Building a yacht: superyacht construction process

Building Your Own Yacht Process, Superyacht Construction, Marina Architecture, Buildings

Building A Yacht Of Your Own

29 June 2020

Building A Yacht Of Your Own – What Is The Process?

29th June 2020 – Imagine building your very own superyacht, designed to your specific needs, tastes and desires. While building a yacht is more complex and may take years of research and planning than buying new yachts or motor boats for sale , it will also be as exciting and fulfilling as all the future journeys you will enjoy onboard it. But where to start? How do you go about tackling your very own superyacht construction to realise your own new build yacht ?

A Look Into Building A Yacht – How To Go About It?

Every custom-built superyacht starts with a vision, based on personal preference and taste, and the type of onboard lifestyle desired. What kind of cruising is required, which luxuries would you like onboard, for example a spa or swimming pool, and is a helipad necessary? With a world of options to consider, the future owner will naturally be the driving force behind their own superyacht construction, but to ensure the smoothest journey possible, they will need a team of experts to work on such a big project.

The Superyacht Construction Team – Key Players

The process of building a yacht will involve a great number of decisions, so having the support of a knowledgeable and experienced team is imperative.

The owner may wish to engage a respected yacht broker to build the team, knowing that they spend a significant amount of time liaising with key players across the yachting industry. They will also ensure the owner’s interests are protected, while providing access to some of the world’s most exciting and ground-breaking yacht builders.

Key players will include a professional yacht designer and naval architect, who will be chosen depending on the type and style of superyacht construction required. An engineer will be engaged for detailed design, and an interior designer will need to work in conjunction with both, designing the layout and cabin suites to meet the owner’s requirements.

You will also need to engage an owner’s representative to oversee the superyacht construction on your behalf. In some cases, the vessel’s future captain may take this role, and offer guidance and reassurance throughout the design and construction stages. They will also negotiate the most favourable terms and protect the buyer’s interests.

Dedicated Project Management Team for Building A Yacht

In addition, when building a yacht, a project management team will be engaged to oversee the day-to-day details, from coordinating the production of the technical specs to running a tender process with shipyards, through to price and contract negotiations.

As the superyacht construction progresses, they will act as the go-between for the different parties involved, and ensure that every element of the project is handled efficiently and to the highest standard. Some will work full time, while others with short-term specialisms may be engaged during particular phases of the build.

The Shipyard – The Heart of Superyacht Construction

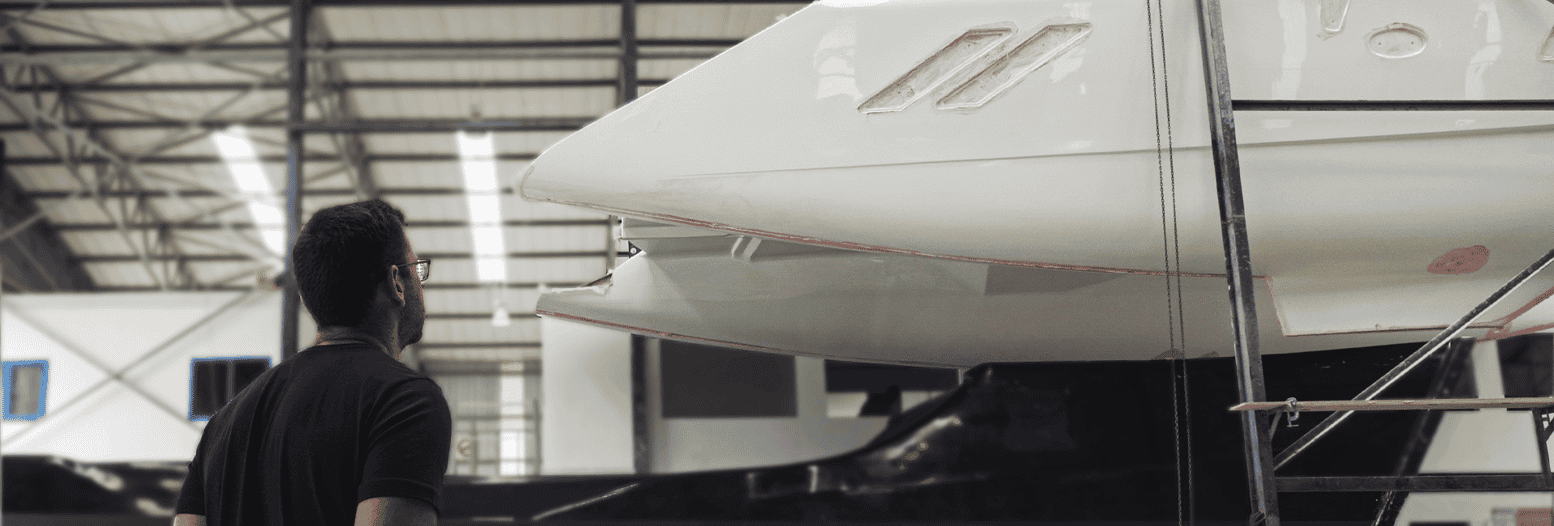

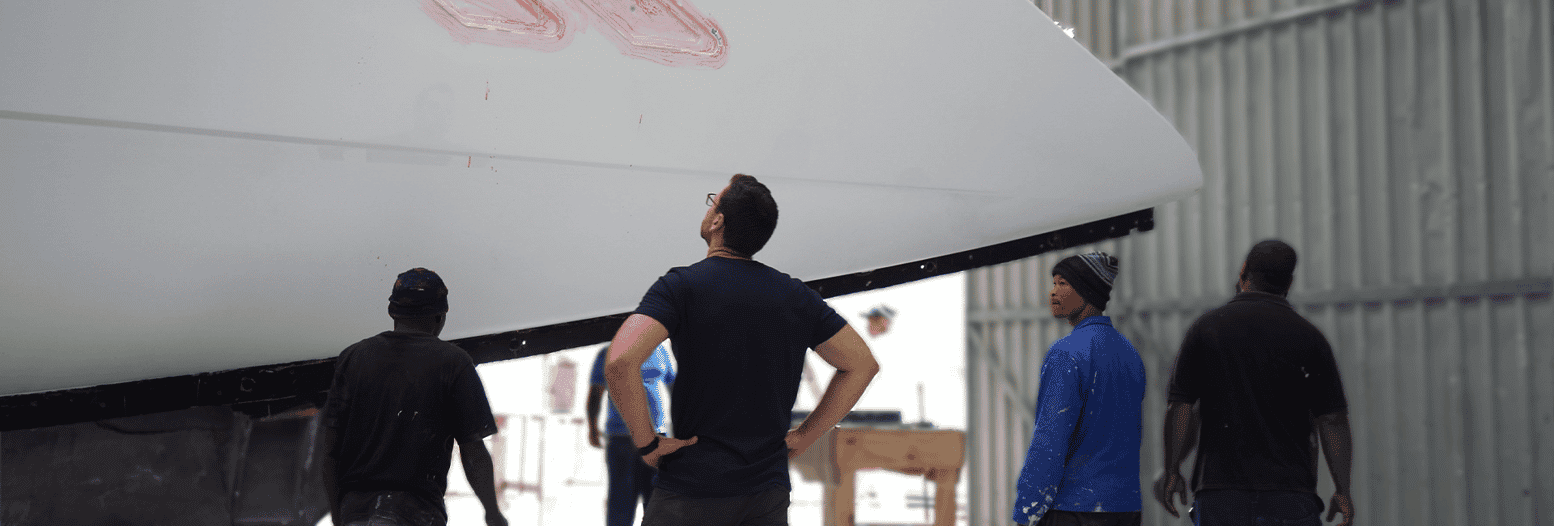

The shipyard is where the superyacht construction finally gets underway, using its state-of-the-art equipment, experienced representatives and skilled craftsmen. Involved from the design stage, the shipyard will work closely with the project manager and/or owner’s representative, as well as both the interior and exterior designers to ensure that the end result not only fits the owner’s specifications, but also meets marine legislation and technical requirements.

With the complexities of changing international legislation, it is the project manager’s job to liaise with all parties to ensure that everyone is kept up-to-date on any necessary design changes or alterations.

The Legalities

An experienced team of maritime lawyers will be engaged to write contracts that set the guidelines for the build and protect the buyer from technical issues and delays. Detailed build milestones and payment schedules will also be drawn up. On the vessel’s completion, lawyers will advise on flag registration and handle all other regulatory aspects, as well as the operational setup and ownership structure.

Sea Trial – Exciting & Essential

After successfully building a yacht to the owner’s requirements, surveyors will be needed to establish the vessel’s performance and seaworthiness during a sea trial, an essential part of the construction of any new superyacht. During a sea trial, all parties work together to fine-tune the systems and iron out any issues.

Typically a sea trial takes place on open water and can last several days. The yacht’s crew will usually be engaged six months to a year before completion, and will play an integral part in putting the superyacht through its paces. These will include testing the vessel’s speed, manoeuvrability, equipment and safety features.

Also present onboard will be technical representatives from the shipyard as well as those from any major systems used, the owner’s representative, and governing and certification officials.

The certification officials are employed by a classification society, a third-party service that assures the quality of construction – the nautical equivalent of an MOT. The classification certificate they issue will be required for registering the yacht and obtaining marine insurance. It may also be required before entering certain ports or waterways, and will be of interest to future charterers and potential buyers.

Owner’s Supply

Most custom yacht contracts do not include what is known as the Owner’s Supply – any additional items the owner desires after building a yacht, such as tenders and water toys, audio-visual and entertainment systems, loose furniture, tableware, and decorative objects. Each will need to be procured, insured, managed and integrated into the yacht itself before final delivery.

Building A Yacht – The Final Delivery

At last the big day arrives: the superyacht is delivered to her delighted owner, and launched with much fanfare and celebration. The proud new owner is now free to enjoy their very own, truly unique superyacht out on the open water.

The process of building a yacht might be a complex, long-term commitment and a major investment, but a custom-built vessel is limited only by the owner’s imagination. For all the effort and work involved, there can be nothing more thrilling than realising a new build yacht that fulfils all your dreams and requirements, enjoying it with family and friends for many years to come.

Boat Design Articles

Guide to best European shipyards

New Yachts 2018

Yachtsman’s House on the Isle of Wight

Marina Architecture

Building a Superyacht

Boathouse Articles

Comments / photos for the Building A Yacht Of Your Own – What Is The Process? page welcome

Building a Yacht: Top Things to Know About the Yacht-building Process

Owning a yacht and having the freedom to explore our beautiful planet by boat is a dream shared by many. But building a yacht is a long and complex process. Should you be one of the fortunate ocean explorers who will get the opportunity to have your semi custom yacht built from scratch, you will undoubtedly require the services of an experienced and knowledgeable boat builder.

Knysna Yacht Company is a boutique yacht-building company based in the picturesque coastal town of Knysna on South Africa's world-famous Garden Route, and crafting beautiful, artisan-made semi custom yachts for clients around the globe is what we do best.

Having your yacht designed and built by a professional, acclaimed yacht builder like KYC will not only see you sailing off in a unique boat that was built to the highest standards. It will also ensure that you are a pivotal part of your yacht's design and construction process, right from the very outset.

While KYC builds your yacht, your input will not only be valued, it will be sought out and encouraged, with your particular tastes and preferences incorporated in every aspect of your boat's construction.

Continuous consultation and communication with the KYC team of expert yacht builders will see you taking to the seas in a boat that not only complements your personal style, but one that can truly be your home on the high seas.

Read on as we take a closer look at the various aspects of the semi custom yacht building process.

#1: What are the trademarks of a semi custom yacht?

When you first start to do your yacht-buying research, you'll no doubt come across various types of yachts available for purchase. Most of these will be standard, production yachts.

With a production yacht, what you see is truly what you get. There are virtually zero customizations that you can make to the layout or interior of an off-the-shelf production yacht,

A semi custom yacht, however, will afford you much more opportunity to add all those little touches that will make your boat a true extension of your personal style and tastes.

Even though semi custom yachts are built on a standard hull, when it comes to trims and finishes, appliances and the interior layout, that is all up to you.7The planning and design of a semi custom yacht can be compared to working with a home builder. Many larger home building companies have several base floor plans to select from, with the selection of cabinets, finishes, layout, and other details entirely up to the owner. It's the same with the design of a semi custom yacht.

#2: The advantages of a semi custom yacht

You might be wondering if a semi custom yacht is a better option than a standard production yacht. Buying a production yacht may save you money, but going for the cheapest option is not always the best choice.

There are clear advantages to having your own semi custom yacht built by professional yacht builders. One of those advantages is that you will personally be involved in the entire process of your yacht's construction.

A semi custom yacht build takes around 12 months to complete, allowing you ample time to really get stuck into the various design, building and finishing aspects of your boat.

In addition, you will almost certainly be cementing a long-lasting relationship with the dedicated team that is building your boat. Should you choose KYC as your yacht builder, this relationship will continue long after your boat's build is complete.

With a semi custom yacht, the price may be higher than what you'd pay for a standard production yacht (although the costs of KYC's boutique semi custom yachts compare very well with some new production yachts on the market).

But, if you choose to go for a semi custom yacht, you'll be getting much more than just a boat.

You'll be setting sail in a vessel you can take immense pride in, because you would have played a central role in crafting your boat to your exact tastes and specifications. If you select KYC as your yacht builder, you can also look forward to the many benefits of becoming a member of the KYC family of yacht owners.

This means you'll enjoy the support and expertise of an experienced team of yacht-building professionals for many years to come.

#3: Semi custom vs. production yacht

The advantages of having your own semi custom yacht built for you may be clear, but how do these boats compare to standard production yachts ?

Well, one major difference is alterations. When you're having a semi custom yacht built, you can make changes as you go. With a standard production yacht, you are buying the boat pre-made. Alterations to a production yacht after the fact can cost a lot of money, and may not be that simple – or safe – to execute.

Why would altering a production yacht post-sale be a safety risk? A production yacht's design and aesthetics may hide pre-existing flaws in the boat's construction. In itself, this could already pose potential safety risks. Making further changes or additions to a yacht that may already contain pre-existing design flaws would not be a wise course of action, and could be very dangerous indeed.

If you're involved in every step of the build of your semi custom yacht, you will have the opportunity to closely inspect your boat at every stage of its construction. This is a valuable advantage that could potentially allow you to avoid safety issues and layout problems relating to your boat.

#4: Building a semi custom yacht

If you choose to have yacht builders build your semi custom yacht from scratch, you'll be involved in every step of the process. For this reason, it will be in your interest to know as much as possible about your boat's building process.

So, what is the actual process of building a semi custom yacht?

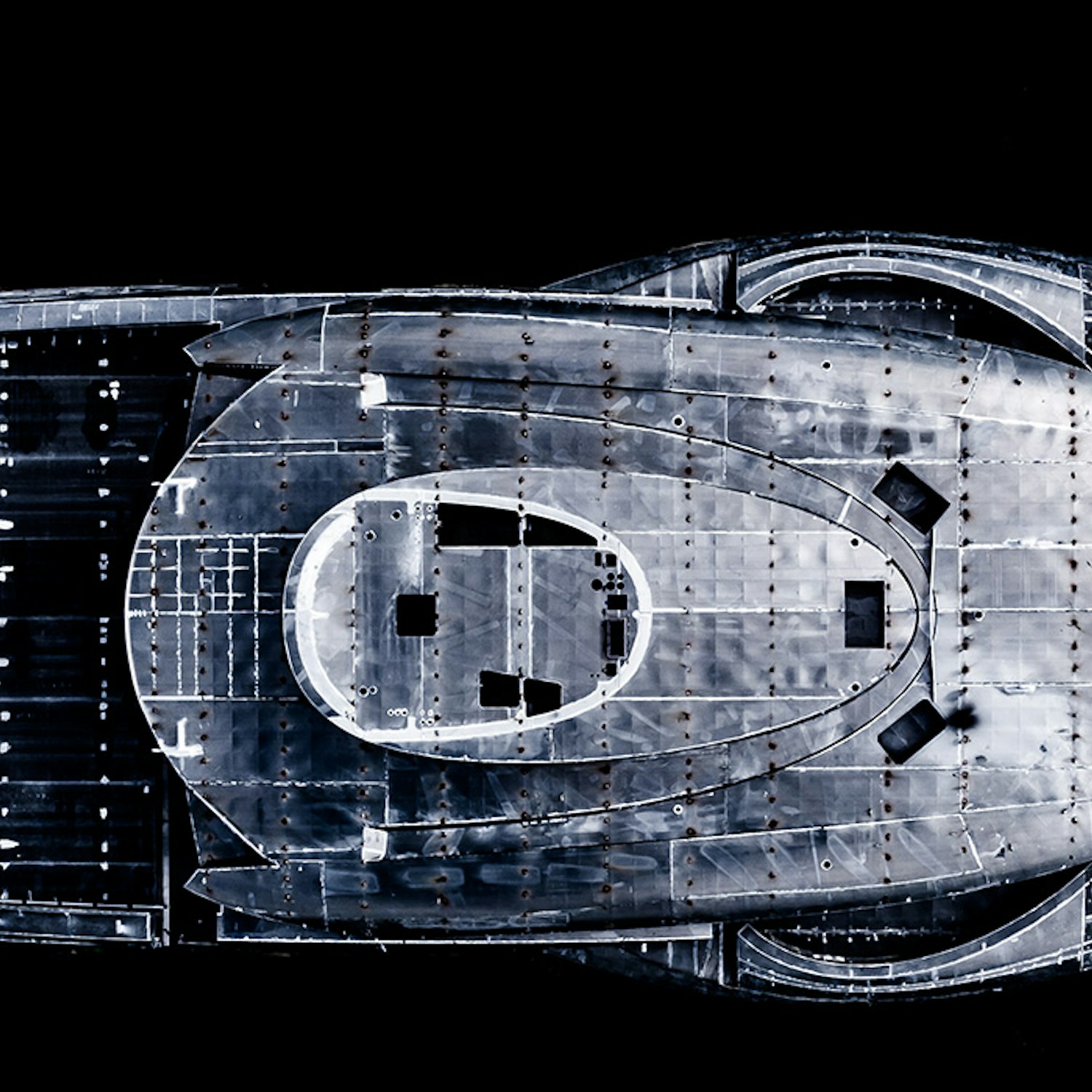

Building the hull

The first stage of the yacht-building process involves the "bones" of your yacht. During this stage, your yacht's hull and superstructure are made.

Unless they have commissioned a completely custom yacht to be built from the ground up, boat owners typically aren't involved in the selection of their boat's hull. However, it is important to know what this process involves.

Constructing a boat's hull is a process that takes four to six months to complete and takes place in a boat builder's aluminium or steel workshop. A steel yacht hull is extremely durable, but it will add a lot of weight to the overall weight of your boat.

Steel is one of the most common hull-construction materials, as it can be constructed and maintained with low technology, and at a relatively low cost.

Aluminium or alloy hulls are one of the better options available for hull construction, as they are so much lighter. These hulls offer the durability and longevity of steel hulls, but add only a fraction of the weight of a steel hull to your yacht.

After your yacht's hull is complete, it will have to go through a rinsing and priming process before your boat will be ready for the next step in its construction: finishing.

Finishing the yacht

Once your yacht's hull is complete, the second stage of your yacht's build can commence. This is the part where you'll start to see your boat "come to life".

The finishing process of your yacht is made up of several stages, including:

- Installing the yacht systems

- Interior and exterior carpentry

- Insulating the yacht

- Varnishing the yacht interior

- Spray painting the hull/superstructure

- Installing the mast

Semi custom yachts are beautiful machines. And, under such a boat's surface, a lot goes on to keep that beautiful machine moving and functioning as a self-contained living unit on the water. A large network of wiring and systems will be expertly installed to keep your yacht running smoothly and safely.

Yacht systems

It takes several systems for your new boat to run, including a navigation system, anchoring system, electrical system, propulsion system, air conditioning system, water systems, and more.

Each of your yacht's systems requires an expert team possessing the necessary knowledge and expertise to install it correctly and efficiently. Some people set sail with a yacht engineer as part of their crew team, to keep everything running smoothly onboard. However, KYC offers all new Knysna yacht owners a complimentary, 2-week training period during which they are shown and taught everything they need to know in order to maintain their yacht's systems themselves.

Gel coating & interior and exterior carpentry

A yacht's gel-coating process is done with a resin that bonds with the fibreglass surfaces throughout your boat. Gel coating ensures no leaks and cracks on a yacht's surface, but it can also be applied to add more colour to your boat.

Since most yacht hulls and exteriors are finished in fibreglass, gel coating becomes an extremely important part of the yacht-building process.

After gel coating, the interior of the yacht receives a protective varnish. The yacht exterior is also gel-coated and waterproofed to prevent leaks and ensure the boat is completely sealed.

Carpentry is also an essential component of your new yacht. Marine carpentry experts are required for both the interior carpentry (think bathroom cabinets, kitchen counters and seating), as well as the decks and other carpentry aspects on the boat's exterior.

Yacht builders and their teams

If you select to have your yacht built by a big yacht-building company, a project manager will be appointed to oversee your yacht's construction, making sure the entire process runs smoothly. Project managers are typically the face of a boat-building company, and clients will deal with their boat's project manager as their point of contact throughout their yacht's construction process.

Underneath the project manager, you'll likely have a team of engineers, systems installers, artisans, an interior designer, and a few legal team members.

Should you choose to have your semi custom yacht built by KYC, you will be dealing directly with KYC’s owners. You will also have access to your under-construction yacht at all times, ensuring that the lines of communication remain open and that your needs are being met.

Selecting the right yacht builder

It's essential to choose the yacht builder best suited for your particular project. There are several questions you should ask yourself before selecting a company to build your yacht.

First, you will have to decide on the type of vessel you want. Many boat builders specialise in certain types of boats. Knowing what type of boat you want will be the first step toward deciding which yacht builder is right for you.

Next, you'll want to figure out how far you'll typically be sailing. This is known as your yacht's range. If you're only planning on doing shorter sailing trips, that will require a specific type of boat. If you want to sail out on the ocean for weeks or months at a time, that will require a different kind of boat entirely.

Finally, ask yourself how long you're willing to wait for your new boat . This wait is known as your lead time. If you're okay with waiting 2-4 years for your yacht to be built, then you can consider selecting a fully custom yacht.

Semi custom yachts, including KYC’s artisan-built Knysna 500SE and Knysna 550 yachts can be completed much faster. This will vary from builder to builder, but most semi custom yachts have a much shorter lead time than a fully custom boat that is built from scratch.

Financing a semi custom yacht

Financing a boat that is yet to be built is notoriously difficult, with most banks and financial institutions only willing to provide loans for completed boats. At KYC, we offer clients a Yacht Construction Financing Option, allowing them full flexibility to pay off building costs over the boat's complete building timeframe.

Become a yacht owner faster

Let us answer your yacht-building questions!

Read our blog article on yacht financing and learn more about KYC's unique Yacht Construction Financing Option.

Let us answer your yacht-building questions

There are lots of points to consider when you're thinking of having a boat built.

Our team of KYC yacht-building experts will help you navigate the yacht-building process to ensure that your journey towards ultimate freedom is smooth sailing every step of the way.

Don't hesitate to send us a message at [email protected] and let us know how we can help.

Yacht Maintenance - Top Tips for Protecting Your Investment

Essential things to know about boat insurance, top things to know about yacht solar power, get all the latest to your inbox, discovery awaits.

Build a Yacht

Do you plan to build a yacht of your own.

If yes, read this guide on new yacht construction.

We will go through stages of a superyacht new build and discuss important points that every yacht owner or owner representative needs to know when commissioning custom yacht construction.

New Yacht Construction in a nutshell

Why build a yacht? The answer to this question is slightly different for every superyacht owner. One aspect is true for all: only a fully customized superyacht which was made specifically for you will perfectly fit all of your requirements and tastes.

If you are not satisfied with serial production yachts and seek that unique superyacht to call truly yours – then building a yacht is for you.

Superyacht build is an exciting process which only a handful of people in the world are lucky to experience.

There is nothing like seeing your own superyacht coming to life, first on paper in form of superyacht designer drawings, and then for real at the superyacht shipyard.

New yacht construction is a lengthly and sophisticated process which can take several years to complete. Thus it is very important for every superyacht owner to understand ins and outs to prevent unnecessary mistakes.

We at Yachtowner.co prepared a guide through superyacht build process for you. Let’s dive right in!

Build a yacht. Where to start

Why build a yacht.

Always start your superyacht new build process with why. The better you understand yourself, the easier it will be for superyacht professionals to satisfy your needs.

Why do you want to commission new superyacht construction? What drives you? How are you going to use your boat? What are your requirements? Sit down and make a list of things you would like to see at your new superyacht. Let your dreams flow and capture them on paper.

Look at your requirements and rate them. Group all your requirements into groups: “absolute must have”, “desirable”, “nice to have”. This grading will help yacht designers and shipyard understand your priorities and focus on the right things. Add information about numbers of cabins, speed, cruising range of your yacht, maximum noise and vibrations levels, and anything else which comes to your mind.

Save photos and descriptions of other yachts you like, including finishings type and quality. They will later serve as benchmark for a superyacht designer.

Try to describe the use of your boat in 1 or 2 sentences. A “floating home for my family”, a “fast and furious party boat”, or “an expedition vessel to explore arctic regions”? Give your new luxury boat your personal twist!

Successful yacht build starts with clear communication

By the time you decide build your own yacht, you should already have tried out chartering different yachts or owned some of second hand yachts.

As with anything else, in yachting it is also better to gain maximum experience, yachting knowledge and understanding of your needs, before you start your first large project.

How can you know what you want, if you don’t know which options are available? If you are just starting out in yachting, read our article How to Buy a Yacht .

Yacht design is all about compromises. Aiming to build the fastest boat, for example, implies limiting its overall weight. It means less additional lifestyle appliances on board.

To maintain the speed, a stronger engine is required, which means more fuel storage and less inside space. There are many examples of compromises like this.

Due to its high quality and sophisticated finishings, superyacht construction is much more labour intense than construction of any other type of vessel. Executing change requests gets expensive very soon.

Also, unlike in serial production of planes or cars and due to uniqueness of your boat, the shipyard does not have possibility to fully standardize the production process. Solutions can not be tested for various hundreds of times before the building begins. The shipyard just has one shot to get things right.

The more specific and detailed your understanding of your own preferences, the clearer and faster your communication about them, the better job your superyacht designer, architect and shipyard will be able to execute.

Superyacht Build: Choose the Right Team

You are about to sign a superyacht construction contract which will tie you into working with a shipyard for the next couple of years. Make sure you choose the right people! Superyacht building team can make or break the project.

In general, you will be working with a number of different experts from the superyacht industry during the next couple of years. They will surely have deep knowledge in their specific spheres of expertise.

Surrounding yourself with experienced professionals with no conflict of interest and simultaneously educating yourself on yacht building process will make you feel confident and comfortable in such a specific setting.

Always ask questions, clarify things you might not understand. Maritime industry is full of jargon. It’s ok not to know specific terms. It is much better to ask rather than to not be able to follow a discussion.

Professionals build the yacht for you, but in the end, it is your yacht. You want to make sure that you get the boat of your dreams and have enough knowledge on how it functions.

As a future superyacht owner, you probably already have your favorite yacht designers, naval architects and superyacht brands. If not yet, then check out our Comprehensive list of 195 Superyacht Brands to discover some of the world’s best superyacht builders.

How to Build a Yacht: Design Phase

Now when you already have put your first thoughts on paper, it’s time to make first contact with a superyacht designer and/or a naval architect.

A superyacht designer is responsible for creating an attractive and practical design for your future yacht. A naval architect is typically a professional engineer in charge of construction, design and repair of yachts.

If optical appearance and interior design is your focus, yacht designer might be appropriate to hire. If instead you want to incorporate non-traditional and sophisticated technical elements into your yacht, a naval architect is the right person to contact.

Take the list of your preferences that we discussed in the beginning of this guide and visit several superyacht designers and architects. Browse through previous yacht projects in their portfolios. Make sure that he or she has enough experience in designing similar types of yachts.

Choose two or three best companies. Ask them for preliminary drawings and estimates of fees, and compare. Choose the one who suits you best.

Then visit a superyacht insurance agent and a classification society surveyor . Yacht insurance decides whether the yacht is ready to launch. Classification society is an entity which monitors that the yacht is built according to highest standards and quality.

The surveyor checks if the shipyard builds your yacht to the best quality. It is in your interest to involve these two stakeholders already in the beginning of the process, to avoid unnecessary hassle from the start. Show them the first drawings and specifications of the new yacht that you got from the designer/architect, and ask how they work and what else they need.

Clarify yacht financing . The majority of privately owned superyachts are financed by some kind of a bank loan. It is a savvy financial decision to finance your superyacht by a bank loan.

By negotiating good loan conditions, you can keep your own cash and invest it into a better performing asset classes with higher returns. There is a number of financial institutions worldwide which specialize in superyacht financing.

Think about the flag of your future superyacht . In which country will it be registered? Will it be a Red Ensign Flag ? Choice of the country of registration will affect legal status of your superyacht, so choose carefully.

We cannot stress enough how a well-executed and detailed yacht design is crucial for the following yacht construction! Before starting to build a yacht, one needs to run a full check of all documents, specifications and plans. The better you prepare on this stage, the smoother the yacht building process will be.

Build a Yacht: Shipyard & Construction

The big decision alongside the choice of yacht designer and naval architect, is undoubtedly, the choice of shipyard . This is the manufacturer of your future custom superyacht. The shipyard plays an immense role and has responsibility to deliver your new yacht the way you want it.

Once the preliminary design of your yacht is ready, you can start looking for a suitable shipyard to build your yacht.

How to choose a shipyard to biuld a yacht? Which yacht brand is the best for you? Look out for the following points:

- Shipyard size

- Shipyard’s preferred size of yachts

- Years on the market

- Previous experience in building similar yachts as yours

- Delivery schedule

- Own design team

- Reviews of previous clients

- Resale value of yard’s previous yachts

- Project management skills

- Who is the project manager? Do our personalities fit well?

- Are processes in place?

- ISO standards & compliance

- Procurement department & policies in place

- Financial stability of the shipyard

- Do I have a good feeling with the shipyard?

There is quite a variety of shipyards in the world and it can become a daunting task to choose the best one for you. Send your inquiry to several shipyards, and narrow down your choice to 3-4 best ones based on their answers. Get more details and specifications from them and choose the best shipyard.

The shipyard will assign a project manager and a team to run the building of your new custom superyacht.

The project manager is an employee of the shipyard and is the key person who runs the construction of your yacht. His task is to project manage the build, to make sure everything sticks to schedule and there is no significant cost overrun, and to maintain communication with the owner’s representative.

Cooperation between project manager and owner’s representative is key in successful superyacht construction. Whereas the owner’s representative has power to act on owner’s behalf, the shipyard’s project manager is the one who runs the show on shipyard floor.

Visit the shipyard personally and talk to the general manager and the potential project manager (the latter reports to the former).

Take a look at the facilities. Try to find out how the processes at the shipyard are managed. Are proper project management procedures established? Are processes structured and responsibilities clear?

The better the organization of shipyard’s work, the more likely is your new custom yacht to be completed up to your expectations. One of the ways of finding it out is asking for previous client’s opinions. Ask the shipyard if they can share such contacts with you.

The team will prepare a project plan and a project schedule. After that the execution will start. This is a long, sophisticated but a very exciting process, when you will finally see your yacht materializing.

It is good practise to have a yacht engineer or captain who will be working on the yacht after completion to be part of the team during construction. His detailed knowledge of the new yacht will be invaluable for its daily operation after the handover.

Visit the shipyard once in a while and take photos of different stages on construction. What exciting memories to look back at!

During the yacht construction phase, you are likely to submit some changes. Some issues might arise. But don’t get demotivated, it is normal with a project of such scale.

Proper execution control mechanisms and processes will allow your team to identify potential issues at early stages, while it is still relatively easy and cheap to fix them.

Build a Yacht: Sea Trials & Closing

Finally the construction of your custom superyacht is completed. We know you can’t wait to see your beauty on water!

Launching is the day when your new yacht is put in the water for the first time. It is an exciting and very important moment, which needs to be carefully planned by the shipyard.

Now the yacht needs to be tested in action. This is a period of sea trials . For several weeks, all systems of your new yacht will be tested in operation. This is the final complete technical check of your new luxury boat. Some fixes might be done during this period.

As with a brand new car, some systems on the yacht will take longer time to be fully tested in action. Some fine tunings will surely also be done during the first and second years of your superyacht’s lifetime. It is absolutely normal.

Handover is the final stage of yacht construction project. This is when you sign the final acceptance of the yacht, probably with a list of things which still need to be fixed in the upcoming weeks.

With the handover of the yacht, also all its documentation has to be handed over to you or your team. This includes all the plans, drawings, sea trials results, manuals to all the systems and appliances on board.

Your crew has to have access to all these documents to be able to comfortably transition to the new build yacht.

Give your captain and crew some time to accommodate onboard and get accustomed to the new yacht.

Now you are finally ready to make the first voyage on your new custom superyacht , the moment you have been waiting for so long.

Congratulations!

Build a Yacht: Contract is King

Yacht construction documentation.

When it comes to building a yacht, paperwork matters. With such a large project, all the parties involved are interested in having everything clarified on paper before yacht construction starts.

Unclear or conflicting conditions, missing clauses, mess in communications and emails can substantially complicate building of your yacht. As well as make it much longer and more expensive.

Work with lawyers that have been working with yacht building projects before. They will advice on how to setup contracts, which paragraphs and attachments to include.

You should have the following documentation package: contract, scope of work, technical specifications, terms and conditions, regulations, contract drawings, classification rules, standards, and execution page.

Due to the nature of new yacht construction projects, roles and responsibilities of different stakeholders can overlap. Best practice is to include description of roles and responsibilities of every stakeholder in an attachment to contract, to avoid confusion.

Make sure you understand every clause in the contract personally. The language might be very specific, but knowing what you sign is absolutely crucial, even if you trust the professionals you hired.

In the end, you are the owner and end beneficiary. It is your yacht and your money, you should know what you are signing for.

Keeping all documentation saved and filed properly might be boring, but it is so important! With a project of such magnitude, paper chaos can come quite fast.

Shipyard will file documentation on their side, but your representative should also have own filing system to make sure you have all papers at hand.

Also, after the yacht construction is completed, as-built documentation shall be handed over to you.

Making changes while you build a yacht

Trust us, no matter how well you planned your new custom yacht in advance, you will want to change at least something later.

Change orders and how they will be handled in the building process are an important part to put down in the contract. Having clear rules on how change orders shall be handled and paid for will significantly ease the process. Make all your changes in writing as an attachment to the contract.

Generally, the fewer change orders you make, the better. The sooner they come during the yacht build, the better. They will also be considerably cheaper to implement.

Just think of how much will need to be redone, if you decide to make changes in hull structure once the yacht is almost finalized, interiors are finished etc.? It might be cheaper to build a second yacht…kidding, but you get our point.

Superyacht Construction: Comfort Onboard

Stabilizers.

Comfort on board of your yacht is central to enjoyment of trips and cruises! Seasickness is sadly something that many people get and it can ruin any vacation. No matter how luxurious a yacht, it is still moving in water, and at least some minimal motion will always be there.

Solution to seasickness are stabilizers. If you are sensitive to motion on water, make sure your yacht has a good stabilizer. It will make a great difference in your yachting experience.

There are many stabilizing systems of varous types on the market. Talk to your team at the design stage and later ask stabilizer manufacturer to provide a motion simulation study.

Noise & Vibration

Not so obvious aspect for new yacht owners are noise & vibration levels outside and inside your yacht. We love the speed that strong engines give – but they are loud. Engines cause noise – and so do propellers, generators, bow thrusters, hydraulics, gearbox…

Work with a good noise level specialist when constructing your yacht, to make sure that noise does not exceed your tolerance level. It is much easier and cheeper to minimize noise already during design and construction of your yacht.

Ideally, use another yacht as a reference point for setting acceptable vibration and noise levels. Test it at the dockside and during cruising. When the yacht is moving, you will hear not only the engine noise, but also sound of waves hitting the hull, wind, propellers.

Specify maximum sound levels in every cabin in the yacht building contract. Most people prefer to have at least some noise level in the cabins, not to feel too locked out of their environment. Also, getting below specific levels gets very expensive, and will probably be unnecessary.

Superyacht Build Success depends on Yacht Owner’s Involvement

Yes, as the future superyacht owner you also have an important role to play in superyacht construction. Only with your active involvement in the project, can the yacht designer and shipyard get all the important information and approvals in time and deliver great results.

Only by knowing what a perfect yacht means specifically for you, can they build this perfect yacht.

If the personal time you are willing to spend on the project is very limited, hire a knowledgeable representative.

Owner’s representative is a key stakeholder in a new yacht build, alongside shipyard’s project manager. Owner’s rep is the major contact point for all the other stakeholders. Make sure he or she has necessary experience, knowledge and power to represent you and make decisions on your behalf.

Yacht owner’s representative should be on pulse of construction schedule, cost, and current stage of the building process. Cooperation between the owner’s representative and the shipyard’s project manager is a key relationship in any superyacht new build.

In short: completing a successful superyacht build is only possible with active cooperation from the owner’s side. There are quite a number of new build projects that run into issues due to lack of owner’s participation.

New yacht construction is your biggest dream coming true, it’s fun to take active part it in!

Yacht Construction: Frequently asked questions

What does a custom yacht mean.

A custom superyacht means a yacht which is designed and build specifically to your requirements. A custom superyacht is unique. If you commission building a custom yacht, there will be no other yacht like yours in the world.

How long does it take to build a yacht?

Superyacht construction times vary depending on the size and complexity of the boat . It can take anything from 2 to 5 years to complete building of a custom superyacht.

How much does it cost to build a yacht?

New build custom made superyachts are more expensive than serial production or semi-custom yachts. Their prices can go up to several tens of millions of dollars on average. Exact price range depends on the yacht size, complexity and finishings. The largest yachts in the world cost considerably more than a hundred million dollars, reaching over a billion dollars for the most expensive ones.

Who is involved in a superyacht build?

Yacht owner, owner’s representative, superyacht designer, naval architect, shipyard (full team typically led by a project manager), lawyers, insurance agent, superyacht financing specialist, classification society surveyor, possibly superyacht broker , superyacht captain & crew, to name the main stakeholders.

What are the best superyacht manufacturers in the world?

There is quite a number of prominent shipyards with expensive experience of building superyachts in the world. The exact choice will depend on the size of yacht, your preferences, budget and taste. With superyacht manufacturers, there is no one size fits all, but there are market leaders. Browse through our Comprehensive list of 193 Superyacht Brands to choose your favorite.

Summary: Build a Yacht

In this article, we discussed new superyacht building process from the yacht owner point of view. We highlighted main points you should keep in mind to avoid common mistakes during yacht commissioning and construction.

It is beyond the scope of this article to list all the important aspects of building a yacht. Hiring an experienced superyacht consultant will significantly ease the yacht build for you.

Get the best superyacht professionals onboard, stay curios and ask questions. With every completed yacht new build you will gain your own experience and know your yachting needs better. We know some serial yacht owners who complete a new yacht build project every couple of years. It’s fun!

And last but not least: building your own superyacht is such a unique adventure, which only few people get to experience. The absolutely main thing is to enjoy it to the fullest!

Do you have questions we have not covered?

Ask us in the comments below, or contact us directly at [email protected] ! We will define your needs and find the best solution together!

Article by Yachtowner.co

More Articles

Superyacht Brokers List

List of Best International Yacht & Boat Shows

Disclaimer of liability.

How to Buy a Yacht

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Yes, add me to your mailing list

Privacy Overview

- Yacht Management

- Technical Services

- The Process

- Yacht Finders

9 simple steps to a new yacht building process

Our Director Derek Munro has recently shared his approach to a new build yacht process with The Superyacht Buyer Report. Derek breaks down a complicated process of building a new yacht into 9 simple & manageable steps and gives us an insight of things to look out for during the new build process.

At Divergent Yachting we believe the process of deciding to build a yacht and the build phase are made up of nine simple steps.

Although simple, it is important that the first 6 stages (which are all pre-build works) are dealt with in some detail, therefore making the final 3 stages far more enjoyable.

STAGE 1: STATEMENT OF REQUIREMENTS

To construct a large new yacht, it is essential to have a clear statement of the Owner’s requirements. Key features and performance criteria will all determine the design, price range and the most suitable shipyard. Therefore, the personal input of the Owner and their team at the very earliest stages of a project are most important.

What kind of yacht do they want, where do they want to go, how fast, how many guests, what sort of toys do they enjoy using and envisage storing on their yacht, plus much more will be the basis for the design and the specification.

STAGE 2: CONCEPT

For most Owners, this step is very exciting. This is where the vessel’s shape and form are drawn, and their vision starts to become reality.

The Client should find a Designer that they like and trust, who can appreciate and develop the Client’s desires whilst considering the practicalities of operating a vessel at sea and in charter. Or has the Client seen a yacht from a specific designer or shipyard that they like? Are they after a production yacht, a semi-custom yacht or a fully custom vessel? They all require a differing amount of input from the Client team.

STAGE 3: SPECIFICATIONS

If a fully custom design is the preferred choice of the Client, then developing a detailed specification for use to tender yards is imperative. Therefore, the use of experienced Owner’s representatives, engineers and naval architects is important at this early stage.

If a production or semi-custom yacht is the Client’s preference, then the shipyard concerned will have a specification which will need to be reviewed and where required or wanted, items modified for approval by the yard. Normally, there is some discussion and negotiation if changes are made to the yard’s specification in these cases.

STAGE 4: REVIEWING AND SELECTING CAPABLE SHIPYARDS

Superyacht Owners often prefer a particular shipyard based on brand recognition or their previous experience.

A full review of all capable shipyards before issuing invitations to tender is paramount.

Can they offer the correct security (financial, insurance and physical)?

Do they have the right team for your yacht project?

Do they understand the Client’s ultimate goal, ethos and use of the vessel?

Do their past projects reflect the quality expectation of the Client?

What is the availability to start works and deliver on time?

STAGE 5: TENDERING PROCESS (FOR FULLY CUSTOM BUILD PROJECTS)

The tendering phase relies on the commercial knowledge of the people approaching the selected shipyards.

Ensure you have the right tender package and issue it to suitably qualified and experienced shipyards.

Have a legal team which understands yacht / ship building contracts.

STAGE 6: CONTRACTUAL NEGOTIATIONS AND SIGNING

This process can take some months overall.

This crucial phase can move quickly, so manage the process carefully, keeping everyone informed of progress. Aligning the build specification with the yacht building contract is vital, even under the pressure to sign the contract. A small change could easily add unacceptable time and costs to the build phase.

To reduce the risk of problems later, ensure the Owner’s team, the shipyard and a marine lawyer experienced in large yacht construction contracts work closely together.

STAGE 7: CONSTRUCTION PHASE

Get your Owner’s representative and technical support in early on site.

Owner’s Representation includes commercial management of the contract to cover the build schedule monitoring, Stage payment signoffs and delay claim negotiation. The Client should receive monthly reports on progress and required input from all parties (Owners Supply Item designs and delivery etc).

Technical support includes selecting Owner’s supplied sub-contractors, managing interior outfitting, and inspecting the full build process such as welding, pipework, cable installation, equipment installation and paintwork.

STAGE 8: SEA TRIALS

This is often the most exciting stage of the shipyard phase.

The Client, their Team plus Captain and crew get to test and experience the years of effort for the first time.

All the sub-contractors and suppliers involved in the build are usually represented during the sea trial to ensure that all systems are operating optimally.

Depending on the vessel, a sea trial can be a day or a few days if a complex vessel.

STAGE 9: ACCEPTANCE AND DELIVERY

The Client with their Representative, Lawyers and Shipyard finalise the details of Acceptance and Delivery.

This includes listing any works still outstanding and planning for the Warranty phase.

A Memorandum of Understanding is agreed regarding outstanding works, if there are any that still need completing.

The vessel is registered and handed to the Client.

For a copy of a full article, head over to The Superyacht Buyer Report magazine here .

Comments are closed.

Recent Posts

- Superyacht Investor – Interview

- Cannes Yachting Festival

- Superyacht Technology Network – Interview

- Will you be at the Palma International Boat Show (PIBS)?

- Come and see us at Monaco Yacht Show

- Uncategorized

Privacy Overview

How long does it take to design a yacht?

Published 15 June 2021

In a world where conformity is the norm, the superyacht industry stands apart. Designing a yacht is a wholly personalised process, determined by a wholly personalised brief.

How will your yacht be used? Where will you cruise? Will it charter? What hobbies will it cater for? And of course, what’s the budget? After that, all that remains is to sketch out your dream. That's where our New Build Sales team comes in, to help connect the best commercial, operational, and technical teams and ensure your vision comes to life.

Starting the design process

Beginning the design process is a daunting task, even for the most seasoned yacht owners. But designing a superyacht is a smooth ride with an experienced designer on your side. Preferably one with naval architecture expertise, too. The interior design phase tends to take the longest, but creative flare and knowledge are key to getting it right.

Contact our construction team

Translating your dream superyacht concept to paper is tricky, and this is where our skilled construction team can assist. At Burgess, we understand the building process. We factor in material costs. We project manage the entire process for you. We can even introduce a designer. How long does it take to design a superyacht? As long as you need.

How will your yacht be used?

If you regard your yacht as a boat to sail on, you’ll enjoy the seven seas. But if you design your yacht as a go-anywhere home, you can enjoy the world. Watersports enthusiasts will like a rejuvenating beach club for close-to-the-water action. Intrepid explorers will value amphibious tenders or helicopter capability. If al fresco dining is top of your list, a sprawling sun deck with bar, grill and jacuzzi is a popular option.

Where will you be sailing your yacht?

The balmy Bahamian waters are a popular winter cruising ground, but they require a shallow draft. To best experience the cool trade winds of the Caribbean , a sailing yacht is the ticket. For chic but smaller ports, such as Sydney Harbour or Capri, only yachts below 70m will fit. And if the higher latitudes are calling, be sure to build an ice-class vessel.

What features would you need on your yacht?

Storage can be a contentious issue on board, so if you want to kit the boat out with the latest watertoys and tenders, make sure to leave enough space. Consider crew areas and function, too; their ability to work well under less pressure is best for everyone. Then a cinema on the sun deck for starlit movies, a spa on the lower deck for indulgent relaxation, and an underwater observation lounge can round off a boat design nicely.

How long does the design process take?

Designing a superyacht is the most critical stage, but there is no right or wrong amount of time. The design needs to meet all your requirements, and only then is it complete. With this in mind, the average length of time to design a yacht is between nine months and a year.

Starting the build process

Designing a superyacht that delivers on your dream is one thing, finding a shipyard that can make that design work is another. At Burgess, our expert New Construction team is in constant communication with shipyards around the world and can advise on those best suited to deliver your yacht to the highest build quality, on schedule and to budget.

Building your superyacht

Once the first cut of steel is made, the build has begun. There are several key stages in a yacht build, which include the laying of the keel, joining of the hull and superstructure, and the exterior and interior outfitting. Even the exterior paint job can represent around one third of the total build time.

Every new yacht will go through sea trials to test its performance. This is the first opportunity to find out if the finished boat can reach its contracted top speed, has great manoeuvrability, and for the yacht owner to make any final requests before final delivery.

How long does an average build of a yacht take?

It takes an average of three to four years to build a fully-custom superyacht. Boats built on speculation by a shipyard offer shorter delivery times, which is a great option for yacht owners who don’t want to wait. But for those keen on designing their own fully bespoke superyacht, the longer build time pays dividends.

Delivery of your yacht

Taking delivery of your dream yacht is an astonishing experience, and one that yacht owners relish forever. To take receipt of an exquisite boat tailored to you and your family is an exceptional feat. It is the gateway to private exploration, being exposed to once in a lifetime experiences, and cruising areas only accessible by boat or private jet. It is the final stage in creating a yacht that meets your exact needs and having the freedom to enjoy it.

Build your dream yacht with Burgess

Superyacht new builds are as varied as the people who own them. Every person’s dream has its own meaning, and every yacht design satisfies a unique vision. At Burgess, our yacht brokers and new construction team are always on hand to guide and support you throughout the entire process, from the first sketched line to the maiden voyage, and beyond.

Contact our New Construction team to discuss your options.

To find out more about Burgess’ yachts for sale and yachts for charter , please contact a Burgess broker . Alternatively, get in touch with one of our offices directly: London , Monaco , New York , Miami , Singapore or all other locations .

- Build a yacht

Latest stories

Upcoming events

Sign up to our newsletter

Stay in the loop.

Subscribe to our newsletter to keep updated with all things Burgess.

What would you like emails about?

- Chartering a yacht

- Buying or selling a yacht

- General superyacht news

In order to understand how we use and protect your personal information, please read our privacy policy .

- Mediterranean

- French Riviera

- Corsica & Sardinia

- The Balearics

- Croatia & Montenegro

- The Bahamas

- Caribbean - Leeward Islands

- Caribbean - Windward Islands

- British Virgin Islands

- US Virgin Islands

- New England

- Indian Ocean

- South East Asia

- French Polynesia

- The Red Sea

- Motor yachts for charter

- Sailing yachts for charter

- Latest offers

- Destinations

- New to charter

- Meet the Charter team

- Superyacht videos

- 360° yacht tours

- Corporate & event charters

- Inspiring charter ideas

- Charter FAQs

- Every day different

Charter KADIMO'S

Available between 10 June - 10 July

Elevator serving lower to sun decks means the boat can accommodate all generations

Charter BARBARA

Available 1-12 July and August onwards

Spa facilities including massage and beauty rooms, private master deck and indoor and outdoor cinemas

- Motor yachts for sale

- Sailing yachts for sale

- Yachts for sale over 200 feet

- Yachts for sale from 150 to 200 feet

- Yachts for sale under 150 feet

- Tenders and chase boats for sale

- Yachts under construction

- Meet the Brokerage team

- Berths for sale

- Sold yachts

- Yacht marketing

- New Build Sales

- Refit a yacht

- Delivered yachts

- Yacht designers

- Meet the Technical Services team

- Meet the Yacht Management team

- Crew vacancies

- Meet the Crew Services team

- Procurement Services

- Charter Management

- Sales Management

- Yacht Marketing

- Meet the Insurance team

- 360 degree yacht tours

- Boat shows and events

- Office vacancies

- Talent pool

- Office locations

- Burgess in Asia

- Burgess Blue Oceans

- Strategic partners

- Press centre

- Company Operations

- Crew Services

- New Business

- Technical Services

- Yacht Management

- Burgess Impact Report 2023

Filter your results

- Yachts for charter

- Yachts for sale

How yacht building works!

From design and choice of materials to craftsmanship and the latest technologies, yacht building is an exciting as well as multifaceted process..

Yacht building is a process in which every step is precisely and accurately planned. Each individually designed and manufactured yacht is a true masterpiece and engineering art. To ensure that yacht owners enjoy their boat for a long time, it is important to turn exclusively to professionals and experts for the construction. Qualified designers, technicians and craftsmen accompany the yacht construction from the very beginning. The first step is the vision and conception phase. Once a design has been finalized and confirmed, it’s time for production.

What makes the construction so special, what material is used and what is possible in terms of equipment? We at Merk & Merk as your professional yacht store will tell you how the construction really works.

Why choose custom yacht building?

When you choose custom yacht building, you can enjoy a truly unique piece that comes with exactly what you envision. Instead of a “series model”, where you can at most choose between different layouts, when building you have the chance to determine all the amenities and equipment details yourself right from the start. With such a unique piece, there are no limits to what you can do. You can integrate a swimming pool on the deck, have a helipad included or opt for faster engine power. Other popular yacht design features include safety systems, storage space for jet skis, and unusual shapes. Take a look at our article about the most expensive yachts in the world and get inspired. Almost every shipyard is capable of building special designs. We know ☓ those who do it really well!

Yacht building: from wood to aluminum

In yacht building, similar to house building, different materials can be used for the construction, all of which have their specific advantages and disadvantages. In addition to wood, aluminum plays a crucial role. However, modern composites (types of composite materials such as fiberglass, solid laminate or carbon) can also be considered in some circumstances.

Wood yacht building

Even the very first boat was built from wood. This natural material has undergone constant development in recent years, so that today it is mainly modern plywood and epoxy wood that are used.

Yacht building in metal: aluminum and steel

In addition to steel, aluminum has proven its worth. Its high strength and robustness combined with its lightness make this material a guarantor for aluminum yacht building and it is the first choice especially for long-distance sailboats and large yachts. STEEL is also an excellent material because it is easy to work with, safer in collisions because it is very flexible, easy to repair anywhere in the world, and cheaper to buy. Submarine steel in particular is excellent due to its high strength, with a value of over 155%.

One of our special boats in this case is the one-of-a-kind steel yacht Colin Archer 1860 Lola E. This cutter rigged long keel yacht has a round stern and offers probably the safest way to travel at sea. This long-range cruiser is especially family-friendly and offers three staterooms that will make you feel right at home.

Composite yacht construction

Composite construction, or composites, is one of the most common and, above all, cost-effective methods of yacht building. The material used is usually fiberglass. However, sustainable variants such as basalt and flax fibers are also possible. Carbon fiber-reinforced plastics are increasingly coming into focus.

Competent accompaniment through the yacht building process

Yacht building is a process that consists of many steps. In the first, everything revolves around the wishes and requirements of the customer. At a professional company, cooperation always begins with a comprehensive consultation to get to know the client’s personal requirements. For us, too, yacht building begins with this step.

This is followed by the selection of the shipyard that will take care of the yacht construction. Based on the previously recorded ideas, our experts are able to find the ideal shipyard. Once the decision has been made and the design phase has been completed, the next step is the production phase. The first steel cut is sometimes celebrated in a small ceremony. The entire construction process is supervised by the professionals at Merk & Merk. In addition, we are always available to provide advice. In yacht construction, many different, highly qualified and trained experts work hand in hand. In addition to metalworking, electrical engineering, paint work and finishing must also be taken into account. An entire project team therefore comes together for each yacht build, working closely together in an interdisciplinary manner.

The final step involves the interior fittings and finishing touches. Even during this stage, sea trials can take place. Own representatives and representatives of the responsible shipping classification society meet on the boat for this. Once the Sea Acceptance Test (SAT) has been passed, final approval is granted.

One of the most unforgettable moments is when the yacht is launched into the water for the very first time – the naming ceremony. In most cases, the owners decide on the time of delivery after completion of the yacht construction. We at Merk & Merk will of course take care of the support in organizing the yacht and the commissioning. After the handover, you can contact our experts at any time. We are available for maintenance and troubleshooting as part of our yacht management. In addition, we offer you reliable support after the yacht has been built. So you enjoy the yacht lifestyle carefree and we simply organize the rest.

+385 (0)99 709-4455

Jurjevgradska 2, Marina Tribunj HR-22212 Tribunj, Croatia

Receive exclusive content and special product updates!

Follow Merk&Merk

- Frank Magazine

- Denison History

- Virtual Tours

- Alaskan Yachts

- Azimut Yachts

- Back Cove Yachts

- Beneteau Yachts

- Benetti Superyachts

- Bertram Yachts

- Boston Whaler

- Broward Yachts

- Buddy Davis Sportfish

- Burger Yachts

- Cabo Yachts

- Carver Motoryachts

- Center Console

- Chris-Craft Yachts

- Cruisers Yachts

- DeFever Trawlers

- Dufour Sailboats

- Fairline Yachts

- Feadship Yachts

- Ferretti Yachts

- Formula Yachts

- Fountaine Pajot Cats

- Grady-White

- Grand Banks Trawlers

- Hargrave Yachts

- Hatteras Yachts

- Hinckley Picnic Boats

- Horizon Yachts

- Hydra-Sports

- Intrepid Boats

- Jarrett Bay Sportfish

- Jeanneau Yachts

- Kadey-Krogen Trawlers

- Lazzara Yachts

- Luhrs Sportfish

- Marlow Yachts

- Maritimo Yachts

- Marquis Yachts

- McKinna Motoryachts

- Meridian Yachts

- Midnight Express

- Mochi Craft

- Neptunus Motoryachts

- Nordhavn Trawlers

- Nordic Tugs

- Ocean Alexander Yachts

- Offshore Yachts

- Oyster Sailing Yachts

- Pacific Mariner Yachts

- Palmer Johnson Yachts

- Pershing Yachts

- Prestige Yachts

- Princess Yachts

- Pursuit Yachts

- Riva Yachts

- Riviera Yachts

- Sabre Downeast

- San Lorenzo Yachts

- Sea Ray Boats

- SeaVee Central Consoles

- Selene Trawlers

- Scout Yachts

- Sunseeker Yachts

- Tiara Yachts

- Trinity Superyachts

- Viking Yachts

- Westport Yachts

Building A Custom Superyacht [Complete Newbuild Guide]

![yacht building process Building A Custom Superyacht [Complete Newbuild Guide]](https://cdn.denisonyachtsales.com/wp-content/uploads/2019/07/Building-A-Custom-Superyacht.jpg)

July 25, 2019 11:40 am

The process of building a large yacht explained.

Placing an order for the build of a large yacht is no small undertaking. It is likely the result of a lifetime—perhaps even generations—of wealth building for such a purchase to become an option. When the time comes, how does the client start the process and where does he or she look for suitable partners? The maritime world is famously full of jargon, and the luxury yacht business is no different. Brokers , naval architects, interior designers, class societies, custom yachts, production yachts, flag states, owner’s supply, surveyors, shipyards, subcontractors, builder’s risk insurance , project managers, tank testing . . . you catch my drift.

Thought-through decisions and complicated contracts should certainly be anticipated, but as a wise man once told me about yachting, “At the end of the day, it’s all about cocktails on the beach.” While the dream of being on the water waits at the end of a newbuild process, building a yacht should be an enjoyable and rewarding process in itself.

- Newbuild Process Overview

- Latest Trends In Yachting

- Newbuild Partnerships

- Flexibility

- Project Management

- Newbuild Projects For Sale

- What Sets One Builder Apart from Another?

- What Sets A Brand Apart?

NEWBUILD PROCESS

“Production” Yachts tend to be in the smaller range and the process will likely be simpler than for a custom build. With a finished product already in inventory and available, only minor interior design elements need to be added per the client’s choice. A number of yacht builders will begin building larger yachts in anticipation of finding a buyer later, offering “semi-custom” as an option for elements of the interior layout and design.

For the custom build, the process will look something like this:

Vision > Design > Contract > Build > Sea Trial > Delivery > Cocktails on the Beach

The above is an intense simplification. Each stage involves multiple levels of experts and support staff. The client will want to surround him or herself with qualified attorneys, technical advisors, and translators of the jargon. One other important element to mention is that the design and build contract cost will not be the only outlay required to reach the endpoint. Custom yacht contracts mostly do not include items known as “Owner’s Supply,” i.e. tenders and water toys, audio-visual/entertainment systems, loose furniture, tableware, and more. Each of these will need to be procured, stored, insured, and integrated into the yacht itself as part of the process.

LATEST TRENDS

Step one, “Vision,” allows almost anything to be conceived and delivered in a yacht. There are plenty of “concept designs” available on the internet to offer the client inspiration for their vision, but we have seen a few trends in recent years. The “plumb bow,” the explorer yacht, hybrid propulsion, podded propulsion, as well as attention to environmental impact elements of the design and subsequent operations are all topics which have received attention in the industry press.

PARTNERSHIPS

As with any high-value undertaking, a large yacht construction project will require numerous partnerships and you may be asking yourself, “Who is involved with a custom yacht build process?” With the client at the top, some or all of the following will be necessary for a successful and enjoyable project experience:

A yacht broker , to advise the client on availability and the suitable market for construction and opening budget concepts. A naval architect for concept design. An engineer for detailed design. An interior designer. Attorneys for contract review, tax advice, etc. An insurance broker . A yacht builder , who may also provide some or all of the naval architecture, engineering, and even interior design services. Flag State , to provide surveyors with approval of safety code compliance. Classification Society, a third-party service assuring the quality of construction. Owner’s Project Manager , to record and represent the client’s interests across the entire project. (Depending on the size of the yacht, this may be one person or a team.) Yacht crew. (Depending on the size and complexity of the yacht, it may be wise to start bringing a crew into the project 6-12 months from completion.) Owner’s supply vendors , for audio-visual/entertainment systems, tenders, spares, and consumable supplies all needed to be managed and integrated into the final delivery.

FLEXIBILITY

The best plans are flexible and organized carefully so that changes or delays do not derail a project entirely. With this in mind, each partnership must be equally flexible throughout the project since an owner’s design needs, the yacht’s delivery schedules, and compliance requirements often change.

PROJECT MANAGEMENT

The process of building a large yacht is a long-term commitment and a major investment. A prospective client may consider hiring a project manager to assist with fielding the complexities at hand, protecting the client’s interests in the process and enabling the finished dream to be delivered on time and on budget. For a “simple” project, the project manager may be one person attending the yard on an occasional basis, but for larger builds, expect to see numerous staff on the project management team—some full time and others with short-term specialties needed during particular phases of the build.

NEWBUILD PROJECTS FOR SALE

Denison Yachting represents a number of builders in various regions of the United States with dealerships for Hatteras and Horizon, both of which typically build production or semi-custom yachts. Additionally, Denison is currently offering a number of new construction projects from yards Rosetti, Numarine , and Van der Valk , who all offer fully custom and semi-custom projects. Each year, we commit to visiting various yards in Italy , Germany , and The Netherlands to stay up to date on project availability and maintain relationships with the world’s top yacht builders.

Yacht brokerage houses often show newbuilds for sale. This may be a case where a builder has a design that they are promoting to the market, or maybe have even started construction without a specific client under contract. In some cases, clients or builders will start new construction as a speculative investment intending to sell the contract to a third party.

WHATS SETS ONE BUILDER APART FROM ANOTHER?

Boat International’s Builder Directory includes 1,805 separate entries, so the choices are broad. Builders can be found in Italy, Germany, the Netherlands, the UK, the USA, Turkey, China, Taiwan, Australia, and beyond. Some builders may specialize in a particular material, i.e. GRP, aluminum, or steel, and others may limit the size, the numbers, or the design choices (custom/production.) A client may use any of these to narrow down the selection, but the real distinction between builders will be the manner in which they treat the client. If the client is made welcome in the builder’s facility throughout the process, that builder will more than likely succeed. If the builder is transparent in their process, then they will succeed. If a builder says “yes” to every client request but fails to deliver, then they will likely fail.

Once a client has a particular style of yacht in mind, the selection of suitable builders will narrow down even further and the client’s broker should assist that process with their knowledge of the market. Then the client may consider asking candidate yards to suggest design concepts, then begin the evaluation and decision process. If using an independent naval architect to produce a concept, they may suggest suitable builders for the vision.

WHAT SETS A BRAND APART?

There are innumerable brokerages willing to sell a client a newbuild, and just as many builders who would likely be willing to deal direct. Do all of those companies have the depth of experience, integrity, expertise, and background that is needed to assist a client seeking to embark on such a high-value and complex project? Has that broker taken the time to learn the market options available? Do they have the skills necessary to listen and advise for the client’s benefit rather than their own? Denison has the build and brokerage experience matched with the knowledge and integrity required to take a client to the next level of their yachting dream.

Latest News

NEWS | April 17, 2024

Elton john exclusive.

Elton John Exclusive Ferretti Group VIPs were treated to a very special event in Venice. This article was written by Billy Springer. Photography courtesy of Ferretti Group. I’m rarely at a loss for words. But, after attending a private party, in the most

NEWS | April 15, 2024

Top yacht charter trends in 2024: insights on popular destinations and must-have toys.

Top Yacht Charter Trends in 2024: Insights on Popular Destinations and Must-Have Toys Denison charter specialists share this year’s trends for yacht charter vacations. 2024 has begun with a great start in the yacht charter market. Clients are asking for more destinations, more excursions, more toys. We sat down with the Denison charter

NEWS | April 12, 2024

2024 seattle boats afloat spring show.

2024 Seattle Boats Afloat Spring Show Denison invites you to view a number of available new and brokerage boats at the 2024 Seattle Boats Afloat Spring Show. Since its inception in Seattle in 1978, the Pacific Northwest’s largest floating boat show, the Boats Afloat Show, has consistently drawn

How Yachts Are Built? (The Inside Story)

Have you ever wondered what goes into the creation of a luxury yacht? From the custom design of the hull to the installation of the engine and mechanical components, the building of a yacht is a complex and fascinating process.

In this article, we will take a closer look at how yachts are constructed, from the skilled craftsmanship required to the final product, and how years of enjoyment can be had from these beautiful vessels.

Join us as we explore the inside story of how yachts are built.

Table of Contents

Short Answer

Yachts are typically built using fiberglass or composite materials, such as carbon fiber.

The hull of the yacht is usually crafted using a mold and the deck is usually built using a combination of fiberglass and plywood.

The interior of the yacht is then customized to meet the owner’s needs, and the necessary equipment, such as the engines and sails, is added.

The yacht is then tested for safety and performance before being delivered to the owner.

The Hull of Yachts

The hull of a yacht is the most important part of the vessel, as it serves as the foundation for the boat and provides the structure for the rest of the yacht.

It is usually made of either fiberglass or wood and is designed to be lightweight and durable.

Fiberglass is a popular choice for yacht construction as it is highly resistant to corrosion and is easy to shape into the desired vessel design.

Wood is another option, although it often requires more maintenance and is more likely to be damaged by the elements.

The hull of the yacht is the first piece constructed and is the basis of the entire design, so it is important to get it right.

Once the hull has been constructed, the interior and exterior of the yacht are customized according to the buyer’s specifications.

This includes the placement of windows, cabins, and other features.

After the design is complete, the yacht is put together piece by piece, with the engine and other mechanical components being added last.

Customizing the Interior and Exterior

When it comes to customizing the interior and exterior of a yacht, the sky is the limit.

Skilled craftsmen and designers work diligently to ensure that every detail is accounted for, from the placement of windows and cabins to the type of fixtures and finishes used.

Customers are typically given the opportunity to provide input on the design process, allowing them to create a unique and luxurious vessel that is tailored to their preferences and lifestyle.

The windows, cabins, and other features of the yacht can be customized and arranged in a variety of ways.

Windows are typically placed strategically to provide the maximum amount of natural light without compromising the integrity of the vessel.

Cabins can be designed with luxurious amenities such as custom bedding, cabinetry, and lighting.

Exterior features such as decks and railings can be tailored to the customers tastes, and the yacht can be decorated with high-end materials such as teak, mahogany, or leather.

The customization of a yacht’s interior and exterior is a labor of love that requires skill and attention to detail.

The end result is a luxurious vessel that will provide many years of enjoyment.

Putting Together the Yacht Piece by Piece

When it comes to putting together a luxury yacht, it is essential that each piece is crafted with precision and care.

The hull of the yacht is usually made of fiberglass or wood and is designed to be lightweight and durable.

Once the hull is constructed, the interior and exterior of the yacht are customized to the buyer’s specifications.

Once all the pieces of the yacht are constructed, the next step is putting it all together.

This process is done piece by piece, starting with the hull.

The engine and other mechanical components are then connected and installed.

Once the yacht is complete, it is tested to ensure it is safe and seaworthy.

The craftsmanship and attention to detail that goes into yacht building is truly remarkable.