Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Best Day on the Water

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

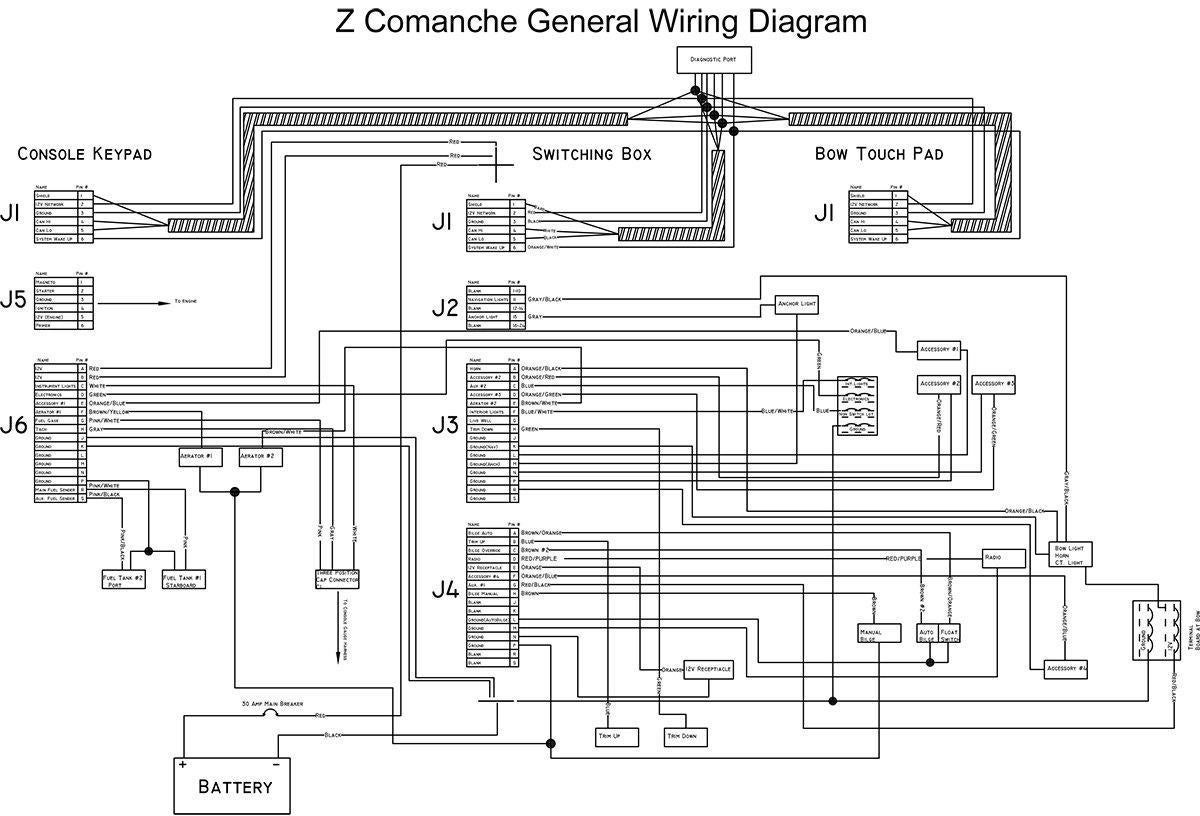

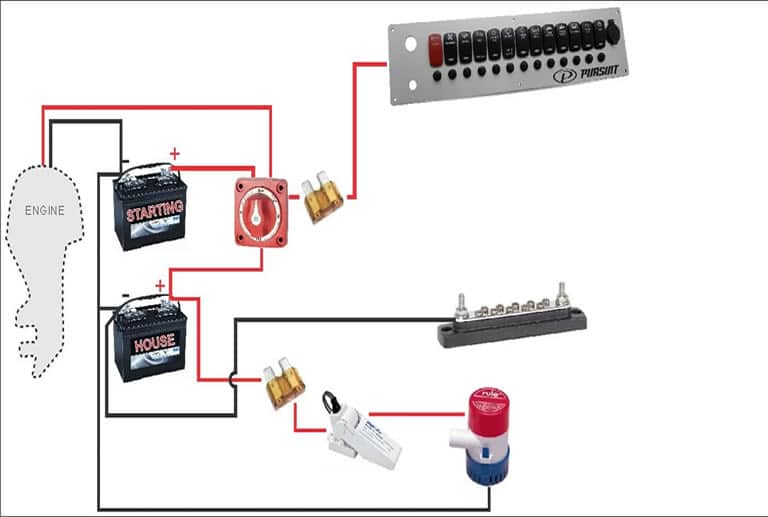

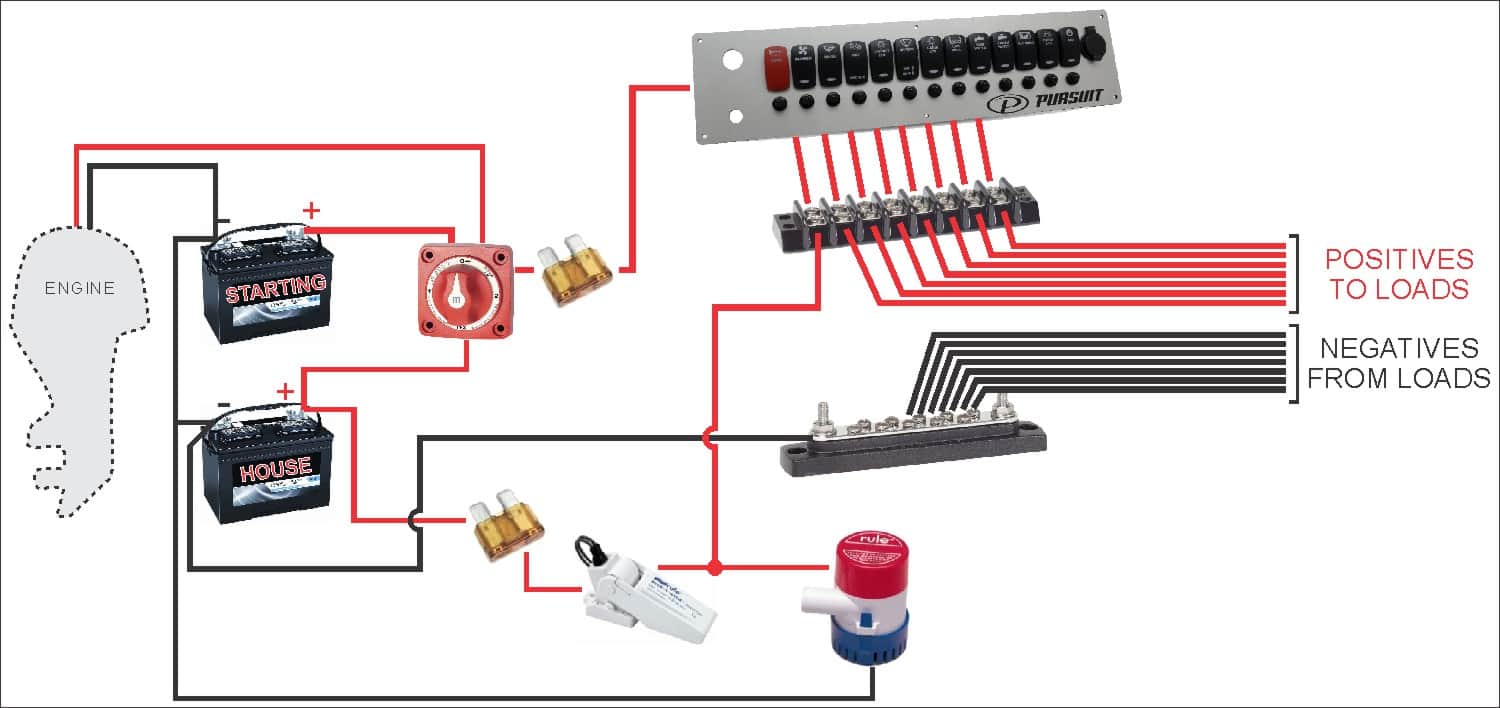

Create Your Own Wiring Diagram

Advertisement

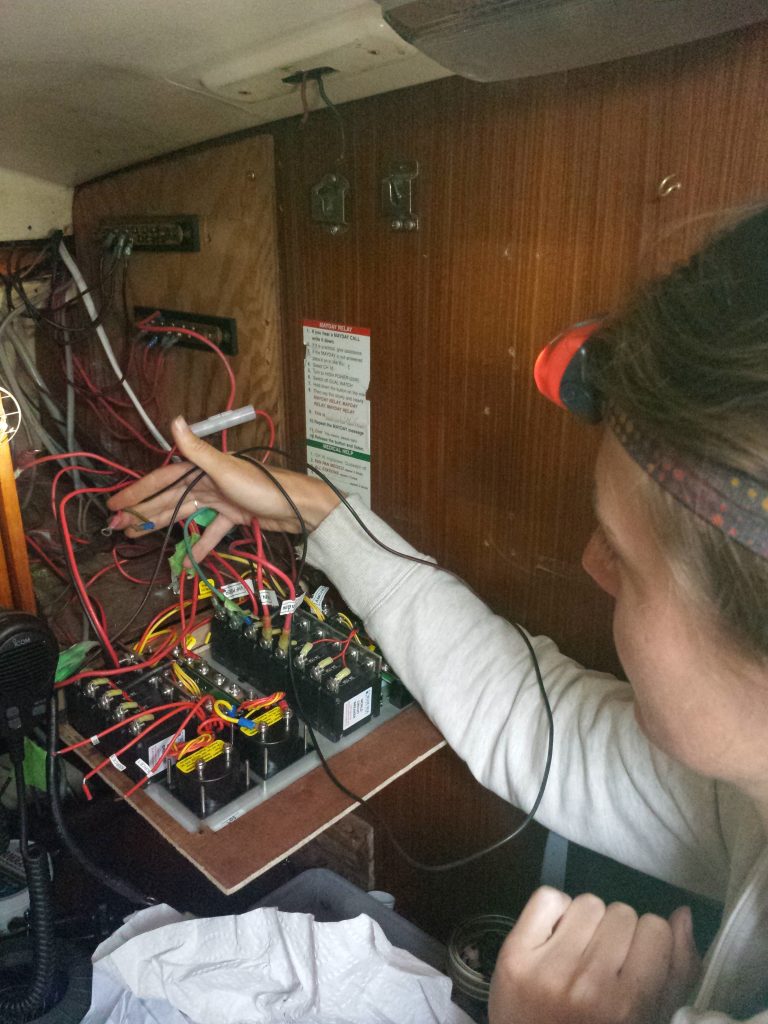

Photo: Ed Sherman

Whether you want to install a new stereo system or trace an intermittent electrical fault, a wiring diagram will save you hours of aggravation. The older your boat, the more likely you are to have either no wiring diagram or one that's worse than none because it's inaccurate. Making your own isn't rocket science, but it does take time, patience, and care. You won't get it all done in a day — or even several weekends — and don't let yourself get intimidated by complex electrical diagrams. Start by focusing on the simpler (and safer) 12-volt DC system aboard your boat. With each wire you trace, and circuit you complete, it gets easier. Eventually you'll have a map of your entire electrical system and a thorough understanding of how the pieces are tied together.

On many boats there are two types of current: alternating (AC) and direct (DC). Serious damage and even electrocution can result from confusing the two. In recently built boats, the two systems should be clearly differentiated and separated, including at the electrical panel. Wires and components associated with each should be distinct and, on newer boats built to American Boat and Yacht Council (ABYC) standards, will use standard color-coding. See chart at below.

AC wiring for 110 volts usually has white for neutral, black for hot, and green for ground (220-volt AC lines have a second hot wire, colored red). Those three wires typically are enclosed in white or gray insulation. You'll see the colored individual wires when they exit the common sheathing at each end. Your diagram should have one line for those three enclosed wires, except as necessary to differentiate them at the ends.

The wiring colors on your boat may be very different, especially if it's older and there's been a lot of "jury rigging" in its past. Make no assumptions about which wires do what. Trace each wire in the circuit from the electrical source to its use. Wire colors will assist you in doing that, even if they don't follow ABYC standards, by helping you identify the far end where it reappears from a conduit or a locker on its way to the equipment it powers.

On boats with both AC and DC systems, the DC system is generally simpler. DC power originates from the battery banks, so there is only one source. The DC electrical system is grounded through the negative bus of the distribution panel, which in turn is grounded through the engine negative terminal or its bus. That means that only two wires run from the distribution panel to each consumer of DC power — a DC positive and a DC negative — versus the three or four wires for each AC electrical user. The simplicity of the DC system, along with its relative safety in comparison to AC, makes it a good place to start.

Tip: Be very careful; don't confuse black DC negative wires on older boats with hot black wires on an AC circuit.

Big Picture: Sources & Uses

Take a careful look at the electrical systems on your boat, listing sources and uses for both AC and DC current. If it runs without the inverter when only battery power is available, it belongs on the DC list. A general idea of how each is connected will help you anticipate what to draw. If you have a good wiring diagram, copy it and blow it up so that you can make clear notes and changes in the future. Anytime you change the wiring or electrical components, write it on the diagram. If you don't have a good diagram, or you're intimidated by the arcane electrical symbols on the one you have, make one from scratch using large paper.

Starting with the batteries, follow the wires through to the end users, noting the selector equipment and any other equipment in line. Some people draw the wires within a sketch of their boat to indicate where they are. In a complex boat, this may ultimately be more confusing than drawing them in abstract and using industry conventions to show electrical components (see Online Extra). Start simply and make sure you know what you're drawing. Use a sharp pencil and try to avoid erasures. As you gain understanding and confidence, you'll likely redraw it several times. Indicate wire colors and gauges (thickness). The lower the gauge, the thicker the wire and the more current it can carry. The gauge should be imprinted on the insulation, with the number followed by "AWG," such as "12 AWG."

Using the list you made for the DC side, match up the breakers on the panel to the DC users. A few stragglers aside, the diagram of your DC system should come into focus. But don't jump ahead and make assumptions. All too often, a circuit breaker will have been reassigned in some past renovation, or a previous owner will have spliced into a wire to obtain power for an added item such as a fan. The only way to figure that out is to trace each wire to see where it really goes.

Tracing A Wire

After getting a basic understanding of your DC system, it's time to get down and dirty. First turn off all sources of power. Unplug from shore power, turn off any inverter and disconnect it from the battery, disable the generator, and remove the positive DC wires from the batteries. Although you're working on DC circuits, these actions will disable the AC side in case you mix up the two. Even after you've done this, DO NOT assume it's safe to touch any exposed wires, terminals, bus, etc.

Start at the source and trace each wire through to its end. The primary source wires will be heavy-duty wires running from your batteries to a distribution panel, or on smaller boats, a busbar. These wires should be few and simple, and much heavier gauge than the ones coming out of the panel/busbar because they supply the current for all those smaller wires. They may run through a selector switch before the panel.

The busbars or circuit breaker panels are the secondary source for most of your wiring, where the current "spreads out" following myriads of smaller wires to all the users on the boat. Hopefully your panel will have labels at the breakers, giving you some idea where these wires go. You may have to cut wire ties to isolate a particular wire contained in a tight bundle. Remember to re-tie the bundles when you're through. The wire you're tracing will often lead into a hole or conduit, but its color should distinguish it at the other end. If not, position a helper where you think the wire exits. Pull or carefully tug on your end, and hopefully your helper can see it moving. If not, try pulling back and forth like a seesaw.

If you just can't trace a wire, use a volt-ohm meter (VOM) to check for continuity (see "Five Ways To Use A Digital Multimeter," Dec. 2013). If you get continuity, you know in theory that the wire coming out of the hole is the same one going in. In some cases, wires going to certain equipment can indicate "ghost continuity" because of ground connections or other features. Physically tracing the wire is the most accurate method, especially on older boats. Once you've identified a wire from its source to its use, you can label it and add it to your wiring diagram.

Labeling And Diagramming

Attach labels to the wires at each end and at appropriate spots along the wire run. This helps when troubleshooting later. Buy labels or use high-quality yellow or white electrical tape and write on it with a quality indelible marker. Oil, grease, and other fumes in the boating atmosphere can cause the glue on labels or even good electrical tape to dissolve.

It's usually best to wrap the tape entirely around the wire, sticking it to itself. Office supply labels for label printers look neat but I've found that the glue on the back seldom lasts long and the labels end up in the bilge. Also label the wires and components on your diagram. You'll probably have to list and number these labels off to the side with a corresponding encircled number at the component. This avoids diagram clutter.

As you trace wires, look carefully for problems, including chafed insulation, hot spots indicated by browned or blackened insulation, little bumps in the insulation (indicates corrosion or overheating inside), a burnt insulation smell, or corroded terminals. Note the problems and fix them before you use the boat again. If you find an unfamiliar component, such as a diode, shunt, or transfer-solenoid switch, ask someone or research the part until you know what it does. This isn't just for accuracy; it will educate you, enabling you to diagnose problems more easily.

In older boats you might find dead wires, where an owner has removed something and disconnected (hopefully) its supply wire at the panel, but left it behind "just in case." Should you take it out, leave a strong nylon messenger string in its place to pull through another wire later. If you leave the wire, label it at both ends and be certain it's dead. Seal each end by wrapping it with electrical tape and then smear electrician's "liquid tape" over the actual tape to keep moisture out and the tape in place.

Voilá! The Final Product

By the time you get through diagramming the DC system, you'll have a good sense of how you want your wiring diagram to look. This is a good time to redraw it before starting on the AC system. AC systems can have more than one source (shore power, generator, inverter). If yours is particularly complex, consider hiring an ABYC-certified tech for an hour or two to walk you through it. Your diagram should clearly differentiate between AC and DC, or you can do a separate diagram for each system. Label which is which and make it obvious where the two types of current run close to, or could be confused with, each other. Make at least one copy to keep off the boat, and store your onboard diagram in a waterproof container such as a Ziploc bag. If it's very large, roll it up in a PVC pipe with two end caps. Glue one on, and use the other as a removable cap.

Diagramming your electrical system is a great winter project, and will be invaluable when you want to install something new.

Example Of A Draft Wiring Diagram For A Simple Boat

- When you make your own wiring diagram use very large sheets of paper for clarity.

- Most boats will have positive and negative busses where area wires come together.

- Equipment coming off a switchboard or circuit panel should be straightforward to trace.

- On a small boat, sketching circuits in the boat outline helps you locate wires later.

- The next step would be to trace the wiring to the instrument cluster and related gauges.

- Start with large cables leading from the batteries to the selector switch/busses.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

Technical Editor, BoatUS Magazine

One of the top technical experts in the marine industry, Tom Neale, BoatUS Magazine Technical Editor, has won nine first-place awards from Boating Writers International, and is author of the magazine’s popular "Ask The Experts" column. His depth of technical knowledge comes from living aboard various boats with his family for more than 30 years, cruising far and wide, and essentially learning how to install, fix, and rebuild every system onboard himself. A lawyer by training, for most of his career Tom has been an editor and columnist at national magazines such as Cruising World, PassageMaker, and Soundings. He wrote the acclaimed memoir All In The Same Boat (McGraw Hill), as well as Chesapeake Bay Cruising Guide, Vol. 1. These days, Tom and his wife Mel enjoy cruising their 2006 Camano 41 Chez Nous with their grandchildren.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

Practical Boat Owner

- Digital edition

Understanding electrical wiring connections for boats

- Pat Manley and Oliver Ballam

- August 16, 2023

Pat Manley and Oliver Ballam demystify boat electrics and explain how to use and make secure electrical wiring connections

Protecting a connector with spray grease. Credit: Fernhurst Credit: Fernhurst

How to make and use electrical wiring connections for boats

Connections are the heart of the electrical system and if we’re not meticulous in making them, they can be its downfall.

- They must be secure.

- They must be supported so that the wiring is not taking any load which might make it liable to being pulled out.

- They must be protected from corrosion .

- They must be accessible.

- They should be identifiable.

Corrosion is the enemy of all cable joints on a boat. Any exposed cable joint should be protected using silicone grease.

The connection may be a joint between just two wires or a joint between multiple wires.

These connector blocks have a clamping leaf which is pushed down by the screw to hold the wire. Credit: Fernhurst

There are a number of different ways to make the joints and you need to consider if the joint is to be permanent or if it needs to be undone from time to time.

The strongest permanent joint, having the least electrical resistance, is a soldered joint made on new, bright wire.

Electrical wiring connections: Without a clamping leaf, as here, there is a risk of breaking the strands of wire. Credit: Fernhurst

However, a soldered joint may melt in the event of a short circuit. Signal wires are small in diameter because they carry a very small current.

They are typically used for instrument wiring and are fairly fragile, so they need special consideration when being joined.

Alternatively there are Wago blocks which don’t use screws, but have a spring contact. Credit: Fernhurst

There are two schools of thought on whether the end of a wire should be ‘tinned’ with solder or not.

Soldered joints use a flux to remove oxidisation from the surfaces to be joined.

Marine grade ‘bus bar’ connector. Credit: Fernhurst

This flux may be acidic and can cause subsequent weakening of the wire.

On small-diameter, multi-strand wire, stresses can be induced by movement at the junction of the soldered wire and the unsoldered wire.

Electrical wiring connections: Multiway connector block. Credit: Fernhurst

The screw of a screw terminal and the crimping process are both unable to ‘squash’ the soldered part of the cable and joints may be less secure.

Most technicians recommend that the ends of the wires should not be soldered.

Electrical wiring connections: Terminal blocks

Also known as ‘chocolate block’ or ‘strip connectors’.

These allow joints to be made and remade as required. Select the appropriate-sized terminal block for the wires to be connected.

Using a wire stripper, remove just sufficient insulation to fit into the terminal.

‘Chocolate block’ connectors – no good for damp places. Credit: Fernhurst

Insert the wire into the terminal and tighten the clamping screw, ensuring that the screw presses down on the centre of the wire’s core.

‘Chocolate block’ connectors are not ideal for use on a boat, unless in a very dry area.

If used, both the wire entries and screw heads must be insulated against moisture ingress with spray grease to prevent corrosion of the cable.

Use crimp eye terminals – no more than four to a single screw or post. Credit: Fernhurst

Do not try to keep moisture out by wrapping it with self-adhesive electrical tape.

Connector blocks or strips should be made from marine-grade materials, which rules out those bought from the local car shop.

Non-ratchet crimping tool. Credit: Fernhurst

If they’re to be used with small-diameter signal wires, such as those used for instrument connections, they should have a clamping leaf to hold the wire, otherwise the wire’s strands may be broken as you tighten the securing screw.

Connection of signal wires is probably the most useful application on board for ‘choc-block’ connectors.

The better ratchet crimping tool. Credit: Fernhurst

For power connections, marine-grade ‘bus bar’ connectors should be used with crimped terminals on the wires, preferably self-sealing ones.

Never wind a wire around a bolt and screw the nut down on top of it – always use a crimped eye terminal.

This is to ensure proper contact and security of the joint. Do not fit more than four eyes to a single screw or post.

Types of electrical wiring connections

Crimped connectors come in a variety of shapes and three different colour-coded sizes.

Using an oversized connector will make a weak joint. Using an undersized connector will mean not all of the strands of the wire will fit into the part which is crimped, making this a bad connection.

So you need to use the correct size connector for the wire being connected.

Crimping tools and connectors are available cheaply from car shops.

The much better double crimp (left) and the cheaper single crimp (right). Credit: Fernhurst

The connectors may be made of steel and/or the metal will be too thin, preventing an adequate crimp pressure.

Most of these are a single crimp, meaning they have one metal ring which is crimped onto the conductor.

The better, more expensive, crimp terminals have two rings – one crimps onto the conductor and the other onto the insulation to give more support to the joint.

The cheap crimping tool will not allow sufficient pressure to be applied, potentially allowing the wire to pull out of the terminal.

Continues below…

Boat wiring explained for the practical sailor

Pat Manley and Oliver Ballam demystify boat electrics and explain wiring and the best techniques for its installation

Understanding boat electrics: switches and relays

Pat Manley and Oliver Ballam demystify boat electrics, starting with switches and relays

How to: troubleshoot your diesel engine electrics

Even when you’ve done all your normal pre-departure checks, sometimes the engine still just won’t start. If you have ever…

How to tidy up boat electrics? Ask the experts

PBO reader John Anderson writes: “I have the mast out of my 30 year old Malo to solve an in-mast…

Ideally, use a ratchet crimping tool, which, although more expensive, will make a secure joint.

This robust tool exerts sufficient force to make a proper joint on any size wire that it’s designed for.

You use a repeated squeezing action and continue until the tool automatically releases at the correct pressure.

It has three anvils, each of a different size. Each anvil is colour-coded − red being for the smallest crimp, blue a mid-sized one and yellow the largest.

The ratchet crimping tool’s anvils are matched to colour-coded crimp connectors, each of a different size and designed for different-sized wires, NOT the colour of the insulation!

You use the red anvil for red connectors, etc.

Spade & bullet connectors

Spade connectors – male and female to fit into each other. Credit: Fernhurst

These come in male and female and can be fitted to the ends of wires so that the wires may be disconnected and remade as required.

Bullet connectors – male and female to fit into each other. Credit: Fernhurst

Ring terminals

Ring terminals. Credit: Fernhurst

These are for attaching a wire to a screw, bolt or post and come in various hole sizes.

Butt crimps

Butt crimps. Credit: Fernhurst

These are tube-shaped connectors with two crimps for joining wires in-line.

They typically consist of a metal tube that’s usually encased in an insulated covering.

Heat-Shrink Crimps

All these connectors are available with a heatshrink sleeve (second), which helps waterproof the connector, or not (first). Credit: Fernhurst

All of the above will be available in heat-shrink variants – where the plastic outer sleeve is replaced by a heat-shrink sleeve, ideally with adhesive lining, which helps to waterproof the connector.

Making a crimp connection: step by step

Credit: Fernhurst

1. Put the wire in the stripper jaws – some stripper jaws have notches suitable for different wire sizes; others automatically close to the correct diameter.

2. Strip the insulation from the end of the wire.

3. Insert the bared wire into the crimp connector.

4. Choose the crimp tool aperture for the correct size – in this case, red.

5. Insert the crimp connector into jaws of the crimping tool.

6. Close the crimping tool jaws around the crimp terminal.

7. Squeeze the crimping tool until the crimp is correctly squashed.

8. Release the handles and check the wire is held securely in the crimp.

Splices: Step by Step

1. Place the first wire in the stripper’s jaws.

2. Remove just sufficient insulation so the wire will go into the terminal AND the insulation will be covered by the terminal’s own insulation.

3. Insert one wire into the terminal. You may need to twist the stands very slightly so they stay together and go into the terminal more easily.

4. Push the wire fully in, so there is no bare wire showing.

5. Insert the terminal into the crimping tool.

6. Squeeze the crimping tool to crimp the wire in place.

7. That’s the first half of the splice created.

8. Strip the second wire and insert it into the other end of the terminal.

9. Now crimp the second half of the splice.

10. With both halves crimped, check the joint – if you can pull the wires out you’ll need to remake the joint.

11. If you’re using a heat shrink-type crimp, shrink the tube with a hot air gun.

12. The finished splice – secure and well protected for the marine environment.

Making a heavy-duty crimp connection: Step by Step

1. Cut the cable to length using heavy-duty wire shears.

2. Remove just sufficient insulation using a craft knife (taking great care not to cut or damage any of the conductors)…

3… so that the bared wire is the same length as the terminal’s collar.

3a. Insert the bared wire into the terminal.

4. Take the heavy-duty crimping tool, adjusting the size as necessary for the gauge of the terminal and cable.

5. Place the terminal in the vice and line it up with the vice jaws.

6. Fully close the vice (having adjusted it earlier it will exert the correct amount of pressure)…

7… to create the crimped terminal.

8. Cut the correct length of adhesive heat-shrink tubing and place this over the joint.

9. Heat the heat shrink tubing with a hot air gun until it has shrunk and made a tight fit over the joint.

10. The finished joint – you can just see some of the sealing adhesive visible at each end of the tubing

The third edition of Essential Boat Electrics (Fernhurst Books, £16.99) is available at fernhurstbooks.com .

Written by Oliver Ballam and the late Pat Manley, it’s a practical guide – with simple language and clear diagrams – to allow owners to tackle electrical jobs on board.

There are tutorials, from wiring a circuit, understanding switches and relays to troubleshooting electrical faults, all using easy-to-follow photo sequences.

The book also looks at tasks such as choosing solar panels and batteries and connecting navigational instruments.

Buy Essential Boat Electrics from Amazon (UK)

Buy Essential Boat Electrics from Amazon (US)

Buy Essential Boat Electrics from Foyles (UK)

Buy Essential Boat Electrics from Waterstones (UK)

Buy Essential Boat Electrics from Google Play

Note: We may earn a commission when you buy through links on our site, at no extra cost to you. This doesn’t affect our editorial independence.

Enjoyed reading understanding electrical wiring connections for boats.

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

Follow us on Facebook , Instagram and Twitter

- Consultation & Design

- Installation & Service

- Boating Tech Talk

- Case Studies

- Testimonials

- PYS Merchandise

- PYS Donation

How To Create A Wiring Diagram For Your Boat

Most new boats include a drawing that outlines the entire electrical system, however these become outdated very quickly as new equipment is installed. For older boats, they can be completely out-of-date or non-existent. Putting together a simple diagram of your boat's electrical system may seem overwhelming but it isn't as hard as you think. It just takes time, patience and the realization that it cannot be completed in a day and will be an on-going project.

Where to Start? If you have an existing drawing, we recommend you enlarge it and make clear notes regarding any changes. If you don't have a drawing, start with a large sheet of paper, and begin with the batteries and the main DC system such as battery chargers, inverter, busbars, and switches. Also include wire size and fuses.

Labelling - In order to complete the schematic drawing, you will have to figure out what each wire is for and where it goes. Once you have established the purpose of the wire, attach a label to identify it. Use marine specific labels or a high-quality labeller. Oils and moisture in the engine room can cause most home office labels to dissolve. While you are tracing each wire, look for signs of chafing or small bumps and change as required.

Many electrical problems start with the connectors, the wires are in a damp environment and are subject to constant vibration. A good connection starts with a good crimp and the secret to a great crimp tool is that it does not pierce the insulation on the wire. Our favourite is the FTZ Cycle Crimp tool that is specifically designed for heat shrink terminals and splices. The bare wire at each end of the connector sleeve must be sealed with heat shrink. Make sure you have a number of different sizes on board, both for correct wire gauge and ring size, along with a good heat shrink torch, such as the Ancor Mini Butane or Butane Pro.

Marine terminals feature pure electrolytic copper to offer the least electrical resistance for best current flow. They are tinned to prevent corrosion from salt and moisture. Ensure that they are UL listed and designed to be used on flexible stranded wire. Look for terminals with a seamless, flared barrel design that makes it easy to insert the wire and gives maximum strength when crimped. A closed-end seals out moisture so your cables stay dry and do not corrode over time. You may be tempted to use less expensive terminals designed for your car or truck but don't.

Along with your crimper, terminals and heat shrink, you should pick up a small tinned wire brush. To ensure you have the best connection possible, keep the posts and connectors free of corrosion. Your onboard fuse kit should include a complete set of both glass and blade (automotive style) fuses. As you are going through and identifying each wire run, make a list of fuses you use. Many marine stores carry small, inexpensive kits with a great assortment. A really great tip is to zap strap or tape an extra fuse in or near the location of the actual fuse. If you have an inverter/charger, make sure you have a Class T fuse onboard as they can be difficult to source while boating

ABYC Standards - If you are thinking of doing any wiring as a DIY project, get a copy of the appropriate American Boat and Yacht Council (ABYC) standards. Boat manufacturers use these standards as an absolute rulebook to design and build safer boats.

There are symbols used by designers and electricians for each device, but if you don’t know the symbols don’t worry. Draw a square, label it with the name of the device (inverter, switch) and show the wires that are connected to it. For DC wiring, positive wires are red, negative wires are yellow (or black in some cases).

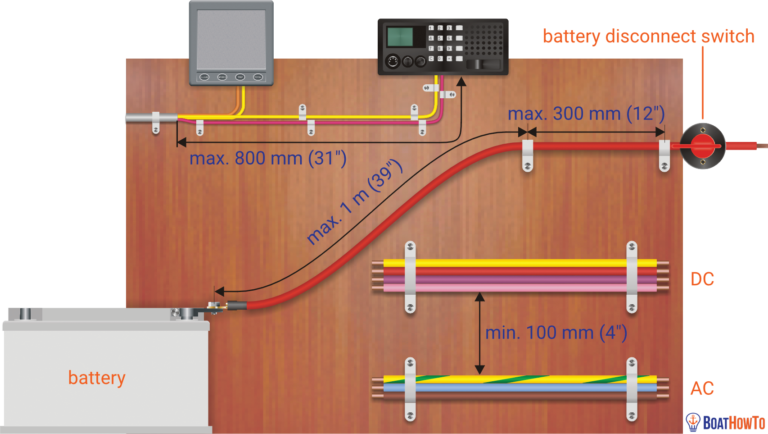

Your boat wiring system should have a marine grade main battery disconnect switch which allows you to open the switch to turn everything off at once. There are some devices on your boat that you do not want to shut off when you turn off the battery switch such as the automatic bilge pump, an automatic fire-fighting system, or propane detector. These will be wired directly to the battery and must be protected with an inline fuse at the beginning of the circuit.

On most boats the ground reference is the engine block which is, in turn, connected to the water via the propeller shaft. Determine if you have a bonding buss for the underwater metals, this is a green wire (or a copper strap) that runs through the length of the boat and connects all of the underwater metals. Although grounding and bonding are frequently referred to interchangeably, a bonding system electrically connects the boat’s underwater metal fittings, such as through-hulls, seacocks, rudders and struts through zincs to protect it from corrosion.

While you are putting together your schematic, make a note of each of the components (ie inverter, charger, generator) with the model number. Then collect all of your Owner’s Manuals, we recommend storing them in an accordion file or binder. While all of this information is available on-line, boaters do not always have access to the internet. The back pages of these manuals typically contain a list of common error messages and resets along with proper installation wiring diagrams. Many boaters include the original bill of sale inside the front cover of the actual manual, which includes a description and date of purchase.

Most yacht clubs, cruising groups or Power Squadrons offer electrical courses either in the evening or on the weekend. For those of you who really want to get to the next step of understanding the what and the why of marine electrical, purchase and read Nigel Calder’s book called “Boatowner’s Mechanical and Electrical Manual”, it is the industry "go to" for marine electrical repair.

A good electrical diagram will save you money because there is nothing more beneficial to a technician or mechanic than an up-to-date schematic. It can save hours of trouble-shooting. As well, the process of spending time with your electrical will help you become more familiar with your boat and get you back on the water faster.

About the author: Jeff Cote is the owner of Pacific Yacht Systems, a full service shop delivering marine electrical and navigation solutions for recreational boats. Visit their website and blog for info and articles on marine electrical systems, projects and more: www.pysystems.ca.

Related Content

Boating Tech Talk Our Marina Only Has 15A Shore Power but I Still Keep Tripping the Breaker?

Boating Tech Talk 3 Bank Battery Charger for 2 Battery Banks?

Boating Tech Talk Can You Explain Battery Combiners, GFCI/ELCI vs. Galvanic Isolators?

Boating Tech Talk Adhesives for Flexible Solar Panels?

Boating Tech Talk Explain Wire Size and Fusing?

Boating Tech Talk AIS Receiver vs. Radar Reflector?

Boating Tech Talk Advice on Selecting an Inverter/Charger?

Boating Tech Talk Common Reasons for Battery Damage?

Boating Tech Talk Advice on Marine Cameras?

Boating Tech Talk How are my Tach and Alternator Related?

Boating Tech Talk Experience with Thermal Cameras?

Boating Tech Talk Automatic Combiner Relay or Voltage Sense Relay

Boating Tech Talk Can You Explain the Difference Between Poly and Mono Solar Panels?

Boating Tech Talk Two Batteries Are Hotter and Need More Refills Than the Other Batteries in the Bank - What Causes This?

Boating Tech Talk What Is The Charging Sweet Spot & Maximum Discharge For My Batteries?

Boating Tech Talk 12V or 24V Thruster?

Boating Tech Talk How Do I Prevent Galvanic Corrosion on My Boat From Boats Around Me?

Boating Tech Talk Gel Battery Rate of Charge?

Boating Tech Talk Advice on Improving Alternator Ouptut?

Boating tech talk help me understand my fuse block.

Copyright © 2024 Pacific Yacht Systems.

Contact Us 604.284.5171

PYS Partners | Privacy Policy

Home » Blog » Boat maintenance & DIY » Learn boat wiring from the experts

Learn boat wiring from the experts

By Author Fiona McGlynn

Posted on Last updated: August 18, 2023

Our review of Boat Electrics 101 , a new online course, co-developed by marine electrics expert, Nigel Calder.

When we bought our 1970s-era sailboat, the boat wiring was a disaster.

We soon discovered a rainbow spaghetti mess of unlabeled electrical wires behind our DC electrical panel. Legacy marine electrical systems from a previous “rewiring” made trouble-shooting and tracing wiring runs exasperating. Lights and pumps regularly failed and we once lost power entirely (despite being on shore power).

In short, living on a poorly wired boat was a nightmare. We needed to learn about our boat’s electrical if we were ever going to go bluewater cruising.

A quick note that this post contains affiliate links (so if you purchase through a link we’ll earn a small commission). We received free access to this course in exchange for a fair and honest review. All the opinions are our own.

Learning how to wire a boat

The good news is that while boat electrical may seem intimidating, it’s actually not all that difficult to get the hang of—but it does have to be done right!

The challenging part was finding a good teacher. We hired an electrician we found on Craigslist to show us the ropes, but this proved to be a complete disaster (with him shorting out the dock mains at our marina and frying our inverter).

After that experience, we resolved to teach ourselves, sorting through the good, bad, (and sometimes, downright dangerous) boat electrical advice available online.

Fortunately, there is now a FAR better way to learn boat wiring…

Boat Electrics 101

Boat Electrics 101 is the online course I desperately wish we’d had at the time. It launched in 2021 and was created by arguably the world’s smartest people on marine electrics including boat systems guru, Nigel Calder.

If you’re not familiar with Nigel, you’ll find his mechanical and electric books in just bout every bluewater cruiser’s library. These guys really know what they’re talking about!

In the course you’ll learn:

- The basics of how electricity works

- Electrical system components and how to safely connect them

- How batteries work (and what you can do to double or triple their lifetime)

- Energy system design: how to balance your energy storage, consumption, and generation

- How to plan a (re)wiring of your boat (including making your own boat wiring diagram)

Unlike my grade 10 science teacher, the course does a great job of taking an important concept and breaking it down with animations, diagrams, and videos.

For example, In one module, Calder demonstrates the importance of circuit breakers by driving a screw through an unprotected wire. The cable immediately went up in flames, filling the room with smoke! Lesson learned.

Best of all, all of their materials follow ABYC and ISO standards. Both Nigel and Michael have been members of American Boat and Yacht Council (ABYC) and the International Organization for Standardization (ISO) committees, so they know the rules and best practices better than anyone.

I’ve taken Boat Electrics 101 and can’t say enough good things about it. If you sign up now, you can take advantage of their early bird offer ($199) and save $100 . Oh, and you keep your access to the course forever (even as they add new material). Even if it saves you hiring a marine electrician just once, the course more than pays for itself.

The rewards of doing it yourself

Learning how to wire a boat was not only rewarding but it made us more capable, self-sufficient boat owners. It’s an essential skill for people with older boats, but even new boat owners will find there comes a day when an electrical component fails or they want to add more bells and whistles.

We’ve saved a lot of money by doing our own marine electrical work (not to mention avoided days stuck in port waiting for a professional marine electrician). So, don’t let marine wiring intimidate you. With the right knowledge and tools, you’ll be well on your way to doing your own marine electrical.

Fiona McGlynn is an award-winning boating writer who created Waterborne as a place to learn about living aboard and traveling the world by sailboat. She has written for boating magazines including BoatUS, SAIL, Cruising World, and Good Old Boat. She’s also a contributing editor at Good Old Boat and BoatUS Magazine. In 2017, Fiona and her husband completed a 3-year, 13,000-mile voyage from Vancouver to Mexico to Australia on their 35-foot sailboat.

Sunday 23rd of January 2022

I learned the hard way about boat electrics when locked onto the engine block and a battery charger on a sailboat connected to shore power with a faulty ground. I was being tazered by 240v.

My friend saved my life by pushing me off the engine with a broom handle!

Yes, understanding boat electrics is something that is as important as navigation!

Oh my gosh, that sounds terrifying! What a nightmare. I'm glad you're okay. That was some good quick thinking on your friend's part!

Terms and Conditions - Privacy Policy

14 Steps To Wiring Your Boat

What you need to know to install or re-wire the electrical system on your boat. a step-by-step practical guide. covers planning, diagrams, wiring, batteries, over current protection and more..

I want to thank Ed Sherman for reviewing this page for accuracy.

A question often asked on boating and boat building forums, and by visitors to my web site, is: “I need a simple wiring diagram for a small outboard boat to wire up the lights and few other things, but no one seems to have one. Is there one, and where can I find it? Are there a set of step-by-step instructions?”

There are wiring diagrams, websites and forums that tell you how to wire an electrical system for large boats and bigger sailboats. But when it comes to small boats there is a distinct lack of information and diagrams for how to install a simple, safe, and reliable electrical system.

The following is meant to apply only to small outboard boats under 16 feet with 50 or 60 horsepower or less. It can be applied to slightly larger boats that have a simple 12V DC system using one or two 12V batteries.

Note 1 : I will not deal with the wiring specifically for the outboard motor and controls. Here is a web site where you can obtain wiring diagrams for most outboard motors. Most new outboards come with a wiring harness and a manual that has wiring diagrams. See Master Tech Marine Outboard Wiring Diagrams .

Note 2: If you are re-wiring a boat with an electrical system installed: Don't rip out that old system yet ! Use the old system to help make a plan in steps 1 through 7. Trace out each wire and put that on your diagram. This will make it far easier to locate wires and equipment. Wait until you actually start installing wiring in step 12. Then replace each set of wires with new. This may take a little more time, but will result in far fewer mistakes and less troubleshooting.

Note 3: Throughout this I will give references to the US Code of Federal Regulations (CFR) requirements that apply to boat manufacturers, and to the American Boat and Yacht Council industry standards. Examples: 33 CFR 183.401, or ABYC E-11. The US Coast Guard Regulations (the CFR) and the ABYC standards are good guidelines to follow for a safe and reliable electrical system. They are used by marine electricians, professional boatbuilders, designers, marine surveyors, and marine repairers. If that’s how the pros do it, so should you.

Step 1. Make a Plan. Decide what you want to install, and where it will go. See Electrical Planning

Step 2. Draw a simple electrical schematic (diagram) that shows each piece of equipment, the fuses, switches, and how all of this will be connected. This is not a diagram of where the equipment is located on the boat. That will come in Step 8. It is simply a diagram of the electrical circuits. Here are two alternative examples. (Click on the diagram to expand.) The first diagram uses a positive buss bar. The second omits the positive buss bar. For clarity I did not use color codes except red (positive) and black (negative).

Do not be concerned if you don’t know electrical symbols. Just make a box or circle and write in what it is, or you can use a picture of the item. As long as you understand what goes where, and how they are connected, it’s Ok. Remember, any 12V DC device must have at least a positive and negative wire connected to it. Put a plus or minus next to the wire or use red for positive and black for negative. On metal boats do not use the hull as a return (negative) path. Connecting your electrical system to a metal hull can result in stray current corrosion.

See also BoatUS diagram:

There are several ways to draw wiring diagrams. The most important thing is that you understand what you are diagraming. It needs to be simple enough and clear enough for you to be able to refer to it in the future and still understand what each item is, what the wiring is and how each item of equipment is connected to the electrical system. That way, in the future if you want to add or subtract equipment you can do so by referring to your diagram and determining where and how the new item fits into the system.

Step 3. Batteries: Decide where you will put the battery. Later we will decide the capacity and type of battery but for now we only need to decide where to put it.

The battery is the source of power for starting, instrumentation, and lighting. There may be a second battery on some boats for running a trolling motor or other equipment.

Batteries should not be too close to anything that can cause an accidental short. There should be 12 inches of space all around them. Batteries must not be directly under or over fuel lines or under other electrical equipment such as a charger or inverter. If they are, there must be a floor or panel separating them. ABYC E-10.7.5 and 10.7.6 Storage Batteries

Batteries need to be in a space that is ventilated to the atmosphere. 33 CFR 183.420(e) This applies to all batteries, not just lead/acid batteries.

Batteries must not move, so they have to be fastened down. 33 CFR 183.420(a)

There should be a tray under a battery for spilled electrolyte, or it should be in a battery box, and fastened down so it won’t move under any conditions. (ABYC E-10.7.2) The Coast Guard does not require a tray or a battery box but ABYC does require some means to contain spills. If it is strapped down in a tray, spilled acid won’t damage the boat and the battery won’t move. The terminals need to be covered with a boot or some other device that protects them from accidental contact with metal tools. But, if the battery is in a box the terminals are protected against accidental contact with tools, spills are contained, and it won’t move.

The battery should be close to the engine. Since starting current is so high, and the wires to the starter are not fused, you want to keep the wires as short as is practical.

The battery should be a combo starting/deep cycle battery, usually sold as a marine battery. An auto battery would do for starting and lights. But, for running a radio, and other electronics while anchored or fishing, a battery with a little deep cycle capacity is needed so the battery doesn’t go flat and leave you stranded when you try to restart the engine.

How big a battery (capacity, not physical size) do you need? That depends on the amount of load on the battery. I will show how to determine that in Step 12.

There is one non-electrical consideration; weight. Lead acid batteries can weigh up to 50 lb. Think about how the weight of the battery will affect weight distribution on your boat, especially if it is on the same side as the helm and controls. You may have to move it to balance the boat side to side. If you have a very low transom, how will the weight of the battery affect the water line at the transom?

Step 4. Battery Switch: Some people think that a battery switch is not necessary on a small boat. I think a battery switch is necessary to turn everything off when you are not using the boat.

Where the battery is located determines where the battery switch goes. It should be close to the battery but easily accessible to be switched off in an emergency. ABYC E-11.6.2.

A good brand is Perko but there are others. Avoid any battery switch that is not UL Marine Listed. There are cheap ones on the market that are not UL listed and can get hot and melt.

A battery switch must be ignition protected. (33 CFR 183.410)

Ignition protection means that it will not ignite gas fumes if they are present. This is extremely important if you have a gasoline fuel tank in the same compartment as the battery.

Use only ignition protected electrical components. You don't want anything in there that will set fuel vapors off. Batteries are not considered a source of ignition because there are no moving parts, but if you make accidental contact with metal tools it can create an arc. So, the terminals must be protected, and battery switches and other electrical equipment in this compartment must be ignition protected.

Buy a switch that has a provision for two batteries because you may want to add a battery in the future. The switch will have three positions. OFF, 1, 2, and BOTH. The 1 position connects the one battery and allows charging of that battery when the engine is running (if your outboard is large enough to have an alternator). The 2 position connects and charges the second battery, if there is one, and the BOTH position puts the two batteries in parallel doubling the battery capacity and charging both at the same time. You won’t need the BOTH and 2 positions now, but this gives you the option to add a second battery.

Step 5. Fuses: Next, install a fuse block close to the battery switch. Fuses must be within seven inches of the source of power (33 CFR 183.455) but you can go up to forty inches if the wire is sheathed. Standard wire loom is fine as a sheath. Be aware, the fuse is there to protect the wire, not the equipment. If you overload wiring it gets hot, melts and starts a fire. We will determine the size of the fuse later. See Step 12. Buy a fuse block with two fuse holders. That way you have a spare if the fuse blows. This is generally a good idea. When installing fuse blocks get ones with more fuse holders than you think you need. You will need them eventually. One or two extra fuse holders is good.

Step 6. Equipment Location: Determine where each piece of equipment will be.

Think about where you want things to go. Depth finders need to be where they are easy to see, but not blocking your vision when operating the boat. Radios should be where they can be easily reached, and for VHF, reach the mike. The back of the console or surface you are mounting them on needs to be easily accessible for access to the wiring.

Step 7 . Locate the fuses, buss bars and switch panels.

Decide where to put fuse boxes, buss bars, switch panels, etc. Each of these must be close to the equipment they power, and easily accessible to be worked on. They cannot be hidden behind equipment or inaccessible panels. This may sound obvious, but I have seen some very bad installations. Also, they should be protected from spray or rain.

Most electrical and electronic equipment comes with pigtails. Pigtails are wires coming out of the equipment and may only be a few inches to several feet long. Sometimes they have a connector attached to the ends of the wire. When determining where stuff goes consider the length of the pigtails, because you don’t want a rat’s nest of wires hanging loose.

Switch boxes: A box or panel where switches can be mounted to control stuff. On a small outboard boat this is usually the dash or the console.

Fuse block: A panel with fuse sockets on it. It can be open or covered.

Buss bar: A block with studs for connecting wires.

Typical Buss Bar: This buss bar is for the negative wires. The large wire on the left is the battery negative.

There are some devices that are connected directly to the source of power and do not go through fuse blocks and switches. They need to always have power. One is the bilge pump. Bilge pumps may have a float switch that automatically turns the pump on when water in the bilge gets to a preset height. This won’t work if the pump is not wired directly to the battery. It is not good practice to wire it directly to the battery though. Wire it to the power input side of the battery switch. It is good to install a switch at the helm that turns the pump on manually.

If your boat has an anchor light, you may also want to wire the switch for the light directly to the power input side of the battery switch. That way you can turn on the anchor light when the battery switch is off.

Step 8. Make a diagram of the boat showing where the wiring, equipment and fuse blocks will be located.

Make a rough drawing of the boat looking down from the top. This is called a general arrangement and shows how the boat is laid out. Using your electrical schematic, put in where the equipment, fuse boxes, buss bars, switch boxes and wiring are going to go. Check this against the actual boat to make sure you aren’t missing something.

Wiring cannot go through pieces of equipment, pipes, tubes, and other solid objects. They can go through walls and bulkheads and panels. Wiring must be easily accessible for installation, trouble shooting and replacement. It must be fastened down at least every 18 inches (ABYC 11.15.4.1.9) so it isn’t or chafing on something. Where wiring goes through a bulkhead, wall or panel, it must have a grommet or padding to protect the wire. 33 CFR 183.445(a)

Your diagram may look something like this; (Click on image to expand)

Step 9. Wiring: Figure out how much wire you need, what size wire you need, and what color it should be. Wire standards.

What about the wires from the battery Switch to the starter? The wire needs to be a very heavy gauge, at least a 4 AWG on small outboard boats, because starters draw a lot of current. Both the positive and negative wires should be the same size. If the outboard has the wires for the starter already installed, the wires from the battery to the switch should be the same size as those wires. The engine manufacturer has determined the amount of amperage the starter draws and correctly sized the wires for the load.

The positive wire (red) goes from the battery to the input side of the battery switch. The negative (black) wire goes to a buss bar. One post on the buss is for the wire from battery to the engine block (ground). Another wire goes from the buss up forward to the dash. The others are for other equipment. There should be as many terminal posts as you need plus a few extra.

Color Codes: The positive wire should be red. Negative can be black, or yellow, or black with a yellow stripe. Throughout the boat negative wires should be black or yellow or a combination. AT the dash or console, all positive wires from the fuse block to the instruments and the equipment, should be color coded using the standard color codes for marine wiring. Direct Current Color Codes: From ABYC E-11.15.2.3 Table 11 and Table 12.

Direct Current Color Codes: From ABYC E-11.15.2.3 Table 11 and Table 12.

Color codes tell you what the wire is for. But label the wire on both ends. A simple piece of tape with a name written on it will do. They do not need to be fancy labels, but if you prefer, you can buy labels at electrical suppliers or hardware stores.

Wire must be marine wire. (33 CFR Sec. 183.435) Do not use auto wire. It is not made to the same standards as marine. Most marine wire is labeled UL 1426. It must be copper stranded wire. It does not have to be tinned, although tinned wire will last longer. On a small boat it is not necessary. Do not scrimp on wire though! Cheap wire could mean the difference between a reliable system and one that you constantly have trouble with. Buy good quality wire. I have seen 100 ft spools of Ancor 16 AWG Tinned Marine Wire for sale on-line for as little as $24.00 USD.

What size wire? American Wire Gauge (AWG) is in reverse order. The larger the number, the thinner the wire. The thickest wires are 00 or 0 AWG. The smallest gauge allowed on boats for a single wire is 16 AWG, or 18 AWG if it’s in a bundle or sheath (33CFR 183.425), but this may be way too thin for the equipment or the length of the wire run. The only exception to this is wire inside electronic devices or part of the electronic controls on the engine. 33 CFR 183.425(g)

The thicker a wire is, the less resistance it has. The longer a wire is the more resistance it has, and so there is a larger voltage drop. You want to minimize the resistance and the voltage drop. So you first need to figure out the wire size based on how many amps are being used, and then by how long the wire is. Use the tables in Appendix A, at the end of this page, to determine the correct size. Don't just guess at wire size and buy larger diameter wire such as 14 or 12 AWG. See Wire Size:

For the purpose of determining wire size, the fuse block the wire is coming from is considered the source of power. For the wires running from the battery to the starter, or to the under-dash fuse block, the battery is the source of power. In the two examples below the fuse block under the dash or console is the source of power.

Here is an example:

A Hummingbird Model 345C depth sounder draws 380ma (milliamps from the specifications). The installation includes a 6 foot power cable of 18 AWG wire. This may be fine for connecting it to a fuse block near the dash. But we need to size the cable running from the battery to the dash. It is going to be at least 10-12 feet long on a 16 foot boat. Double that length for the negative return wire.

Use table 3 in The Appendix for voltage drop. Most boat manufactures use wire rated for 105C (degrees Celsius - the temperature rating of the insulation on the wire). Looking at the table under the column for 105C we see amperages starting at 20 amps, 25 amps, 30 amps, and so on. Following the row for 20 amps to the left column we find 18 AWG.

From the table on voltage drop an 18 AWG wire 20-24 feet long (30 feet in the table) with a 15-ampere load will have less than a 10% voltage drop. But it can only be 18 if it’s in a sheath or bundle. So go up one size to 16 AWG.

Another Example:

Suppose I have three electronics running off a fuse block in the dash or console. Each piece of equipment requires 1 amp at 12 volts to run. The total amperage for the three items is 3 amps. From the fuse block in the dash or console to each item of equipment, there is a positive wire from the fuse to the equipment, and a negative wire running back to the buss. Using 1 ampere, we determine the size the wire should be, by using table 1 and 3 in Appendix A. For instance, if the positive wire is two feet long then the total length of positive and negative wires is 4 feet. Looking at the Table 1, the line for 18 AWG wire at 105C allows up to 20 amps.

So, we could use 18 AWG. Look at Table 3. We see that an 18 AWG wire, 10 feet long, will have less than a 10% voltage drop for up to 5 amperes. Again, we could use 18 AWG but since 18 AWG wire has to be in a bundle or a sheath we add a level of safety by using 16 AWG.

This is done using the tables developed by the US Coast Guard and ABYC. You don’t have to know any formulas to figure it out. The first table determines the wire size based on the load in amps and the second table the size depending on length and voltage drop. You use the larger wire if there is a difference.

See the table in Appendix A at the bottom of this page. or ELECTRICAL TABLE: 33 CFR 183.42: ALLOWABLE AMPERAGE OF CONDUCTORS FOR UNDER 50 VOLTS or: ELECTRICAL SYSTEMS VOLTAGE DROP

Step 10. Wiring tools. Wire connections (terminals). See Connectors :

Tools: Use good quality tools, especially good quality crimpers and wire strippers. Cheap crimpers make bad crimps. Bad crimps make bad connections. Poor wire strippers nick the metal conductor which may cause the wire to break or have a high resistance. See My Page on Practical:

Wire terminals must be used . Connections should never be a bare wire wrapped around a stud or post. This is bad practice, and can easily come loose or result in a high resistance connection. High resistance equals heat, which results in fire. Never use wire nuts to connect wires on a boat! They are prone to vibration and corrosion. ABYC E-11.15.3.7 Twist-on connectors (i.e., wire nuts) shall not be used.

Use crimp type ring or captive spade terminals. Captive spade terminals have a tang on the ends. This prevents them from being pulled off or slipping off the stud or post. Connections must resist being pulled off. In the ABYC wire standard there is a table listing how much of a pull they must withstand depending on the size of the wire. A 16 AWG wire must withstand a ten lb. pull. A 4 AWG wire must withstand a 70lb pull.

You can solder connections if you like but crimp them first . ABYC standards do not prohibit soldering, but they do not allow soldering to be the sole source of support for the connection. (ABYC E-11.5.3.8) This is because solder creates a hard spot in the wire which is not as flexible as the wire itself and not as resistant to flexing and vibration. So, if you solder you must also crimp. Crimp first, then solder.

Seal wire connections with a good waterproof sealant , usually marketed as dielectric grease. There is no requirement to do this, but it prevents water from getting in the connection and wicking up the inside of the wire insulation or corroding the connector.

My method. I do not solder. First I slide a short length of heat shrink tubing onto the wire. https://en.wikipedia.org/wiki/Heat-shrink_tubing How long it is depends on the wire and connector size. Usually if the tubing extends about 1/2 inch (1 centimeter) beyond the end of the connector, that is enough. Then I use dielectric grease. See Wikipedia on Dielectric grease . Dielectric grease is non-conductive grease, usually silicone that is also waterproof and can be used to seal connectors. Before crimping the wire in the connector, I squirt a little dielectric grease into the connector where the wire goes. I then insert the wire and crimp it. Then I slide the tubing down over the connector and shrink it with a heat gun or hair drier so it seals itself around the wire and connector. The combination of grease and heat shrink tubing should keep the water out.

Heat Shrink Tubing And Connectors, AAA protection, How to install and repair. http://youtu.be/jCRsx38WRw8

How to get a good crimp: Marine How to: Wire terminations: https://marinehowto.com/marine-wire-termination/

Step 11. Fuses . How big should your fuses be?

Fuses are rated by amperage and protect the wire from overheating and fire. Fuses must be rated at the same or less rating of the wire. If you have a wire that is rated at 15 amps you need a 15 amp fuse. Each circuit is rated for a certain amperage, such as 15 amps or 20 amps, and more equipment is not added to the circuit if it would cause it to draw more current than the fuse is rated for.

This can become an issue on little boats too if you have more equipment, or something like a powerful stereo system that draws a lot of amperage. Then it should have its own circuit and its own fuse for the circuit.

The question is how many fuses in the block? That depends on how much stuff you are running. I would have a fuse for the lights, one for the instrumentation, and one for any electronic devices, plus a spare. That is four. But for expansion maybe a six or 8 fuse block would be better. Again, in the future you won’t have to buy a new block. See Overcurrent Protection:

Step 12. Installing equipment .

Start with the battery, the battery switch, and the main fuse block.

Selecting a Battery: Batteries are rated by voltage and capacity. We are using a 12V battery. There are two ratings, CCA and MCA See Batteries at:

CCA Means Cold Cranking Amps. MCA means Marine Cranking Amps. These are measures of how many amps the battery can deliver for 30 seconds and maintain the voltage at 12V. Basically the higher the CCA rating the longer the battery will maintain its voltage. Batteries are also rated by amp-hours. 1 amp for 1 hour is 1 amp-hr. Generally the rating is based on how many amps the battery will discharge for 20 hours until the charge drops to 10.5 volts. The higher the amp hour rating, the longer the battery will power your equipment. Also, batteries are rated for Reserve Capacity which is how many minutes it will deliver the same voltage at 80 degrees. An average marine battery should have a Reserve Capacity of 60 to 90 minutes. Anything less is not adequate.

There are four types of batteries commonly used on boats, Wet Cell (also called lead acid, flooded, or flooded lead acid, and sometimes abbreviated FLA), AGM (Absorbed Glass Mat, Gel, and Lithium, but for now I’ll stick with the standard wet-cell battery. They are relatively inexpensive, can be purchased anywhere, and for a small boat, more than adequate. A battery with a CCA or MCA rating of 200-300 should do but we’ll determine that when we calculate the loads. See table below on how to calculate loads. Battery Capacity should be at least twice the load.

To calculate loads, list the equipment you are planning on installing. In the chart below the following items are listed. Navigation lights Bilge Pump Radio (Only when receiving) Depth Sounder engine electrical Instruments GPS Bait well pump Horn Radio TX. (VHF Marine radio. It draws more when transmitting)

Determine from the specifications for each item what the current load is in amps. Separate them into continuous loads (on all the time) and intermittent loads (only on when used). Determine how many hours they will be used. Multiply the amps times the hours to get amp hours. Add up the amp hours.

See Also Electrical Planning

Double the result to determine what the rating of the battery should be. For this case, 200.

Another consideration is the battery group size. Batteries come in different physical sizes. A Group 24 battery is 10 ¼ inches by 6 13/16 inches by 8 7/8 inches. A Group 27 battery is 12 1/6 inches by 6 13/16 by 8 7/8 inches. The physical size is determined mainly by how much space you have for the battery and its weight. A bigger battery weighs more. A large group size does not necessarily mean it will last longer. That is determined by the battery ratings for amp hours and reserve capacity. The most commonly used size on small boats is Group 27.

Install the battery box if you are using one, or a tray, then the battery. Now that you have installed a battery you can begin installing equipment. Install lights and electronic equipment. You want everything in place before you begin wiring. Put in switch panels and fuse blocks.

From Step 5. We need to determine the size of the main fuse at the battery. The continuous loads add up to 10.5 amps. The fuse in a DC circuit should be about 150% of the load so a 15 amp would be appropriate. (ABYC E-11.10.1.5.)

The fuses for each circuit of our example should be at least 3 amps except for the VHF radio because on transmit it draws 6 amps. So, use a 10 amp fuse for the radio circuit. Check the manufacturer's installation instructions for recommended fuse sizes for each piece of equipment. Remember, this fuse is to protect the wire to the equipment, not the equipment. Some equipment may have built in or in-line fuses for that purpose.

Step 13. Installing Wire:

Begin installing wire, starting at the battery and working outward to each fuse block and buss bar, and then on to each piece of equipment. Remember to follow the color codes and label the wires on both ends. If you decide to make any variations from your diagrams make sure you change the diagram for future reference.

Step 14. Turn on the power. Test by turning on each item, one at a time, to see if it works. Troubleshoot as you go. If there is a problem, fix it before you proceed. Once everything has been tested individually, turn on everything, one at a time, until everything is on. If a fuse blows or something doesn’t work the last item you turned on is where the problem lies. Turn everything off, fix it and then try again from the beginning.

An Excellent Article: Avoiding Boat Electrical Mistakes by Ed Sherman; Boat US Magazine https://www.boatus.com/expert-advice/expert-advice-archive/2016/august/avoiding-boat-electrical-mistakes

An excellent article by Owen Youngblood on Wiring Your Boat , from the Metal Boat Quarterly

How to Wire A Boat from New Wire Marine https://newwiremarine.com/how-to/wiring-a-boat/

The USCG Boat Builders Handbook for Electrical Systems is available on-line at https://safeafloat.com/wp-content/uploads/2021/04/I-Electrical-Systems-Final-4-14.pdf

Contact ABYC for a copy of E-11, AC and DC Electrical Systems on Boats. There is a fee. See: https://abycinc.org

Appendix A: Allowable Amperage and Voltage Drop Tables

Note: This is the table that is in the Federal Regulations. The Federal Regulation now uses the ABYC table. It is published in 33 CFR Subpart I sec 183.425. ABYC Standard E-11 has five separate tables based on how many conductors are in a wire bundle.

The table for voltage drop is below. This is only for 12V DC. Contact ABYC for a copy of E-11, AC and DC Electrical Systems on Boats. There is a fee. See: https://abycinc.org

This is the table to determine wire size due to voltage drop based on the length of the wire. This table is for 12 volts only. The top row is the length of the wire in feet. The first column below Total Amps, is the amount of maximum amperage. The number in the row to the right of the total Amps column, is the size of the wire for a 10% or less voltage drop. Example: 25 feet of wire (top row) at 15 amps (first column) the wire would be 14 AWG.

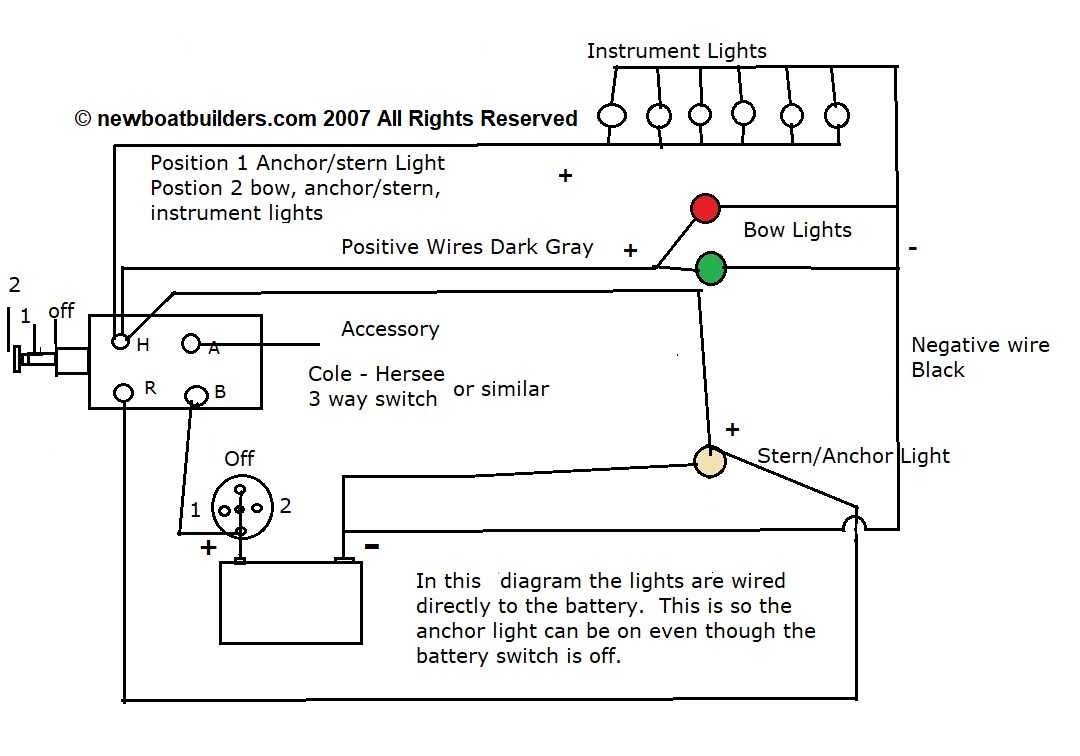

Navigation Lights: I added this section because many people asked for it.

Wiring Navigation Lights for boats with combination red/green bow lights and an anchor/sternlight on a pole. I have been asked many times if there is a standard wiring diagram for hooking up the lights on a small outboard or inboard boat. There are some variations on this but here is how I did it on my boat.

The below diagram is for small boats with a red/green combo light on the bow, and a single sternlight that can also be used as an anchor light. Usually these have a single switch with 3 positions; Off, 1. anchor light, 2. combo bow light, sternlight/anchor light, and instrument lights. The diagram shows a Cole-Hersee switch that is in common use, but there are other manufacturers that also make switches for this, such as BEM and Blue Seas. They all serve the same function. In this diagram the lights are wired directly to the battery. However, some people prefer to wire it through the battery switch so the battery is not discharged if the lights are accidentally left on. It is just a matter of switching the power wire from B on the lights switch, to the number one position on the battery switch.

© newboatbuilders.com 2007 All rights reserved. revised 03/17/2023

Created with Dreamweaver 21.2 ©newboatbuilders.com 2022 All Rights Reserved

Are Your Boat Electrics

Safe & reliable, ...or do they look like this:.

- Your boat's electrics are a "black box" to you?

- You are worried that parts of your system might fail?

- You want to upgrade or install new equipment in a professional manner?

Sounds familiar?

We teach you how to install and maintain a dc system on a boat like a pro, boat electrics 101 , safe & reliable dc systems, your teachers.

Nigel Calder

Dr. Jan C. Athenstädt

Michael Herrmann

We are Nigel, Jan & Michael. We help you understand, extend, and redo your boat electrics. The right way.

I now understand all the electrical systems and how everything works together.

Bob russell - s/v spartina.

Jan, Nigel & Michael, I want to let you know how impressed I was with the BoatHowTo course !! Having purchased a new to me Island Packet 350 this year, I was overwhelmed with all electrical systems on the boat! Modern cursing boats have become very complex and I was lost! Having taken your Boat Electrics 101 course I now understand all the electrical systems and how everything works together . From the very basics, through creating a detailed circuit diagrams of the electrical systems on my boat, my knowledge is years ahead of where I thought it would be at this point. Thanks for a wonderful, extremely useful (and fun) course that takes a lot of the mystery out of sailboat electrical systems!!

Boat electrics is not rocket science ... ...but it still has to be DONE RIGHT !

Electrical systems on boats have become more and more complex over recent years.

Even moderately equipped boats today rely completely on their electrical system . A loss of power means in most cases an emergency at sea. (Or do you still have a sextant and all nautical almanacs on board?)

Boat electrics are often poorly understood, despite being such a vital part of the operation of a boat.

The good news: It's not that hard!

With a bit of time and a commitment to learning, everybody who mastered basic high-school math and physics will be able to understand the DC system on a boat. All it takes is a reliable and easy to understand source of information .

You want to understand your system?

Clearly expressed and illustrated, the course is full of practical information, derek nowek - falmouth, me.

The Boat Electrics 101 course is a fantastic resource for beginners like myself who know little about electricity and even less about boats electrical systems. Clearly expressed and illustrated, the course is full of practical information presented in a way that makes boat electrical systems understandable. Thank you for putting it together.

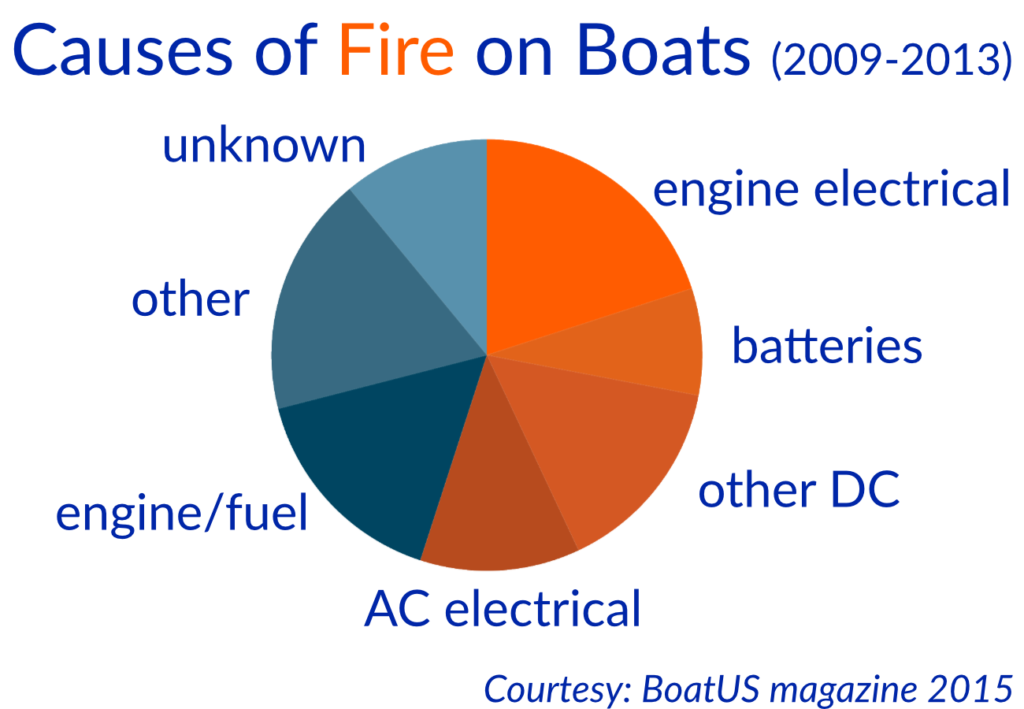

The majority of fires that start on boats are caused by the electrical system !

Understanding your boat's DC system can significantly improve the safety of your boat!

Unfortunately, many owners have only a vague understanding of their boat's electrical system. Or, even worse: They think they know how to install a system and end up making damaging mistakes...

...and teach others these mistakes in blogs or on YouTube.

YouTube is full of videos about Boat Electrics

– many are wrong and some are dangerous.

The internet is a great source of information. And in recent years, many people have shared their experience installing or fixing electrical problems on their boats.

The problem: Many of those people are not professionals!

It's easy to put a professionally looking video on YouTube...

...but it is hard to tell, if this actually is professional advice - or misleading BS.

If you follow bad advice on how to varnish teak and you end up with a mess, in the worst case you lose time and a bit of money.

If you follow bad advice on how to connect batteries and your boat ends up in flames, this is a different story.

A typical example of bad advice...

...is soldering. Soldering is often praised as a great way of connecting wires. On a boat, it is not. Soldered connections are rigid and tend to break when exposed to the vibrations common on boats.

This is why electrical installation standards from the American Boat and Yacht Council (ABYC) and the European International Organization for Standardization (ISO) both explicitly prohibit soldering as the only means of connection!

You want know how to do it right?

Your brand new boat is properly wired..., ...or maybe not.

When visiting boat shows, Nigel likes to inspect the electrical systems on brand new boats . Unfortunately, this has become quite frustrating: a shockingly high number of production boats come with badly installed electrics – straight from the boatyard.

These batteries were installed on a brand new boat. What's wrong here?

- Inadequate support against sliding off the shelf

- Parallel connections badly designed - this will lead to premature battery death

- Too many cables on the positive battery post

- No overcurrent protection devices anywhere near the positive battery pole

This installation might look neat at first glance. But:

It is unprofessional and asking for trouble!

You want to assess your system, i now feel empowered to research and undertake this work on my own., mark sweetnam - ireland.

Wow, what an outstanding course – thank you so much. I intensively studied each lesson, took notes (frequently pausing the video to do so), read and made sure I fully understood the lecture notes and then likewise all comments. The entire course took me about 6 full days to complete. In my own case I have owned a 30 year old Swedish boat (Najad) for the past 10 years. It has both 12V and 24V house systems, with two alternators. I got the batteries replaced about 8 years ago (with Victron AGM) but am now looking to upgrade the electrics in numerous ways, and obviously to audit and rectify any OCP or other shortcomings. New batteries will obviously be needed shortly but I also want to add solar. But mainly I want to either get rid of the 12V bank (and use DC-DC converters for the 12V house load) or add 12V-24V-B2B charging both for redundancy and to use full capacity of both 12V and 24V alternators and shore power battery chargers. I now feel empowered to research and undertake this work on my own. Thanks again.

Who or what are ABYC and ISO ?

The ABYC E-11 and the ISO 13297 standards cover the principal electrical systems on small craft.

Even though they are legally non-binding, they are based on decades of experience of hundreds of experts in the field.

So, instead of trying to figure things out for yourself (with potentially disastrous consequences), it is a good idea to follow these standards as closely as possible.

All three of us are members of various standards committees of the ABYC and ISO, Nigel and Michael for decades. Everything we teach at B OAT H OW T O is compliant with ABYC and ISO standards.

There is no one who knows the standards better than us.

The American Boat & Yacht Council (ABYC) is a non-profit, member organization that develops voluntary global safety standards for the design, construction, maintenance, and repair of recreational boats. As an independent consensus-based body, the industry experts at the ABYC (including Nigel Calder from B OAT H OW T O ) work together with the sole purpose of protecting the safety of the boating public.

The ABYC’s Standards and Technical Information Reports for Small Craft cover all major boat systems. The development and regular review of these standards provide boat building guidelines that correlate directly with a significant reduction in the number of boating accidents over the past six decades.

The International Organization for Standardization (ISO) develops high quality voluntary International Standards. The sub-group of the ISO that addresses small craft (up to 24m/70 feet), is known as Technical Committee (TC)188 (of which Michael Herrmann and Jan Athenstädt from B OAT H OW T O are both members). This committee has developed a set of standards that are closely aligned with the ABYC standards.