Good handling ability and high performance under sail

- User-friendly embarking and disembarking

- Provides ample living and accommodation space

- Presents a reasonable resale value

It’s worth noting that, in general, catamaran boats tend to offer a fair resale value mainly because of scarcity and the high price accorded to production models. So, if you build a well-constructed catamaran, you are bound to get a return that’s much higher than the cost of materials upon resale.

It’s also good to consider whether the design you settle on is from an established designer. This is significant because documentation of the building process is just as valuable when it comes to selling the boat.

How Much Would It Cost To Build Your Own Catamaran?

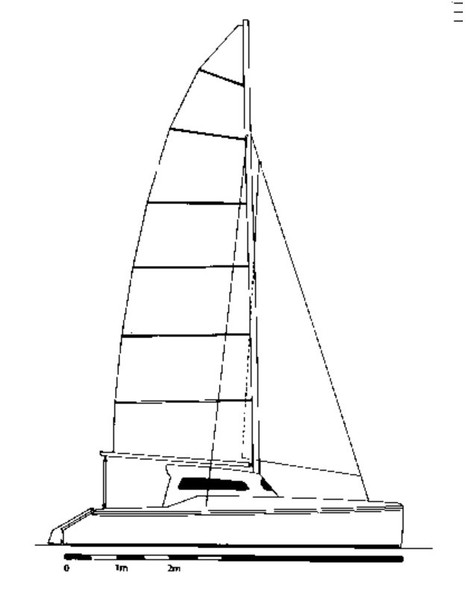

The cost of building your cruising catamaran will depend heavily on the size of the boat you plan to build and the skills you bring to the table. To give you an idea of probable costs, a professionally built 40 foot (12.1 m) long cruising catamaran could go for up to $300,000.

Though building it yourself will undoubtedly be cheaper, most DIY boatbuilders tend to underestimate the expected costs. Your final costs should cover not only the cost of material and equipment but also the labor and time it would take to come up with the final product.

If you were to build a 40-foot (12.1-meter) catamaran, your cost of materials would range between 20-30% of the total cost. Therefore, for $300,000 total, the boat’s materials would range between $60,000 and $90,000. The hull tends to range between 15-35% of the total build. Again, this depends on the finish and furniture.

But before you even start working on the DIY project, you will need to figure out where to do the work. If your home has ample space, then you can opt for a backyard building. But if you live in a small apartment, then you might want to consider renting a small garage at first and then move on to a boatyard later. This is one of the significant costs involved in building your multi-haul.

What You Will Need

To get a clearer picture of how much the entire project would cost, let’s have a look at what else you will need to purchase.

- Good design plans

- Working space

- Ground tackle

- Matting and roving

- Equipment such as the engine, windows, rudders, deck fittings, mast, and rigging

In addition to the above, you also need to install plumbing and electricals. You may also want to consider going electric rather than using diesel. Not only will this drastically reduce your maintenance costs, but you get to use the regenerated power for all of your housing needs while sailing.

Some catamaran boat designs help you save costs by advocating the use of less expensive corpus materials. Most of the material goes directly into making the boat, which means there is hardly any wastage on vacuum bagging . With this method, there are few molds and temporal building forms and fewer fillers to grind off as waste. All these factors reduce the time and cost it takes to build your catamaran boat.

That said, building a boat of any kind is a huge financial undertaking. As such, you still need to have the financial ability to keep building; otherwise, your project will stall or take much longer than anticipated. Instead of enjoying yourself and making memories cruising to faraway lands, you might end up spending all your time building a seemingly never-ending boat.

To reiterate, this project is more of a labor of love, given that it involves a tremendous amount of manual work. Calculating an hourly rate on the time spent building the boat and adding this cost to that of materials may make it seem a very pricey exercise. However, it is vital to understand that your time matters, and every hour you spend working for “free” should be included.

With that in mind, you need to ensure that you are fully devoted to the boat construction project and are sure you want to do it before you begin. Stopping halfway because it seems like too much work would be incredibly costly.

How To Build a Catamaran

When it comes to building a cruising catamaran, you have 3 main options:

- You can buy an old boat and refurbish it.

- Purchase a bare hull plus deck molding for a home-boat building.

- Start from scratch and build everything, including the hull, on your own.

As mentioned above, renovating an existing boat may end up being more costly than starting from scratch. To build a catamaran boat from scratch, follow the below step-by-step guide.

Prepare the Essentials

Before you jump into such a large project, there are several important aspects to consider:

- Buy your plans from an established catamaran designer. You can also get inexpensive, easy-to-build catamaran designs online.

- Get access to a large working space or build a shed . Depending on your climate, you may need to opt for climate control to avoid an excess of moisture in humid areas.

- Decide on your choice of hull material. This could be fiberglass, aluminum, steel, wood, or ferroconcrete.

- Start working on a bill of materials estimate. Include everything that you think you need to get a better idea of the initial costs.

Build the Mast Beam

Using wood and epoxy, cut and glue together the pieces of wood that will form the mast beam. Most of the work at this stage can occur in a garage since it involves building small parts. Still, the work could take up to 4 months, so be prepared to put in long hours.

Build the Boat Hull

Now, it’s time to build the boat’s hull. A catamaran comprises two hulls which are connected with a deck. Below is a short video showing how to build a hull mold:

This work requires a larger facility, so you might need to move out of the garage and into a boatyard. If you don’t have access to a larger workshop, consider building a shed where you can work as you do the construction. Make sure there’s enough room to fit the boat and also allow you to work comfortably. To cover the shed, you can use opaque white tarps.

Sheathe the Hull

Get all the materials you require for this stage in the construction, such as lots of resin, fiberglass, and foam for use in the hull cores. You’ll also require matting and glass roving to sheath the hull .

Sheathing helps to make the hull impervious to water and other marine borers. But first, you need to prepare the hull using a rotary sander. To make it as smooth as possible, use light, sweeping strokes. This is a very dusty task so be prepared to wear a facemask and safety goggles.

Install the Bulkheads

Next is installing the plywood bulkheads . You might need to call in friends to help turn the hulls or use a crane. In this step, you will need to laminate the hull sides on the molded hull panels and bond them above the bulkheads. Ensure the bulkheads are snug and sealed in place.

Construct the Interior Structure

Over the next couple of months, the boat work will involve joining the hulls together with the beams that you had made back in the garage. Then, install the cuddy cabin, decks , and the cockpit . Soon the boat will start to take the shape of a catamaran.

Next, proceed to construct the major structural components such as stairs, hatches, mini-keels, and the interior. Then comes the work of fairing the boat, which is quite labor-intensive.

Finally, it’s time to apply primer on the catamaran boat and start the paintwork. Before painting the boat, you will need to do additional sanding to finish off the two layers of primer as well as fill all the pinholes. Since it’s a large boat, the catamaran has lots of surface area; thus, the sanding could get extremely exhausting—mentally and physically—at this point.

The painting can take a while, too. The hulls are the easiest to paint, but the topsides, non-skid, as well as masking and prepping could seem never-ending.

The final stretch involves working on the center bridge deck cabin and other final touches like installing the engines, electricals, and plumbing. This is also the time to fix the rudders, rigging, mast, windows, and deck fittings.

Launch Your Cruising Catamaran

After many months or years of hard work, your cruising catamaran is finally ready to test the waters. After lowering the boat into the water, check carefully in case there are leaks. If none, you can set up the sails and take your catamaran out for your first cruise.

Below is a short video that takes you through the entire boat-building process:

If you don’t have deep pockets, don’t despair. It’s also possible to build an inexpensive catamaran boat, as shown in this post from the coastal passage .

The Pros of Building a Catamaran

Though it will be a costly endeavor, there are so many things to look forward to should you decide to build your own catamaran:

- It can be lots of fun.

- You get to have a new boat.

- It’s an excellent hobby for DIY enthusiasts.

- The effort is rewarding.

- It offers a great learning experience.

- You get the exact kind of boat you want.

- You can alter building plans and tailor the boat to suit your specific needs.

- It might be cheaper than buying a new boat.

The Cons of Building a Catamaran

Though there are a number of positive aspects to a DIY build, it is just as important to keep in mind that it won’t always be easy:

- Maintenance costs can be quite high.

- It’s both mentally and physically exhausting.

- It might require some technical know-how.

- It can take many months or even years to complete.

- It requires a lot of commitment to finish the DIY project.

- It might be challenging as well as expensive to get insurance.

- You will spend almost all your free time building the boat.

DIY Cruising Catamaran Tips and Tricks

If you are new to boat building, it would be a good idea to build a small boat first. This would give you a good indication as to whether you’d enjoy tackling a more extensive project like building a catamaran. Again, if you are the handy type, fixing your own electronics could also save you a significant amount of money.

Here are more tips and tricks to get the most out of your DIY cruising catamaran:

- Lower your costs. Bring down your costs even further by sourcing for parts and supplies at marine surplus outlets, Craigslist, eBay, or wholesale suppliers.

- Enhance your resale value. Most home-built boats are not easy to sell since they tend to be too customized. To enhance your resale value, it’s advisable to work with a standard design from a well-established naval architect.

- Follow the design instructions. Make sure to follow the designer’s instructions regarding the type of materials and tools to use during the build to avoid making costly mistakes.

- Maintain your original budget. Avoid any additional customizations once you have started building the boat. Using good plans and sticking to them ensures that your budget doesn’t spiral out of control.

Final Thoughts

Building a catamaran is about more than saving money. It’s fun, exciting, fulfilling, and can be a great learning experience. While it might take many months of back-breaking work, comparative shopping and sourcing for materials will help you save a lot of money. Still, at the end of it all, you’ll have a beautiful catamaran boat, all ready for your first cruising adventure.

However, if you have neither the time nor the energy to build your own catamaran from scratch, refurbishing an existing hull might prove faster and easier. It also works out much cheaper than buying a new boat.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

One thought on “ DIY Cruising Catamaran: Complete Building Guide ”

Hello, I am a French Quebecer who is original, imaginative, creative and who finds that all boats and catamarans have a huge flaw and a very big lack of logic. I would have a brand new concept…. I am sending this message to any catamaran creator – designer to make those who have the opportunity and the intelligence to want to know about my innovative idea which will finally upset the market much richer. An idea that will totally change the concept of sailing, navigation and save so much worry!! All I would ask for is a small percentage of each sale of the new product. To be able to make me produce one when I have enough!! It is certain that like that, you just want to tell me: come on Mr. Lessard give us your idea but do not take your word to help me in return! But, if you are the kind of man to have only one word and maybe have a proof of your good faith if the realization of the project would make it… I will be very happy!! Giving it to everyone wouldn’t bother me either…. all I would like is to be able to find flax fiber (too expensive carbon) to be able to try to make my catamaran myself. Because not rich! Have a nice day and looking forward to having a message!!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

Time For a Catamaran Adventure

Isn't Time For Yours?

Building Your Own Catamaran

Building your own catamaran is another option to getting into your own boat. In this page we will go over the advantages, considerations, and a detailed history and journal of our boat-building adventure with Light Wave . We hope this will give you a clear picture of what lies ahead if you go this route, including:

- Construction methods

- 9 essential design features

- Review of the four leading catamaran designers for home builders

- Construction times

- Budget: How much did it cost to build a basic cruising catamaran?

- Layout of our catamaran, LightWave , and lots of pictures

- Carllie’s article from September 2000 Multihulls Magazine: “The Boat Builder’s Wife “

- Equipment outfitting

- Radio and communication outfitting

- Dinghy selection and considerations

- Having a boat custom-built for you

Because of the huge dollars needed to buy a new or even a used catamaran, we would never have gotten a catamaran if we hadn’t built it ourselves.

Let’s start by saying that building any type of larger boat, especially a catamaran, can be one of the most intellectually and physically challenging things you will ever do.

It has been said that building a large boat is the closest a man can come to giving birth to a baby. In other words there is going to some discomfort and pain along the way; you will question yourself on whether this was such a good idea; it’s very difficult to reverse the decision; and though friends will support you, you will be on your own most of the time with your significant other if he/she is game.

Know your boat

You will intimately know every part of your boat. You will know where every wire, hose, bolt, bulkhead, rib, and support is because you installed them!

Pride of ownership

We have often thought what it would be like to just buy a boat from a manufacturer, and know that while owners who have spent a lot of cash (or future life to pay off the lien) their often possessive and competing-with-the Joneses could not begin to compare to our quiet glow of happiness and akinship we feel with Light Wave .

Our boat is like part of the family. So much time was spent on her that we have a major emotional investment. Every time we see our vessel – from a distance at anchor or approaching her in our marina, we say, “What a pretty boat! I can’t believe we built it!” Then that sense of accomplishment settles back in and we feel we have indeed earned the privilege of all of the beautiful experiences we have had sailing, cruising, exploring the beautiful BC Coast and much further a field (or should we say “an ocean”?).

You will be able to pay for the materials as you go and “donate” your time to the cause.

Get a newer design

Many of the production boats that are out there are designs of many years ago because the manufactures have to recoup their capital investment on the mold and production setup. When you build your own you have much newer designs to draw from.

Details on Our Boat Building Adventure

We had sailed our first boat Wave Dancer for five years and had many adventures on the British Columbia coast. In May 1996, I had just returned from a little one-week solo trip in the Gulf Islands of BC when I bought the book, The Cruising Multihull by Chris White (Future link to book review on our web site).

This is the book that got me going (Carllie was not yet convinced). I must have read it a half dozen times over the next 6 months, each time becoming more convinced that this was the way to go for our next boat. It was really still pre-internet web site days so I wrote to all the designers that were listed in the back of the book. Over the next several weeks packages of information started appearing in the mailbox (there is just something about getting packages in the mail – I guess it’s the anticipation). I would pour over these preliminary printed pages with pictures and accommodation layouts. Next, I put a few dollars down to buy the information packages and study plans from the top prospects.

I waited patiently for the study plans. It was like the night before Christmas when I was kid. Oooh the wait! Finally they came, and again I carefully scrutinized the next level of detail. Things were getting a little more serious. The top contenders were:

- Richard Woods

- Chris White

- James Wharram

Click here to read my comments and reviews on their catamaran designs as well as those of Jeff Schionning.

I remember initially drooling over the Atlantic 42 by Chris White, still one of my favorite designs. It seemed to be so seaworthy (by the way if I run into about $800,000 USD any time soon, I am going to buy an Atlantic 55). The most important piece of advice that came out of the material was from Richard Woods:

“Build the smallest boat you‘d be happy with it.”

Axiom #1: The hours to build a catamaran is in almost in direct proportion to its weight.

Which brings us to Axiom #2:

Axiom #2: It takes about 1 hour to create 1 pound of finished boat.

In our case we spent 3,500 hours ( click here for full details on the construction hours ) to build a 4,000 lb. boat (just a little less than 0.9 hours per pound). If a boat’s empty weight is 8,000 lbs., it will probably take about 6,000 hours to build.

When you think about it, you can only mix and handle so much material per hour. More boat weight, more material, more hours. Sure there are some economies of scale on a bigger boat, but usually the systems become more complex and these take longer to install.

This decision process took 8 months and I figured we’d launch in 6 months. It was now January of 1997. Little did we know it would be 26 months and 3,500 hours between the two of us until we launched on June 5, 1999. We ordered the full plans and we were off and running.

We were ready to build, but where would we start the process? First of all, we live in a tiny 480 sq. ft. apartment in Vancouver. Back-yard building wasn’t exactly an option so I found a small garage nearby that we rented for 5 months.

After about 4 months in the garage, I had made all the small parts and it was time to build the hulls. This meant that we had to go larger facilities. We found space at Shelter Island Marina and Boatyard in Richmond. This is the biggest boat yard in the Vancouver area with dozens of commercial and private projects, big and small, under way.

We were out of money by then, so we sold our first boat so we could buy resin and fiberglass. It was a traumatic time as we said goodbye to our beloved Wave Dancer . We were now committed. We than had all the foam for the hull cores, barrels of resin, and huge rolls of matting and roving needed for the fiberglass skins delivered to our “domed stadium”. We kicked ourselves many times that we didn’t take a picture of this raw material stacked in one corner of the empty shed, so we could later show “before” and “after” photos. It was time to build the hulls.

Over the next several months we proceed to join the hulls with the beams I had built in the garage, and then to install the cuddy cabin, cockpit, and decks. By the spring of 1998, it was staring to look like a catamaran. Through the spring and summer of 1998, we continued with the major structural components: mini-keels, hatches, stairs, and interior. Then we went on to the very laborious work of fairing the boat before painting. Don’t under estimate that job!

By October 1998 we were ready to prime the boat and start painting. I really thought this would go quickly. I forgot that I would have to do two more complete sandings to sand off and finish the two layers of primer application. In addition we had to fill countless pinholes – a laborious process somewhat like hiking up a mountain – each time you get to what you think is the top, you see another summit!

The boat seemed to get bigger and bigger. Believe me, there is a lot of surface area on a catamaran. I clearly remember that last sanding: I had reached the end of my physical and mental endurance – I was exhausted. I was ready to move on to the next phase – any phase but more sanding!

We now started spray-painting the hulls bright yellow. It was around this time we decided on our boat name of Light Wave . The painting took over a month: the hulls being the easy part, it was the topsides, the nonskid, and all the masking and prep that seemed to take forever. Happily, the worst of the dust was gone.

By March 1999 we were in the home stretch. The center bridge deck cabin was completed so we took a week off from our paid jobs and lived on the boat in the shed so we could work all day and not waste time commuting. March, April and May were frantic months as we finished all the final touches: engine installation, rudders, windows, deck fittings, electrical, plumbing, mast, and rigging. See our outfitting page (for more details on what we picked and why, and things we would do differently now.

Initially, our electronic systems were relatively basic but included GPS and autopilot see the following link for all our electronic outfitting choices and reasoning for more details.

It was May 22, 1999 and we decided that Saturday, June 5th would be “Launch Day” so we could send invitations to all of our friends. On the Friday night before Launch Day, we still had a number of final things to do, many of them outside. Unfortunately it was pouring rain. We were tired and very wet but the boat had to go into the water next day so we persevered on till everything was ready.

The moment of truth came as Light Wave was lowered into the water. While still in the slings of the Travelift, I jumped aboard to check for leaks. Of course there weren’t any! More food and laughs and tours of the boat for all attending. It was a great day.

Emotionally drained that night, we slept in Light Wave in the water for the first time. It was another week before we actually went out for our first trip as we had to sell the shed, setup sails, and install some final deck hardware.

To sum it up, building a catamaran was a great experience. We learned a lot. Carllie and I grew closer together through it all. We had a great time doing it. We had a beautiful catamaran to show for it. Now it was time for a catamaran adventure !

[email protected]

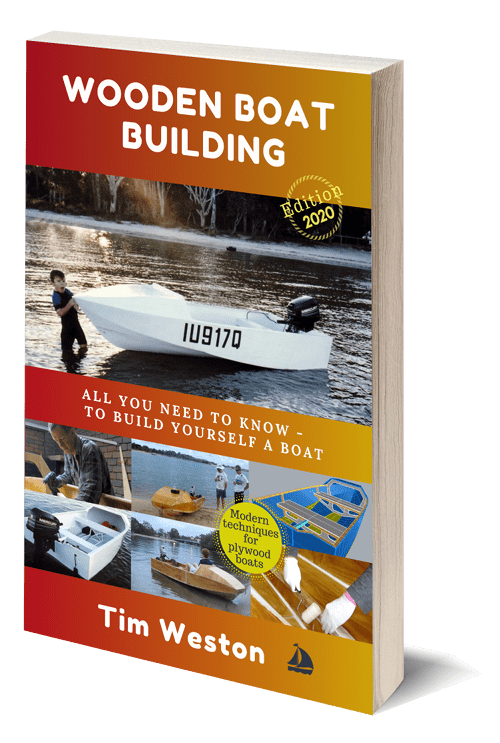

The Kit Process

Building your own boat can be a daunting prospect, however to demonstrate each step in the kit assembly process, we've created this guide for you to study. as you can see our kits are the ultimate in building efficiency and have been streamlined over 30+ years to ensure that you're on the water faster and with less effort., how does it all go together.

The first step to building your dream catamaran begins with a strongback – this is a square frame used to position the temporary frames that will be used to form the hull shape. This frame will be set up and must be square and accurate, a string or laser level can be used to achieve this.

The forebeam is now installed along with the striker attachment fitting, as shown above. The bridgedeck is installed shortly after and taped onto the bulkheads with webs installed, this now completes what is a quite stiff and strong platform to work on.

Now that the bridgedeck is in place, the forward webs and dash will be fitted. At this stage, all furniture and internal work begins, with the main panels left off for ease of access when working.

- No products in the cart.

Catamarans and Trimarans

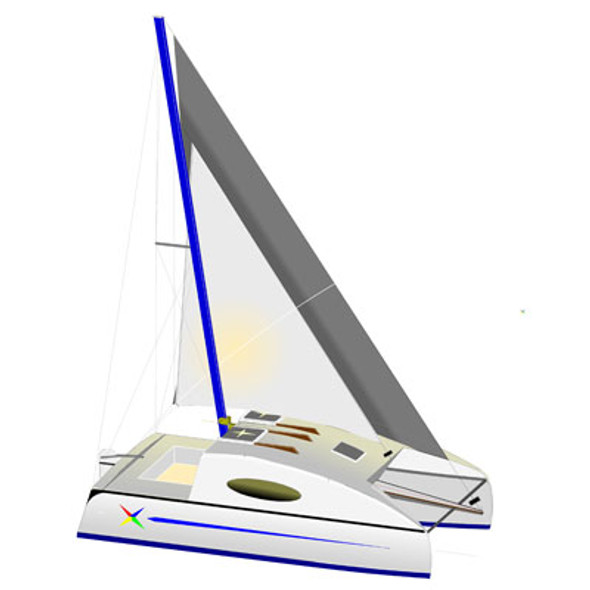

Catamaran and Trimaran Boat Plans make it a reality to build your own catamaran or trimaran. Multi-hulled sailing vessels are a special class of boat. A very different mind set is required when thinking about sailing a multi hull, let alone getting your head around building one.

There are some unique challenges building a multi-hull sail boat, the extra beam added by each hull for instance can create storage issues while under construction. Hartley boat plans make the build process straight forward for even amateur builders. However with all things considered, building a multi can be an amazing journey.

Fast Twin Catermaran

Lively 28 Cruising Trimaran

Lively 35 Cruising Trimaran

- Where do I start?

- Catamaran Designers

- Bridgedecks & Turret

- Cockpit & Steering

- Hulls, Frames, Plinths & Anchor

- Top Coat

- Winches and Mast

- Our Books

- Our Videos

- Terms of Use

- Contact Us

building a catamaran

A collection of sailing catamaran building logs, from sailboat plans to yacht launch. This 11.6m 'EASY Series' catamaran, joining other catamarans to lat and longs unknown...join us on our journey

Scroll down this page to read more...

Plywood and Epoxy Catamaran

This 'glass-over-ply' sailboat is proof that a DIY'er can successfully build an ocean-going multihull. Plywood construction is the cheapest building method available and very forgiving while one hones their skills. Finishing with a solid fiberglass outer is also a task made easier, given the amount of glassing and gluing needed during such a project.

It will soon become evident that parting with a few dollars provides a strong foundation for your catamaran building decisions. Having reliable Boatbuilding Resource Books , WILL HELP fast track your decisions prior to, during and post building.

We also wanted a light sailing catamaran that we could beach with ease. This now allows us to save money on one of the biggest maintenance DIY chores, sailboat antifouling without having the costly expense of slipway fees.

Keep scrolling...

how to build a boat.

"it takes a strong desire and a will to achieve. building a large catamaran is achievable".

Our build in 3-minutes

Many sailboat plans to choose from.

Is it cheaper to build or buy.

There are many yacht plans to choose from, but dont kid yourself. Many have tried to do it on the cheap and their result shows.

If there was a cheaper way, the sailboat designers would tell you. Afterall, they would use that reason to sell there plans!

If you want a yacht with all 'bells and whistles', keep working because it does cost money.

Enough waffle, jump into the website and have fun

Catamaran Sailing

DIY boat projects on Pure Majek from new navigation equipment, anchoring systems, rewiring yacht electronics diagrams, AIS and much more. We carry updates and rate products such as antifoul, solar fans and even galley items.

Its been ten great years since launch and we look at things that have worked and those we would change.

Join us and be inspired.

Welcome to sailboat planning and building.

Setting achievable goals and how to stick to them. From the planning process, what and why we did many things, importantly, things we would do differently. The following pages draw on these experiences described in far more detail in our book 'A Sailing Catamaran Building Adventure'

Important Information Terms of Use located in 'ABOUT US'

© 2024 www.diycatamaran.com All Rights Reserved

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

DIY Simple Catamaran Sailboat Design

Discussion in ' Boat Design ' started by WilliamPrince , Oct 10, 2013 .

WilliamPrince Junior Member

Hey folks, I am planning on building a small catamaran sailboat, in order to sail around the coast of Baja California. There is only light winds, and no strong currents, but of course I want to make the strongest boat possible. I am also on a pretty low budget, so I'm thinking that I will mostly be building out of 2x4s and plywood (laminated plywood for the hull, and treated with some extra waterproofing.) The basic design for this boat I have drawn and attached to this post, but I have some further questions. Firstly concerning my pontoons. My pontoons will be the decidig factor in the success of my boat. They must be bouyant enough to hold me and maybe one other person, as well as the rest of the craft, and sturdy enough to withstand some reasonably stormy seas. Of course I won't be taking them out in a massive storm, but they still need to be seaworthy. Originally I was going to build them with 2x4s and plywood, similarly to this instructable , slightly thinner and much deeper, but the same idea of building. The problem is, I don't have a whole lot of woodworking experience, and making 2 seaworthy pontoons would be a stretch even if I did. So I have a few questions concerning these pontoons: How large will they have to be to support myself, some gear, and the boat? What is the best design for this particular pair of pontoons? Is that duckboat adequate? Would I be able to build a good pair? Given the right tools and the right lumber? If I don't build them, what is a good thing I can look for to use as a substitute? A pair of canoes seems kinda silly... The pontoons are my main problem, and most important. But I do have one more thing that concerns me and that is the mast. The mast will be either wood or aluminum or steel, and will also support the boom of course. There will be a LOT of pressure on these parts during full sail, so I need to make sure they will not fail me at a critical moment. What is the best material for the mast? How can I attach it to the deck in a firm and sturdy way? Will the frame of my weak little thing be enough to provide the support from the guylines and shrouds? I know this is a lot of questions, but really any critiques of my design, or any help is GREATLY appreciated. Thank you very much!

Attached Files:

eyschulman Senior Member

large used aluminum canoes not silly.

Skyak Senior Member

Here is a good free catamaran design for two. It uses a similar technique to the duck boat you referenced. http://svensons.com/boat/?p=SailBoats/Hobby_Kat Aluminum tube would be best for the mast, as long as there is no lightning.

gordanm Junior Member

Perhaps this would fill the bill ?: Slidercat

Manfred.pech Senior Member

Here you will find more Catamaran designs: http://www.duckworksbbs.com/plans.htm . May be this one is interesting for you: http://www.duckworksbbs.com/plans/sf/dayboats/cats/hawk/index.htm

Thank you for all the designs, they are all interesting and I will definitely take them all into account... I have a few further questions. As for construction, would the stitch and glue method be strong enough to build a pair of seaworthy 17 foot catamaran hulls? Obviously I will put some ribs in, but the method itself just seems iffy to me... Also, about cold molding. Somebody today told me that I was crazy to even try to cold mold my own boat, especially a 20 footer. Is this possible? I'm on a budget as well... What sealant would be best to use? Polyester resin is ******* expensive, about 50$ a gallon, and I don't really have access to tree sap resin which I would rather use. Regardless, am I an idiot to even attempt to cold mold this thing as an untrained amateur? He talked about it as a mastercraft trade, and highly warned me against it... What are your thoughts?

El_Guero Previous Member

Quit listening to bathroom lawyers, even real lawyers can get you in trouble. First, you need a real design. Second, you need to up your budget - cut back on beer for a month or two. Third, poly resin is ok, but you would be better off spending the money on epoxy. Get ready for sticker shock. Use MARINE GRADE PLYWOOD. Any other ply disintegrates quickly when wet. $500 might be possible, but it would be a very tight budget and would need some 'used' material.

WilliamPrince said: ↑ Thank you for all the designs, they are all interesting and I will definitely take them all into account... I have a few further questions. As for construction, would the stitch and glue method be strong enough to build a pair of seaworthy 17 foot catamaran hulls? Obviously I will put some ribs in, but the method itself just seems iffy to me... Also, about cold molding. Somebody today told me that I was crazy to even try to cold mold my own boat, especially a 20 footer. Is this possible? I'm on a budget as well... What sealant would be best to use? Polyester resin is ******* expensive, about 50$ a gallon, and I don't really have access to tree sap resin which I would rather use. Regardless, am I an idiot to even attempt to cold mold this thing as an untrained amateur? He talked about it as a mastercraft trade, and highly warned me against it... What are your thoughts? Click to expand...

Okay, talking to a bunch of people, and the drive to build a successful seafaring craft had prompted me to raise my budget somewhat. I am still looking to spend as little as possible, but I am willing to spend money on something that will hold my vessel together. I have heard a lot from different people, and opinions differ; here are the main conflicts I am still unsure about. Mode of Construction I could build it as shown in my original "duckboat" instructional, not sure what to call that method of construction. Starting from the frame, and attaching the plywood to the chines and clamps around the frame. Or I could try the stitch and glue method with epoxy. I'm not sure exactly how to do the stitch and glue method, nothing a few hours on the internet couldn't fix I'm sure. Also I do have doubts as to the strength of this method, but I guess it has been tried and tested. I would put at least 3 ribs in each hull anyways, even if I was using stitch and glue. What Wood to Use I had not even heard of marine plywood until a few days ago, and my original plan was going to be to use regular plywood (maybe some type of laminated plywood), and treat it with some lacquer or varnish to waterproof it. Would this work? What would I treat it with? My other option is to use marine plywood, which I still don't entirely understand the benefits of. I will still need to treat the outside with some finish to waterproof it, so why is it worth the extra money? Epoxy, Tree Sap, 5200, Oh My! The way I see it, I need some type of goop for 3 main uses. The first use of goop (I use goop here to refer to all these different products) will be to adhere 2 pieces of wood together. I will need to glue frame pieces to other frame pieces, and plywood to the frame. Which goop is the best for this? Secondly, I need to fill any gaps or stress zones in the construction with some sort of filler, like caulk, or synthetic rubber or something. What is the best material to do this? Lastly I want to lay down some protective layer over the outside of my boat. This can be whatever, I am very open to suggestions and exploring new alternatives. I have heard about tree sap resin, epoxy resin, synthetic resin, fiberglass + epoxy... How can I decipher all this and choose the best and cheapest one for my boat? Thanks again everybody you have been very helpful!

Marine grade plywood is a world better than non marine grade. BS1088 and above plywoods use water proof glues and the wood they are using is amongst the best for water resistance if the surface gets pierced. They have solid surfaces, in B grade or A grade. They have no voids in the cores - a huge difference. The best plywood you can find underneath the quality of marine grades are exterior grade construction plywoods, these do not have solid (veneer) surfaces. The glues are not necessarily WBG glue - water proof. The woods used quickly degrade if exposed to water for periods of time. And they have internal voids. You can over come some of the deficiencies, but you increase your maintenance costs and lower your resale value greatly. And I almost forgot, marine grade plywoods, okoume is about the top grade, have consistent weight control per sheet. And usually okoume is about the lightest weight for the strength plywood out there.

Slightly easier would be SOF framed hulls. You cold deck the hulls with okoume plywood, or even cherry and teak for beautiful looks. Using polyester skin would reduce the weight and the cost of the hulls.

philSweet Senior Member

Building a monohull would be easier and quite a bit cheaper for a given level of performance. That's for the performance you'll get for 500 - 1000 bucks. If you check a few boatyards, you can probably find a 25' sailboat that you can sail away in for $500. Bring a bucket, some rags, and a gallon of bleach. Are you planning to sail the Pacific coast of Baja, or the coast of the Gulf of California?

SamSam Senior Member

I want to hear more about tree sap resin.

WilliamPrince said: ↑ Okay, talking to a bunch of people, and the drive to build a successful seafaring craft had prompted me to raise my budget somewhat. I am still looking to spend as little as possible, but I am willing to spend money on something that will hold my vessel together. I have heard a lot from different people, and opinions differ; here are the main conflicts I am still unsure about. Mode of Construction I could build it as shown in my original "duckboat" instructional, not sure what to call that method of construction. Starting from the frame, and attaching the plywood to the chines and clamps around the frame. Or I could try the stitch and glue method with epoxy. I'm not sure exactly how to do the stitch and glue method, nothing a few hours on the internet couldn't fix I'm sure. Also I do have doubts as to the strength of this method, but I guess it has been tried and tested. I would put at least 3 ribs in each hull anyways, even if I was using stitch and glue. What Wood to Use I had not even heard of marine plywood until a few days ago, and my original plan was going to be to use regular plywood (maybe some type of laminated plywood), and treat it with some lacquer or varnish to waterproof it. Would this work? What would I treat it with? My other option is to use marine plywood, which I still don't entirely understand the benefits of. I will still need to treat the outside with some finish to waterproof it, so why is it worth the extra money? Epoxy, Tree Sap, 5200, Oh My! The way I see it, I need some type of goop for 3 main uses. The first use of goop (I use goop here to refer to all these different products) will be to adhere 2 pieces of wood together. I will need to glue frame pieces to other frame pieces, and plywood to the frame. Which goop is the best for this? Secondly, I need to fill any gaps or stress zones in the construction with some sort of filler, like caulk, or synthetic rubber or something. What is the best material to do this? Lastly I want to lay down some protective layer over the outside of my boat. This can be whatever, I am very open to suggestions and exploring new alternatives. I have heard about tree sap resin, epoxy resin, synthetic resin, fiberglass + epoxy... How can I decipher all this and choose the best and cheapest one for my boat? Thanks again everybody you have been very helpful! Click to expand...

- Advertisement:

Okay thank you VERY much for pointing me to the West Systems Build/Repair manual... I finally think I understand epoxy, as much as I ever will at least. The only thing slightly off-putting is that all these additives are pricy... How much of this stuff am I gunna use? Let's say I use it to glue joints with the stitch and glue method, and epoxy fiberglass over the entire thing. Is that one gallon of epoxy resin? 20? That price tag could go way up real quick. What about polyester resin? That stuff is like 10x cheaper here, could I substitute that for any part without seriously endangering the integrity of the ship? Regardless, you just answered a LOT of my questions, thank you kindly. I am diving into the dimension-specific design of my hull, and the more I learn, the more I realize that I am in over my head. The more I hear about the importance of a point of balance in the hulls, and planing vs. displacement hulls, and every little nuance that I never imagined existed, the more discouraged I become. But I am determined to build this thing and I want to do it right. Of course, designs for a 20 foot cat are something that people shell out money for, so I wont ask for you guys to point me to the free ones (although if there are ones, I also won't say no...) I would however like to learn whatever information you have to offer me on the matter - what are the main concerns I should be aware of, is a 2.5 foot beam good for a 20 foot hull? How deep should they be? I'm thinking of tapering to a point in the front, and slowly becoming a flat bottom in the back (similar to the slider design mentioned earlier in the thread). I mean, maybe I am overthinking it, but I feel certain that assuming that any ol' shape will be successful is underthinking it. Answers or insights to any of these questions, is, as always, greatly appreciated. Thank you Skyak and El_Guero for your helpful insights, very much appreciated.

Simplest Pocket-size DIY Boat Ever

24' Cuddy + (Re)Design = A DIY Sports Coupe?!

Cheapest DIY Bugout Sailboat

DIY sails, rigging, daggerboards for kayak - reasonable expectation for sailing to weather?

14' Aluminum boat 1953 Commander we think. DIY Strip down & repair

DIY Dinghy with Laser 4.7 sails

"Current Situation" DIY Efficient Solar/Electric Powered Newport 17 Project

DIY power barge

Inexpensive, DIY auto-bailer solutions for small sailing dinghies

Hull shape/DIY plans recomendations for planning 16' 40Hp boat?

- No, create an account now.

- Yes, my password is:

- Forgot your password?

MIKE WALLER

Yacht design.

WE SPECIALIZE IN BOAT PLANS FOR AMATEUR BUILDERS

We provide stock boat plans for both monohull and multihull sailing vessels, including sailing skiffs and sharpies. Our designs mainly feature timber construction, in plywood or cedar strip plank composite construction, using the W.E.S.T. system (wood epoxy saturation technique). Our designs are intended mainly as cruising boats, although several have done well in racing. All designs are suitable for amateur boat builders.

MONOHULLS

multihulls , photos from our builders.

Photo galleries are provided on each design page where available

24 Foot Sailing Trimaran

Introduction: 24 Foot Sailing Trimaran

Indonesian style, built out of recycled stuff. Here we are busting out through the surf in 30mph winds at Stinson Beach California on the maiden voyage. The boat works great! There are no swimmers or surfers out because of the rough conditions. The kids are on the beach making forts out of their boogieboards instead of surfing. Specifications: Hull Length 24 ft at deck Hull 22" wide amidships at deck, 18" wide inside hull (there's a wide lip at deck) Hull 24" deep amidsnips. The hull round bottom is a semicircular arc of 8.25" radius. Hull rocker is about 4" measured from points 16' apart. Outrigger crossbeams are 14' 7" long 3.5"x2.5" fir beams tapering to 3x2.25" at ends The outrigger floats are 4.5" diameter, 19 feet long with foam plugs in ends. ~134lbs buoyant. The plugs in the front of the floats are shaped into a nose that protrudes 6.5" more. 1.5" diameter stainless steel tubing connects the crossbeams and floats. The Sail is an 8 sq. meter crabclaw / leg-o-mutton sail on 14ft. windsurfer masts. The mast is supported by three stainless steel cable stays. Total cost of materials was $200 or less. The outrigger floats are fiberglass chemical pipes full of empty plastic soda bottles. The main hull is made from a pair of old 16' catamaran hulls cutoff and glassed end-to-end. Junked catamaran hulls are easy to get. If you can't find a free hull, build a hull like the Kenya Canoe but bigger. Use scavenged plywood from crates if you want it free. The wood for the crossbeams came from a big pallet, with the nails and crossboards pulled off. Then I scarfed them together for extra length. The sail is blue tarp on windsurfer mast spars. Great action photos by kenny

Step 1: Beaching After the Maiden Voyage

Star , Damon and myself rode the boat in on the back of a big wave, just like the Malibu Outrigger manual recommends. Then we carry the boat up the beach. The sail helps us and we scamper up the beach and get clear of the break zone before the next wave hits. What a great boat. Unlike trials of previous boats in Mexico and Kenya which got badly damaged by surf landings, this boat is fine. It helps that there's a lot of wind and the boat is faster than the waves.

Step 2: Cartopping

Here it is on top of the ugly truckling. It assembles quickly without tools. The main hull is the heaviest part, about 90 lbs. It takes two people to lift it onto the roof rack because it's so big. The other parts are a lot lighter and one person can handle them. 4 or 5 people can ride in the cab of my truck. The boat could carry that many also, so it's a good match. We could only get three people to volunteer for the maiden voyage because the conditions were so rough, but there was room for more.

Step 3: Or on a Trailer

To launch it from a trailer, you drive to the boat ramp, assemble the boat while still on the trailer, then launch and land it in the usual way.

Step 4: Inspiration

I once tried to sail to Cuba in an outrigger canoe. There were some problems. When I was almost to Havana my rudder broke so I couldn't sail, the current carried me away, I was caught in a storm, etc. etc. I spent a lot of time trying to not to die and hallucinating from exhaustion. I also spent a lot of time thinking about the perfect hull shape for a sailing canoe. In the following year I traveled to Indonesia and Papua. I learned a lot by gaping at and measuring sailing canoes there. Here are some Makassarese (Sulawesi) canoes I saw in Jayapura Harbor, Papua. In severely technical terms, here's what I was looking for in a hull: 1) High prismatic coefficient (fat ends) 2) Round bottom 3) Straight sides in the middle 4) Just the right amount of rocker. Curved like a banana. 5) A beam to length ratio of around 12:1

Step 5: Cut and Paste Catamaran Hulls Together End-to-end

I found a pair of 16' catamaran hulls for sale on craigslist that were exactly what I was looking for. By no coincidence, they were designed and built by Karl Westbroek, an engineer from Malang, Java, Indonesia. They were a nice bright yellow that emphasized their banana-like shape. Hence Karl's original name for his catamaran, "Bananas". I wanted my hull to be pointy at both ends. These hulls had square transoms at the stern. So I had to cut off the sterns and butt up the pointy ends to make my hull. To figure out the right place to cut them I slid a piece of paper over the hulls to find a special transverse curve called the "Geodesic". That's the shortest path between two points on opposite sides of the hull. I cut the hulls, butted them up, and checked to make sure the keel and sides met at a reasonably fair curve.

Step 6: Thinning the Edge

Before we can start glassing, we need to grind down the existing fiberglass so it's a smooth transition. Michael Kearney helps me out by grinding the edge thin on the inside of the joint.

Step 7: Jigging It Up

Next we clamped and screwed a bunch of sticks to the outside of the hulls to hold them in alignment. Jrlee checks that the decks are parallel.

Step 8: Glassing

Jrlee mixes some epoxy. We cut and lay out strips of fiberglass cloth on a piece of plastic on the deck. We soak the cloth with epoxy. We layup the glass into the hull, squeegeeing and painting the epoxy so the cloth is fully saturated. The wider strips of cloth go over the narrow strips, so the rough edges of the cloth aren't exposed.

Step 9: Rough Fairing

I mix some glass microballoons with epoxy and slather that all over the outside of the hull. When it sets up I grind it flat with a sanding disk. While I'm doing that Danny comes and suggests a better way.

Step 10: Rapid Fairing

He's glued a board to a sanding pad and glued a full sheet of 80 grit sandpaper to that. He creates an artificial snowstorm while sanding the hull, and in a few seconds it's smooth and faired. Wow.

Step 11: Glazing and Finish Sanding

Next I squeegee some body putty over the nicks and imperfections. When that's dry I wet-sand it with a sanding block.

Step 12: High Build Sanding Primer

Next come a couple of coats of fast-dry high build sanding primer, then some wet-sanding with a sanding block, and finally a coat of yellow paint. The hull is all one hull now.

Step 13: Outrigger Floats

A friend gave me some fiberglass chemical pipes. They are 19 feet long and 4.5" in diameter. I would have been worried about the chemicals but the pipes were brand new. Actually they might be intended as covers for glass pipes. I tied strings to the necks of some 2 liter soda bottles and shoved them into the pipes. The string is to keep the bottles from floating away in case of a disaster. I carved some minicel closed cell foam to make plugs for the pipes. I shaped the front plugs into the noses seen here. The flat front feature is like the "manu" on the front of a Hawaiian canoe. As it plows into a wave, it sprays the water away forming a giant air bubble around the float. The bubble rises through the wave, pulling the float up with it. It works really well.

Step 14: Float Blocks

The outrigger floats are 4.5" diameter fiberglass chemical pipes. I made some wooden blocks to rest on them. They will be the "feet" of some short legs made of stainless steel tubing. Those in turn get connected to the crossbeams. Just like Ezekiel, the foot bone's connected to the leg bone, the leg bone's connected to the thigh bone. Here I am testing the first block I made to see if it fits the pipe right.

Step 15: Cutting Curved Grooves With a Tablesaw

I setup my ghetto tablesaw, which is a circlesaw screwed to a board. Yes, it's very dangerous. Don't do it. I set up the fence at an angle to the blade. I made a lot of cuts of increasing depth in a block of wood until I had a nice round trough cut in the bottom of the block.

Step 16: Wooden Shoes

Then I repeated the process on some narrower blocks, cut holes the right size all the way through with a hole saw.

Step 17: More Wooden Shoe Cobbling

I glued a wooden disk in the bottom of the hole so the tubing leg wouldn't touch the float directly. I heated up the block to cure the epoxy quicker. Don't breathe those buttery fumes! When the epoxy was set up I shaved the protruding plugs off with the tablesaw. I drilled some lashing holes in the sides of the blocks and cut the corners off the ends so they would enter the water better. Jumping ahead, let's go sailing and I'll show you how this stuff turned out.

Step 18: Hot Spring Break

Star organized a trip to a hotspring on the coast that's only exposed at the lowest tide of the month. We camped nearby on friday night, woke up at 5 am to hike down. It's pretty amazing. There's a main pool and also a cave full of hot water that goes back into the cliff face. We relaxed in the hot spring until the tide rose and waves of cold water started washing into the spring. Then we hiked back up to the truck and it was time to put the yellow canoe in the water. So we drove to Stinson Beach and parked as close to the beach as we could. We unloaded the canoe parts onto the grass in the park there.

Step 19: Lashing It All Together

We swarmed over the canoe, lashing all the arms and legs to it with bicycle innertubes. The front beam takes most of the load, so it has a double tube 'H' shaped stainless tubing leg that connects the beam to the float. The foot of the 'H' rests in sockets in a wooden block. The bottom of the wooden block is carved to fit the top of the float tube. The float is lashed to the block with spectra string and innertube. That part stays lashed permanently.

Step 20: Carry It to the Beach

We had plenty of help from relaxed sleep-deprived pals from the hotspring trip. When it was all tied together we picked it up and carried it to the water.

Step 21: Please Return!

In case something went wrong and we lost the paddles we wrote plaintive messages on them in hopes that someone would return them. These are instant paddles made in a few minutes from a hockeystick, a board and some string, but they're so nice it would be a shame to lose them.

Step 22: Farewell Hugs

The wind had increased to a gale. The sea was rough. Time for farewell hugs!

Step 23: Raising the Sail

We hoisted the sail and watched the waves. The surfers were all on shore so we couldn't use them to judge the size of the waves. But at least we didn't have to worry about hitting them.

Step 24: Launching!

Star , Damon, and I carried the boat to the water just as a big wave washed ashore. We jumped on, sheeted in the sail, and started paddling at the breakers.

Step 25: So Far So Good

The boat took off like a racehorse. It's easy to steer with a paddle. It goes to windward just fine. We sped toward the outer break. Wait a minute. That's a big wave coming!

Step 26: What's Going to Happen?

We hit the wave and there was whitewater everywhere. We kept going through it, and when we could see again we were still moving fast and there was hardly any water in the hull. The boat works in surf!

Step 27: Sailing and Landing

We sailed around until one of the lashing buttons broke, then decided to head back in. We surfed in on a wave, outran it, and executed a perfect landing on the back of a wave. Jubilation! The boat could have handled more passengers and rougher conditions.

Participated in the Earthjustice United States of Efficiency Contest

Recommendations

Arcade Student Design Challenge

Stay Warm Contest

All Things Pi Contest

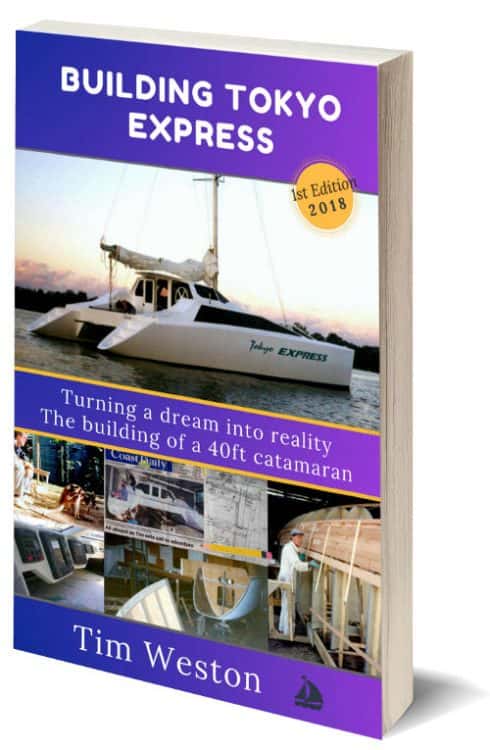

Tokyo Express

- Small Boats

- Geelong Model 850

- Plans (all)

- Noosa Plans

- Tewantin Plans

- Geelong Plans

- Daggerboard Plans

- Daggerboards

- Consulting / Drafting

- Terms & Conditions

- Privacy Policy

Select Page

Catamaran & Small Boat Building

to my website. Here you’ll find photos, stories and information on building boats large and small, with tips and tricks I’ve picked up along the way. I built this website originally to accompany my YouTube channel . The blog section has information on various topics.

A 12m cruiser/racer catamaran – 2 yrs & 9 mths to build – launched 15th August 1997. Details of the build.

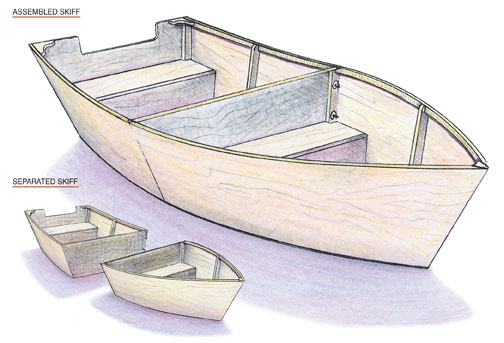

Small boats

Small boats you can build in your garage. A good family project and a way to get a taste of boat building. See how they were built.

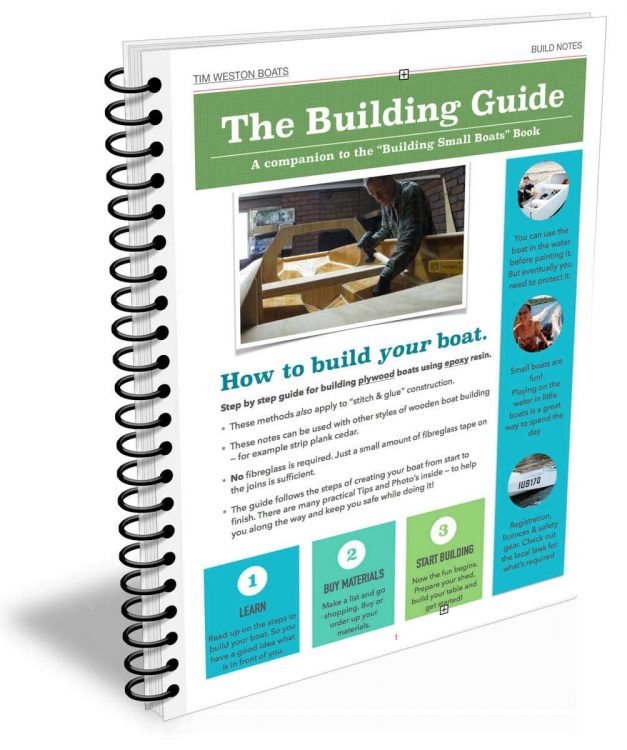

Plans to build your own boat. Packed with information for the first time builder. Start building your boat now.

Where to start

Building your own boat and sailing off over the horizon, is a dream that lives inside many. Well at least that’s the impression I get from the many people I met while building Tokyo Express (TE) and the feedback now f rom the videos on YouTube. After years of dreaming, at 39 years of age I finally turned that dream into reality with the launching of Tokyo Express. This website is about my journey.

You don’t need expensive kits

or exotic materials to build a boat. You don’t need expensive tools or a degree in engineering either. I fabricated most of the parts and systems on Tokyo Express (TE) from scratch. Steering system, steering wheel, doors, hatches, fore beam, catwalk, daggerboard, rudders, engine mounting, generator, electrical system and plumbing.

Even the mast I bought as a kit. I had more time than money so I built everything I could. There were no exotic materials used and yet I ended up with a robust, lightweight and extremely competitive boat that was lighter than a typical production boat.

If I hadn’t been designing and redesigning many parts of the boat, learning for the first time how to do things and building a shed, the boat would have been finished a lot quicker.

On the Tokyo Express page

page you will find an overview of the steps I took building TE. If you are thinking of starting a similar project, this is a good place to start. It was a lot of work, but it was also the most rewarding project I have undertaken. It was well worth the sweat and tears. Please look around. Email me if you have questions…

Recent Posts

- Catamaran vs Monohull

by Tim Weston | Mar 11, 2019 | Building , Cruising

Catamaran vs Monohull If you are thinking of building or buying a yacht, you have a significant choice to make, before you even start looking at individual boats. Do you want one hull or two? Deciding between a catamaran and a monohull is a big decision and one worth...

- Going fast – in small boats – hull speed.

by Tim Weston | Sep 30, 2018 | Building , Plans

Going fast - in small boats (with a small motor) This article looks at how to go fast, in a boat with a small motor. Plodding along at snail’s pace can get a little boring. No matter how relaxed I am and how much time I have nothing puts a smile on my face quicker...

Search Site

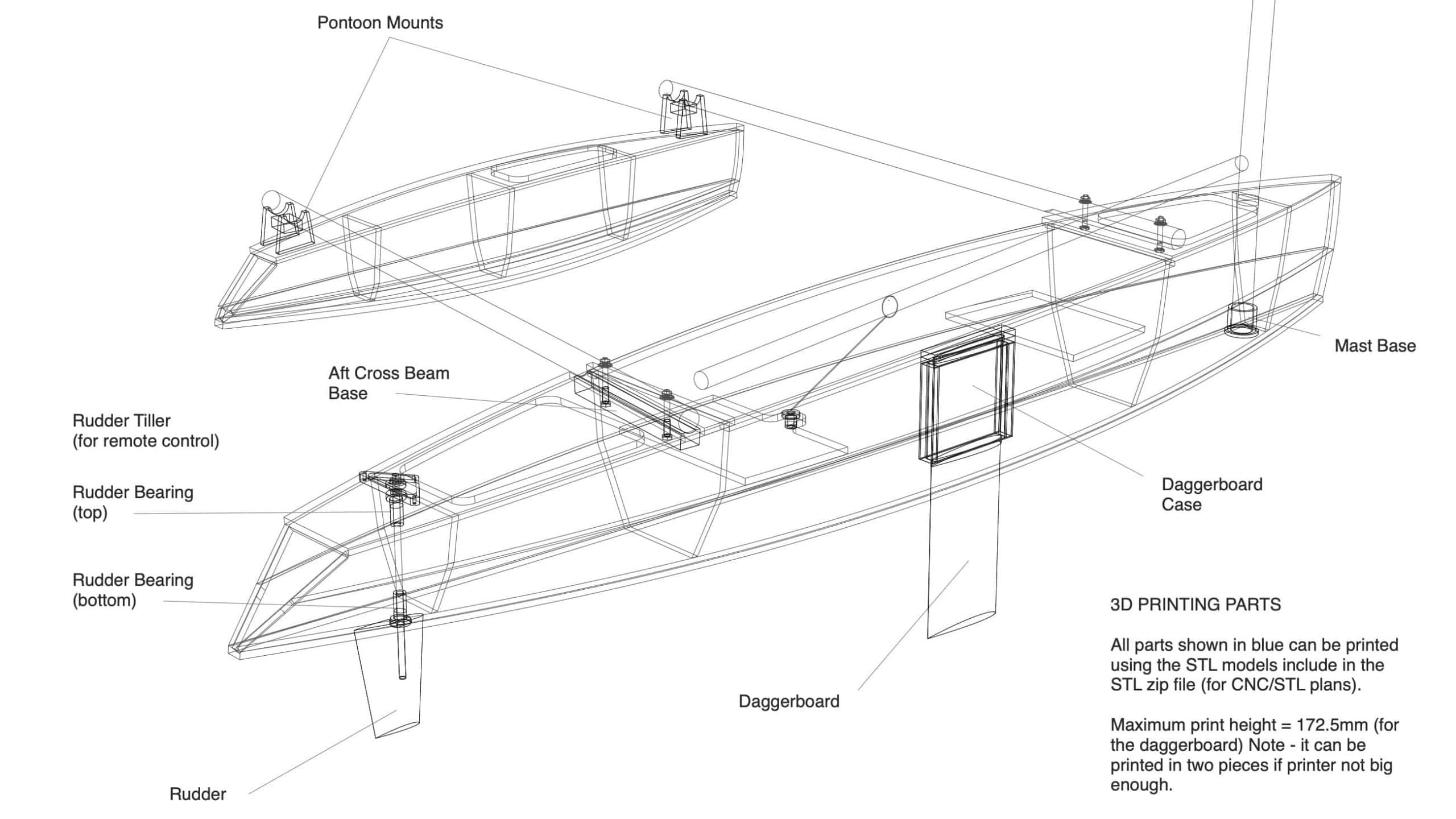

New book – just released.

Watch the Video Series – (1 hour & 45 mins)

- Keeping safe – while building your boat

- Catamaran size – how big a boat do you need – ocean sailing

- How much does it cost to build a boat – a 40ft Catamaran?

Get the Guide – Free

Tim Weston Boats

2022©timwestonboats.com

[email protected]

Privacy Overview

27 Homemade Boat Plans You Can DIY Easily

Building a boat might sound like a big project – and depending on the kind of boat you want, it can be. However, with the right plan, it’s far from impossible, offering you the prospect of owning a boat without spending huge amounts of money on it.

For anyone who thinks that sounds like a fun challenge, we’ve had a look online to see what other people have been trying – and as a result, here are our favorite 27 DIY boat plans you might like to have a go at copying at home.

Table of Contents

1. How to Build a Boat – Popularmechanics.com

2. how to build a sneak boat – kara hummer plans, 3. know how: build your own boat – sail magazine, 4. build a 7.5ft boat with 2 sheets of plywood, 5. build your own 12′ x 4′ simple aluminum boat – boat design net, 6. diy foldable boat for only 30$ fits in car backseat, 7. build a wooden boat – mother earth news, 8. portable boat plans, 9. weekender sailboat build, 10. swamp boats, 11. welcome to my dreamboat project, 12. homemade pontoon boat: 8 steps (with pictures) – instructables, 13. $100 homemade kayak, 14. how to build a recumbent pontoon pedal boat – mother earth news, 15. how to make boat using pvc pipe and 42cc 2-stroke engine, 16. pontoon boat picnic table: 8 steps (with pictures) – instructables, 17. wooden boat building step 1: lofting boat plans, 18. homebuilt pontoon boat/double-hull kayak, 19. homemade cooler fishing boat with foldable pontoons, 21. diy boat plan: a rowboat can support a trolling motor, 22. building a wooden boat: 12 steps (with pictures) – instructables, 23. one sheet sampan, 24. building a cheap sail catamaran, 25. couple builds wooden yacht in backyard – 5-year amazing time lapse, 26. plywood lath coracle, 27. diy simple wooden toy boat: woodworking for kids, lots of great plans for all kinds of boats.

If you’re toying with the idea of building your own boat, this post will be a fascinating read. In it, this DIYer explains how he dusted off some decades-old plans for building a boat to try his hand at his ancestral trade. It takes you through the process in great detail, giving you plenty of info about each step, so once you’ve finished reading, you’ll have a much better idea about whether this is a project you want to tackle.

Check More Details

For anyone who enjoys duck hunting and who wants to try building their own sneak boat, this is a video for you. In it, this YouTuber explains how he tackled a similar project, giving you all the tips and advice you’ll need to make a success of your project when it’s your turn to try.

This post is not exactly a plan as such, but it’s full of the kind of useful information that any first-time boatbuilder should know. The writer starts off by listing all the reasons why you really shouldn’t build your own boat – and if after reading that, you’re still determined to go ahead with it, his experience and advice will help make sure you make the best job of it.

Depending on what you hope to achieve – as well as your previous DIY and boat-building experience – your chances of success when trying to build your own boat can vary enormously. However, if what you hope to make is a modest boat of the kind you can take into a lake for a day of fishing, that’s the kind of thing most people can hope to achieve. And if that sounds like you, this video tutorial will show you how to make a serviceable 7.5ft craft from two sheets of plywood.

The aluminum boat this post teaches you to make is suitable for rowing or being propelled by a small motor . It’s ideal for sheltered inland waterways for activities like fishing, and if that sounds like the kind of thing you want to make, this post includes pdf plans that tell you exactly how to do it.

Making a DIY boat doesn’t need to cost a fortune, and if you’re on a limited budget, this is the plan for you. In it, you’ll learn how to make a small foldable boat that you’ll be able to fit in the back seat of your car – without spending more than about $30. Sound like something you’d like to try? Then give the video a watch!

In this post, you’ll find detailed instructions for making a simple yet elegant wooden boat that would be perfect for fishing trips out onto a lake or many other similar activities. We like the way this plan includes a simple step-by-step guide along with plenty of diagrams to show you exactly what you need to do, allowing you to make something just like it at home.

This is a great resource for anyone who is thinking of building themselves a simple pleasure craft since it contains not just one but several relatively easy boat-building plans. You can browse the plan and choose from a swan boat, a sheet ply skiff, a composite cruiser and several others. And then when you know which one you want to build, this site has all the details you’ll need to make a success of it.

For those looking for a more ambitious project, this video should be worth a look. In it, you get to see the development as this YouTuber’s sailboat took shape between September 2001 and summer 2002. It’s not exactly the kind of plan you’ll be able to follow exactly, but his impressive work should be a source of inspiration. Then it’s just down to you to find out how to build something similar yourself.

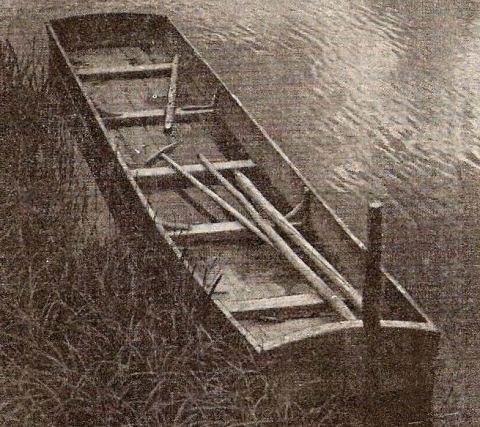

As you can see from the photos in this post, boats like this have been around for many years – and boats like this are found around the world anywhere that shallow waters or swamps exist. They’re simple to make too, and this plan gives you all the info you need to make one, including sourcing the wood from growing trees and putting the whole thing together. A fun project and one we’re sure plenty of people will enjoy attempting.

If you’re looking for a long watch – and a possible source of inspiration – this video is the first part of a multi-episode series about how this YouTuber went about building his dream boat. For those who are interested, it’s sure to give you some ideas about what’s possible – as well as plenty of ideas for how to tackle it.

We love the way the boat in this tutorial looks. It’s so basic and unpretentious, but it also looks like a whole lot of fun. Want to know how to make one yourself? Then check out this post for more details.

Buying a ready-made kayak can set you back a whole lot of money, but with a few basic DIY skills and a little bit of determination, you can build one yourself for much less. This video teaches you how to make one for only $100, offering a saving that sounds too good to refuse.

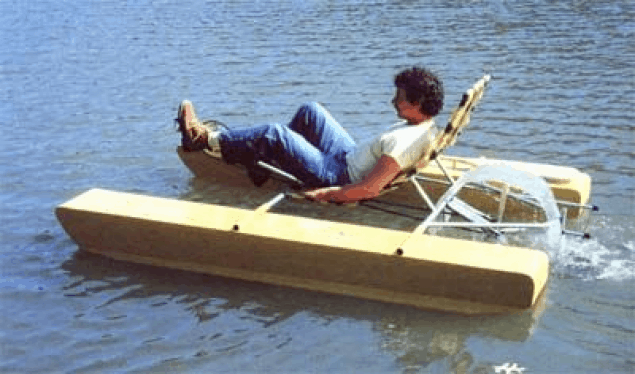

If you’ve ever wanted to own your own pedal boat , this is the plan for you because it teaches you how to build one yourself! It discusses important issues like flotation and gives you all the information you need to complete the project. And if you think you’d like to have a go, why not see if you can build something similar?

Here’s an original idea we loved! In this video, this YouTuber shows us how he built a functioning boat – out of PVC pipe! It’s certainly unconventional, but it looks like it works perfectly. So if anyone is looking for a fun and off-the-wall to try project, this could be just the thing!

The boat in this plan is one of our favorites because, while technically it’s a DIY pontoon boat , in practice, it’s more like a floating picnic table. With a boat like this, you can power out to the middle of the lake before cutting the engine and enjoying a nice lunch in perfect tranquility. This is something we’re thinking of trying ourselves!

This video is the first instalment in a series of tutorials detailing how this YouTuber built a boat from scratch. This part deals with the start of the project and lofting the boat plans, but if you like the way he works, you can also check out the other videos he’s uploaded and see how the final thing turns out.

For anyone who wants to make a functional boat without spending a fortune, this plan is perfect. The boat it teaches you to make is very “DIY” since it’s made of nothing more than PVC piping and some other similarly inexpensive materials. However, it looks like it floats, so if that’s all you need – and you aren’t too worried about looking flash – this is a plan that could be fun to copy.

If you like fishing and you’re looking for ideas for an individual fishing boat, you’re going to love this video. In it, we get to see this YouTuber’s eccentric creation that, to us, looks a bit like a floating armchair perched on top of three coolers. But that sounds like all you need for a great fishing trip, right? And we’re sure lots of people will enjoy trying to make something similar.

The sub-heading to this plan is “as simple as it can get”, and that’s a pretty accurate way of describing this boat, both in terms of design and construction. The details state it has a displacement of 230lbs, so it can comfortably accommodate one person, allowing you to get out on the water without spending much money at all.

This short tutorial gives you a simple suggestion for building a motorboat that is both easy and inexpensive to make. In the video, you can see that the boat struggles a little with two people in it, but it still works. This could be a great project to attempt for anyone who wants to have a go at building their first boat, and if that includes you, it’s recommended watching.

This is the third plan we’ve included from the Instructables website, but this is by far the most professional of the three. The boat this tutorial teaches you to build looks as though it could have been made by a professional. The plan is easy to follow though, so if this is the kind of boat you want, this is a post that should be well worth a look.

As this post explains, a sampan is a type of boat from Southeast Asia, and the word “sampan” comes from the Chinese meaning “three planks”. They are a popular boat in the region because they are easy to construct and extremely reliable, and if you’d like to try building one yourself, this plan will teach you how to do it.

This is a plan for anyone who’s up for a challenge because in it, you’ll learn how to make a DIY sail catamaran. The video is only about five minutes long, but as long you have some reasonable DIY skills and a bit of common sense, it shouldn’t be too hard to replicate, so why not see if you’re up to the task?

While not many people will have the time, skills or determination to finish a project like the one in this video, we still thought it merits a place on our list because of how impressive what they did is. Over five years, this couple built their own boat from scratch, and this video documents their progress. Check it out – it will blow your mind!

Among the very first boats ever invented, the coracle is a simple design that’s easy to make and fun to play about in. And if you think you might like to have a go, this is the plan that will teach you how to do it!

Perhaps building a real full-sized boat might be a bit much for you – but if you have kids, maybe making a miniature toy one with them could still be fun. It could also be a way to fire their creativity and imagination, and who knows? When they grow up, maybe they’ll build a real one for you in return!

As you can see, whatever kind of boat you hope to build, there are all kinds of plans that will show you how to do it.

We’ve enjoyed collecting these plans for you, so we hope you’ve enjoyed reading and watching them too. And above all, we hope we’ve helped you find the plan you were looking for to build a DIY boat of your own.

Related posts:

- 16 Homemade Plywood Boats Plans You Can DIY Easily

- 17 Homemade RC Boat Plans You Can DIY Easily

- 16 Homemade Boat Swim Platform You Can DIY Easily

- 15 Homemade Dog Dock & Boat Ramp Plans

3 thoughts on “27 Homemade Boat Plans You Can DIY Easily”

What makes a boat stable in the water is it the keel

i want to make a model for a school project out of tinfoil and hot glue it together and were going to put pennies in and see if it floats is there too much wait?

i meant to say weight not wait

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

- Plans & Kits

- Plans by type

- Qty in Cart

DUO 900 Study Plans

DUO 900 Plans

Wizard Study Plans Download

Wizard Plans Download

Strike 20 racing trimaran using a F18 beach cat for hulls and rig

Strike 16 Main Hull Only Plans Download

Wingmaran 15 Study Plans Download

Wingmaran 15 Plans and Templates Download

ECO 520 PDF

MaXi The Cat Plans PDF

Janus (full plans) Download

5m rodcat beach catamaran plans.

- Total: items /

- Add all to cart

Adding your products to cart

catamaran cruising

searching serenity, remote anchorages, crystal clear waters, & stunning coral.

mySerenity has been sold. We will be back in 2024 with more exciting news.

Cruising vanuatu, malokilikili island, vanuatu oct 2023.

One of our top 5 places ever visited… View More

Maewo Island, Vanuatu Sep 2023

An island shrouded in mystery and intrigue, where ages old culture still exists... View More

Pentecost Island, Vanuatu Sep 2023

While known for its 'land diving', other treats outside travel brochures await... View More

Christmas Tree Worms Sep 2023

Stunning colours of this amazing little creature that burrows into its host coral (or rock)... Watch More

Lamen Bay, Epi Island, Vanuatu Sep 2023

2 cyclones had 8 months previous, devastated these outer islands. We capture the new fragile regrowth, of colour and life... Video Here

Lifou Island, New Caledonia Sep 2023

The Loyalty Islands are governed by New Caledonia. The local chiefs oversee the local challenges of day-to-day life on these islands... Video Here

Dillans Bay, Vanuatu Sep 2023

An out-of-the-way island, where life is slow, the people are happy and subsistence living rules... Video Here

Tanna Island (Vanuatu) - surprise... Sep 2023

A special delivery to a Tanna school from a school in Australia. 300kg of books and stationary... View More

Malokilikili Island, Vanuatu.

Tanna Island greeting, Vanuatu.

cruising New Caledonia

New caledonia corals aug 2023.

The south pacific corals, just beautiful. Sea miles ticked by through New Caledonia and the Loyalty Islands... View More

Ouvea (Loyalty Islands) Aug 2023

Also in our top 5 locations. Just beautiful... View More

New Caledonia...wow Jul 2023

Stunning crystal clear waters, coral and cultures of the south east pacific. An incident requiring surgery on passage... View More

3rd Degree Burn - in the Pacific Jun 2023

There is always that one unexpected incident that will bring you unstuck. This is my story... View Story

Overwater resort, New Caledonia.

Lihou reef, CORAL SEA, Australia

cruising Australia

Yeppoon to brisbane oct 2022.