The Didi 26 is a 26.25ft fractional sloop designed by Dudley Dix and built in carbon fiber or composite by Mboats International (NOR) since 1997.

The Didi 26 is an ultralight sailboat which is a very high performer. It is very stable / stiff and has a low righting capability if capsized. It is best suited as a racing boat.

Didi 26 for sale elsewhere on the web:

Main features

Login or register to personnalize this screen.

You will be able to pin external links of your choice.

See how Sailboatlab works in video

We help you build your own hydraulic steering system - Lecomble & Schmitt

Accommodations

Builder data, modal title.

The content of your modal.

Personalize your sailboat data sheet

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Sailboat Design and Construction

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Dudley Dix / Didi 26

- Add to quote

After 8 years of serious (& fun) consideration, I have finally set my heart on the boat I wish to build. :smile The Didi 26 A few years ago, I was interested in the Van de Stadt 34 ( VDS34 ), then just last year, Sam Devlins' Soooty Tern , and finally, Dudley Dix's DD26 I received the plans yesterday, and I could not be more thrilled! The actual build will not take place for years yet though, but what will happen is the distinct pleasure in planning this build out, right from the start, in a relaxed, enjoyable state-of-affairs. We are currently circumnavigating on our N62, and have our hands full with that. The DD26 plans will keep my powder dry while I'm at work, and remind me I have some sailing days ahead of me when our Voyage has come to it's natural end. I have never built anything before, but the desire to build one's own boat, and then sail it , has become an obsession for me,, & yes I know I need mental help. Perhaps some sailing folk out there would like to discuss the boat or the future build? Cheers.

Very good choice. Dudley is a friend of mine. I'm pretty it was me who gave him the nickname Didi.

Hi Bob, Great to see you here! I thought the "Didi" was/is a brilliant suggestion (Dudley Dix = DD = Didi) I thought it was clever. Mind you, it doesn't really take much to impress me. By the way, while you're here,,, I love your latest designs,,,very cool! & please keep all that yacht design info coming this way,,,food for the soul.

Buying plans is a fun activity but Get to building! woot woot yeah!

Andy, The DD looks like a more fun boat from a sailing prospective. Probably simpler and easier to build too. As much as I like Sam and staff, his plans are not as modern as i would like from a home build.....IMHO thank you marty

I too think that you made the right decision to switch to the Didi 26. I know Dudley pretty well. He is a very talented designer who seems to have a wonderful mix of being artful, inventive, practical, and technically knowledgeable and conscientious. He seems to have a real understanding of the materials that he employs in his designs, an clear understanding of amateur boat building which in part derives from the boats that he has built for himself. His designs tend to be very well thought out so as to produce designs which sail as well as and appear to be professionally constructed even though being very buildable by an amateur. The Didi 26 has always struck me a particularly clever design that fits a whole lot of boat into a small package. Personally, I really like the hull form and rig and think that is a very usable interior layout for a small boat. From talking with Dudley, I am convinced that this method of building should be pretty quick, assure a fair hull and decent shape control, and be suitable to a single amateur builder working on their own. My only concern, and I certainly could be very wrong on this, is that I suspect that the radius chine and the external center spline will require a quite a bit of fairing to achieve the very fair shapes that you see in the pictures of the completed boats. Of course, the designer in me always wants to tinker a bit. All things being equal, I would like probably want to stretch the boat a couple feet and make it a 28 footer, moving the forward berth and leading edge of the cabin aft by a foot or even 18" and increasing the flat area of the fore deck, and widening the forward berths and table. Personally I would want a little wider side decks, and take the 'crick in the neck penalty. I would probably split of the extra length into galley and settee. I might lose the bench seat between the halves of the galley and add a flip up seat at near the companionway stair. But then again, as some designers might have replied to my tinkering, if I wanted to make those kinds of changes to a design, I probably should have designed the boat myself, which I couldn't, at least not as competently as a real yacht designer, and as Dudley has done in this case. We will all be looking forward to seeing progress pictures. Good luck with the project, Jeff

Denise, Marty & Jeff, Thanks for your support and participation in this thread. Right now, I'm going through the various electronic drawings, while I'm working offshore Vietnam. Each time I open a DWG, a hundred individual questions spring to mind. I'm having fun chasing the answers down. Some decisions made so far: 1. I'm going to order this boat in Kit form. Best possible chance for a successful, timely, & ship-shape finish 2. WEST system epoxy 3. Considering synthetic standing rigging, like Coligo. < what's you thoughts on that?

A couple quick thoughts here: I am a big proponent of being organized in tracking information as you are building any project. One of the things that I recommend to anyone building a boat is to keep a log (preferably electronic but hand written works as well) with various sections in it. One of those sections should be questions and answers. As you develop questions, record them in the log, with references to the drawing if applicable. As you get answers, record them. I would draft a sequence of construction, although I think I recall that Dudley actually may provide that with the packet. But as you look at the sequence, it is helpful to try to insert milestones when items need to be purchased in order to have the tools, parts, and materials on site and ready when you get to that step. I would also carefully consider how and where you will store completed parts. (I once designed a trimaran for a fellow who built it in a ground floor apartment. The outer hulls were built first and stacked in a hallway to the kitchen with their beam set by the width of the hallway. The main hull was built last diagonally across the living room with the length and beam of the main hull designed with the longest length and width that could be rotated and taken out the door.) Similarly I would keep a log of 'open items'. This is intended to remind you of tasks that need to be completed. For instance, you might have time to prime and get a first coat of paint inside a locker, but never got the final coat(s) of paint on that area. You log that as an open item so you don't forget that still has to be done. Similarly, when I use bed hardware using sealants that are not butyl (I have become a big fan of butyl), I install the item and do not fully torque down the bolts until the sealant has cured. I would record in the log those pieces of hardware that need to have the fastenings given a final torqued, and then check them off as they are completed. I would keep a log of immediately needed items by which I mean items needed in the next week or two, thereby being able to group purchases to minimize shipping. I would also keep a longer term shopping list broken down by task. There is no point in buying things too early and have them lying about to be in the way, or get lost or damaged. But for example, you might have a line item in your long term shopping list which is something like 'installing the sink'. There you might indicate a milestone at which everything needs to be ordered and list all the materials, parts and tools required, such as the sink, hoses, faucet, pump, seacock, hose clamps, thread tape, sealants, hole saws, backing plates and everything else that you will need to do that task. You put that list together by thinking through each step of the process. This also is a chance to think about the tools that you are likely to need, and at what point in the construction would be best to do each piece of the work. In other words, in that example, it may make sense to install the seacock before installing the counter top, or before doing the final cabinet installation. Lastly I would keep all receipts, if only tossing them into a box for future filing. It is my understanding that some states will accept the proof of tax paid on purchased parts in lieu of paying a tax on the boat when you register it. You will need to check that for your state. As to your questions, I think that ordering the boat in kit form is a good idea. While it saves construction time, more importantly it insures that the boat is more precisely constructed. While I have used and basically like West System products, and the Gougeon Brothers are heroes of mine, the professionals that I know who have done glued wood and saturated wood construction professionally have been big fans of MAS epoxy products. The claim that the MAS products minimize the amine blush issues of most epoxies, and that MAS products are less likely to cause allergic reactions. This is second hand information, but it came from several people who I consider reliable sources. I have just looked into the synthetic rigging issue for tdw. Frankly, I only spoke with one rigger at this point, but he believes that synthetic rigging is in its infancy and still has issues with UV degradation and chafe that result in a much shorter reliable lifespan than SS wire. His position is that synthetic standing rigging only has a place on race boats. That may change as the materials are getting better but that was his point for now. Jeff

very very interestested in this thread, please post process and updates... I had dreams in my early twenties to build a "mini" dudley dix design and do some solo ocean racing...my thought was it was the only possible way I could ever race in such a way as to not break the bank I wonder if anyone has used his designs lately for such a purpose Like others have mentioned 26-28 ft is a perfectly reasonable first build length...I think over 30 and it would get daunting... please keep posting! good luck

where do you keep her when not in use Joms?

In the water some seasons over winter (they get ice in Sweden, but not too much/too often here in DK), otherwise under a tarp. The last years admittedly in a shed where the new owner is refitting her (cockpit + below). Have to admit that it's hard to get plywood in the same quality these days which is strange with better glues (but maybe not wood). /Joms

There are many many plywood T-Birds here in the lower salish sea area. I believe lots north of the border too. Alas, I have seen some, not well taken care of, painted etc, that need help! Could also be that the plywood from the 60's and 70's was not as well made as later versions too, glue is not as good.....similar to the synthetic shroud lines, or laminated sail cloth when it first came out a decade or two ago. Today the sail cloth will last as long, not get mold etc as some of the earlier stuff. Same could be said for dacron based sails too. Early stuff not as good as todays products. Have not heard the issue with Mas vs West. I know Sam Devlin ONLY uses Mas epoxy when building his boats. ANother builder I know of, will only use WEST systems. Sounds like both are similar, but in a couple of chemical differences that are still needed to get the product to cure. West has Chem a and B in resin, Mas has a and B in hardener. so they can not be mixed to cure correctly. I may be off a bit in description, but this is how I was told for simple practical purposes. I may be as right as I am wrong on this too. Kits also make the project go quicker. as I noticed with step day building a Glen-L 21CB model in the 70's. THe built a boat he had to do from a plan, including lofting etc. Took many many more years etc to finish. The two I built, at least had full size plans for parts, so made it easier than lofting....but still took some time. Not sure there is a right or wrong here, only opinions....... marty

Hi Jeff, Great post,,, - you got me thinking! I was already recording thoughts, ideas, addresses, etc into "Notes", which quickly had to be reorganized into an Excel spreadsheet. But after reading your post last night, I came to realize that perhaps Project Management software may be more appropriate. After 20 mins on google, I downloaded OmniPlan (I'm using a Mac), and created a new "DD26 Build Project". Over the next week I'll be populating the software with Tasks, Milestones, etc,,, I've only been using the program for 30 mins, and I'm finding it incredibly useful!,, so Cheers! It's going to be fun fleshing out the project in spare time, airport lounges, etc. I currently only have the electronic DWG files. The plans-package has been sent to Singapore and I'll pick it up in a few months when I pass through the office. This flexibility offered by Dudley, was another reason I chose DIX plans. Synthetic rigging is something that has really intrigued me ever since crawling all over HUGO BOSS in North Vancouver a few years ago. All the standing rigging, chain plates, tun-buckles, pad-eyes, etc, were all soft,,, I'm sure I left some drool on the deck. It looked so cool I have never forgot it. Perhaps by the time I actually get to build the boat, the UV & Chaffe properties may have improved. What ever is best at the time will be used. Hi Denise, I first became over-awed with Wood-Epoxy building looking through the online build pages of Covey Island ,,, boats like NINITA, & SIR EDMUND (oops,,,sorry drooling again). Soon after I became aware that building with plywood saturated in Epoxy is a bonafide, professional, modern technique. And after speaking with Sam Devlin about it, he confirmed it's strength, value and longevity. RM Yachts in France build with it exclusively. I'm sold. I'll most likely be making a doll of you, and you may experience some back-pain if I hear any more critical thoughts about plywood. :wink Question for today : Which keel? two keels are offered. The lift keel, which is standard (1' 8" - keel-up), and the fixed (5' 7"). I'm inclined to go for the fixed, purely for the simplicity. less = more. In every way, I want a simple boat, unless the benefits far outweigh the simplicity principle.

A few more quick thoughts, I am glad that you are organizing you information. It should really help with the frustration level during the build. I don't think that Dudley's list of tools is complete. In his book 'Boat Building' Howard Chapelle highly recommended having a comfortable 'worry chair' in all boat shops. This is the place to stop and think out how to get past those impossible moments. Hugo Boss is a very high budget disposable race boat whose life span is expected to be limited by the next 'best thing on earth' that happens to make it obsolete. It can afford to replace all its rigging after every leg of a race or after every major race. You are building a small simple boat. The keel answer is not an easy one. I have to think the lifting keel is more expensive and a little more complex to build. But if you live on the U.S. east coast, or somewhere like it, or if you plan to trailer the boat, then the lift keel is pretty compelling. I also think that the fixed keel has merit if the boat stays in the water year round in saltwater. Jeff

Here on the wet coast many tri's and cats were built with diagonal fir plywood.As most are livaboards (with wood stoves) rot has not been a major problem inspite of the less than high quality of the basic material. In Thailand boats made with better quality plywood have not been so successful. In spite of epoxy and reasonable care moisture and then insects tend to have their way with it. Although I've not personally built cold moulded hulls of veneer ,my observations have been that it is superior to ply..The veneer is easily (fir at least) obtained at a local mill or self band sawed here in the land of good wood so the loss of a bit of spiling on each strip would not be a killer and is the only fit needed while planking up.

Hi, I have built a Didi 26liftkeel in 2002-2003, it is a fun boat to sail, like a big dingy, very fast, I believe mine is the fastest 26' sailboat in South Africa. I painted the inside with a plascon paint after epoxy, it is clean airy and very dry, no moisture can enter the wood or ply anywhere. Ply epoxy in my opinion is the most durable production method and material, no fatigue, therefore my 13 year old boat is basically brand new. I broke the mast and have now replaced it with a selfbuilt carbon fibre mast which is much stiffer and lighter than the aluminium mast. Regards Philip Malan

Thanks for the info Philip. Always good to hear from a fellow Didi "Bro". (although I can certainly not be included in that euphenism, as I've not done **** towards the build yet). I continue to think about my future (in sailing) as my wife and I circumnavigate the globe on our Nordhavn 62 . But,,, as I we progress through the South Pacific Islands, I'm being subjected to the best sailing eye-candy I have ever seen! My opinions on what is going to serve my future needs are changing [again :eek] I do believe the DD26 will serve my needs when the time comes,,, but the Trimarans have also caught my attention again and who knows where this will end?? :svoilier:

Hello Sailnet team, Just wanted to check-in, and keep this thread alive, as it's been a couple of years. 😮 No tangible progress has been made, but I continue to plan. Mostly this occurs in spurts of time, only to be put down again as our travels (and my job) take precedence. We are now in Australia with our boat, and hopefully should get into Indonesia and Singapore by years end. The time is flying by! Another purpose of this update to see if any more DIX Builders are out there, and if they could offer any advice from their build. ciao.

- ?

- 173.8K members

Top Contributors this Month

March / April Issue No. 297 Preview Now

Sailboats - Racing

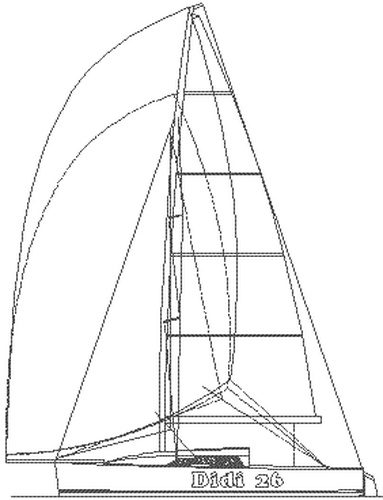

The Didi 26 is a radius chine plywood cruiser racer with options of lifting or fixed keel and tall or short fractional sloop rigs. She has compact but comfortable accommdation for 4 people in racing or cruising configurations. The racing configuration has a long trench cockpit with two quarter berths below and the racing configuration has a short cockpit with wide bridgedeck and transverse double berth below. Accommodation also includes a small galley and enclosed heads. Powering is with an outboard or small saildrive diesel. Keel bulb options are a side profile that is easily cast by an amateur or a more streamlined beavertail bulb that is more suited to casting by professionals. See the Didi 23 for a smaller version of this concept.

Design Specifications

1340-1272 N Great Neck Rd #343 Virginia Beach VA 23454 Phone: (757)962-9273

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from plans & kits.

Roberts Spray 36

THALAS 16'

From the community.

1899 Bristol Channel Pilot Cutter Carlotta

Original 55’ pilot cutter in superb condition following extensive award-winning restorations in C

20' Rambler, Harry Bryant Offsets, $26,500.

Built in 2015 with custom cabin. Beam 6ft 9in. Cedar on white oak frame.

Nordic Folkboat

1952 Folkboat built in Copenhagen and imported to San Francisco. March 2023 survey available.

1955 Lyman Runabout 20ft

1955 Lyman. Great boat loved the memories. Bought it for my wedding and had it restored.

- Row boat plans

- Sailboat plans

- Power boat plans

Didi 26 by Dudley Dix

Radius chine plywood trailer-sailer.

URL: http://www.dixdesign.com/26didi.htm

Description:

Affordable performance

- Economy of plywood

- Radius chine hull, stitch & glue cabintop

- Round bilge from sheet material

- Within abilities of amateur builders

- Easily handled fractional rig

- Two rig options

- Lifting or fixed keel options

- High performance racing for Dad

- Comfortable weekending for the family

- Too big for you? See the Didi 23

A high performance trailer sailer which you can build for yourself from plans, this design was drawn as a little sister to the DIDI 38 which I designed and built for myself in 1994/95, and the more recent DIDI 34 , Didi MG30 and the Didi Mini , to the Mini 6.5 rule. Most recent addition to this range is the Didi 23

Simple Plywood Construction

It employs the same basic radius chine plywood construction technique, scaled down to suit the smaller boat but takes it a step further into the plywood precut kit concept. The small size of the vessel permits the elimination of the laminated floors needed to support the keel loads in the larger boats. Keel loads are, instead, carried by bulkheads and the structure of the keel box. All of these parts are plywood and epoxy filleted together, making for simplified construction.

The backbone is also of plywood, on edge, slotted through the bulkheads as a self-jigging eggcrate arrangement to assist setting up the framework. It extends from the stemhead to the transom and has large radius structural fillets to tie it into the hull skin.

Assembly of the hull follows the principles of model aeroplane construction, with stringers slotted into the bulkheads for attachment of the skin. The hull skin is single skin plywood to the sides and bottom and the radius is done in two layers.

Deck construction is done in a similar way, all in single skin plywood. The cabintop is designed with a multi-chine skin and is assembled over the bulkheads by the stitch and glue method for a strong and lightweight structure.

Suggested plywood for construction is Israeli Gaboon ply throughout. Epoxy coated and painted inside and out to hull and deck, a good standard of finish is achievable with little or no fairing aside from forming fillets at internal angles. The addition of a layer of glass fabric to the outside will give increased resistance to knocks but will add weight and require fairing, thereby adding a fair amount to construction time and cost.

Two Keel Options

The standard keel is a vertical dropkeel with a 400kg bulb on the end of the high aspect foil. It is lifted by a tackle system led to a cabintop winch. Fully retracted, the bulb remains below the hull, with a draft of 0,5m. Sailing draft is 1.7m. The bulb can be done in either a simple vertical sided foil section for owner casting or a torpedo shape for professional casting. The rudder has a fixed blade and is transom hung on conventional pintles.

We have now added a fixed keel option as well. This uses a hollow aluminum casing for the foil, constructed over tubular inner framing and fitted with the same bulb options as the lifting keel. The casing is bolted through the hull bottom to an aluminum support box, which is bolted to the internal structure of the hull.

The cockpit and bridgedeck together are 3m long, giving plenty of space for working the boat while racing or socialising or sunning when cruising. The only winches on the boat are a pair of 16:1 self-tailers on the cabintop. They are located where they can be operated from the companionway, the bridgedeck or the weather rail. They are oversized to ease keel handling so sail trimming will be a cinch.

Easily Handled Rig

The rig is deck stepped on a hinged foot, fractional with two sets of swept spreaders. This makes her easy to handle with a small crew whether racing or cruising. Shrouds go to outboard chainplates to minimise rig loadings. The working headsails are non-overlapping and sheet inside the shrouds. A light drifter can be flown outside the shrouds and sheets to the spinnaker blocks on the quarters.

The fractional and masthead spinnakers are asymmetric, set on a retractable pole on the foredeck. The inboard end is fitted on a radiused transverse track to allow the outboard end to be projected up to weather for sailing at deeper angles. Extension and retraction of the pole can be done from either rail, with the pole retracting to whichever side is convenient at the time.

Cruising Rig Option

- Detuned rig for cruising or stronger wind areas

- Fully inter-changeable with tall rig

- Mainsail excl roach = 17.55sq.m (189sq.ft)

- Sail Area Main + Jib = 29.01sq.m (312sq.ft)

- P = 9.00m (29'6")

Weekending or racing accommodation

Down below she has sitting headroom throughout. She has a small galley with two-plate cooker, sink, icebox and a seat for the cook. The dropkeel casing forms one side of the enclosed heads compartment, which includes a bin type wet locker. The dinette table drops to convert the pair of single V-berths into a double. The prime berth in the boat is a large transverse double under the bridgedeck, great for use on moorings or at anchor. Aft is loads of storage space accessible from the berth.

Alternatives on the basic design are already available. A longer cockpit has been drawn, more suitable for the gofast racer. Down below it goes along with a pair of quarter berths, also more suited to the hairy chested racer and use under sail. Both layouts are included in the stock plan package.

Auxiliary power is provided by an outboard clamped to the transom or saildrive inboard.

As shown here, she is in cruiser/racer configuration, with lightship displacement of approximately 1000kg and cruising displacement of 1500kg. In stripped racing configuration, she will be about 200kg lighter. Although not designed to their limits, she was drawn to fit within the class rules of the now defuct Australian Level Class 800 Association, a set of rules that was formulated to give boat-for-boat racing for trailer sailers.

Full Size Patterns

Included in the stock plan package are full size patterns of the backbone and various other components, plotted onto mylar film on our large format inkjet roll plotter. Bulkhead shapes are simple and easily set out from clear diagrams, the setting out taking about 2 to 3 hours per bulkhead. For those who would prefer to have full size patterns for the bulkheads, we can also supply them as an optional extra. Choose the building option to suit your own needs. Whichever route you choose, we will be available to assist with advice if any problems arise.

Boats about same size as Didi 26

Questions? Suggestions? Contact us at: [email protected]

Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

Didi 26 is a 26 ′ 2 ″ / 8 m monohull sailboat designed by Dudley Dix and built by Mboats International starting in 1997.

Rig and Sails

Auxilary power, accomodations, calculations.

The theoretical maximum speed that a displacement hull can move efficiently through the water is determined by it's waterline length and displacement. It may be unable to reach this speed if the boat is underpowered or heavily loaded, though it may exceed this speed given enough power. Read more.

Classic hull speed formula:

Hull Speed = 1.34 x √LWL

Max Speed/Length ratio = 8.26 ÷ Displacement/Length ratio .311 Hull Speed = Max Speed/Length ratio x √LWL

Sail Area / Displacement Ratio

A measure of the power of the sails relative to the weight of the boat. The higher the number, the higher the performance, but the harder the boat will be to handle. This ratio is a "non-dimensional" value that facilitates comparisons between boats of different types and sizes. Read more.

SA/D = SA ÷ (D ÷ 64) 2/3

- SA : Sail area in square feet, derived by adding the mainsail area to 100% of the foretriangle area (the lateral area above the deck between the mast and the forestay).

- D : Displacement in pounds.

Ballast / Displacement Ratio

A measure of the stability of a boat's hull that suggests how well a monohull will stand up to its sails. The ballast displacement ratio indicates how much of the weight of a boat is placed for maximum stability against capsizing and is an indicator of stiffness and resistance to capsize.

Ballast / Displacement * 100

Displacement / Length Ratio

A measure of the weight of the boat relative to it's length at the waterline. The higher a boat’s D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more.

D/L = (D ÷ 2240) ÷ (0.01 x LWL)³

- D: Displacement of the boat in pounds.

- LWL: Waterline length in feet

Comfort Ratio

This ratio assess how quickly and abruptly a boat’s hull reacts to waves in a significant seaway, these being the elements of a boat’s motion most likely to cause seasickness. Read more.

Comfort ratio = D ÷ (.65 x (.7 LWL + .3 LOA) x Beam 1.33 )

- D: Displacement of the boat in pounds

- LOA: Length overall in feet

- Beam: Width of boat at the widest point in feet

Capsize Screening Formula

This formula attempts to indicate whether a given boat might be too wide and light to readily right itself after being overturned in extreme conditions. Read more.

CSV = Beam ÷ ³√(D / 64)

From designers drawings. Plans offered, completed boat or in kit form. Shorter rig: I: 9.08m J: 2.7m P: 9.0m E: 3.9m ISP: 9.71m

Embed this page on your own website by copying and pasting this code.

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

- .UNDEFINED BUILDER

Didi 26 - .UNDEFINED BUILDER / STW003422

Dudley Dix Yacht Design

News about what is happening at Dudley Dix Yacht Design, from new designs to boat shows or anything else of interest to our followers.

Thursday, September 1, 2016

Didi 26 opportunity, no comments:, post a comment.

Welcome to another boat building project. This site will take you along the different steps of building a 26 foot racing sailboat. Sport Boats as they are now called are very expensive and out of reach for many people. The DIDI 26 is one of the best design available for the amateur builder. It is a light boat with large sails and a bulb keel. Dudley Dix did an excellent job with his DIDI line of boats. There are many projects of other amateur builders . The DIDI 26 offers good performance and provide good accommodation for the weekend cruise. Being a trailerable boat makes it extremely versatile for either racing venues and cruising destinations.

I will continue updating the site and discuss the boat's sailing performance and its other qualities. Click on some of the pictures for better clarity. Any questions or comments, email: Marc Beaupre.

Building a Sport Boat DIDI 26

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Discussion in ' Sailboats ' started by J.D.Hogg , Jun 27, 2006 .

J.D.Hogg Junior Member

I've come to really like the didi 26 from Dudley Dix. Does anybody have any knowledge or experience with this design? Is there anything similar, either production boats or plans(shallow with board up, fast, comfortable)? Preferably cheap.

DGreenwood Senior Member

http://www.devlinboat.com/ Here is another designer you might check. You would be hard pressed to beat Dudleys design work for simplicity and clarity. His plans are very complete and he has good support. ( very important) If you are after speed he is a racer himself and appreciates an agile boat. I have not built the 26 myself, but I am a builder and have seen his plans and talked to him. Good solid design work with realistic advice on costs and hours. Listen to him carefully and you will not end up with a rotting lawn ornament that you can't finish.

Wellydeckhand Previous Member

Dix Dudley is a good guy with clear no nonsense explaination....... his plan is resonable anyway, why copy if you can get good stuff and advise from him. Slap me later if I am wrong............. WDH

Yes his reputation is reassuring as well as the many completed projects, but I'm not yet sure I can afford to build. Moving to the coast soon, Manteo area probably, to get more experience and have better access to resources, but I'm doing my research (dreaming) now.

mojounwin Junior Member

Could also try Barry Colson. He has a 26 ft performancer cruiser. Should be in a simlar performance range as Didi but has more interior volume and head room. Although once your building your own boat you can adjust head room to suit yourself. I'm currently building one http://mojounwin.tripod.com/ Check out Barry's webite http://www.colsonyachtdesign.com/ Cheers Mike

Thanks. That looks like it will be a nice boat soon. How is the mast stepped?

G'day JD, The mast is stepped on the cabin roof with the front edge of centreboard case being the compression post. It is of course a lifting keel. As you can see the construction is strip plank so a little different to Didi's method. I wonder what the pros and cons of strip planking vs cold moulding are? Cheers Mike

Milan Senior Member

mojounwin said: Could also try Barry Colson. He has a 26 ft performancer cruiser. Should be in a simlar performance range as Didi but has more interior volume and head room. Although once your building your own boat you can adjust head room to suit yourself. I'm currently building one http://mojounwin.tripod.com/ Check out Barry's webite http://www.colsonyachtdesign.com/ Cheers Mike Click to expand...

Raggi_Thor Nav.arch/Designer/Builder

Milan said: ....One of the builders of Diidi 26 rised the deck and cabin for about 20 cm to get a bit higher interior for cruising. He has nice informative site, I'll try to find the link, I have it somewhere in favorites… Click to expand...

- Advertisement:

Raggi_Thor said: Did you mean Erik Naese in Finland? http://www.naese.com/ Click to expand...

- No, create an account now.

- Yes, my password is:

- Forgot your password?

- Recent Photos

- The Commons

- Flickr Galleries

- Camera Finder

- Flickr Blog

- The Print Shop

- Prints & Wall Art

- Photo Books

- Stats Dashboard

- Get Auto-Uploadr

- Plans & Kits

- Plans by designer

- Plywood Monohull Sailboats

Didi 23 Plans

Write a review.

- Create New Wish List

Description

Additional information.

Compact performer

~ Based on Didi 26

~ Economy of plywood

~ Radius chine hull, stitch & glue cabintop

~ Round bilge from sheet material

~ Within abilities of amateur builders

~ Easily handled fractional rig

~ Two rig options

~ High performance racing for Dad

~ Comfortable weekending for the family

The Didi 26 is our most popular small keelboat design, with well over 100 plan sets sold and launchings occurring regularly. Over the years that we have been selling it, I have been asked often if we have a similar concept available in a smaller size. Now we can offer just that, in the new Didi 23. This is a contracted version of her bigger sister but maintains beam and height, so that the interior retains comfort and functionality for weekending.

The result is a boat that is 12.5% shorter and lighter than the Didi 26 and with the rig reduced proportionately. This should give a cost saving of about 15%. It will also be easier to launch and retrieve because of reduced weight.

Simple Plywood Construction

Construction detailing and scantlings are the same as for the Didi 26, so the Didi 23 will be a robust little boat. Keel loads are carried by bulkheads and the structure of the keel box. The backbone is also of plywood, on edge, slotted through the bulkheads as a self-jigging eggcrate arrangement to assist setting up the framework. All of these parts are plywood and epoxy filleted together, making for simplified construction.

Assembly of the hull follows the principles of model aeroplane construction, with stringers slotted into the bulkheads for attachment of the skin. The hull skin is single skin plywood to the sides and bottom and the radius is done in two layers.

Deck construction is done in a similar way, all in single skin plywood. The cabintop is designed with a multi-chine skin and is assembled over the bulkheads by the stitch and glue method for a strong and lightweight structure.

Suggested plywood for construction is okoume (gaboon) ply throughout. Epoxy coated and painted inside and out to hull and deck, a good standard of finish is achievable with little or no fairing aside from forming fillets at internal angles. The addition of a layer of glass fabric to the outside will give increased resistance to knocks but will add weight and require fairing, thereby adding a fair amount to construction time and cost.

Two Keel Options

The standard keel is a vertical dropkeel with a 350kg bulb on the end of the high aspect foil. It is lifted by a tackle system led to a cabintop winch. Fully retracted, the bulb remains below the hull, with a draft of 0,5m. Sailing draft is 1.7m. The bulb can be done in either a simple vertical sided foil section for owner casting or a torpedo shape for professional casting.

We have a fixed keel option as well. This uses a hollow aluminum casing for the foil, constructed over tubular inner framing and fitted with the same bulb options as the lifting keel. The casing is bolted through the hull bottom to an aluminum support box, which is bolted to the internal structure of the hull.

Rudder options are a fixed blade or a rudder box with daggerboard blade. Both are transom hung on conventional pintles.

The cockpit and bridgedeck together are 2.6m long, giving plenty of space for working the boat while racing or socialising or sunning when cruising. The only winches on the boat are a pair of 16:1 self-tailers on the cabintop. They are located where they can be operated from the companionway, the bridgedeck or the weather rail. They are oversized to ease keel handling so sail trimming will be a cinch.

Easily Handled Rig

The rig is deck stepped on a hinged foot, fractional with two sets of swept spreaders. This makes her easy to handle with a small crew whether racing or cruising. Shrouds go to outboard chainplates to minimise rig loadings. The working headsails are non-overlapping and sheet inside the shrouds. A light drifter can be flown outside the shrouds and sheets to the spinnaker blocks on the quarters.

The fractional and masthead spinnakers are asymmetric, set on a retractable pole on the foredeck. The inboard end is fitted on a radiused transverse track to allow the outboard end to be projected up to weather for sailing at deeper angles. Extension and retraction of the pole can be done from either rail, with the pole retracting to whichever side is convenient at the time.

Weekending or racing accommodation

Down below she has sitting headroom throughout, with two layout alternatives. She has a small galley with two-plate cooker, sink, icebox and a seat for the cook. The dropkeel casing forms one side of the enclosed heads compartment, which includes a bin type wet locker. The dinette table drops to convert the pair of single V-berths into a double. The prime berth in the short cockpit version is a large transverse double under the bridgedeck, great for use on moorings or at anchor. Aft is loads of storage space accessible from the berth.

The long cockpit version has identical accommodation forward of the cockpit but replaces the large transverse double berth with two conventional quarter berths.

Auxiliary power is provided by an outboard clamped to the transom. An internal saildrive option is also included on the drawings.

Full Size Patterns

Included in the stock plan package are full size patterns of the backbone and various other components, plotted onto Mylar film on our large format inkjet roll plotters. Bulkhead shapes are simple and easily set out from clear diagrams, the setting out taking about 2 to 3 hours per bulkhead. For those who would prefer to have full size patterns for the bulkheads, we can also supply them for an additional 50% on the stock plan price. Choose the building option to suit your own needs. Whichever route you choose, we will be available to assist with advice if any problems arise.

Cruising Rig Option

~ Detuned rig for cruising or stronger wind areas

~ Fully inter-changeable with tall rig

~ Mainsail excl roach = 13.44sq. m (145sq. ft)

~ Sail Area Main + Jib = 22.21sq. m (239sq. ft)

~ SA/Displ = 18.84

~ SA/WS = 1.84

~ P = 7.88m (25'10")

Bill Of Materials

CHIPBOARD (for setting out bulkheads if building from offsets) 1,83x2,74m (6'x9') 16mm (5/8") - 1 sheet MARINE PLYWOOD 1,22x2,44m (4'x8') (preferably Gaboon or Okoume plywood) 4.5mm (3/16") - 6 sheets (use 4mm if 4.5mm is not available) 6mm (1/4") - 4 sheets 9mm (3/8") - 20 sheets 12mm (1/2") - 6 sheets SAWN PINE (for building stocks etc) 25X125mm (1"x5") (rails) - 18m 50x50mm (2"x2") (bulkhead legs) - 15m 75x75mm (3"x3") (posts) - 8m CEDAR or similar, selected, free of knots, shakes fractures etc 12x22mm (1/2"x 7/8") (washboard slides) - 5m (17') 22x22mm (7/8"x7/8") (radius stringers, deck stringers, joinery cleats) - 89m (292') 22x22mm (7/8"x7/8") Triangular fillets (keel box, cockpit) - 16m (53') 22x32mm (7/8"x1 1/4") (bulkhead cleats) - 4m (14') 22x44mm (7/8"x1 3/4") (berth bearers, beams, hatch slides) - 19m (63') 22x64mm (7/8"x2 1/2") (sheer clamps, hatch frame) - 20m (66') 22x100mm (7/8"x4") (companion ladder) - 4m (14') 23x32mm (29/32"x1 1/4") (tangent stringers) - 34m (112') 32x32mm (1 1/4"x1 1/4") (side & bottom stringers) - 31m (102') 44x44mm (1 3/4"x1 3/4") Triangular fillet (foot braces) - 5m (17') SAPELE MAHOGANY or similar dense hardwood 69x69mm (2 3/4"x2 3/4") (keel foil) - 17m (56') RESIN & GLASS (for coatings and reinforced areas) Epoxy resin (low viscosity 100% solids) - 50kg (110lb) 50mm (2") Wide woven tape - 70m (230') 75mm (3") Wide tape - 14m (46') 300g/sq.m (9oz/sq.yd) Woven roving - 2sq.m (22sq.ft) 450g/sq.m Biaxial fabric - 9sq.m (87sq.ft)

This design has metric and imperial measurements.

Radius Chine Plywood Trailer-sailer

LOA 7.00m (23'0") LWL 6.61m (21'8") Beam 2.47m (8'1") Draft lift keel 0.5/1.7m (1'8"/5'7") Draft fixed keel 1.7m (5'7") Displ to DWL 1300kg (2865lb) Displ light 875kg (1929lb) Ballast 380kg (838lb)

Related Products

Didi Mini Plans

Didi Mini Mk3 Plans

Didi cruise mini plans.

Kalostyn Plans

IMAGES

VIDEO

COMMENTS

DIDI 26. Save to Favorites . Beta Marine. BOTH. US IMPERIAL. METRIC. Sailboat Specifications Definitions ... 1997), states that a boat with a BN of less than 1.3 will be slow in light winds. A boat with a BN of 1.6 or greater is a boat that will be reefed often in offshore cruising. Derek Harvey, "Multihulls for Cruising and Racing ...

The prime berth in the boat is a large transverse double under the bridgedeck, great for use on moorings or at anchor. Aft is loads of storage space accessible from the berth. ... Testimonial from Eirik Naese - Owner/builder of a modified Didi 26 in Finland. "Regarding building the design is very smart and building (I am an amateur) has been a ...

The Didi 26 is a 26.25ft fractional sloop designed by Dudley Dix and built in carbon fiber or composite by Mboats International (NOR) since 1997. The Didi 26 is an ultralight sailboat which is a very high performer. It is very stable / stiff and has a low righting capability if capsized. It is best suited as a racing boat.

The Didi 26. A few years ago, I was interested in the Van de Stadt 34 ( VDS34 ), then just last year, Sam Devlins' Soooty Tern, and finally, Dudley Dix's DD26. I received the plans yesterday, and I could not be more thrilled! The actual build will not take place for years yet though, but what will happen is the distinct pleasure in planning ...

Didi 26. The Didi 26 is a radius chine plywood cruiser racer with options of lifting or fixed keel and tall or short fractional sloop rigs. She has compact but comfortable accommdation for 4 people in racing or cruising configurations. The racing configuration has a long trench cockpit with two quarter berths below and the racing configuration ...

Didi 26 by Dudley Dix (LOA: 8 m). Radius chine plywood trailer-sailer. Specs, plans, building logs, photo and video gallery. ... It employs the same basic radius chine plywood construction technique, scaled down to suit the smaller boat but takes it a step further into the plywood precut kit concept. The small size of the vessel permits the ...

Would be a fun family-able boat, especially nice with the small jib and large main if you are on the river. There aren't many used boats available like it, so probably worth building the 26. The trailerable part is fun. I've been thinking about a quick family boat myself, and have been getting more serious about an F24 tri or the like.

Didi 26 is a 26′ 2″ / 8 m monohull sailboat designed by Dudley Dix and built by Mboats International starting in 1997. ... The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more. Formula. D/L = (D ÷ 2240) ÷ (0.01 x LWL)³ D: Displacement of the boat in pounds. LWL: Waterline ...

Marc Beaupre launched his aluminum version of our Didi 26 in June 2005, in British Columbia, Canada. He did the conversion to aluminum himself. Marc said "We have sailed the boat a few times and I am totally amazed of how well balanced she is. There is a very slight weather helm. She is also very fast. Thank you so much for such a nice design."

DIDI 26 CONSTRUCTION PHOTOS Page 1 - Bulkheads & stocks Page 2 - Hull stringers Page 3 - Hull skin Page 4 - Deck skin Page 5 - Keel foil ... This was to add more safety factor to cater for navigation or boat-handling errors that could result in groundings or serious knockdowns. The changes have added structure in areas that would be under ...

The Didi 26 produced by the builder .UNDEFINED BUILDER and designed by Dudley Dix Yacht Design, is a cabin cruiser for cruising/regatta, rigged Sloop ... read more on Sailing The Web, the ultimate sailboat database

Building a Didi 26 radius chine plywood-epoxy high performance trailer sailer designed by Dudley Dix. The design is modified a little by the amateur owner/builder Eirik Naese, in order to make it more cruising oriented. ... Date Building a Didi 26 was added to the Boat Design Directory: 13-Nov-2000 Number of Visitors who visited Building a Didi ...

Her price is CAD5500. She can't be built to this stage for that price, so appears to offer a new owner a fast leg-up on getting a Didi 26 onto the water. As usual, purchase of a boat like this should not be concluded without an in-depth inspection by an experienced boatbuilder or surveyor.

The DIDI 26 is one of the best design available for the amateur builder. It is a light boat with large sails and a bulb keel. Dudley Dix did an excellent job with his DIDI line of boats. There are many projects of other amateur builders . The DIDI 26 offers good performance and provide good accommodation for the weekend cruise.

Onboard video of the Didi 26 "Triton" sailing at 18 knots while racing on Table Bay in Cape Town. The log shows 10.9 knots but was not working, it was 18 knots by GPS.

Didi 26. Discussion in 'Sailboats' started by J.D.Hogg, Jun 27, 2006. Joined: May 2006 Posts: 49 Likes: 0, Points: 0, Legacy Rep: 10 Location: Richmond, Virginia J.D.Hogg Junior Member. I've come to really like the didi 26 from Dudley Dix. Does anybody have any knowledge or experience with this design?

Didi 26 radius chine plywood racer/cruiser trailer sailer. Options of tall or short rig and fixed or lifting keels. 78 photos · 1 video · 10,373 views. By: Dudley Dix. did26rig by Dudley Dix. did26rig-short by Dudley Dix. did26aco by Dudley Dix. did26sec by Dudley Dix. bulkheads by Dudley Dix.

First, we have transplanted the lifting keel of the Didi 26 trailer sailer into the hull. This keel has a glass covered hardwood foil and lead beavertail ballast bulb for efficiency. ... Sail area (main + jib) 29.35sq.m (316sq.ft) Sail Area/Wetted Surface 2.45. Sail Area/Displ 24.9. Displ/length 135. Prismatic coef .54. Block coef .44. Fineness ...

Didi 26 "Haylaz" sailing in Turkey. For more info go to http://dixdesign.com/26didi.htm .

The Didi 26 is our most popular small keelboat design, with well over 100 plan sets sold and launchings occurring regularly. ... Construction detailing and scantlings are the same as for the Didi 26, so the Didi 23 will be a robust little boat. Keel loads are carried by bulkheads and the structure of the keel box. The backbone is also of ...

Internations ex-pats at Marmara sea, sailing with the Didi 26 S/Y Haylaz sailing boat.www.kitsandboats.comwww.ertugyacht.comwww.3Line.com.tr

Homebuild Didi 26 sailboat by Sacit Ertug at the 2011 aniversary race for Dardanelles War2011 Canakkale Sehitleri yarisi

The result is a boat that is 12.5% shorter and lighter than the Didi 26 and with the rig reduced proportionately. This should give a cost saving of about 15%. ... Construction detailing and scantlings are the same as for the Didi 26, so the Didi 23 will be a robust little boat. Keel loads are carried by bulkheads and the structure of the keel ...