Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

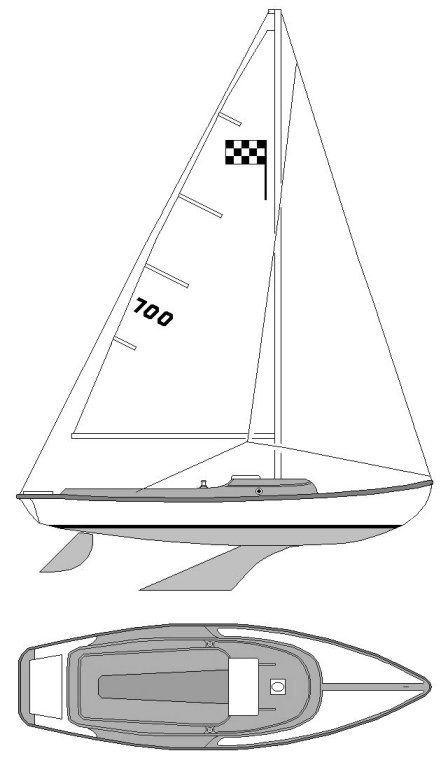

Victory 21 is a 20 ′ 11 ″ / 6.4 m monohull sailboat designed by Ted Carpentier and built by Coronado Yachts and Henry R. McCune, Shipbuilders between 1959 and 1980.

Rig and Sails

Auxilary power, accomodations, calculations.

The theoretical maximum speed that a displacement hull can move efficiently through the water is determined by it's waterline length and displacement. It may be unable to reach this speed if the boat is underpowered or heavily loaded, though it may exceed this speed given enough power. Read more.

Classic hull speed formula:

Hull Speed = 1.34 x √LWL

Max Speed/Length ratio = 8.26 ÷ Displacement/Length ratio .311 Hull Speed = Max Speed/Length ratio x √LWL

Sail Area / Displacement Ratio

A measure of the power of the sails relative to the weight of the boat. The higher the number, the higher the performance, but the harder the boat will be to handle. This ratio is a "non-dimensional" value that facilitates comparisons between boats of different types and sizes. Read more.

SA/D = SA ÷ (D ÷ 64) 2/3

- SA : Sail area in square feet, derived by adding the mainsail area to 100% of the foretriangle area (the lateral area above the deck between the mast and the forestay).

- D : Displacement in pounds.

Ballast / Displacement Ratio

A measure of the stability of a boat's hull that suggests how well a monohull will stand up to its sails. The ballast displacement ratio indicates how much of the weight of a boat is placed for maximum stability against capsizing and is an indicator of stiffness and resistance to capsize.

Ballast / Displacement * 100

Displacement / Length Ratio

A measure of the weight of the boat relative to it's length at the waterline. The higher a boat’s D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more.

D/L = (D ÷ 2240) ÷ (0.01 x LWL)³

- D: Displacement of the boat in pounds.

- LWL: Waterline length in feet

Comfort Ratio

This ratio assess how quickly and abruptly a boat’s hull reacts to waves in a significant seaway, these being the elements of a boat’s motion most likely to cause seasickness. Read more.

Comfort ratio = D ÷ (.65 x (.7 LWL + .3 LOA) x Beam 1.33 )

- D: Displacement of the boat in pounds

- LOA: Length overall in feet

- Beam: Width of boat at the widest point in feet

Capsize Screening Formula

This formula attempts to indicate whether a given boat might be too wide and light to readily right itself after being overturned in extreme conditions. Read more.

CSV = Beam ÷ ³√(D / 64)

The VICTORY 21 was first manufactured by Henry R. McCune (later the builder of the YORKTOWN sailboats) as a one-design class boat. Some 126 boats were built before the operation was sold to Wesco Marine in 1964. Another model called the AURORA 21 had the same hull but with a larger cabin. Changes to the original design made by Wesco included making the cockpit self-bailing and installing a sliding hatch on the cabin. Between 1969 and 1970, the boats were built by Coronado Yachts. Later, production was resumed by Catalina Yachts where it became the CAPRI VICTORY.

Embed this page on your own website by copying and pasting this code.

Discover Related Sailboats

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Class Contact Information

Click below

Class Email

Class Website

One-Design Class Type: Keelboat

Was this boat built to be sailed by youth or adults? Both

Approximately how many class members do you have? 30

Photo Credit:unknown

Photo Credit: Julie Skaff

About Victory 21

The Victory is a 21 foot long, one design, all fiberglass keelboat with graceful lines. It was designed by naval architect Ted Carpenter in the Fall of 1959. In 1970, starting with Hull #150, production rights were transferred to Frank Butler of Catalina Yachts. Currently, the Victory is most actively raced in California with competitors mainly coming from the Fresno and San Diego areas using just Main Sail and 110’s though spinnakers and 150% genoas are also recognized as class legal sails. The three major invitational regattas each year for the Victory 21’s include: the High Sierra Regatta held at Huntington Lake sponsored by the Fresno Yacht Club (FYC), the SCYA Midwinters held at the Mission Bay Yacht Club (MBYC) and our National Championships which rotate between Huntington Lake (FYC), Mission Bay (MBYC), and San Diego Bay (Convair Sailing Club). All class events are governed by the class rules established by NAVSO (last updated in 1987)–the National Association of Victory Sloop Owners.

Boats Produced: approximately 700

Class boat builder(s):

Catalina Yachts, though I have not heard of any new Victory 21’s being produced since the 1980’s.

Approximately how many boats are in the USA/North America? 450

Where is your One-Design class typically sailed in the USA? List regions of the country:

The Victory 21 is primarily sailed in Central and Southern California. There used to be strong fleets also in Santa Barbara, California; Berkeley, California; Dallas, Texas and Oklahoma.

Does this class have a spinnaker or gennaker? Yes

How many people sail as a crew including the helm? 2

Ideal combined weight of range of crew: 400

Portsmouth Yardstick Rating: 276 for both spinnaker and genoa based upon our last PHRF certificate from 2000

Boat Designed in 1959

Length (feet/inches): 21′

Beam: 6’3.33″

Weight of rigged boat without sails: 1,200 lbs including the 500 lbs. keel with an optional 200 lb. lead bubble on the keel

Draft: 3′ .33″

Mast Height: 23′ 6.5″

Tuning Guides

Class rules (pdf doc).

Back to One-Design Central

Copyright ©2018-2024 United States Sailing Association. All rights reserved. US Sailing is a 501(c)3 organization. Website designed & developed by Design Principles, Inc. -->

From dusty project to race ready

A young couple restores a victory 21 built nearly 40 years before they were born.

My heart pounded as adrenaline flooded my veins, the wind biting my cheeks as we threaded through the oncoming vessels that were fighting for our prime position. It was the 69th annual High Sierra Regatta, and the

sixth anniversary of my partner Chris and I crewing together aboard our Victory 21 sailboat. The regatta on Huntington Lake in California’s Sierra Nevada is always memorable, not for the sailboat racing, but for the race to the starting line, which has become a tradition for us to just barely make. So it was true to form that we found ourselves towing the Victory for four hours to the Ventura Harbor Boat Yard where we’d reserved a spot to work on the boat, just two weeks before the start of the regatta.

The Victory 21 was designed by Ted Carpenter and became one of the first production boats built by Frank Butler, who would go on to found Catalina Yachts. By 1962, Butler had built 126 of the little sloops. Our Victory 21, hull No. 553, came into the family when Chris and his father picked it up in 2008 as a project boat. It was a great platform for young Chris to cut his refit teeth on projects like fiberglassing.

That experience would come in handy not just for working on our own boat, but also for redoing the original projects Chris had taken on with his father. The under built foredeck and fraught chainplate mounting were due for a refit, 20 years after they’d last been worked on.

The original chainplates fix consisted of a long piece of angle iron mounted under the port and starboard deck to act as a backing plate for the three “chainplates” to affix to. Although this design served its purpose, the serious pitfall of this design was that the load from the rig went directly into the deck rather than the hull, resulting in breaking most of the tabbing away from the deck-to-hull joint, adding to the insufficient strength of not only the rig but the boat itself.

To fix this, Chris fiberglassed large, overbuilt foam core knees to the hull and deck to allow for a much more robust chainplate attachment point. After the knees had been glassed in, the attention was turned to the foredeck, which had previously been supported with a pair of T-shaped supports created from 2-by-4s. To improve on that very outdated fix, Chris decided to add in beam-to-beam stringers along the belly of the deck to disperse the load of the entire deck. With a template made we cut out strips of Divinycell PVC foam core and sandwiched layers of 1708 fiberglass biaxial mat and thickened epoxy until the four prominent, yet minimal, stringers were glassed in place.

With the fiberglass work complete we had also started checking fairing and sanding the hull and rudder off the list, and we went on to removing the metal track that the bump-rail sat inside, well, what was left of it anyway. The original screws were mild steel, which caused them to decay inside the hull-to-deck joint. Armed with a drill, I made holes around the sheared-off bolts then pulled out what was left of the metal using needlenose pliers, a procedure similar to a game of Operation. While I did this, Chris routed out the spider cracks and blisters then faired them using System Three Quikfair epoxy. At the end of the day we sat back and appreciated the clean canvas in front of us; our once royal blue boat was now stark white bearing all of her faults, looking naked and vulnerable. Chris wore most of her blue paint on his forearms and around his face where his respirator wouldn’t reach, looking like he lost a fight with a Smurf.

The next day the pink patches of fairing compound we spread the evening before were ready to be sanded along with the epoxied hull-to-deck joint, giving us a smooth surface for primer. It took two hours but by noon the sanders were retired and the boat was wiped down with an acetone dampened microfiber to remove any leftover debris. Together we mixed and filtered the two-part primer that looked like mud, filling a paint tray and rolling it on in even layers. When 2 p.m. rolled around the boat was an awful shade of blush, but all smooth and one color ready to receive her new topsides paint.

We chose to go with Awlgrip paints since we were impressed by the application, result and durability when we’d used it on our Cheoy Lee 41 Avocet. Considering the Victory is only in the water (usually fresh) a few times a year we decided this paint would be a good option and started to browse the catalog for her new color scheme, ultimately landing on red. Dale, the master painter in Ventura Harbor Boatyard and good friend of ours, pointed us in the direction of which shade of red to use, giving us the best result. With Dale’s help, we cracked open the can of paint and got to work rolling and tipping.

“More paint!” Chris said as he continued the red takeover. I carefully brought him the mixing container filled with the paint he had filtered, filled the tray then stepped away from the splash zone. With the camera in my hands I captured the last bit of white being covered by the rich red, Chris’s reflection bouncing off the hull as he continued to paint vigorously. He dropped his applicators and stood back, flecks of red splattered on his arms and cheeks from working so quickly with the roller, but his smile pushed the spots on his cheeks up like freckles as he admired his work. We both noted a few oddities on the port bow (where he started) but were positive after it was sanded and the second coat was applied that it would not be an issue. I was thrilled to witness this big moment, as we were seeing the light at the end of the tunnel and the start of a new beginning for our little boat. It was a bittersweet process to have sanded away the work Chris and his dad did all those years ago, but I’m sure he would be proud of us and the accomplishments we have made on both our boats. The second coat of paint had gone on smooth and rich, a crimson reflection bouncing back at us as we smiled ear to ear, and just like that, the boat was red.

Also in Features

- Keeping history alive

- Chasing a dream

- Gifts for Sailors

- New Boat Showcase

- The tradition continues

- America's Cup for All

- Race to Molokai

- The wide, wide world of multihulls

- All for one, one for all, in the Abacos

- Allure of Anguilla

Also from Marissa Neely

- DIY custom bug screens

- Hunting for sailing treasure

- Reduce the roll

- Young Again

The Victory 21 is a 21.0ft masthead sloop designed by Ted Carpentier and built in fiberglass by Coronado Yachts between 1959 and 1980.

690 units have been built..

The Victory 21 is a light sailboat which is a very high performer. It is stable / stiff and has a low righting capability if capsized. It is best suited as a racing boat.

Victory 21 for sale elsewhere on the web:

Main features

Login or register to personnalize this screen.

You will be able to pin external links of your choice.

See how Sailboatlab works in video

We help you build your own hydraulic steering system - Lecomble & Schmitt

Accommodations

Builder data, other photos.

Modal Title

The content of your modal.

Personalize your sailboat data sheet

Victory 21 Tips and Techniques

Bottom work, bottom preparation, wash right away.

If you are taking your boat out of the water after a long time, you will be able to use a pressure wash to remove bottom growth. Don't wait for it to dry or it will harden and become difficult to remove.

If you have a well maintained boat, your bottom preparation may require little more than a good scraping. The only thing to really be concerned about is to guarantee compatibility of your new coating over the old. If in doubt, remove it.

Removing Old Bottom Paint

I am assuming you have a "bad" bottom and want to start over. For heavy removal start with an electric orbital sander at 1400 RPM using a 36 grit disk. On my boat, the primary sanding was stopped with about half the primer layer left on and finished with an air powered random orbit sander running on 80 psi with a 40 grit disk.

Take precautions to protect your lungs as bottom paints can contain poisons! Eye and ear protection is a must when using power tools.

There are no boat yards or hoisting equipment at the Great Salt Lake, so I used a 2-ton hydraulic engine hoist to lift the hull in front and back off the trailer to sand these hard to reach spots.

Levitating the Victory

Hoisting a victory.

One excellent tip about bottom work was obtained from Wesley Bachman of the Convair Sailing Club . You can actually suspend a Victory from the sternmost keel bolts using an "L" shaped piece of metal. Off course, this assumes you have some sort of frame to support the boat from above.

Ed Pearson owner of Victory 21 #427 "Pteropod" writes about Hoisting a Victory

I use a hoist to launch my Victory. I have a lifting plate (a piece of 2.5 inch X 2.5 inch stainless steel "angle-iron") attached to the keel via the aft-most keelbolts. Unfortunately the center of balance of the boat is about a foot aft of the end of the keel root. This may, in part, be due to the fact that my boat has a bulb-keel. But the result is that hoisting the boat in-line with the lifting plate would be something of a disaster (i.e., the boat would tip way back, forcing the mast into the hoist). The fix is to use a bridle attached to the lifting plate and the eye in the stern fitting (where the backstay attaches to the deck/hull). The attachment point for the hoist on the bridle is, in principle, dictated by the balance of the boat. In practice, on my boat anyway, the balance point is just aft of the companionway (but I can move it a bit by shifting gear around). The bridle that I use is made of stainless steel cable with thimbled eyes at either end and a large steel ring in the middle for the hoist hook to attach. You can, however, make a bridle out of heavy-duty nylon webbing. You also have to attach a couple of stabilizing lines between the hoist-bridle junction and the sides of the boat (I use the genoa fairleads for the attachment points) to keep the boat from tipping to one side or the other (and it _will_ tip without them) . This all may seem complicated but it is actually much easier, and safer, than hoisting with slings, and it is a lot easier on the trailer than using a ramp.

Ed Pearson's Victory 21 # 427 Pteropod being launched by a hoist

Slinging the victory.

I noticed my Victory had gelcoat cracks on both side right below the toe rail on the bow and stern. These appear to be caused by improper slinging. If your sling is not set to hold the sling open on top with a spreader, the weight of the boat will cause the sling to bend to toe rail inward and fracture the gelcoat if not the fiberglass of the hull.

Keel Specifics

Fairing the keel.

Fairing the keel is a matter of special interest. All low and exposed areas should be ground out using a dremel and coated with Duraglass body filler. All bare metal and bare fiberglass must be primed before filling. A great deal of time must be spent fairing the keel to a smooth and uniform surface.

Keel Bolt Replacement

Removing a keel.

Richard L. Strasia , Victory 21 #315, has undertaken a much more involved process. In order to fix a problem with hull stress cracks around the keel, he has actually dropped the keel. There is plywood stiffener in the bottom of the hull which the keel bolts to. This plywood can become rotted and allow the hull to flex around the keel. This boat had a fairly serious problem with hull flex and cracking so by dropping the keel and replacing the plywood, Richard will restore hull strength.

Removing a Keel-- Note Stress Fractures in Hull

Painting the bottom, preparing the hull for new bottom paint.

In fact, if you are preparing above water line surfaces to be painted, you should use the desiliconizer prior to sanding; otherwise, you may actually end up with residue in the sanding scratches which is then even more difficult to remove. You can't get the surface too clean!

Gelgoat below the water line at this point is ready to apply the new paint. Any bare metals or fiberglass must be primed with VC No-Sand. This is an extremely unfriendly material in terms of being breathed so make sure you have plenty of ventilation!

Applying and Choosing Bottom Paints

The materials you choose to coat your boat's bottom with depend partially upon whether or not you will be trailering it. Many anti-fouling paints have a very short life span out of the water. For this reason, I recommend using a "hard" paint such as Micron CSC Extra. A barrier coat can be applied to prevent blistering. I used Interlux 3000/3001 which is a two part epoxy paint. Both types of bottom paint were applied with a 10 inch roller. I used a high quality resin core dacron roller.

To Sand or Not To Sand?

The mathematics of smoothness, ed's rebuttal to my dimply hull theory.

I've heard similar speculations along these "lines" before, and I have often wondered myself if this would work. So when I saw your theory I sat down and worked it out. The numbers are probably not exactly right, because I had to make several assumptions (size, shape, and location of the roughness for instance), but the gist of the analysis should hold true.

Here goes nothin':

Although in principle this would work for what fluid engineers refer to as a "bluff body", such as a cylinder or a golf ball, it shouldn't apply to a "streamlined section", such as a sailboat hull. Even if you consider the hull a bluff body (and I've seen some production hulls that come pretty close), the drag coefficient is only lowered within a certain range of velocities. For a golf ball in air (a small object in a fluid that isn't very viscous) the drag coefficient is lowered between about 20 m/s (meters/second) and 80 m/s (about 40 to 160 mph). For a Victory in normal salt water (a much larger object in a much more viscous fluid; of course, the water in GSL is even more viscous) the drag is only lowered between about 0.01 and 0.04 m/s (about 0.02 kts and 0.08 kts). More importantly, above 0.04 m/s dimpling will _increase_ the drag coefficient. At about 2 kts the drag coefficient will be about doubled. Of course, this is assuming that the hull is acting as a bluff body, which it really isn't. For a streamlined section roughness will _always_ increase the drag coefficient of the hull at all but the very slowest speeds (for a Victory, speeds below about 0.3 kts). Therefore, when dealing with boat hulls, its always prferable to have as smooth a surface as possible.

Note that the roughness of roller or brush marks in paint isn't exactly what engineers refer to when making these sorts of analyses, it is actually much "smoother". Therefore, the increase in drag coefficient at higher speeds is probably not as great as my calculations would indicate.

One thought that came to mind is that dimpling the mast might lower its drag coefficient during high winds (i.e., it would act something like a golf ball). Dimpling would lower the drag coefficient of a 15 cm thick mast in air between about 8 kts and about 30 kts. But above 30 kts dimpling would increase the drag (right when one wants as little drag as possible), so I guess that that wouldn't work either. :(

On the other hand, if we wanted to sail really fast boats, we wouldn't be sailing a 40 year-old design. :)

Hull Speed or How Fast is Fast?

Bottom line question then is this: How much wind velocity is it going to take to get a Victory to maximum theoretical hull speed? I've never heard of one planing, and mine never has...

Much trickier question, at least if you want to figure out the answer from _theory_! The main problem is that it is very difficult to predict what the coefficient of drag is going to be without doing some empirical work (hence, all of the tank testing that is done by marine architects). It also depends upon such things as the point of sail, the sea conditions, etc. I doubt that it would be possible to get a Victory to really plane (the hull just isn't the right shape; i.e., no large flat areas).

However, I am able to get my boat well past hull speed without too much trouble. Here I am "surfing" rather than "planing", the distinction being that I can go fast enough so that the stern wake in just beyond the stern of the boat, but the boat isn't really "skipping" across the water. Theoretical hull speed for a Victory is about 5.2 - 5.3 kts (the over-hanging stern could add almost a half a knot to that), but on several occasions I have had my boat up to 6.8 - 7 kts, according to my GPS. Even if one assumes that the GPS readings were a bit off (due to currents, selective availability, plain old error, etc.), it's been obvious from the shape and position of the wake that I was well past hull speed.

Without too much chop on the water you should be able to get past hull speed in a 20 kts wind. Saturday the Pteropod was surfing rather nicely, at about 6.5 to 6.8 kts, on a close reach in about 15 to 25 kts of wind. When we turned downwind for the run back to the marina, she still did 5.5 to 6 kts in bursts, but it was a bit harder to keep her surfing as the wind was starting to die. If you do get your boat to surf, you can really feel the difference when she settles back into acting like a true displacement hull. It feels like someone put the brakes on for a few seconds, and then the "hole in the water" made by your wake seems much deeper.

PHRF Rating Information

All lists of PHRF for the Victory 21 I have seen show the rating as 276.

Leveling the Boat

Marking and masking the stripe.

Mark the hull at close intervals from the original marks with the water level until the boot strap top is reposistioned. The less vertical the hull section, the closer you should mark your lines. To do the bottom, start at the most vertical part of the side of the hull and measure down the width you want the boot strap to appear, two and one half inches for example, then tranfer the marks around the hull. Obviously the stripe will be wider at the bow and stern, but it will appear uniform when viewed from the side. I don't know of any way to do this using a water level without two people. Your assistant simply tells you to raise or lower your end until it brings the water to the original mark he is watching, then you mark your spot.

Buffing and Waxing

COMMENTS

The VICTORY 21 was first manufactured by Henry R. McCune (later the builder of the YORKTOWN sailboats) as a one-design class boat. Some 126 boats were built before the operation was sold to Wesco Marine in 1964. Another model called the AURORA 21 had the same hull but with a larger cabin.

Victory 21 is a 6.4 m monohull sailboat designed by Ted Carpentier and built by Coronado Yachts and Henry R. McCune, Shipbuilders between 1959 and 1980. Designer. Ted Carpentier. Builders. Coronado Yachts. Henry R. McCune, Shipbuilders. Association. Victory 21 Site. # Built. 690. Hull. Monohull. Keel. Fin. Rudder. Spade. Construction. FG.

I'm new to the forums, and wondered if anybody remembers, or still might have their Victory 21 sailboat. We have resurrected the Victory fleet at Mission Bay Yacht Club in San Diego, with 8 active boats. In it's hey-day, MBYC had 33 Victory's, and over 40 boats for a Nationals Regatta were not uncommon.

About Victory 21. The Victory is a 21 foot long, one design, all fiberglass keelboat with graceful lines. It was designed by naval architect Ted Carpenter in the Fall of 1959. In 1970, starting with Hull #150, production rights were transferred to Frank Butler of Catalina Yachts.

From beloved project boat to fresh and ready to race, the young owners brought new life to the Victory 21 many times their senior. Chris Neely photo. sixth anniversary of my partner Chris and I crewing together aboard our Victory 21 sailboat. The regatta on Huntington Lake in California’s Sierra Nevada is always memorable, not for the ...

The Victory 21 is a 21.0ft masthead sloop designed by Ted Carpentier and built in fiberglass by Coronado Yachts between 1959 and 1980. 690 units have been built. The Victory 21 is a light sailboat which is a very high performer.

Victory 21 Sailboat History. History of the Victory 21. The Victory sloop was designed by Ted Carpentier, naval architect, and first manufactured by Henry R. McCune in 1959. It was designed as a one-design class boat, fully competitive in any range of of comparable boats. Some 126 boats were manufactured before it was sold to Wesco Marine.

Victory 21 Sloop and NAVSO. This site is divided between information about the Victory sloop and about the National Association of Victory Sloop Owners (NAVSO). The site's Victory Sloop section includes Repairs, Tips and Techniques which covers a variety of subjects from bottom painting to hoisting and from the physics of hull smoothness to a ...

A Hoisting Description. Slinging the Victory. Fairing the Keel. Keel Bolt Replacement. That Crazy Board in the Bottom of the Boat. Removing a Keel. Preparing the Hull for New Bottom Paint. Applying and Choosing Bottom Paints. To Sand or Not To Sand? The Mathematics of Smoothness. Hull Speed or How Fast is Fast? PHRF Rating Information.

This group was designed for Victory 21 and Aurora 21 owners to meet and exchange stories, help, ideas, and pictures of their experiences with their Victory 21 sailboats. Please feel free to...